Method for preparing hydrophobically modified xanthan

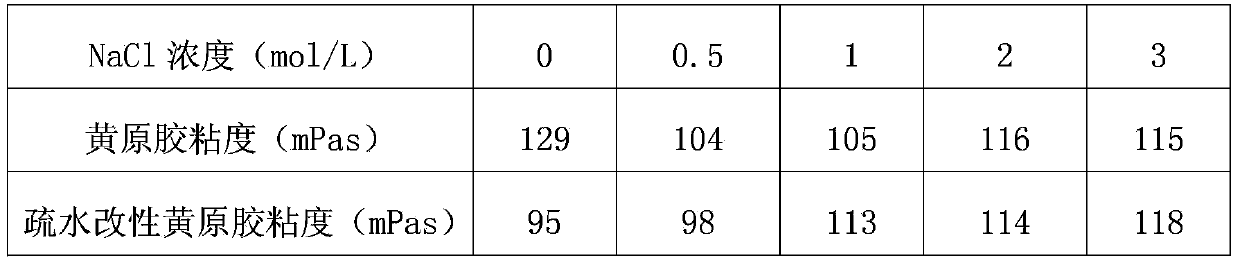

A technology of hydrophobic modification and xanthan gum, which is applied in the field of preparation of hydrophobic modified xanthan gum, can solve the problems of high cost of environmental protection wastewater treatment, poor salt resistance and temperature resistance, difficult wastewater treatment, etc., and achieve high yield, Good salt resistance, convenient storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

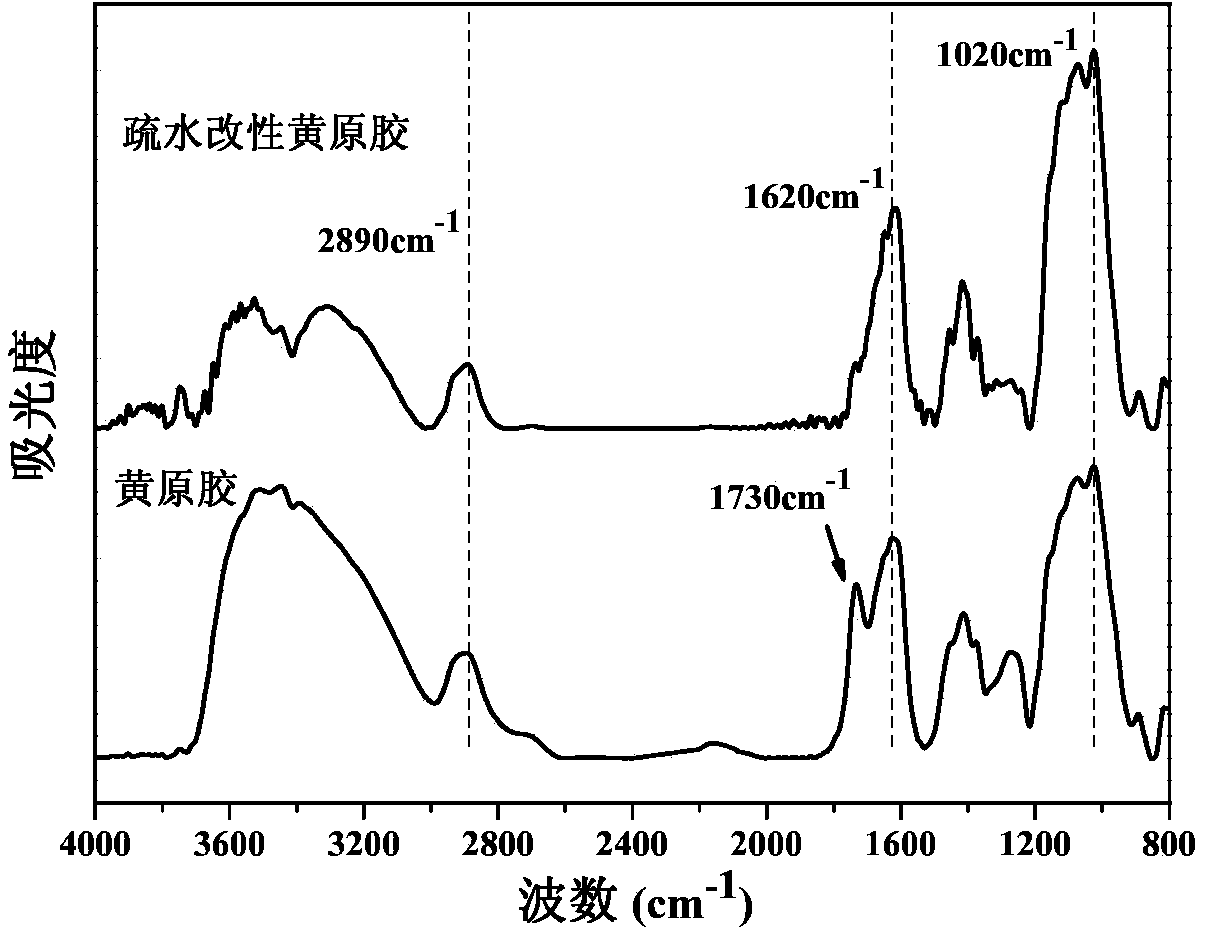

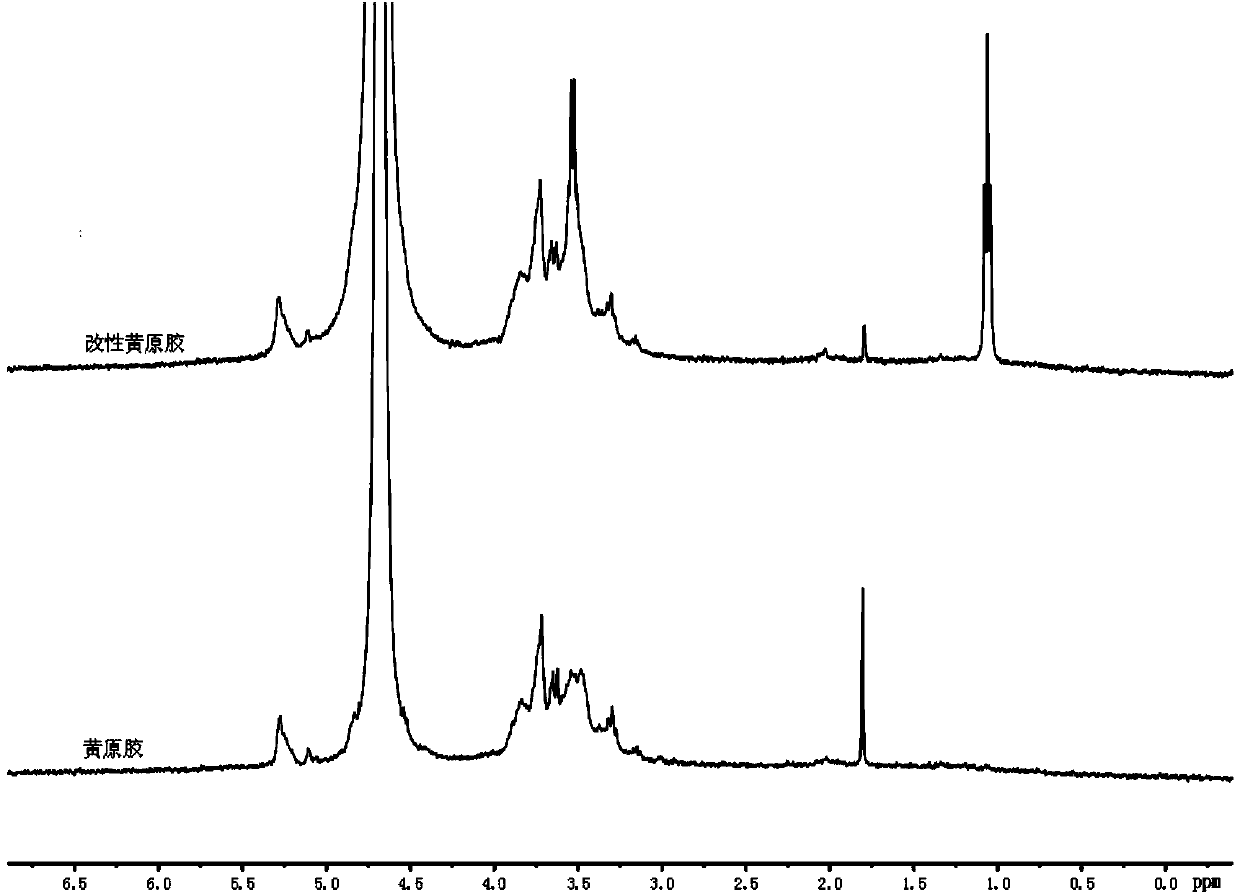

[0032] Under the condition of stirring at room temperature, add 0.192 g of 30% mass concentration ammonium dodecyl ammonium sulfate solution to 8 g of water / isopropanol (1:4 mass ratio) mixed solvent, pass N 2 After bubbling for 15 minutes, add 1g of tetradecane bromide and 0.15g of solid sodium hydroxide in turn, then add 4g of xanthan gum (the content of active ingredients is 89.1%), and continue to pass N 2 Bubble for 5min. 70°C constant temperature reaction for 7 hours. The resulting reaction solution was poured into absolute ethanol, and a solid was precipitated. The solid product was precipitated and washed three times with 90 wt % ethanol aqueous solution, filtered with suction, and dried at a constant temperature at 30° C. for 72 hours. 3.89 g of hydrophobically modified xanthan gum was obtained. According to static light scattering test, its molecular weight is 6.06 million. The infrared spectrum of gained hydrophobically modified xanthan gum is as follows: figure...

Embodiment 2

[0041] As described in Example 1, the difference is that the amount of xanthan gum added is 2 g to obtain 1.87 g of hydrophobically modified xanthan gum.

Embodiment 3

[0043] As described in Example 1, the difference is that the amount of tetradecane bromide added is 0.5 g to obtain 3.87 g of hydrophobically modified xanthan gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com