High-salt and high-COD wastewater electrolysis electrode and electrolytic oxidation treatment method

An electrolytic electrode and electrolytic oxidation technology, which is applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of short service life of electrodes, low efficiency of electrolytic oxidation, and reduced service life of electrodes, and achieve stable electrolysis , stable voltage and current, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0044] This embodiment is an electrolysis experiment of a single strand of wastewater in a pharmaceutical factory workshop. The experimental power supply uses a DC pulse constant current source with a constant current of 9A and a voltage of 4.2V. The raw water samples and the indicators of electrolysis for 1 hour, 2 hours and 3 hours were tested respectively.

[0045] The results are as follows:

[0046] Inspection index

[0047] As can be seen from the above table, the removal rate of ammonia nitrogen is 100%, and the removal rate of COD is 94.1%. It can be seen that the electrolytic electrode of the present invention has a stronger removal effect for ammonia nitrogen and COD in sewage.

Embodiment 7

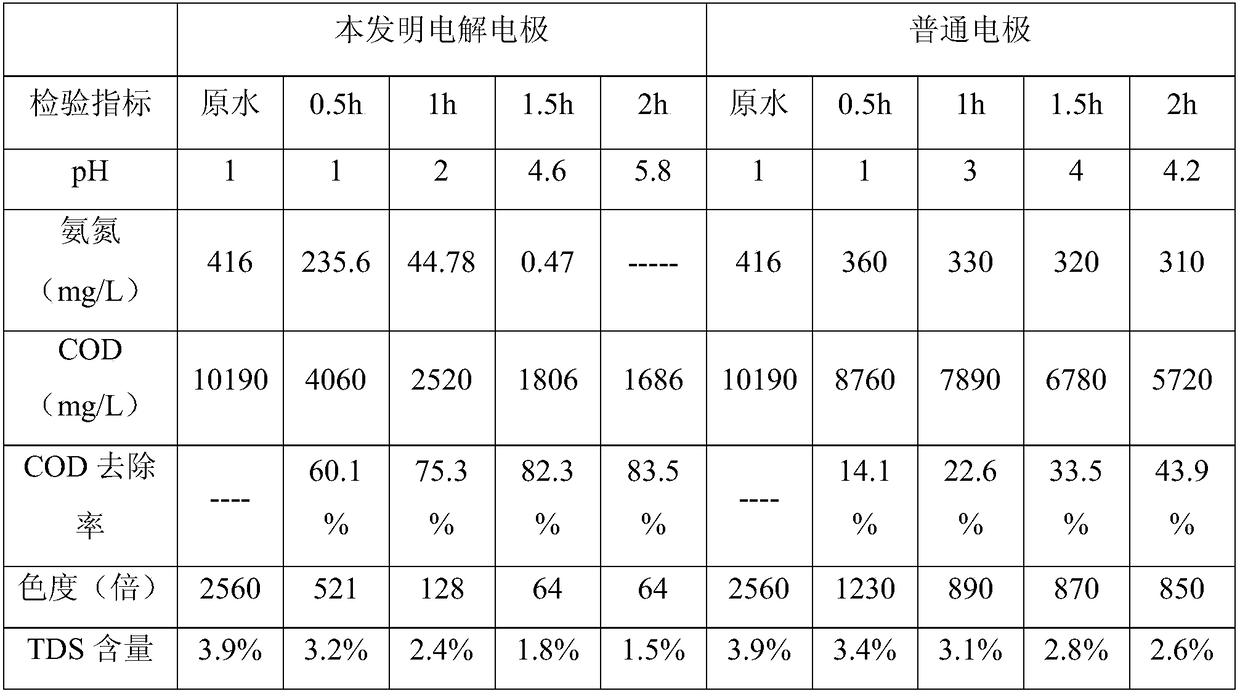

[0049] This embodiment is an electrolysis experiment of high-concentration (high-salt and high-COD) wastewater from a pharmaceutical factory. The experimental power supply uses a DC pulse constant current source with a constant current of 9A and a voltage of 3.2V. The raw water samples and the indicators of electrolysis for 1 hour, 2 hours and 3 hours were tested respectively.

[0050] The results are as follows:

[0051] Detection Indicator

[0052] As can be seen from the above table, the removal rate of ammonia nitrogen is 100%, and the removal rate of COD is 87.3%. It can be seen that the electrolytic electrode of the present invention has a stronger removal effect for ammonia nitrogen and COD in sewage.

Embodiment 8

[0054] This embodiment is an electrolysis experiment of comprehensive wastewater from a pharmaceutical factory. The experimental power supply uses a DC pulse constant current source with a constant current of 9A and a voltage of 4.8V. The raw water samples and the indicators of electrolysis for 1 hour, 2 hours and 3 hours were tested respectively.

[0055] The results are as follows:

[0056] Detection Indicator

[0057] As can be seen from the above table, the removal rate of ammonia nitrogen is 100%, and the removal rate of COD is 91.2%. It can be seen that the electrolytic electrode of the present invention has a strong removal effect for ammonia nitrogen and COD in sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com