Method for preparing Al-Li alloy through molten salt electrolytic method

A technology of aluminum-lithium alloy and molten salt electrolysis, which is applied in the field of preparation of aluminum-lithium alloy by molten salt electrolysis, can solve the problems of increasing the cost of aluminum-lithium alloy, and achieve the effects of stable electrolysis process, simplified preparation process and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

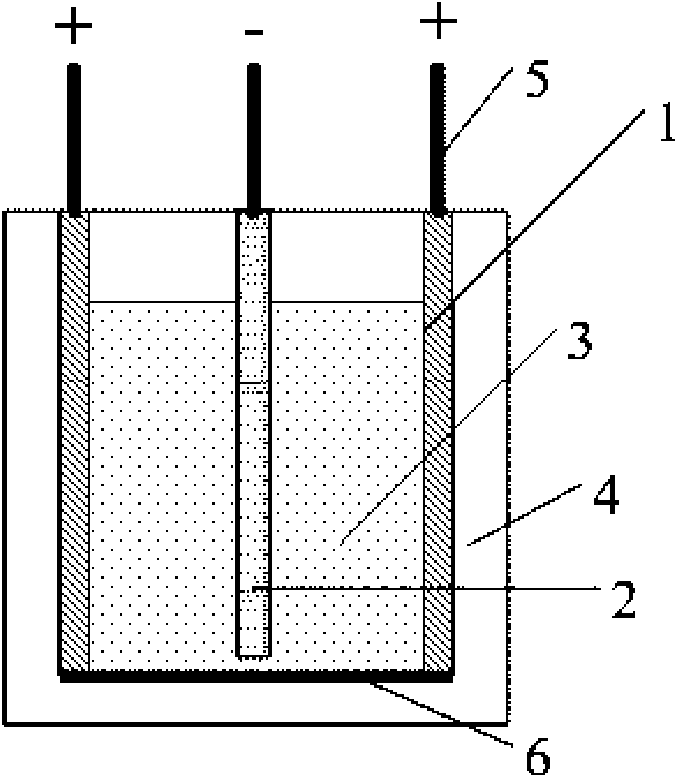

[0030] The structure of the electrolytic cell used is as follows figure 1 As shown, the plate-shaped cathode 2 is placed in the middle of two graphite anodes 1, the electrolytic cell shell 4 is made of stainless steel, and the corundum insulating plate 6 is laid on the bottom, the lower end of the graphite anode 1 is in contact with the corundum insulating plate 6, and the electrolytic cell adopts an external Heating mode; the anode and the cathode are connected to the power supply through the electrode lead 5. The cathode 2 of the electrolytic cell is made of aluminum.

[0031] Potassium fluoride and lithium fluoride are uniformly mixed to obtain a mixed material, and the weight content of lithium fluoride in the mixed material is 33%.

[0032] Put the mixed material in the electrolytic tank, heat the electrolytic tank until the mixed material melts into a liquid state, the temperature is 550±5°C, then raise the temperature of the mixed material to 580±5°C, add lithium oxide...

Embodiment 2

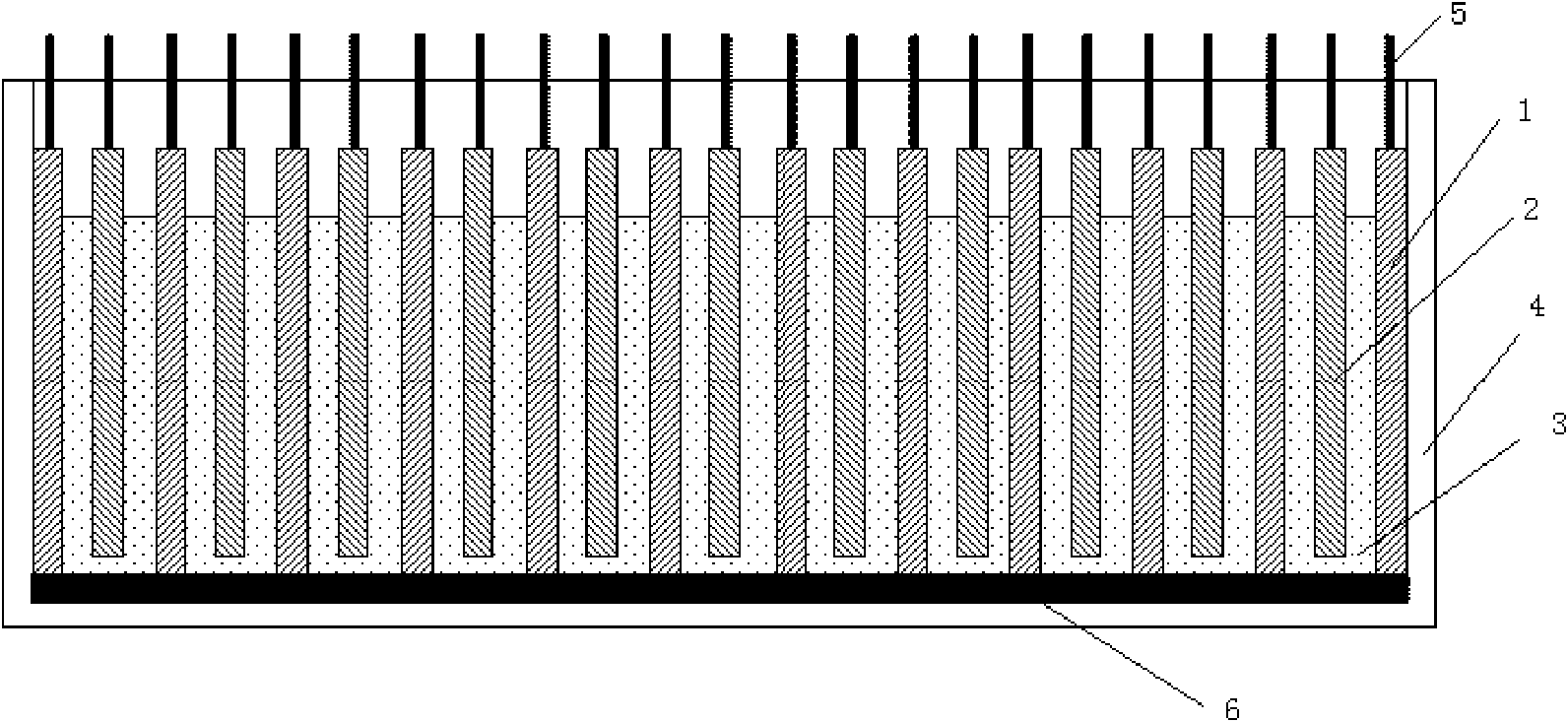

[0037] The electrolytic cell used is a multi-chamber cell with a structure such as figure 2 As shown, the material of the anode is graphite. The two poles of the electrolytic cell are composed of 12 graphite anodes and 11 plate-shaped cathodes. Each cathode is placed in the middle of two adjacent anodes. The material of the electrolytic cell shell is stainless steel. The corundum insulating board is laid on the wall, the anode is plate-shaped, and is evenly distributed in the electrolytic cell, and the lower end of the anode is in contact with the corundum insulating board; the heating of the electrolytic cell adopts an external heating method, and the distance between two adjacent anodes is equal.

[0038] Potassium fluoride and lithium fluoride are evenly mixed to obtain a mixed material, and the weight content of lithium fluoride in the mixed material is 22%.

[0039] Put the mixed material in the electrolytic tank, heat the electrolytic tank until the mixed material melts...

Embodiment 3

[0044] The electrolyzer structure that adopts is with embodiment 1.

[0045] Potassium fluoride and lithium fluoride are uniformly mixed to obtain a mixed material, and the weight content of lithium fluoride in the mixed material is 52%.

[0046] Put the mixed material in the electrolytic tank, heat the electrolytic tank until the mixed material melts into a liquid state, the temperature is 550±5°C, then raise the temperature of the mixed material to 580±5°C, add lithium oxide into the electrolytic tank and mix evenly to obtain A liquid mixed electrolyte, the weight percentage of lithium oxide in the mixed electrolyte is 10%; wherein the area of the cathode aluminum plate is 200cm 2 , a thickness of 5mm, a mass of 135g, and a total weight of the mixed electrolyte of 1000g.

[0047] Apply electricity to the electrolytic cell for electrolysis, the current density is 0.07A / cm 2 , the electrolysis time is 1.0~1.2h, after the electrolysis is over, replace the cathode and contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com