Preparation method of silicon-manganese alloy

A silicon-manganese alloy and molten salt technology, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of volatilization loss of silicon and manganese alloys, increase the cost of silicon-manganese alloys, and complicated operation steps, so as to achieve stable electrolysis process and reduce The effect of energy consumption and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

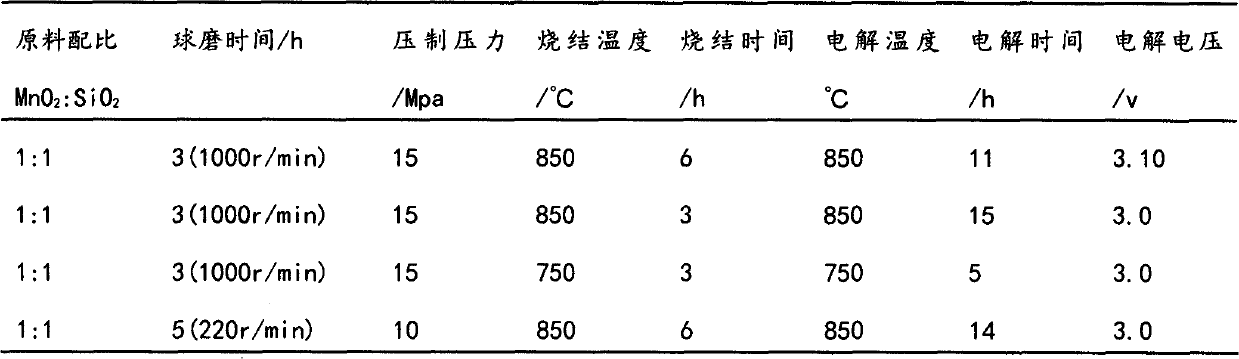

[0018] Embodiment 1-4, as shown in the form:

[0019]

Embodiment

[0021] 1. Preparation of cathode

[0022] Use high-purity SiO 2 powder, or SiO 2 and MnO 2 Mix powder (molar ratio 1:1) as raw material, weigh 1g, SiO 2 and MnO 2 The mixed powder needs to be milled in a ball mill for 3 hours to keep the particle size uniform and the SiO 2 and MnO 2 Mix evenly, and then select appropriate tablet pressure to form tablets, control the sintering temperature to 850°C and sinter in a muffle furnace for 6 hours to enhance the strength of the cathode sheet.

[0023] 2. Molten salt pretreatment

[0024] Weigh 250g of molten salt, in molar ratio CaCl 2 ; NaCl=1:1 weighed, ground and mixed, kept at 100°C for 2h to remove physically adsorbed water, then raised to 400°C for 4h to remove physically bound water. After cooling to 120°C, put it into a vacuum drying oven for later use, and slow down the speed during the heating or cooling process of the molten salt to prevent the molten salt from sintering.

[0025] 3. Pre-electrolysis process

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com