Small-scale water electrolysis apparatus and system thereof

A small-scale water electrolysis technology, applied in electrolysis components, electrolysis process, water/sewage treatment, etc., can solve the problems of high maintenance cost, low electrolysis efficiency, high price, etc. Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

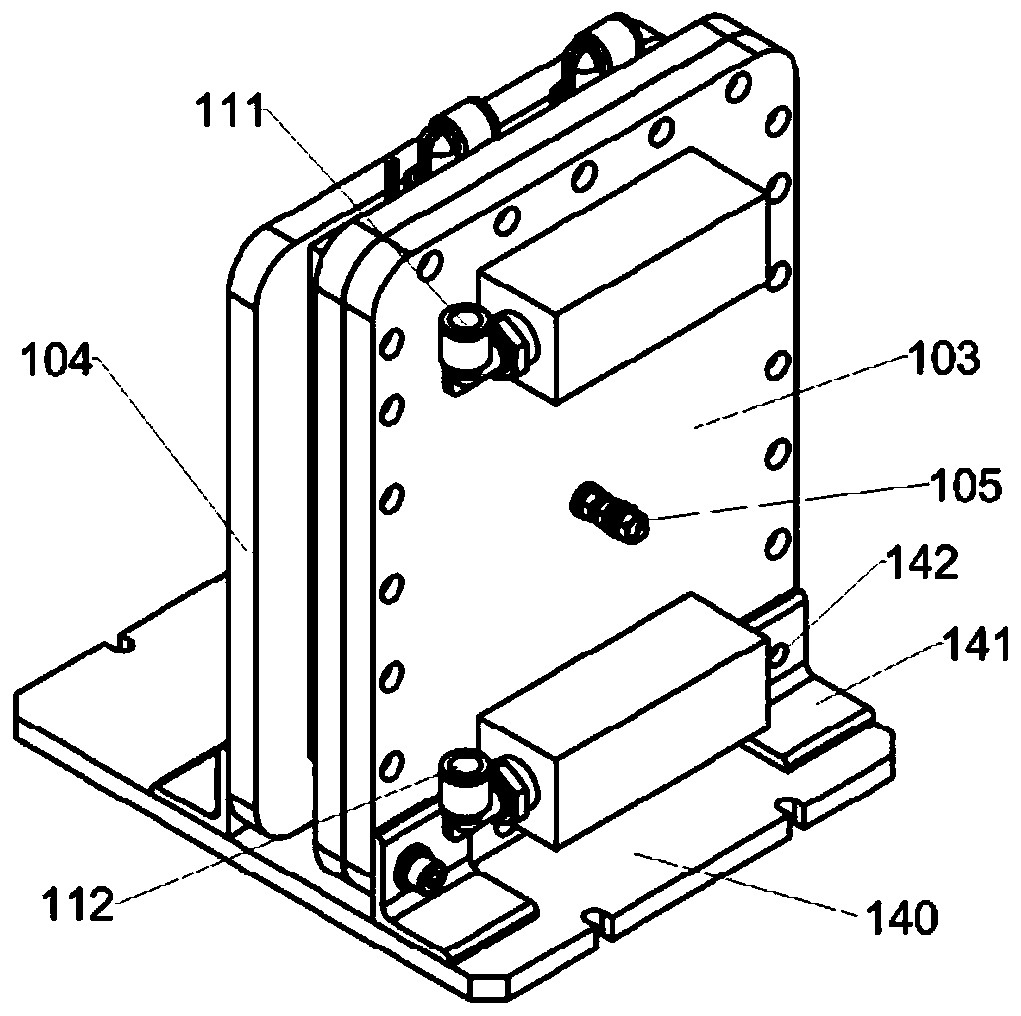

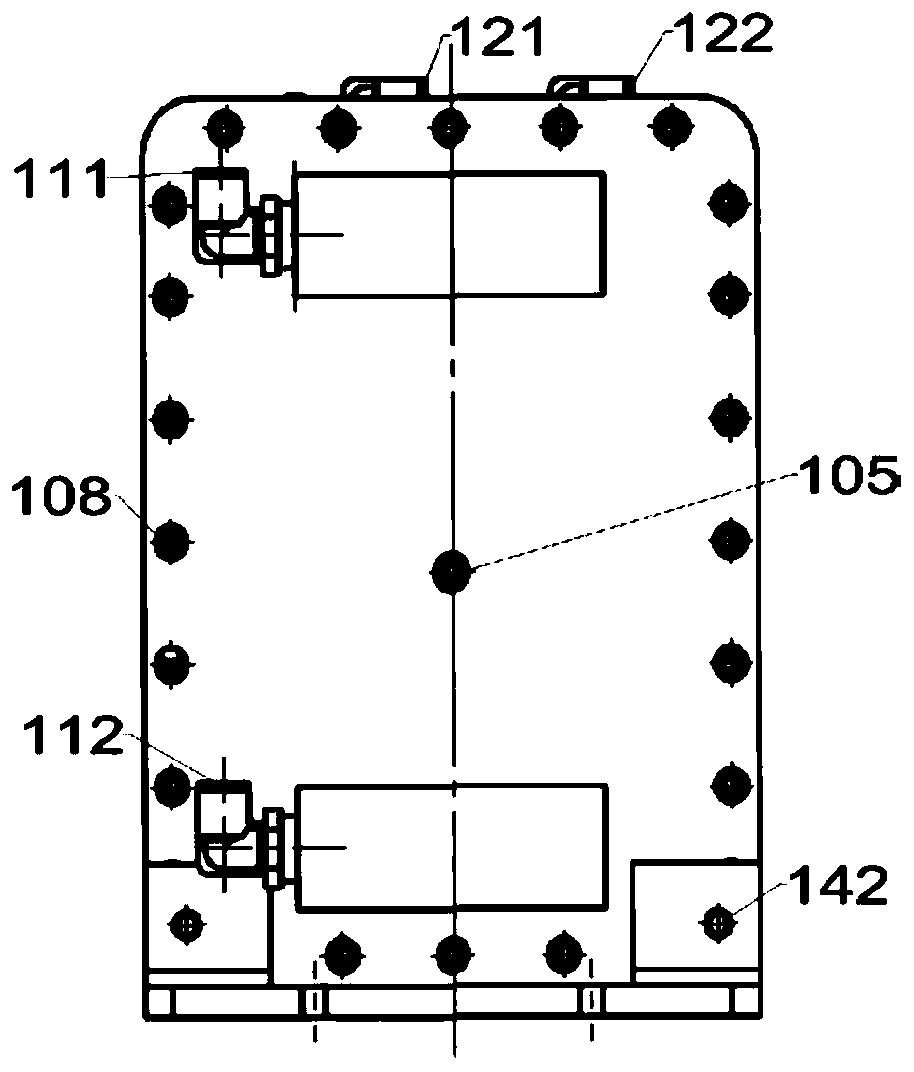

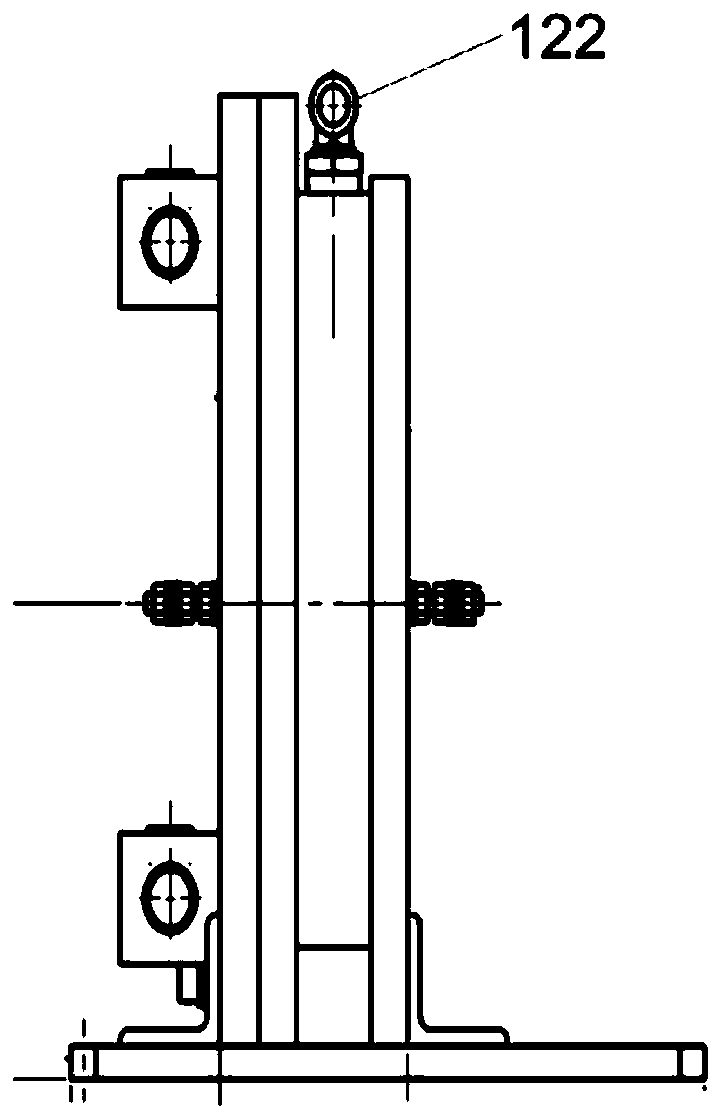

[0031] See Figure 1-5 As shown, this embodiment provides a small water electrolysis device 100, which includes an anode chamber 110, a cathode chamber 120, and an electrolytic membrane 130, and also includes a first electrolytic tank outer frame 103 and a second electrolytic tank outer frame 104. The edge of the outer frame 103 of an electrolytic cell and the edge of the outer frame 104 of the second electrolytic cell are provided with a plurality of corresponding limit mounting holes 108 for fixed connection; the electrolytic membrane 130 and the outer frame 103 of the first electrolytic cell form an anode chamber 110 The electrolytic membrane 130 and the outer frame 104 of the first electrolytic cell form a cathode chamber 120; the anode chamber 110 is provided with a first water inlet 111 and a first water outlet 112 at an upper part of one side opposite to the electrolytic membrane 130; An electrolyte inlet 121 and an electrolyte outlet 122 are provided on the top of the c...

Embodiment 2

[0038] See Image 6 As shown, this embodiment provides an electrolyzed water system, including the electrolyzed water device 100, the circulating water tank 200, and the electrolyzed water circulating tank 300 described in the first embodiment; the electrolyte circulating tank 300 is provided with a circulating pump 303 through a third The water pipe 301 and the fourth water pipe 302 are respectively connected to the electrolyte outlet 122 and the electrolyte inlet 121; the circulating water tank 200 is connected to the first water inlet 111 and the second water inlet 111 through the first water pipe 101 and the second water pipe 102, respectively. A water outlet 112 is connected; the circulating water tank 200 exchanges liquid with the outside through the water purification pipe 201 and the electrolysis water pipe 202 on the top.

[0039] In this embodiment, such as image 3 It also includes a rack 400, which is divided into an upper rack 401 and a lower rack 402; wherein the upp...

Embodiment 3

[0043] See Image 6 As shown, this embodiment provides an electrolyzed water system. The working principle of the electrolyzed water system is as follows: prepare sodium chloride in the electrolyte circulating tank 300; clean water enters the water circulating water tank 200 from the water purification pipe 201, and the upper part of the circulating water tank 200 A water pipe 101 enters the anode chamber 120; the circulating pump 303 generates electrolyte water from the electrolyte circulation tank 300, which is sent from the bottom of the electrolyte circulation tank 300 to the electrolyte inlet 121 through the third water pipe 301, and enters the cathode chamber 120; the power supply positive connector 105 and power supply negative The connector is connected to a rated voltage power supply; through the electrolytic membrane 130, the chloride ion in the electrolyzed brine undergoes an ion exchange reaction, and hypochlorous acid (HCLO) is generated in the anode chamber 110, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com