Method of reusing sampling material, edge cutting material and disqualified prepreg and copper-clad plate manufactured by using method

A technology of prepreg and copper clad laminate, applied in the field of copper clad laminate, can solve the problems of backward process equipment, environmental pollution, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

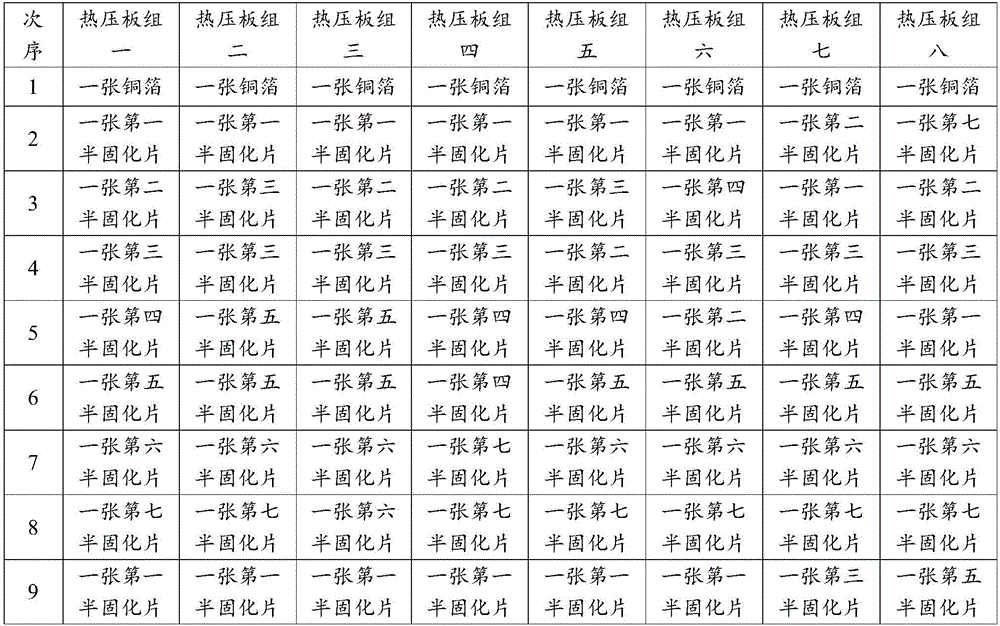

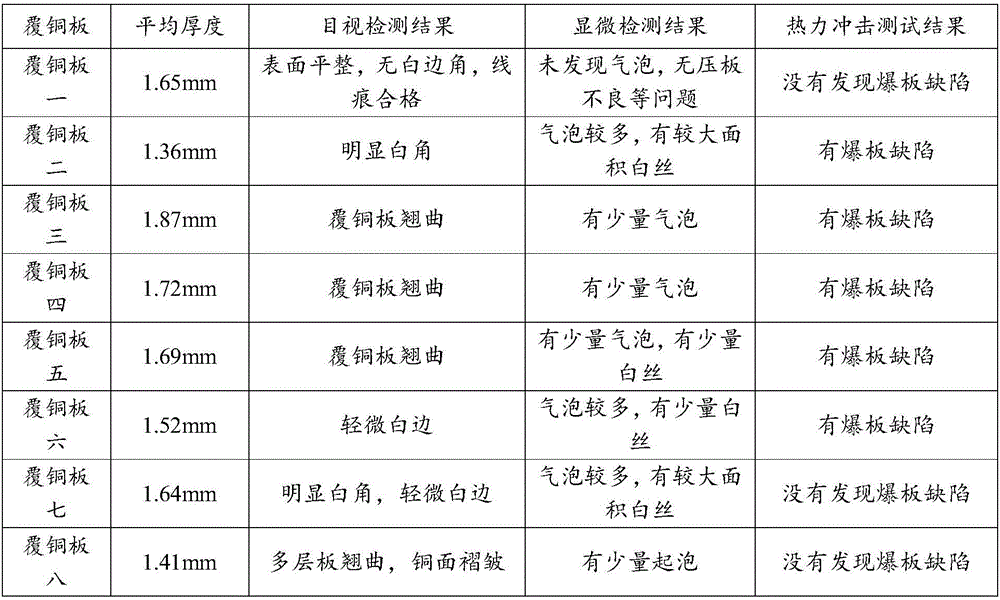

[0087] Example 1 Influence of the prepreg combination and its stacking sequence on the performance of copper clad laminates

[0088] (1) Select copper foil, sampling materials of qualified prepregs, trimming materials of qualified prepregs, and pressing plate materials shown in Table 1, and according to the specifications of 1065mm×1265mm, copper foil and pressing plate materials shown in Table 1 are respectively Carry out cutting, put together the sampling material of the prepreg qualified product into the second prepreg, and put together the trimming material of the prepreg qualified product into the fourth prepreg, for subsequent use; wherein, the first prepreg, the second prepreg, the third prepreg, the first prepreg The fourth prepreg, the fifth prepreg, the sixth prepreg and the seventh prepreg all include electronic grade glass fiber cloth with brand specification 7628 and organic resin glue soaked in the surface and inside of the electronic grade glass fiber cloth with ...

Embodiment 2

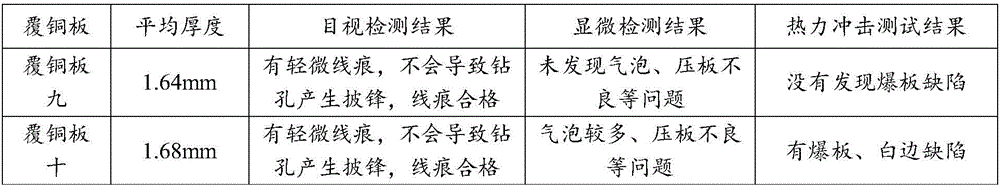

[0111] Example 2 Influence of Hot Press Forming Process on the Performance of Copper Clad Laminates

[0112] (1) Select copper foil, sampling materials of qualified prepregs, trimming materials of qualified prepregs, and pressing plate materials shown in Table 4, and according to the specifications of 1065mm×1265mm, copper foil and pressing plate materials shown in Table 4 are respectively Carry out cutting, put together the sampling material of the prepreg qualified product into the second prepreg, and put together the trimming material of the prepreg qualified product into the fourth prepreg, for subsequent use; wherein, the first prepreg, the second prepreg, the third prepreg, the first prepreg The fourth prepreg, the fifth prepreg, the sixth prepreg and the seventh prepreg all include electronic grade glass fiber cloth with brand specification 7628 and organic resin glue soaked in the surface and inside of the electronic grade glass fiber cloth with brand specification 7628...

Embodiment 3

[0123] (1) Select copper foil, sampling materials of qualified prepregs, trimming materials of qualified prepregs, and pressing plate materials shown in Table 4, and according to the specifications of 1065mm×1265mm, copper foil and pressing plate materials shown in Table 4 are respectively Carry out cutting, put together the sampling material of the prepreg qualified product into the second prepreg, put together the trimming material of the prepreg qualified product into the fourth prepreg, according to the stacking order of the pressing plate materials in the hot pressing plate set one in Table 2, the obtained pressing plate Materials are sequentially stacked to form hot-pressed plate group eleven, hot-pressed plate group twelve, and hot-pressed plate group thirteen, for standby; copper foil and eight qualified prepregs are stacked to form hot-pressed plate group fourteen, for standby; , the first prepreg, the second prepreg, the third prepreg, the fourth prepreg, the fifth pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com