Manufacturing method of three-layer metal clad steel plate

A manufacturing method and metal cladding technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low safety factor of the explosive cladding method, no effective solution, safe environment pollution, etc., to overcome the hard cracking reaction. , Improve the yield and added value, the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

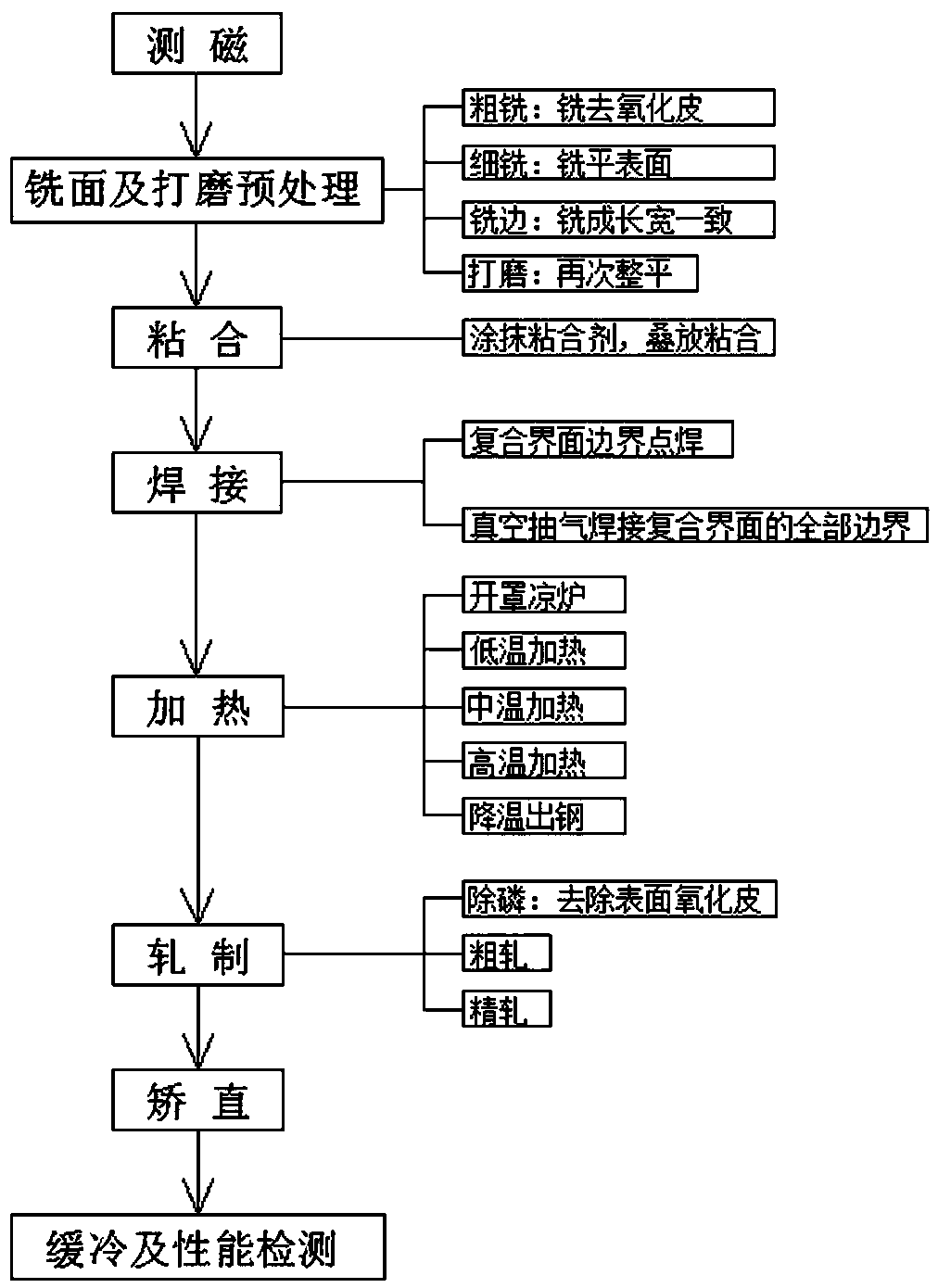

[0034] A method for manufacturing a three-layer metal clad steel plate. The metal clad blank steel plate is made of ordinary carbon structural steel. The specific steps are as follows:

[0035] S1. Magnetic measurement: Determine the size of the composite billet steel plate and roll the size. The size of each composite billet steel plate is not greater than 370mm. Measure the magnetic content of each composite billet steel plate. The composite billet steel plate needs to be degaussed to reduce the excessive magnetic content;

[0036] S2. Pretreatment: milling and grinding the surface to be compounded of the composite billet steel plate; milling includes rough milling, fine milling and edge milling; rough milling first mills off the oxide skin on the composite surface of the composite billet steel plate, and then fine milling The composite interface is milled and flattened, and the length and width of the composite interface are milled to be consistent by edge milling; the grind...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is:

[0051] The metal composite blank steel plate is selected from low-alloy structural steel;

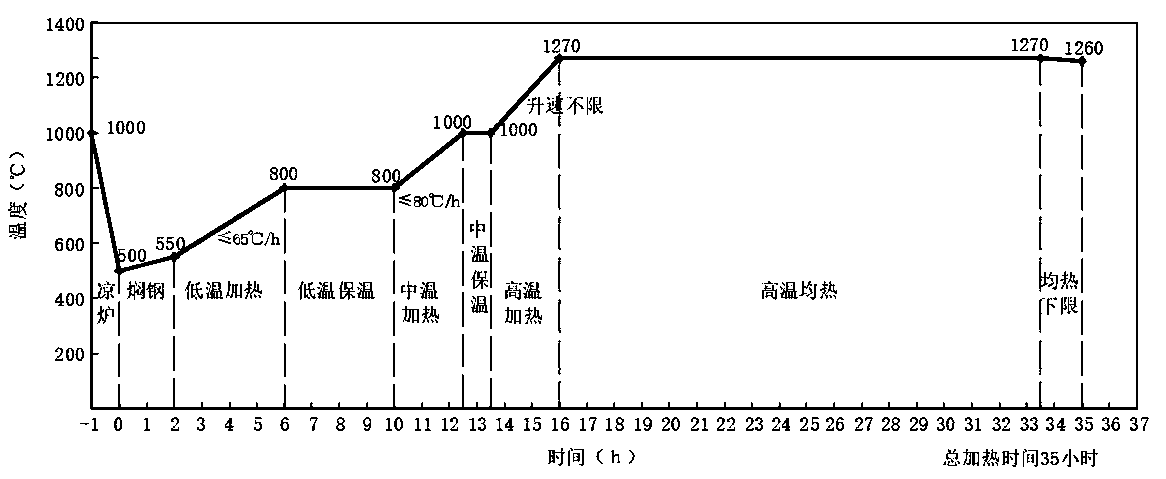

[0052] In the step S5, the heating rates of the low-temperature section heating, the medium-temperature section heating and the high-temperature section heating are all strictly controlled, the heating rate of the low-temperature section heating is not greater than 65°C / hour, and the heating rate of the medium-temperature section heating is not greater than 80°C / hour , the heating rate must be gradually increased, no, in the process of heating and stress release slowly offset from the base temperature to the target temperature position to avoid cracking of the clad steel plate due to stress release during heating; the heating rate of the high temperature section is not controlled, The initial temperature of the heating in the high-temperature section is as high as 1000°C. Long-term heating has made the heating temperature...

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 1 is:

[0060] In the step S5, the heating rates of the low-temperature section heating, the medium-temperature section heating and the high-temperature section heating are all strictly controlled, the heating rate of the low-temperature section heating is not greater than 65°C / hour, and the heating rate of the medium-temperature section heating is not greater than 80°C / hour , the heating rate must be gradually increased, no, in the process of heating and stress release slowly offset from the base temperature to the target temperature position to avoid cracking of the clad steel plate due to stress release during heating; the heating rate of the high temperature section is not controlled, The initial temperature of the heating in the high-temperature section is as high as 1000°C. Long-term heating has made the heating temperature of the composite steel plate uniform and the stress has been released. Therefore, the heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com