Chemical method for preparing halogenation methylamine lead photoelectric thin film in large-area manner

A halogenated methylamine, photoelectric thin film technology, applied in metal material coating process, coating, solid-state diffusion coating and other directions, can solve problems such as difficulty in large-area preparation, achieve a wide range of laboratory device research and industrial application prospects, overcome the The effect of demanding requirements and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparatory work: Sputter a 60nm-thick elemental lead film on the surface of a clean base material, and the film thickness is controlled by film thickness monitoring. Lead film area is 6cm 2 , the total mass of lead is about 0.41mg. The elemental lead thin film is ready for use after deposition.

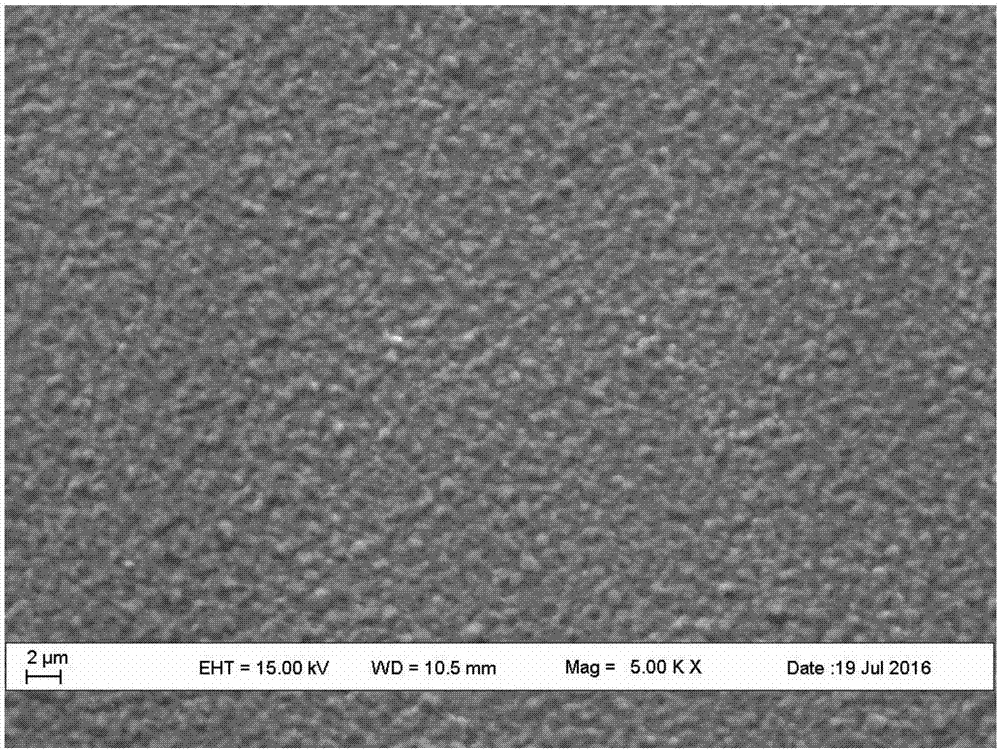

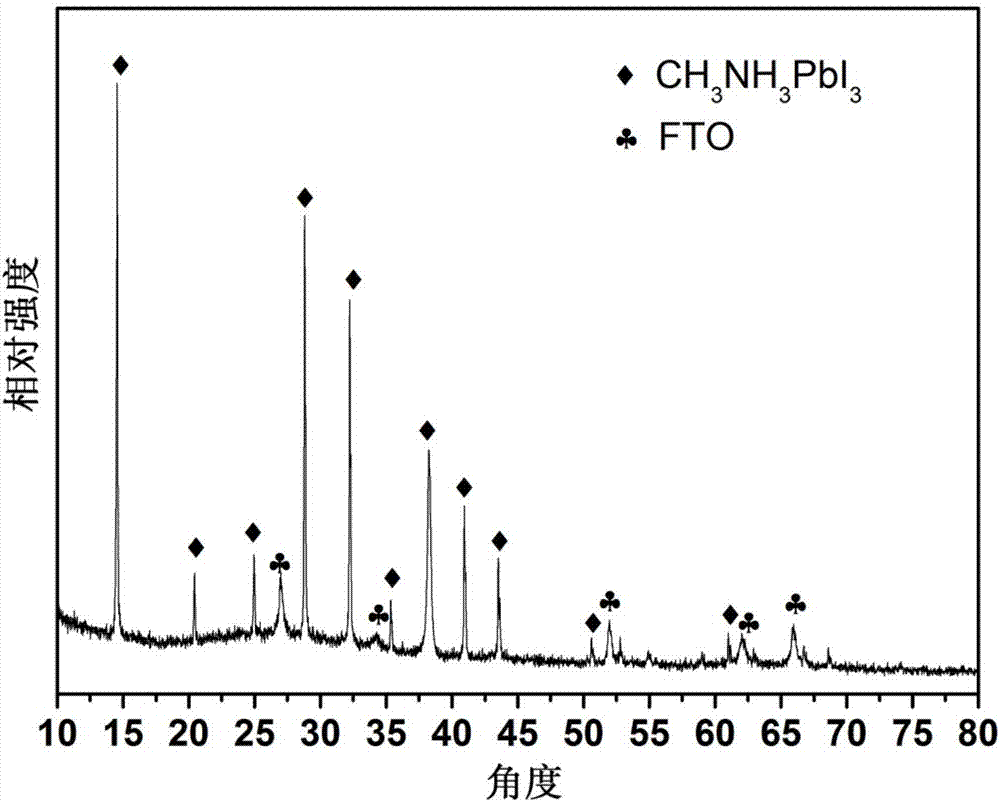

[0042]2. Reaction steps: Weigh 43 mg of methylamine iodide and place it in a crucible, place the substrate sputtered with lead elemental substance on top of the methylamine iodide powder and cover the crucible lid, and use an oil pump to evacuate the tube furnace to 0.01Mpa , and then feed nitrogen, repeat the operation 3 times, then vacuumize, and heat up under the vacuum condition of 0.01Mpa. Heating at 200°C for 50 min, and cooling to room temperature naturally with the furnace after the reaction is complete. Nitrogen gas was introduced to normal pressure, and the prepared methylamine halide lead film was taken out. SEM photo see figure 1 , XRD picture see figure ...

Embodiment 2

[0044] 1. Preparatory work: Sputter a 60nm-thick elemental lead film on the surface of a clean base material, and the film thickness is controlled by film thickness monitoring. Lead film area is 6cm 2 , the total mass of lead is about 0.41mg. The elemental lead thin film is ready for use after deposition.

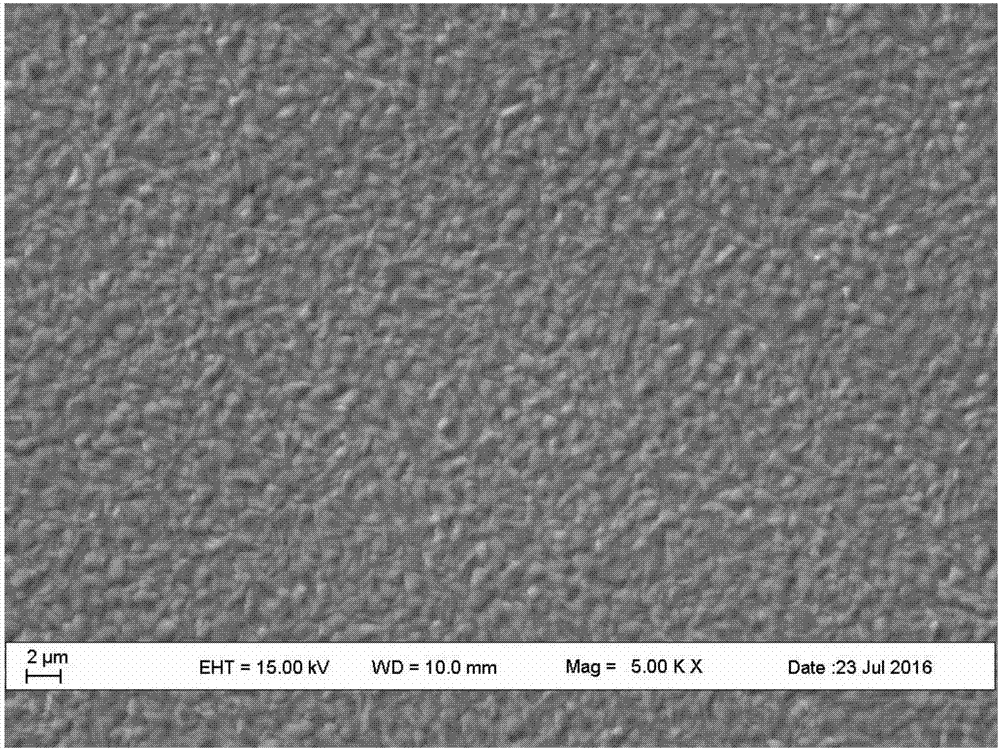

[0045] 2. Reaction steps: Weigh 30 mg of methylamine iodide and place it in a crucible, place the substrate sputtered with lead elemental substance on top of the methylamine iodide powder and cover the crucible lid, and use an oil pump to evacuate the tube furnace to 0.01Mpa , and then feed nitrogen, repeat the operation 3 times, then vacuumize, and heat up under the vacuum condition of 0.01Mpa. Heat at 270°C for 3 minutes, and cool down to room temperature naturally with the furnace after the reaction is complete. Nitrogen gas was introduced to normal pressure, and the prepared methylamine halide lead film was taken out. SEM photo see image 3 , XRD picture see Figu...

Embodiment 3

[0047] 1. Preparatory work: Sputter a 50nm-thick elemental lead film on the surface of a clean base material, and the film thickness is controlled by film thickness monitoring. Lead film area is 6cm 2 , the total mass of lead is about 0.34mg. The elemental lead thin film is ready for use after deposition.

[0048] 2. Reaction steps: Weigh 40 mg of methylamine iodide and place it in a crucible, place the substrate sputtered with lead elemental substance on top of the methylamine iodide powder and cover the crucible lid, and use an oil pump to evacuate the tube furnace to 0.01Mpa , Then feed nitrogen, repeat this operation 3 times, then heat up under the vacuum condition of 0.01Mpa. Heat at 270°C for 3 minutes, and cool down to room temperature naturally with the furnace after the reaction is complete. Nitrogen gas was introduced to normal pressure, and the prepared methylamine halide lead film was taken out. SEM photo see Figure 5 , XRD picture see Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com