Method for extracting heparin sodium from cattle lungs

A technology of heparin sodium and bovine lung, which is applied in the field of extracting heparin sodium, can solve the problems of low product yield, low product yield, and high production cost, and achieve the effects of simplifying the production process, reducing production cost, and improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

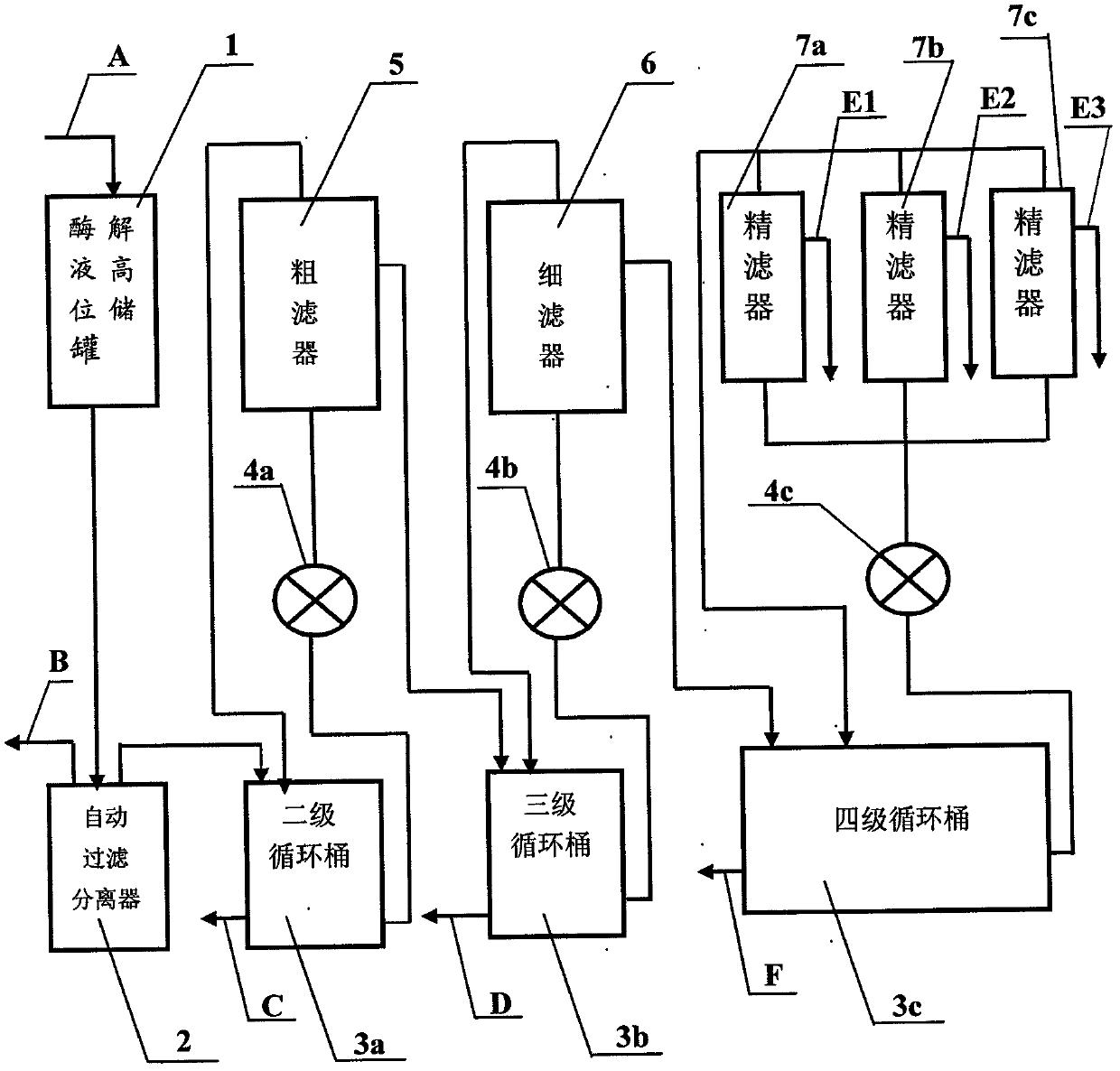

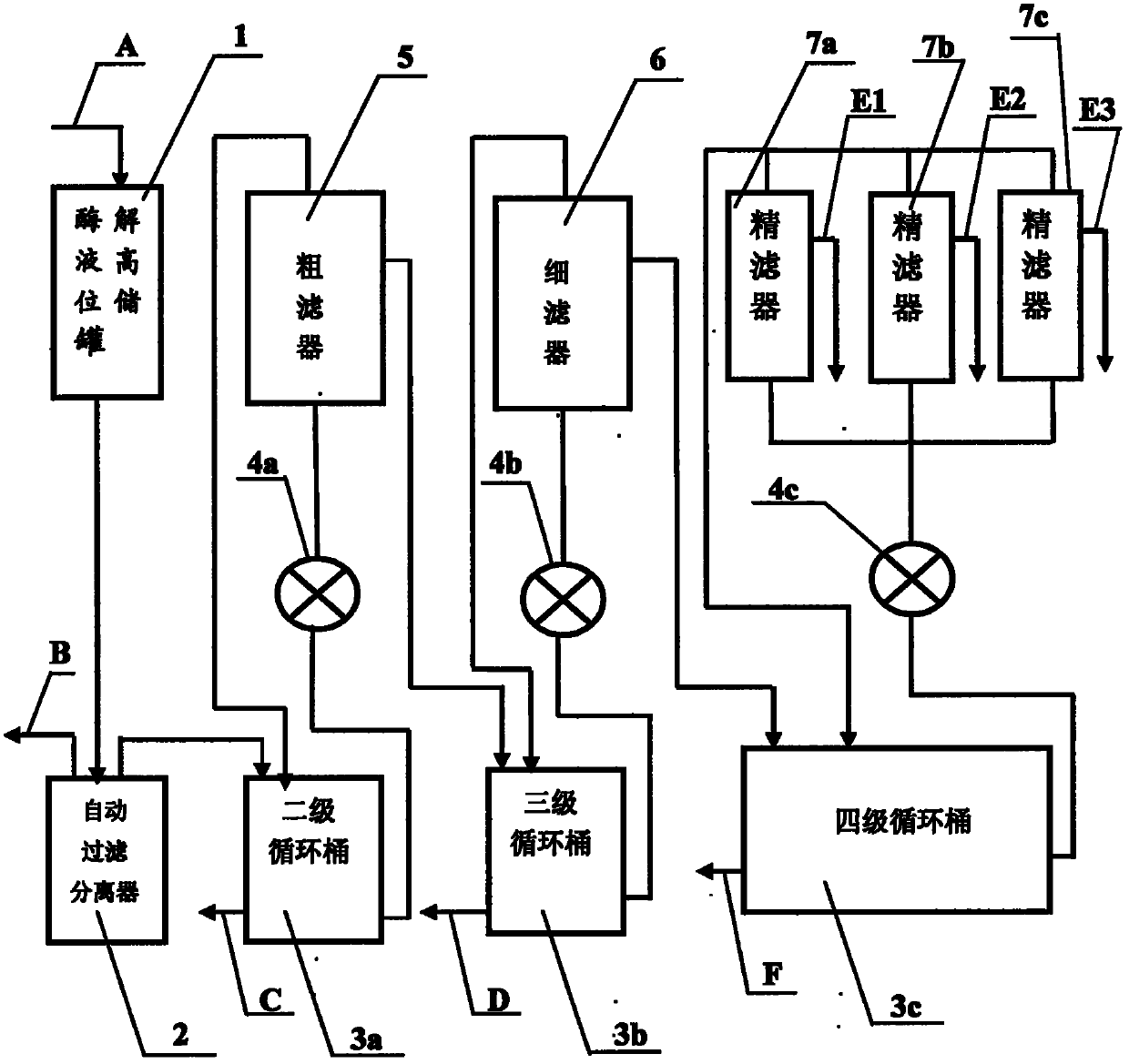

[0019] Example 1: See figure 1 , A method for extracting heparin sodium from bovine lungs, characterized in that it comprises the following steps:

[0020] (1) Pulping: remove the large trachea and external cortical fat in the bovine lung, mince it, and homogenize it into a slurry, bovine lung: water = 1:2-3, adjust the pH to 9;

[0021] (2) Enzymatic hydrolysis: heat the above slurry to 39-41°C, add protease according to 1.5-3.5% of the slurry mass, carry out enzymatic hydrolysis for 3-4 hours, monitor the change of pH, control the pH to 7.5-8.5, filter enzymatic hydrolysis Then add heparin sodium special complex enzyme at 0.5-1.5% of the mass of the slurry, raise the temperature to 49-51 degrees, control the pH to 7.5-8.5, keep the temperature for 3-3.5 hours, and monitor the titer of the enzyme hydrolysate. End of change enzymatic hydrolysis;

[0022] (3) Enzyme inactivation: add protein precipitation agent and NaCL to the enzymatic hydrolysate obtained in step (2). The protein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com