Closed flotation system with dross blowing device

A flotation and flotation cell technology, applied in flotation water/sewage treatment, etc., can solve the problems of slag scraper that is prone to failure, and achieve the effects of avoiding secondary pollution, overcoming scum overflow, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

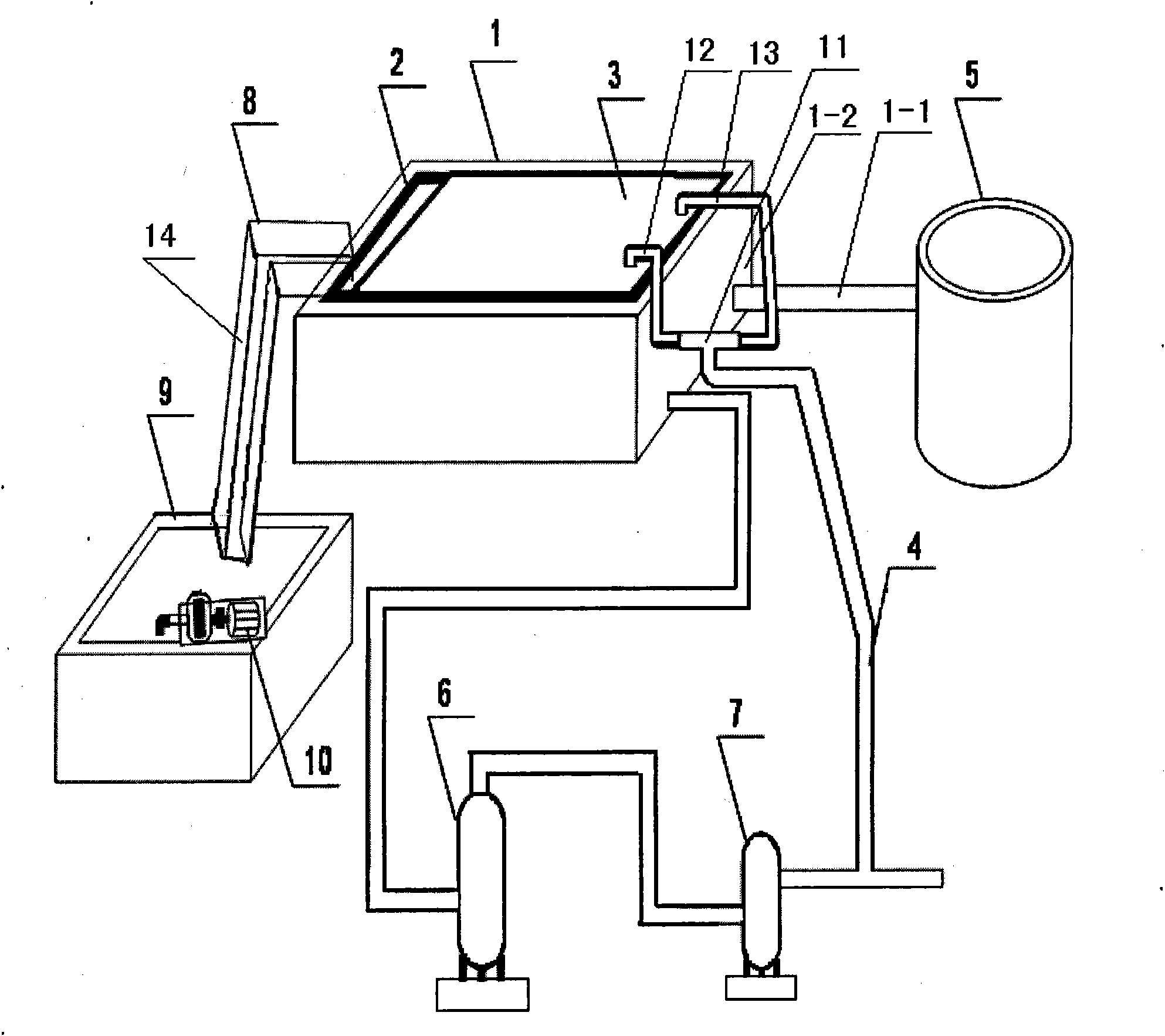

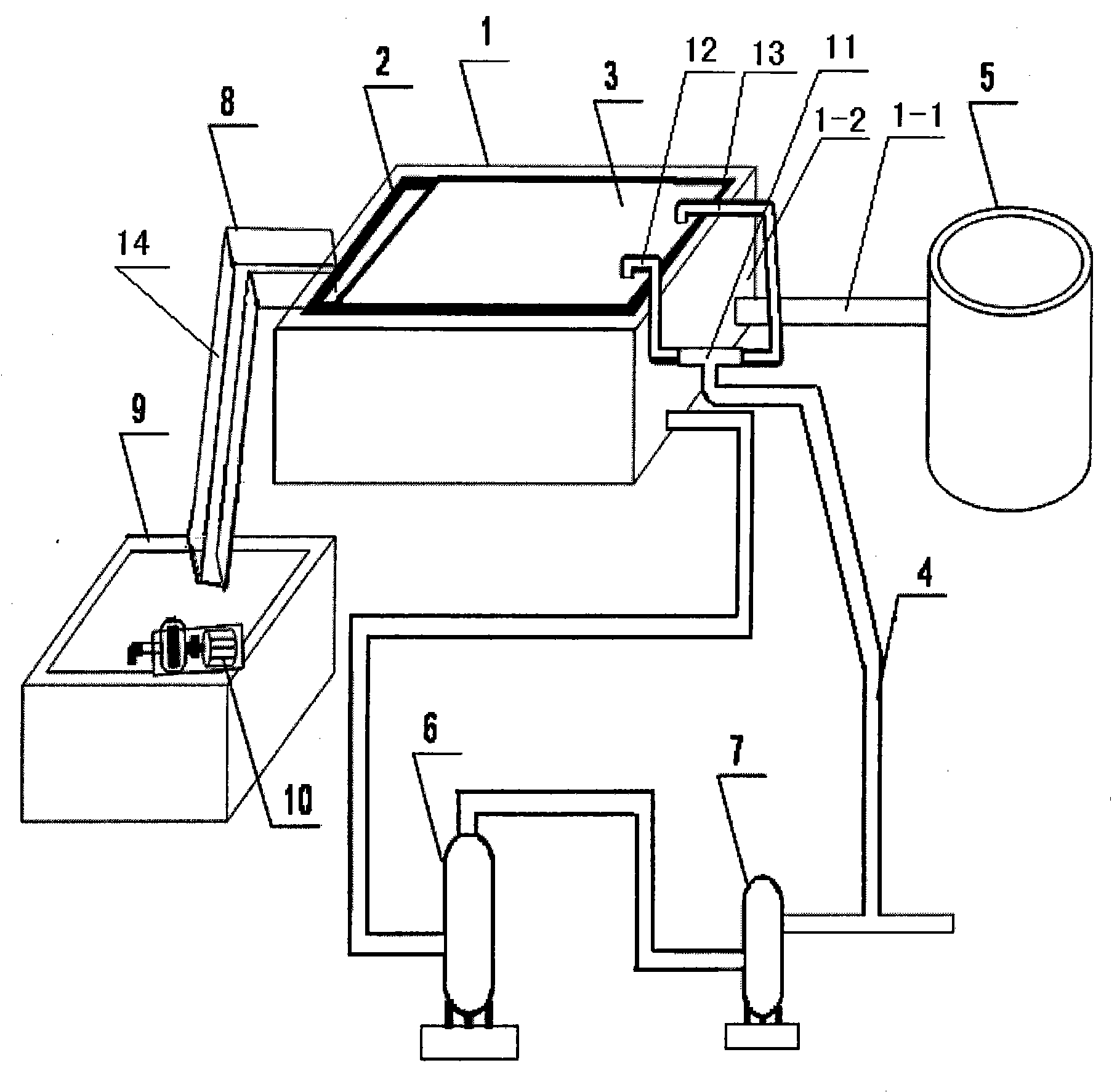

[0006] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. figure 1 The part with the reference number 5 is the degreasing tank, and the waste water flowing out from the degreasing tank 5 flows into the flotation tank 1 through the waste water inlet pipe 1-1. This embodiment includes a flotation cell 1, which also includes a compressed air pipeline 4, a tee pipe joint 11, a No. 1 blowpipe 12, a No. 2 blowpipe 13, a sealing gasket 2, a sealing plate 3, a slag removal tank 8, and a scum tank 9 , chute 14 and water pump 10, sealing plate 3 is covered on the top of flotation cell 1 and the upper opening of flotation cell 1 is closed, and sealing pad 2 is arranged on the pool wall contact place of sealing plate 3 and flotation cell 1, compressed air One end of the pipeline 4 communicates with one end of the three-way pipe joint 11, and the other two ends of the three-way pipe joint 11 communicate with one end of the ...

specific Embodiment approach 2

[0007] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes a container tank 6 and a buffer tank 7, the air inlet of the buffer tank 7 communicates with the compressed air pipeline 4, and the air outlet of the buffer tank 7 communicates with the air intake of the container tank 6 mouth, the gas outlet of container tank 6 communicates with the bottom of flotation cell 1. Such setting can make the slag deposited at the bottom of the flotation tank 1 be washed up by air bubbles, water flow, etc. generated by the gas fed in, so that the water can be treated more cleanly.

specific Embodiment approach 3

[0008] Specific implementation mode three: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the other end of the No. 1 blowpipe 12 and the other end of the No. 2 blowpipe 13 are evenly distributed along the length direction of the side wall 1 - 2 of the flotation cell 1 . Such setting makes the distribution of the air flow for purging the scum more reasonable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com