Patents

Literature

65results about How to "Solve the spillover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh bone powder-contained tabletting candy and manufacturing method thereof

InactiveCN105076626ACompletely retain nutrientsDoes not involve high temperatureConfectionerySweetmeatsAntioxidantMagnesium stearate

The invention discloses a fresh bone powder-contained tableting candy and a manufacturing method thereof, and aims at providing the fresh bone tankage-contained dextrose candy which is rich in nutrition and unique in taste. The technical point is that the tableting candy comprises the following components in parts by weight: 1 to 50 parts of bone tankage, 1 to 40 parts of sweetening agent, 1 to 30 parts of milk powder, 1 to 20 parts of resistant dextrin, 1 to 20 parts of maltodextrin, 1 to 20 parts of vegetable fat powder, 0.01 to 10 parts of antioxidant, 0.01 to 24.4 parts of phytosterol and 0.01 to 2 parts of magnesium stearate. The fresh bone powder-contained dextrose candy and the manufacturing method thereof belong to the technical field of food manufacturing.

Owner:广东骨全能生物食品科技有限公司

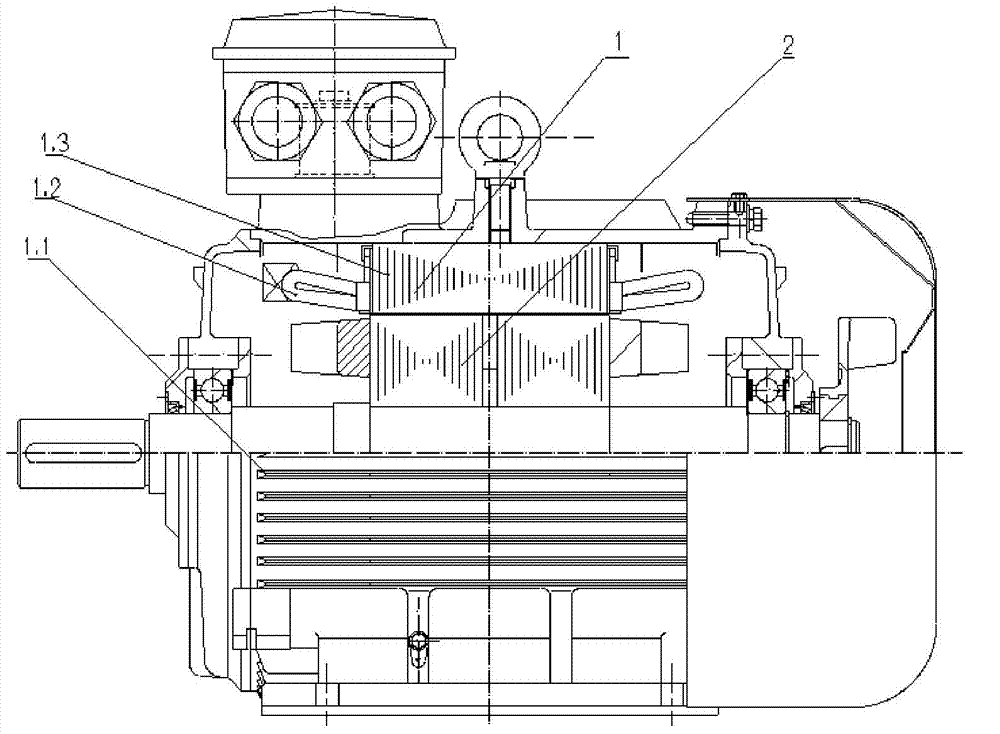

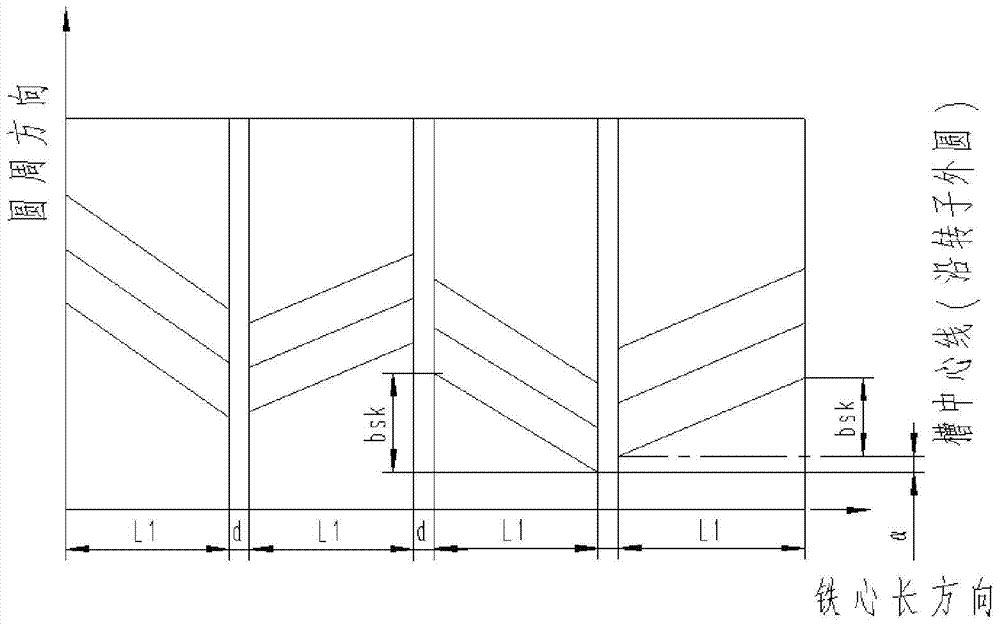

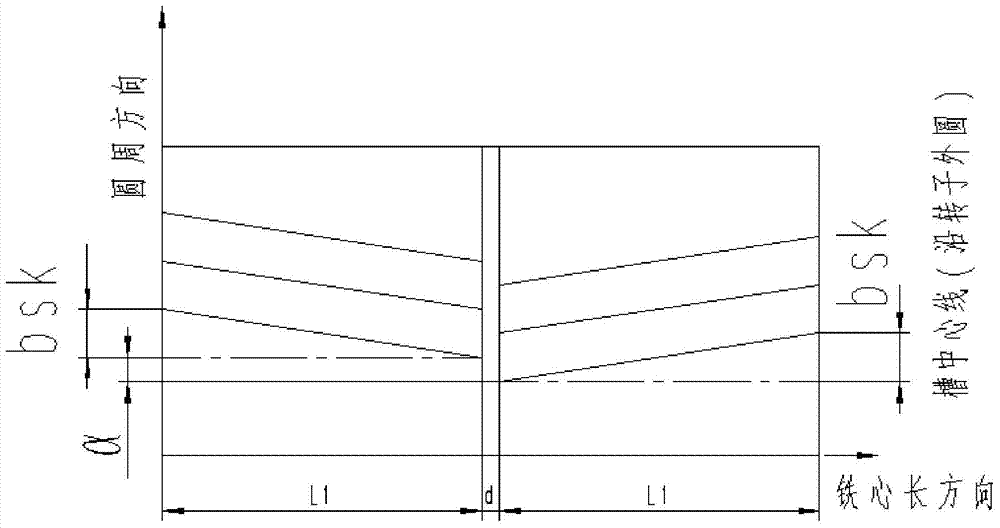

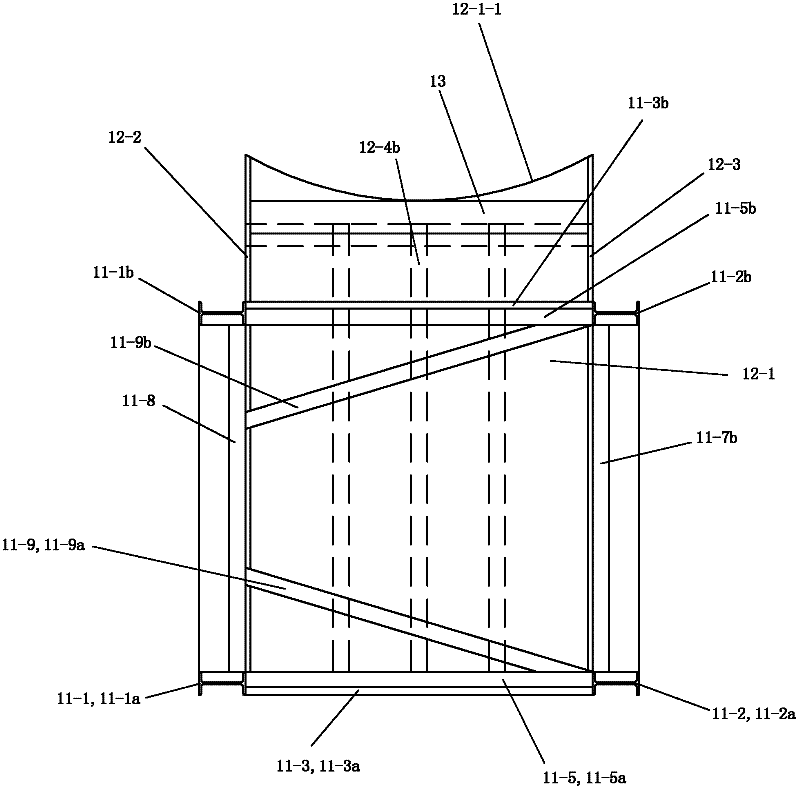

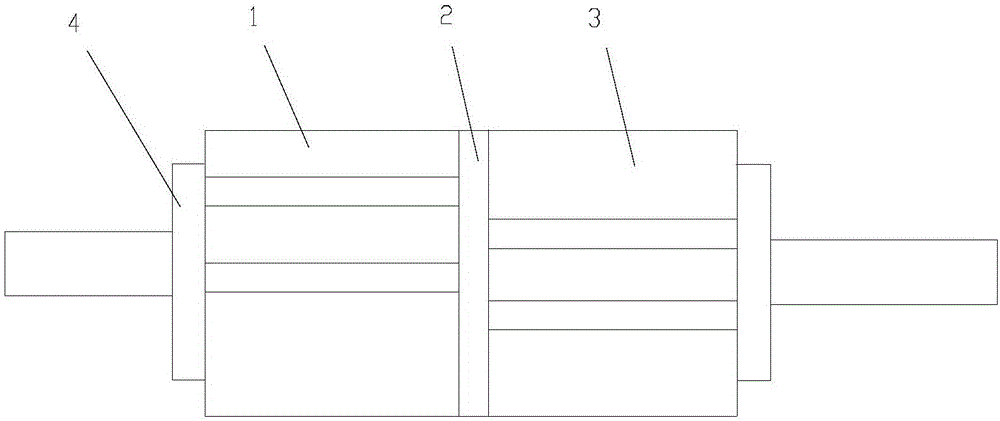

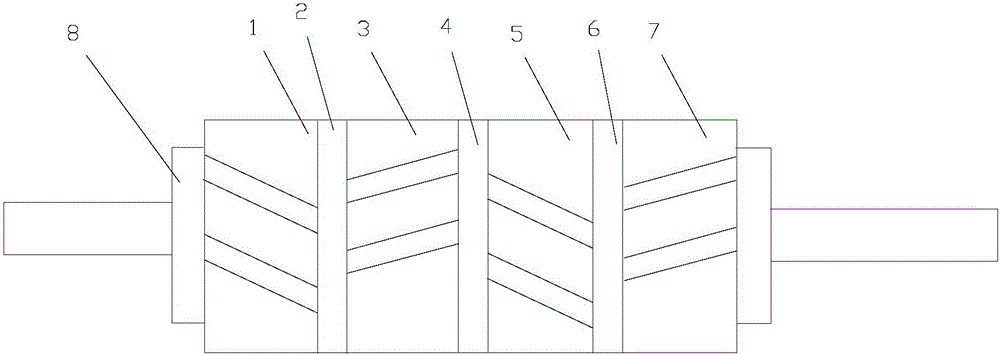

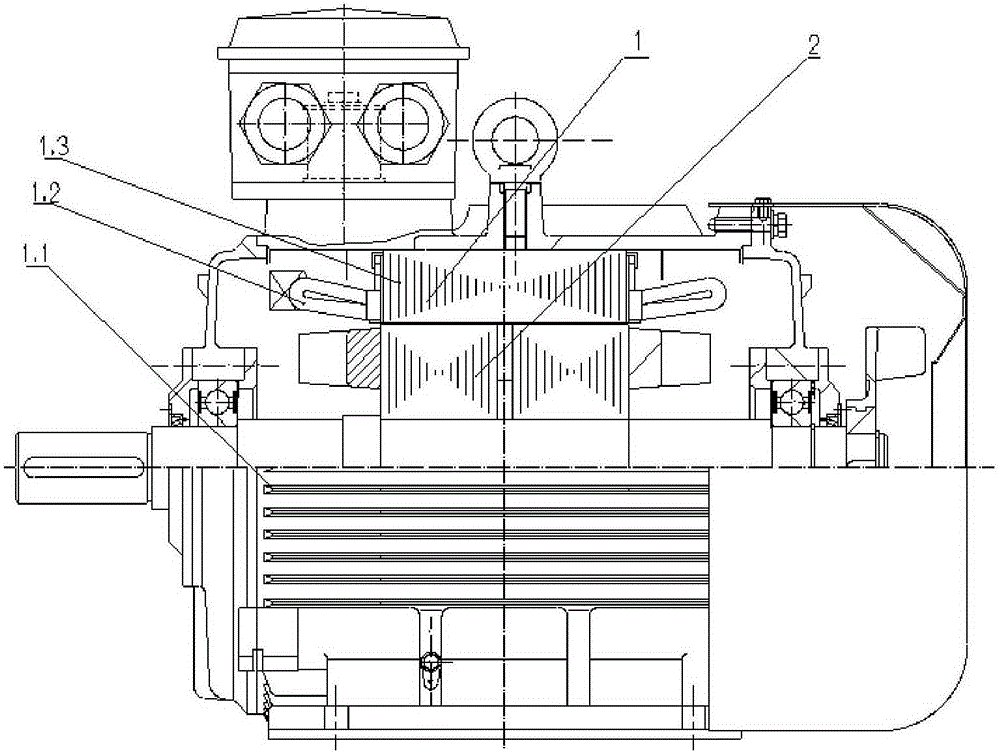

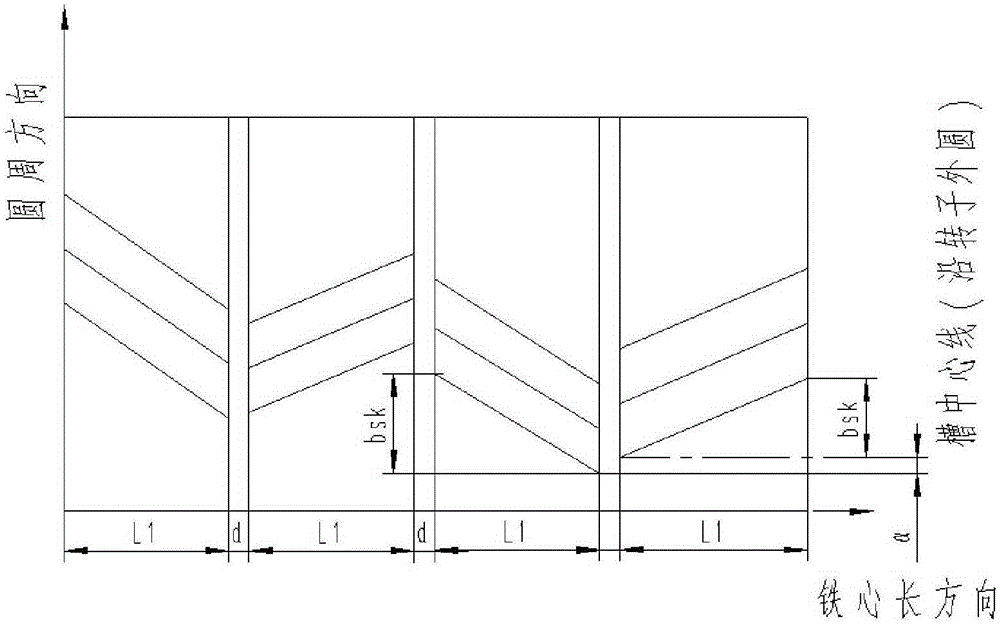

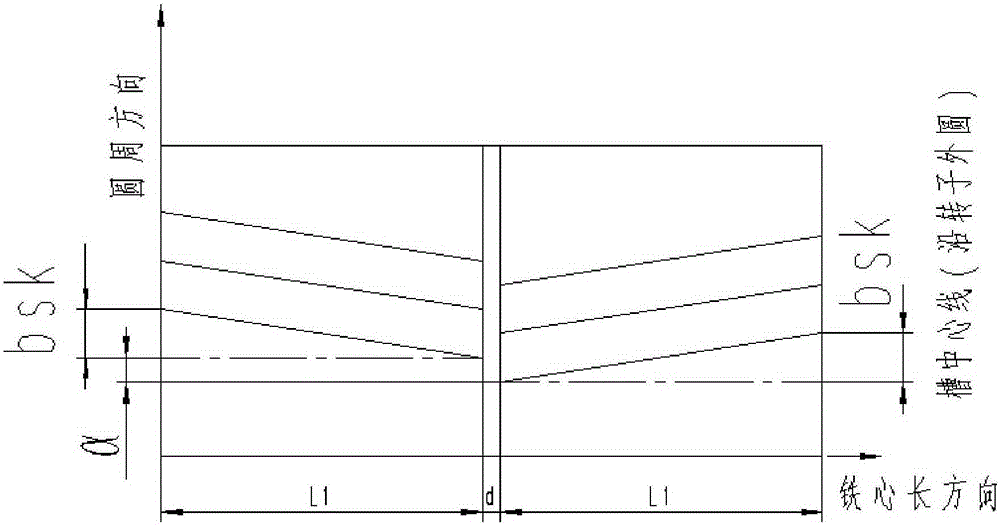

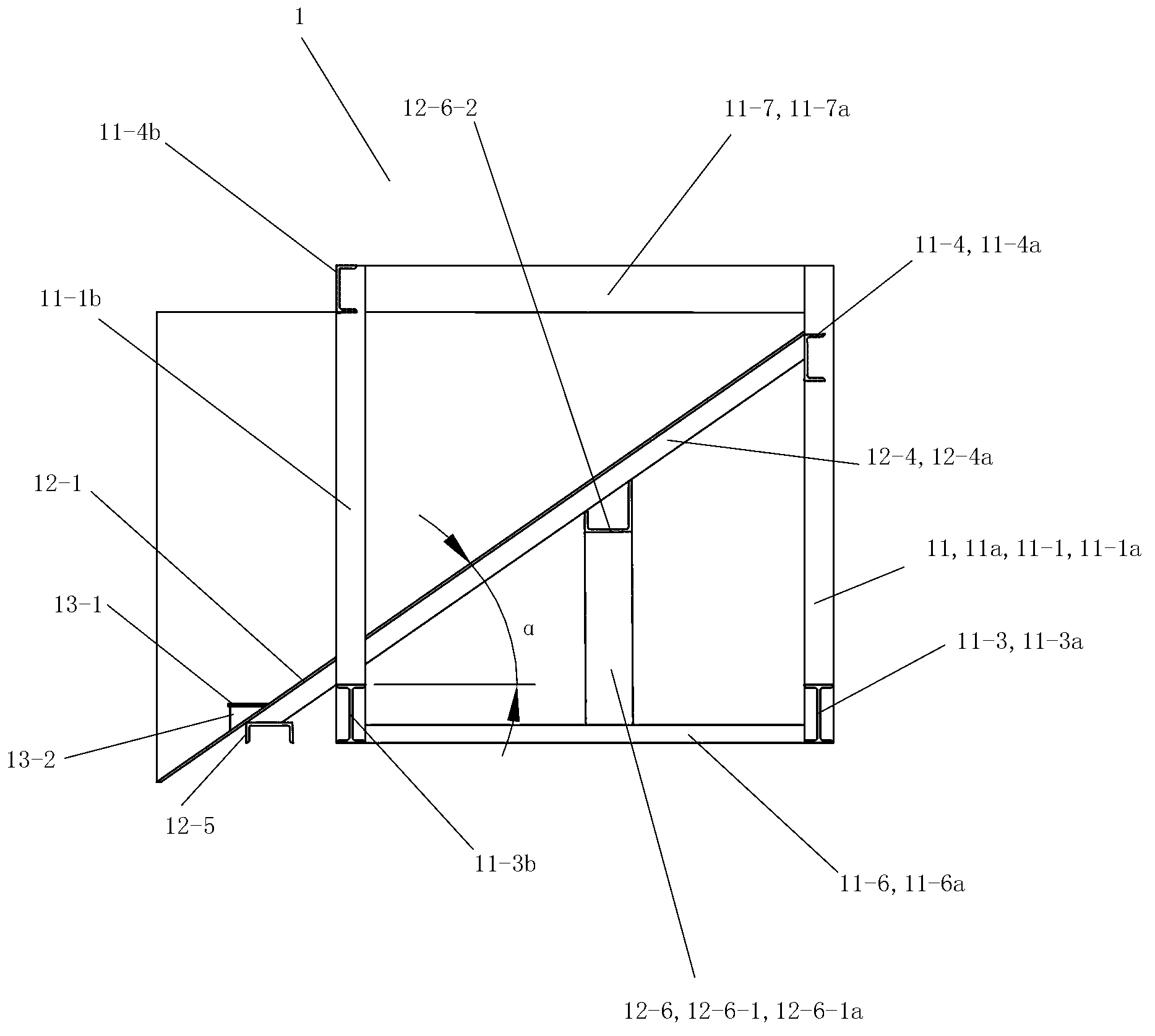

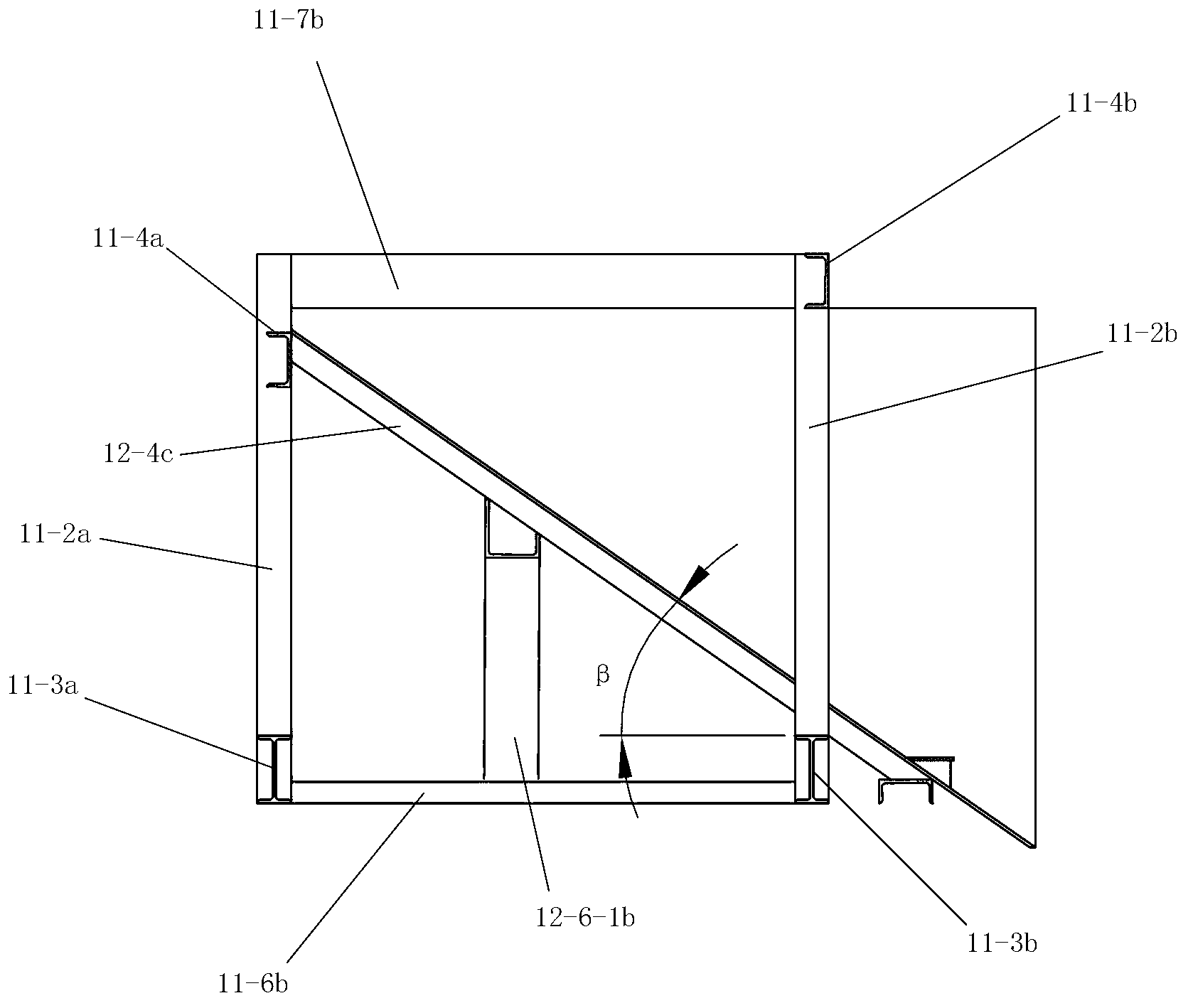

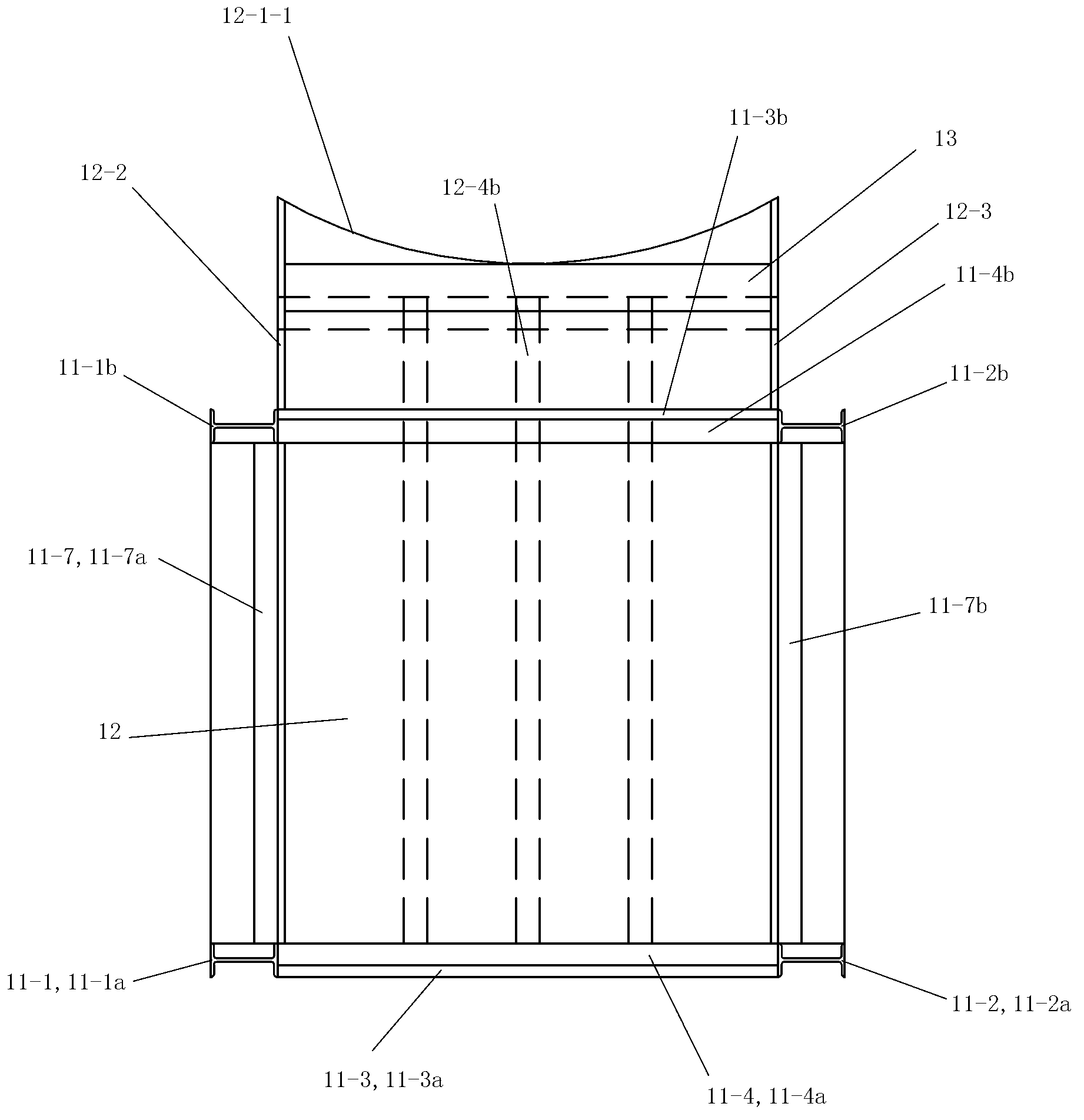

Chute low-noise motor

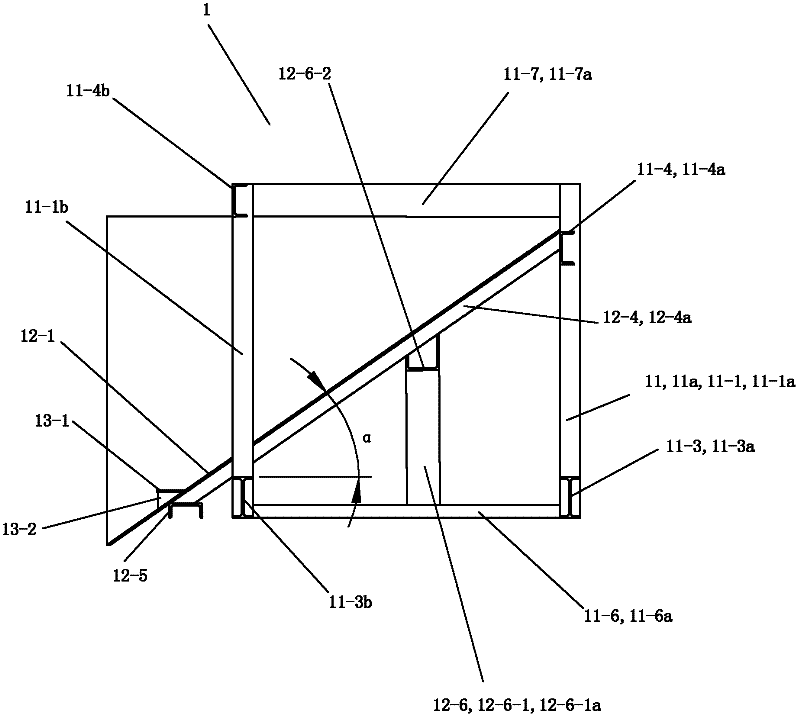

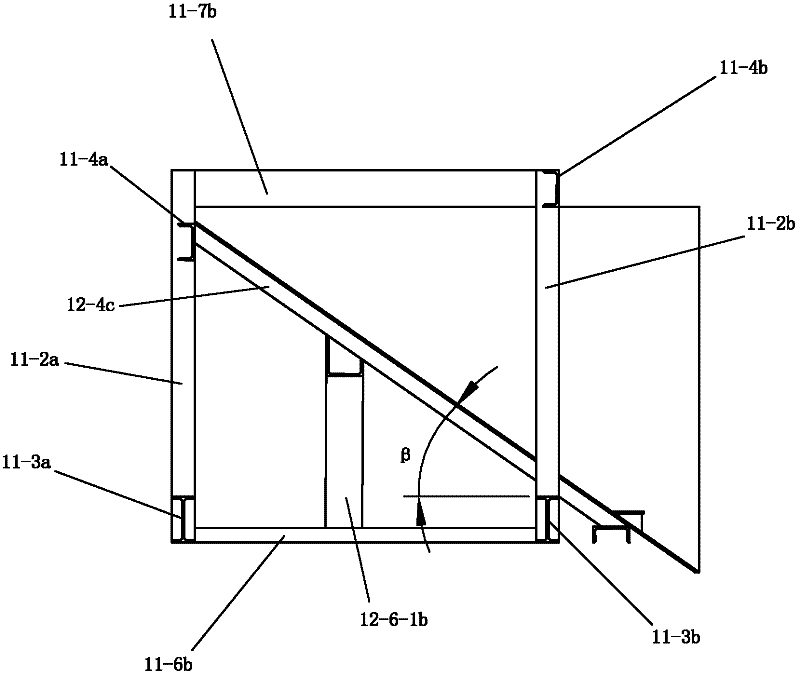

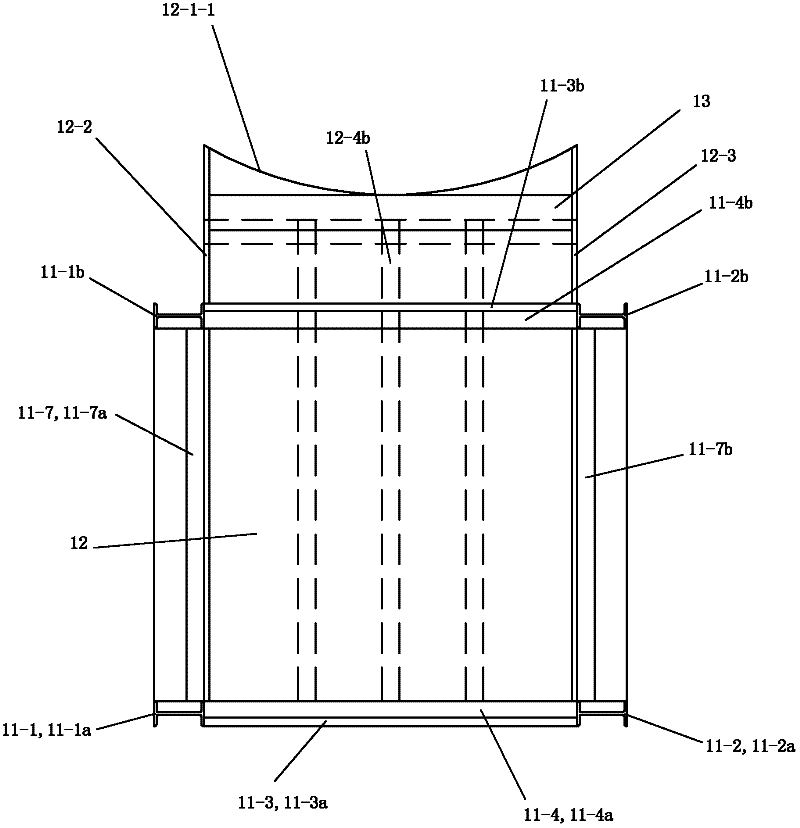

ActiveCN103501065AEliminate axialEliminate torsional vibrationMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to a motor, in particular to a chute low-noise motor, which comprises a machine seat, a stator, a rotor and a rotating shaft, wherein the stator, the rotor and the rotating shaft are arranged on the machine seat, the rotor comprises at least two sections of rotor iron cores, the rotor iron cores are punched and laminated by a false axis inclination angle taper key method to form chute iron cores; chutes of the adjacent chute iron cores are in opposite directions and are in arrangement in a way of staggering for an angle alpha. Therefore, the chute low-noise motor has the following advantages that 1, great-degree optimization is respectively realized in aspects of vibration, noise, iron core laminating quality, cast aluminum quality and chute cast aluminum rotor structure adopted by a high-power motor, and the chute low-noise motor is suitable for small and medium-sized cast aluminum rotor structure alternating current motors with higher vibration and noise requirements; 2, the stress uniformity and the rigidity of iron core laminating punching are fundamentally ensured, the iron core laminating quality is improved, the influence of deformation on vibration noise is reduced, the aluminum overflowing and bubble problems are solved, and the quality of the cast aluminum rotor and the motor performance reliability are improved.

Owner:中国船舶重工集团公司第七一二研究所

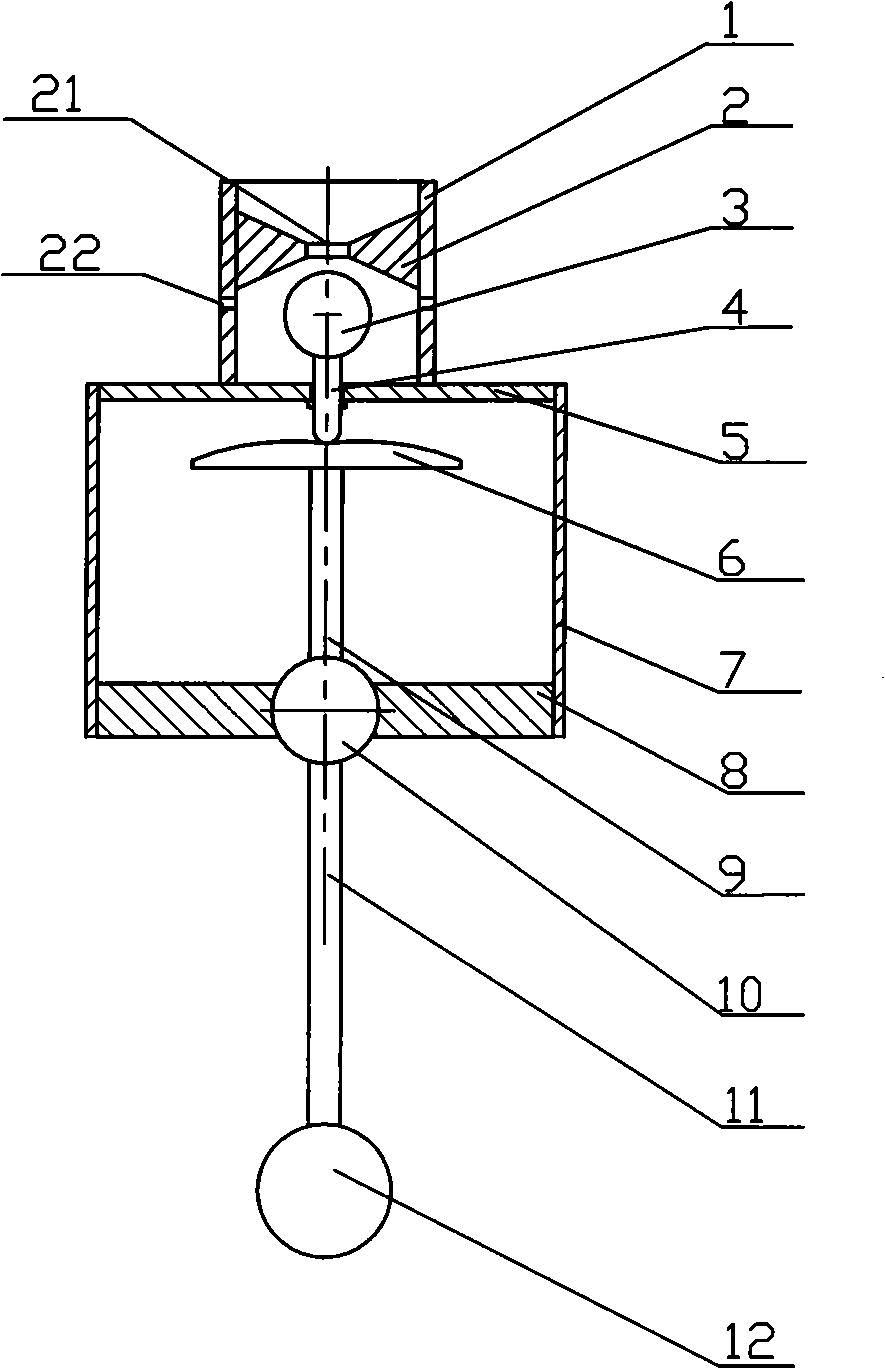

Self-closing valve for preventing liquid overflowing when container is dumped

ActiveCN101315133ASolve the spilloverSolve Collection IssuesOperating means/releasing devices for valvesLarge containersValve stemCam

The invention relates to a self-closing valve capable of preventing liquid overflowing when a container falls down, which comprises a valve mechanism. The self-closing valve is characterized in that the valve also comprises a supporting mechanism and a swing mechanism, and the valve mechanism, the supporting mechanism and the swing mechanism are symmetrically distributed on the same central axis line from top to bottom; when a container falls down, the swinging of a heavy hammer drives a ball bearing to rotate, so that a universal vertical cam is driven to perform corresponding swinging to jack up a valve stem and a valve clack, and the valve stem and the valve clack form compact surface contact or line contact before the content in the container is spilled out to seal the inlet / outlet port on a valve base. The inventive self-closing valve effectively solves liquid overflowing problem when the container falls down, and avoids many troubles due to failing to close the container filled with liquid or closing behind time by an operator; and also effectively solves the collection and storage problems of volatile liquid by arranging an exhaust valve. Therefore, the inventive self-closing valve has simple structure, and can be widely used in places requiring automatic prevention of liquid overflowing when the container falls down or prevention of volatilization and sputtering of volatile liquid.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

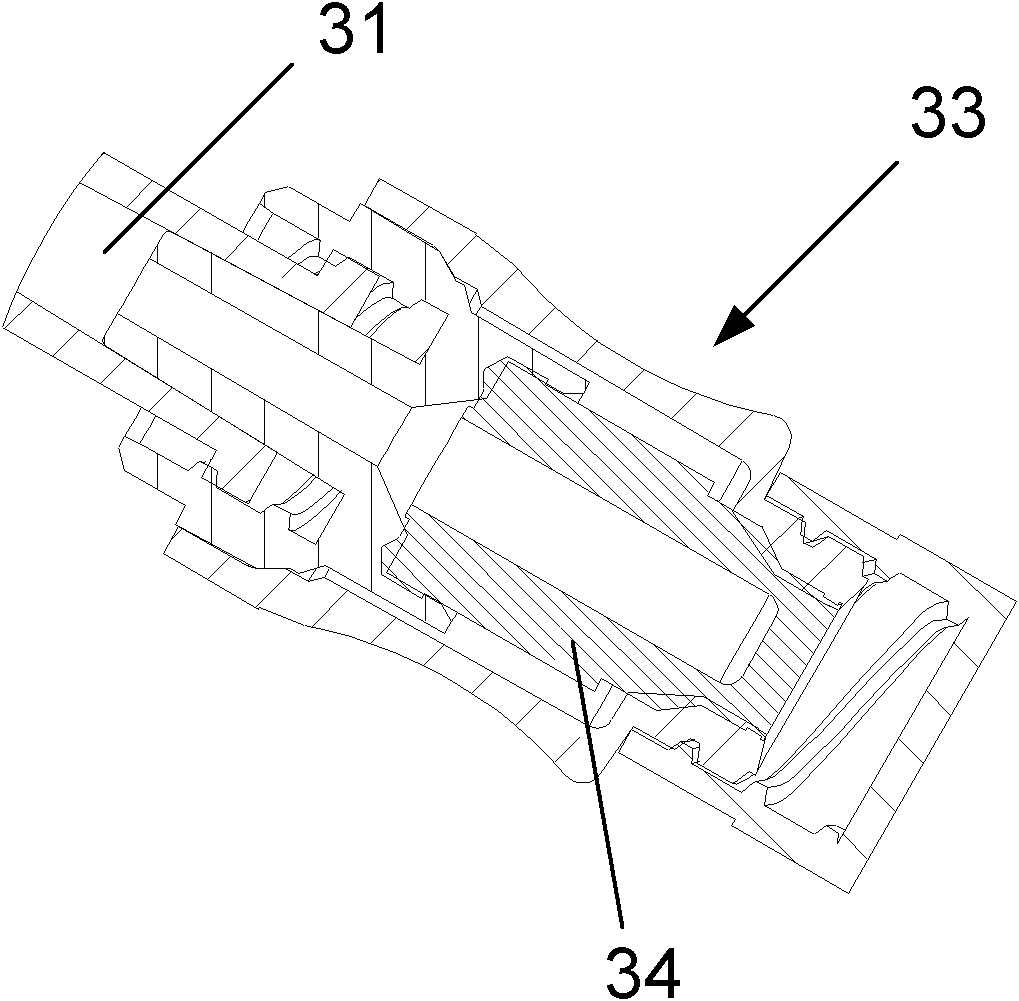

Rectum balloon dilatation catheter

InactiveCN101991906ASolving the Problems of ColonographyConvenient defecographySurgeryDilatorsBalloon dilatation catheterImaging quality

The invention relates to a rectum balloon dilatation catheter which comprises a catheter, a Y-shaped joint and a balloon, wherein the balloon is arranged at the head part of the catheter; the catheter comprises an outer catheter and an inner catheter arranged in a sheathing structure; and one end of the Y-shaped joint is connected with the tail part of the catheter, one end is a liquid injection port and an air injection port. The inner catheter is communicated with the liquid injection port, the outer catheter is communicated with the air injection port, and the catheter wall at the head part of the outer catheter is provided with a small hole for communicating the inner cavity with the balloon. The rectum balloon dilatation catheter is mainly used for improving detection quality and developing a new detection method. The invention has wide application range in clinic and can obviously improve image quality.

Owner:SHANGHAI KINDLY MEDICAL INSTR CO LTD

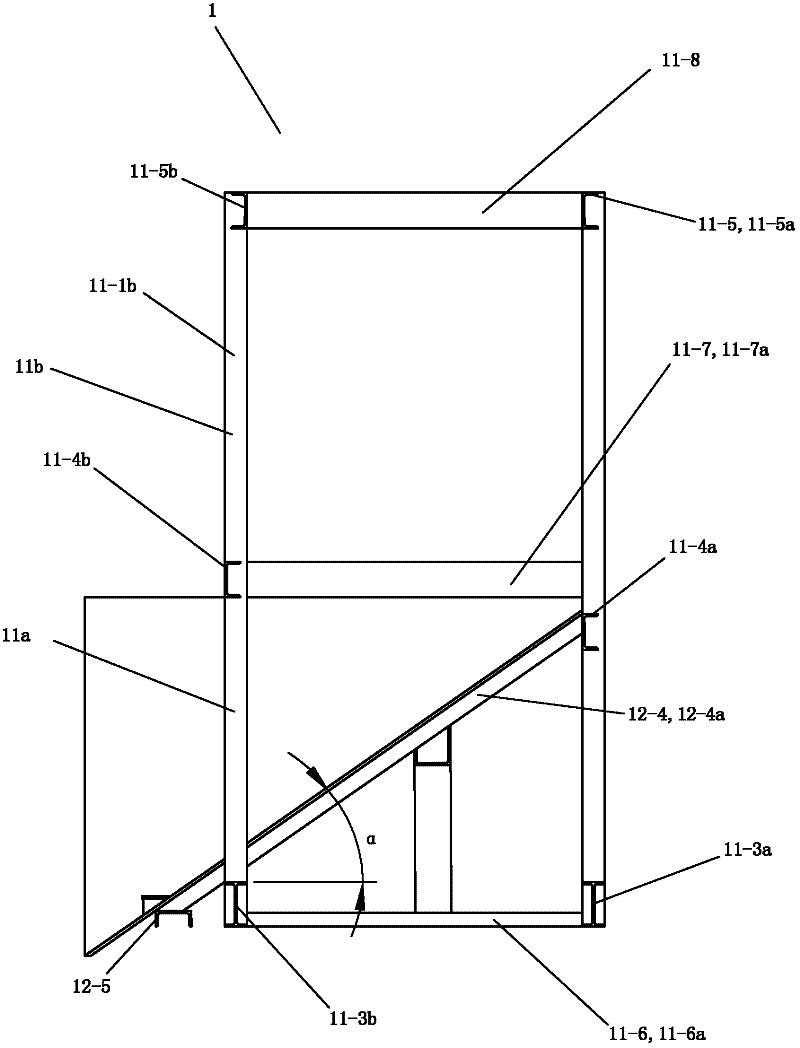

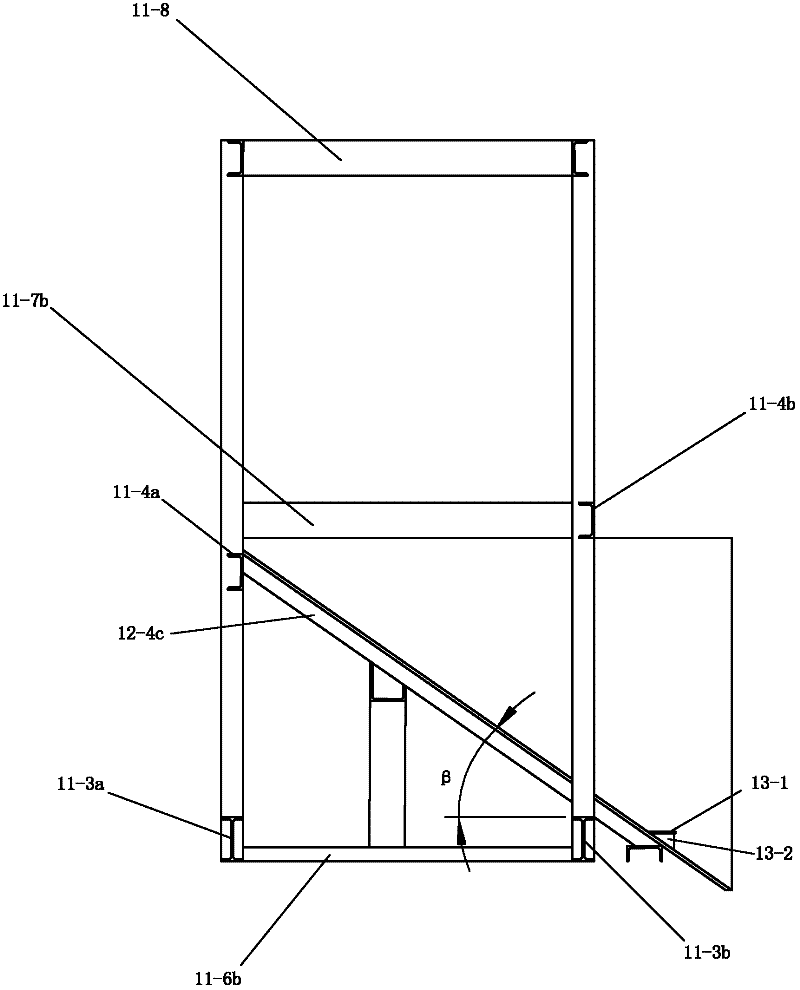

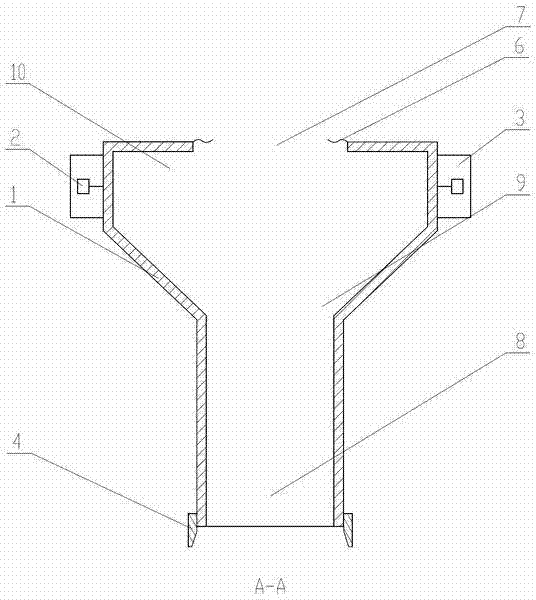

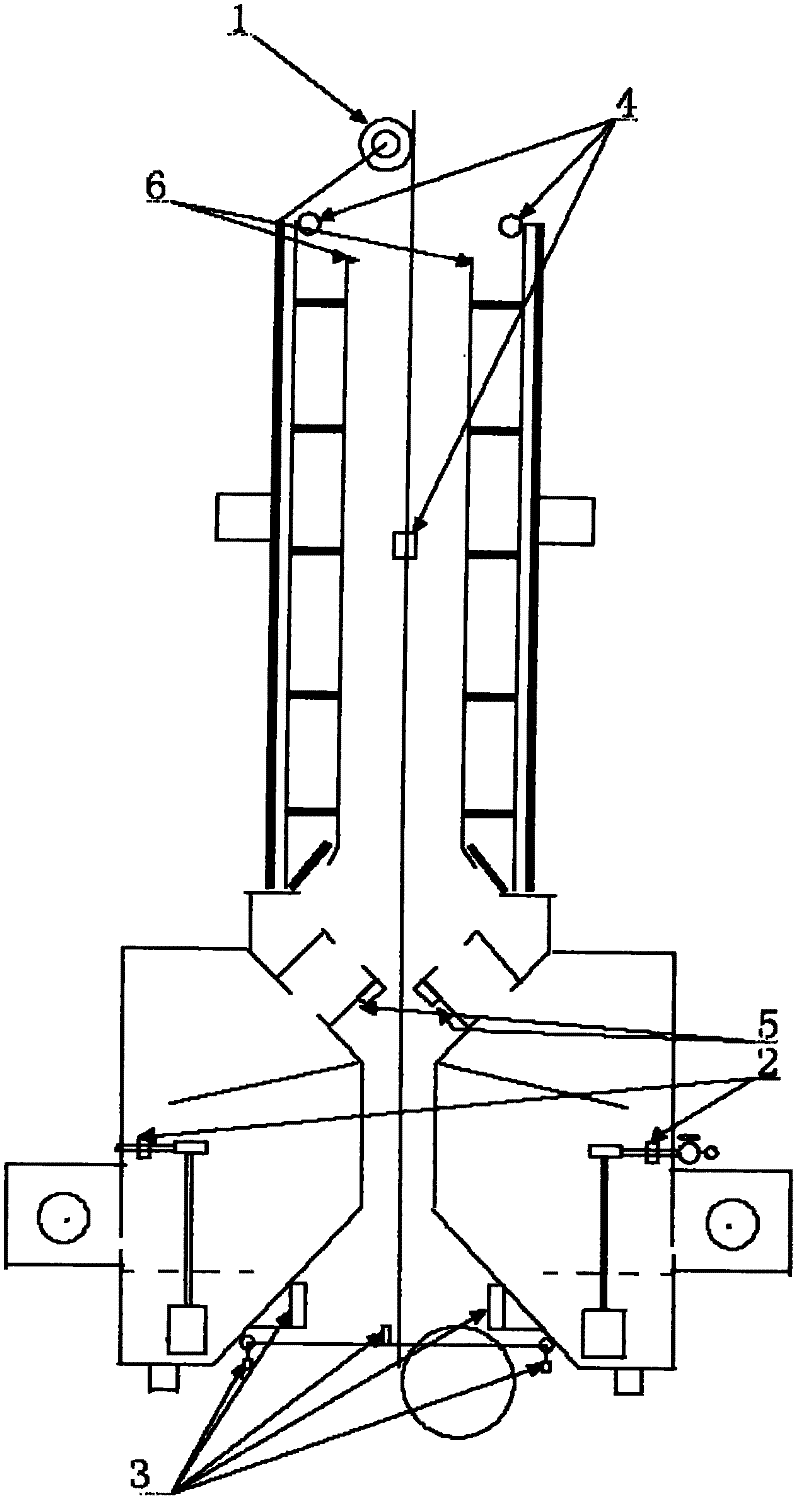

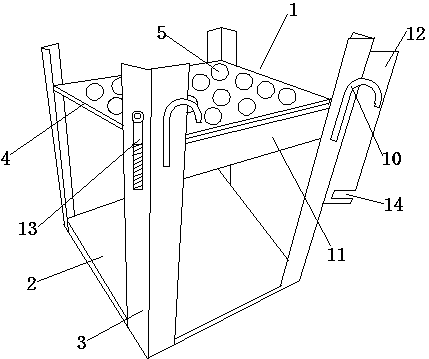

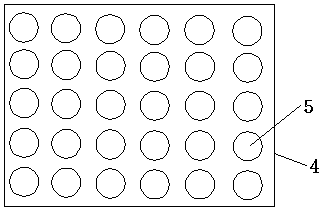

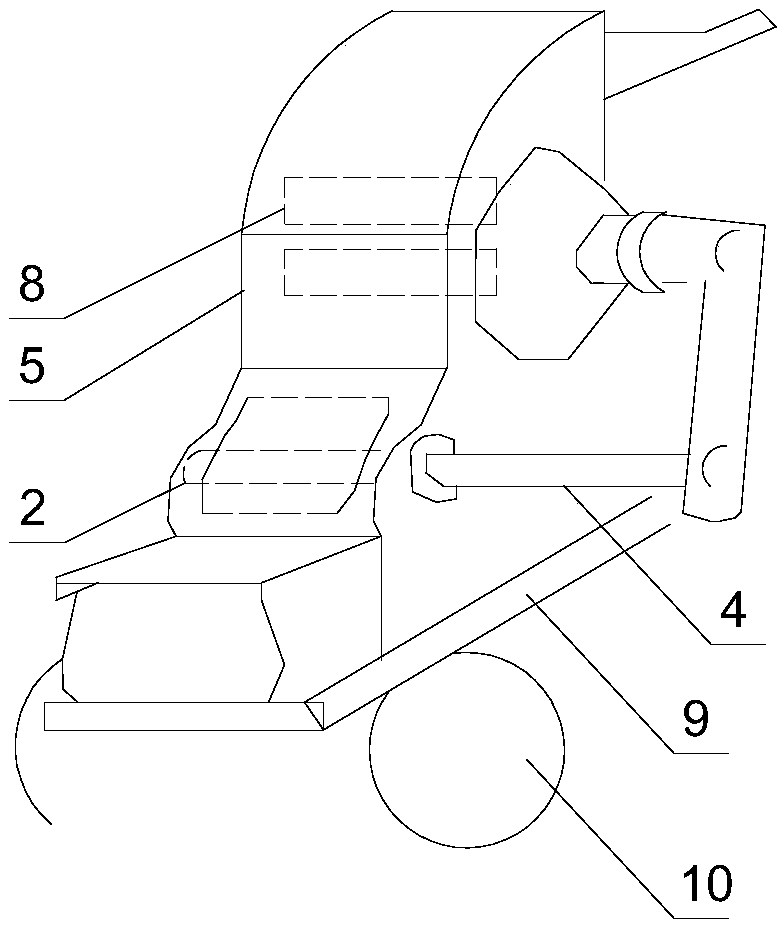

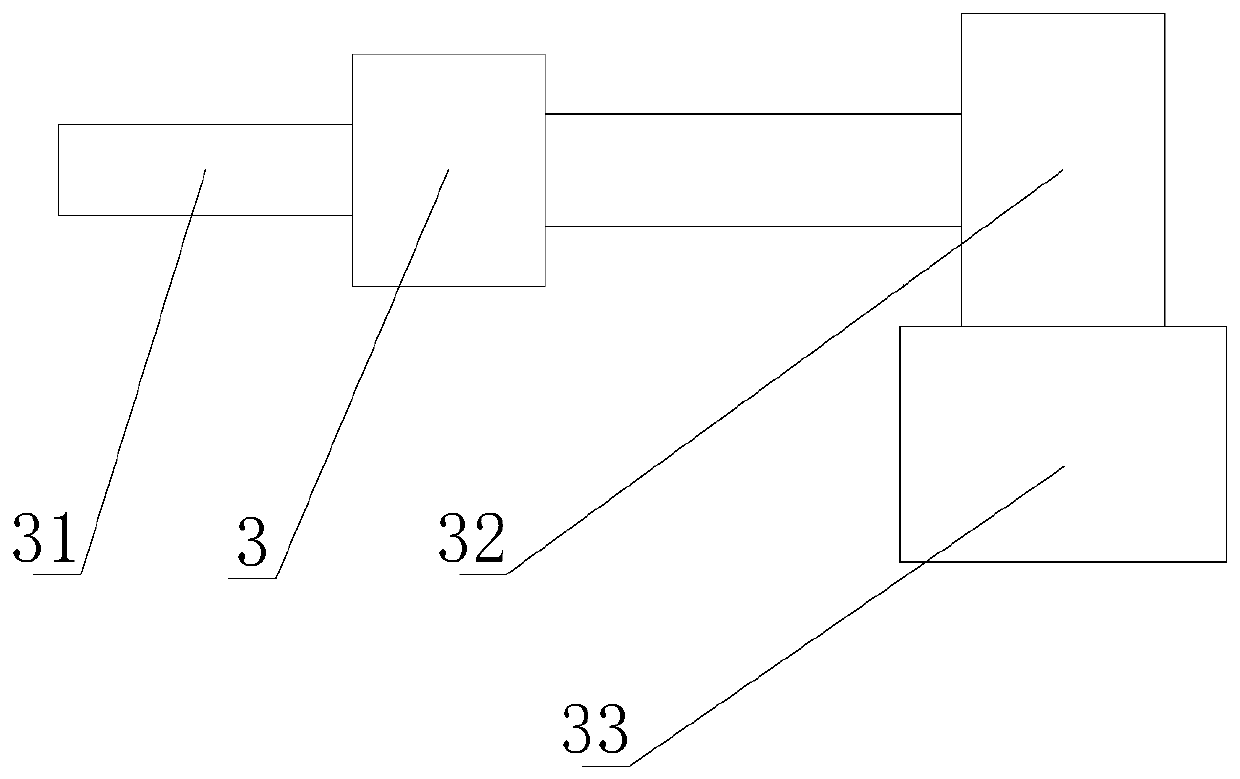

Charging system for cupola furnaces

ActiveCN102519243AMeet the requirements of safe productionSimple structureCharge manipulationVertical furnacesEngineeringStructuring element

The invention discloses a charging system for cupola furnaces. The charging system comprises a feeding device and two material guide devices, wherein the two material guide devices are respectively arranged at the front side of the corresponding cupola furnace and are divided into a left side material guide device and a right side material guide device according to different left and right positions of the two material guide devices, and the two material guide devices respectively comprise support structure elements and material guide structure elements and are basically symmetrical relative to a radial vertical surface positioned between the two material guide devices. Each material structure element comprises a material guide groove, an opening of the material guide groove faces the upper back part, the front end part of the material guide groove is fixedly connected onto a support frame, and in addition, the material guide groove is arranged in an inclined mode that the front part is higher and the back part is lower. Guide rails of the feeding device are horizontally arranged above the front and back middle parts of the two material guide devices in the left and right directions, so a hopper can discharge materials above any one of the two material guide devices, and the use of two cupola furnaces can be met.

Owner:姚立猛 +1

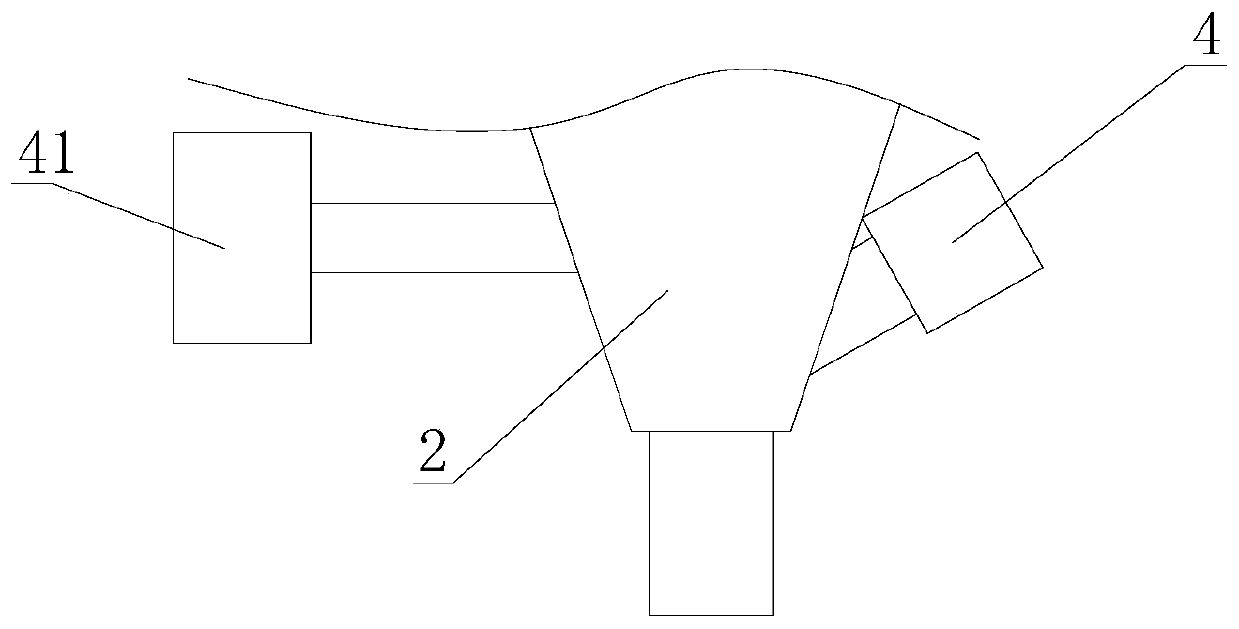

Material guiding device, cupola furnace body, and cupola furnace body provided with material guiding device

ActiveCN102410725AMeet the requirements of safe productionSimple structureCharge manipulationVertical furnacesCupola furnaceChimney

The invention discloses a cupola furnace body provided with a material guiding device, which comprises two parts: the cupola furnace body and the material guiding device. The cupola furnace body is a lateral charging type furnace body and comprises a furnace bottom part, a furnace cylinder part, a furnace body part and a chimney part sequentially from the bottom up. The charging opening of the furnace body is located at the lower part of the chimney part, and has a height of 400mm to 1500mm and a width equal to 80% to 100% the inner diameter of a hearth body of the furnace body. The material guiding device comprises a supporting structure piece and a material guiding structure piece, the material guiding structure piece comprises a material guiding groove opened upwards and rearwards and fixedly connected to the supporting structure piece, so that the material guiding groove is overall arranged in an inclined way higher at the front part and lower at the rear part. A sealing structure is formed between the material guiding groove of the material guiding device and the charging opening of the furnace body on the left side, the lower side, and the right side; and material in a hopper can be introduced into the furnace body through the material guiding groove from the outside.

Owner:姚立猛 +1

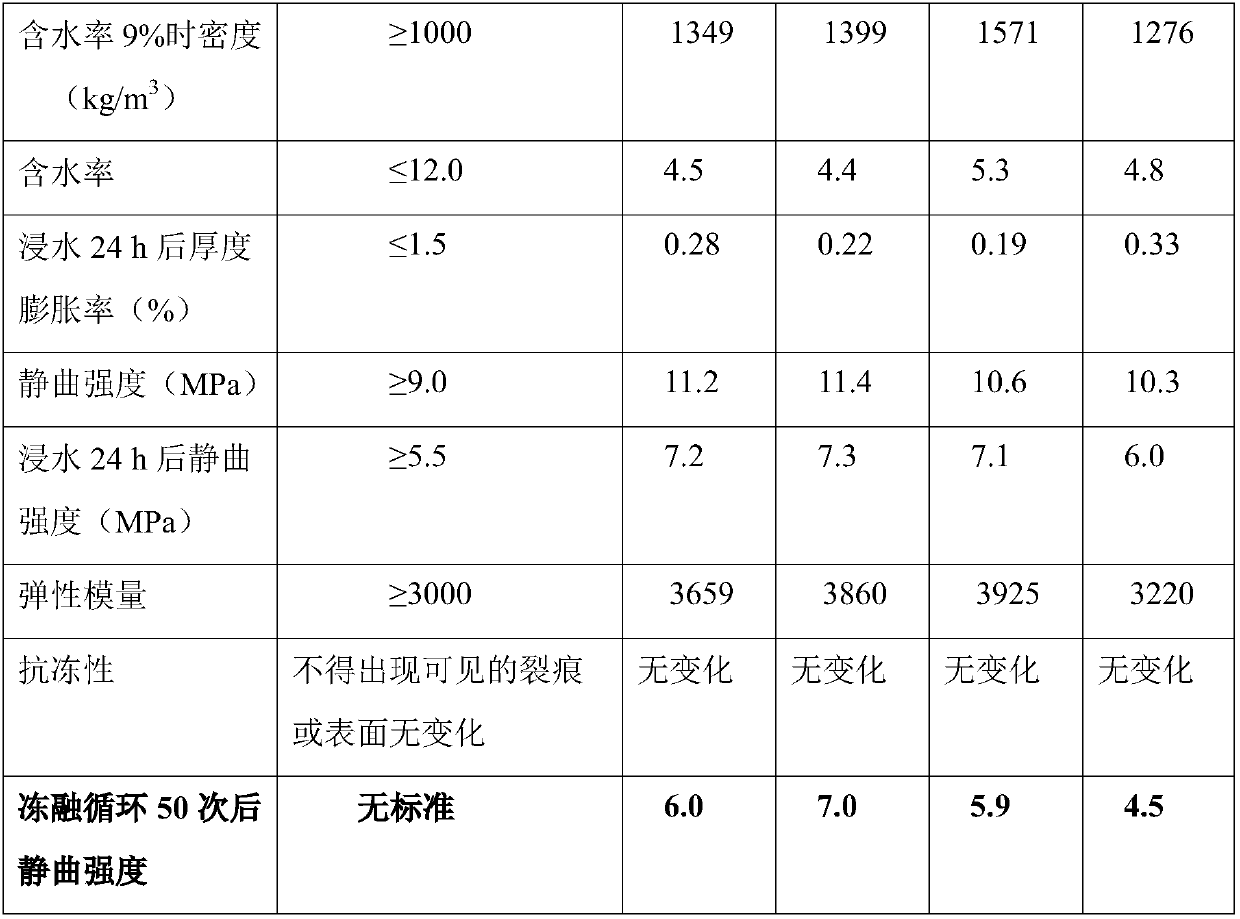

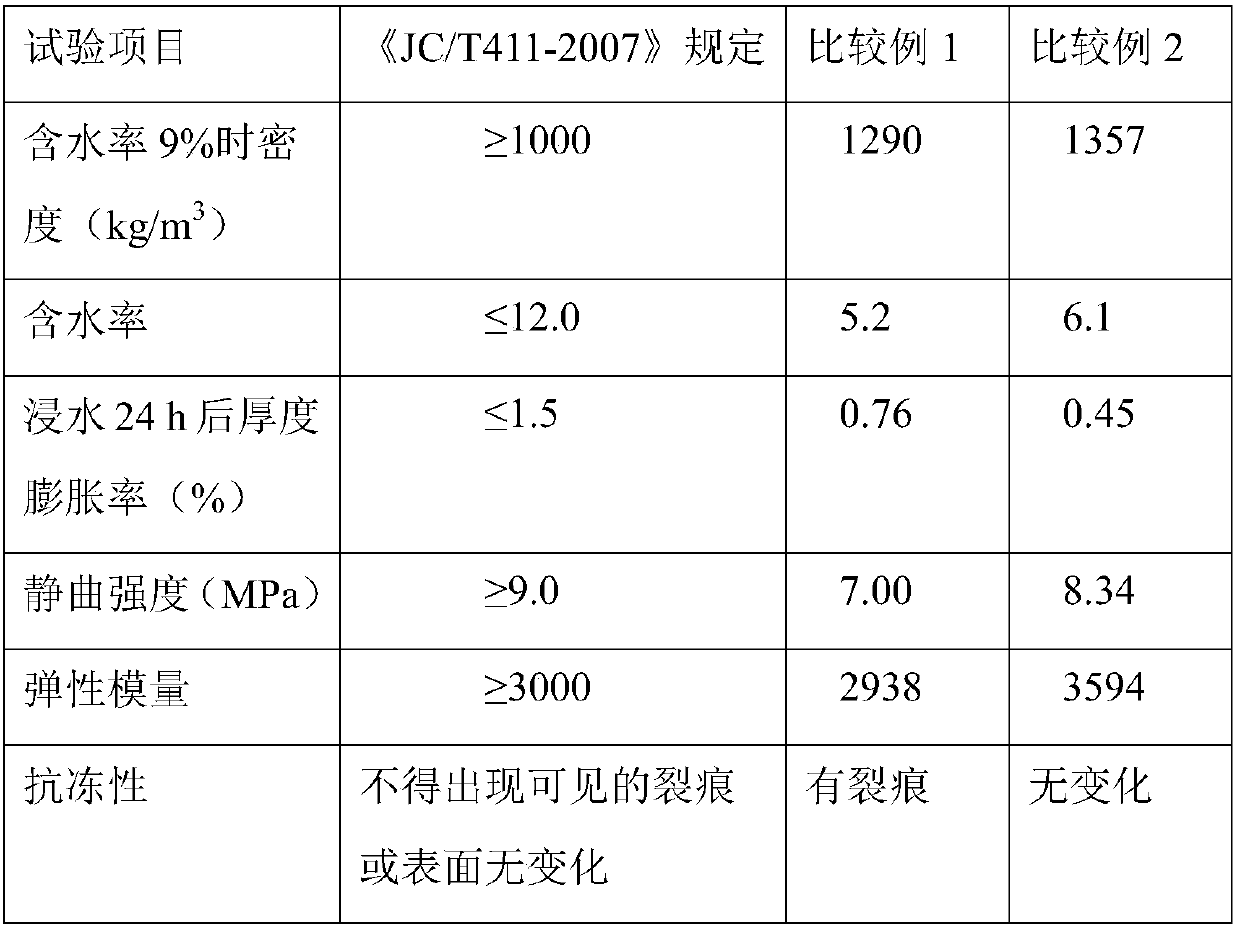

Geopolymer-based rice straw fiber board and preparation method thereof

ActiveCN107555870AThe manufacturing process is non-toxic and harmlessIncreased durabilityCement productionFiberSlurry

The invention provides a geopolymer-based rice straw fiber board, which is prepared from the following raw materials in parts by weight 57 to 60 parts of liquid sodium water glass, 30 to 35 parts of metakaolin and 8 to 12 parts of rice straw fiber. Meanwhile, the invention provides a preparation method of the geopolymer-based rice straw fiber board. The method comprises the following steps of mixing the liquid sodium water glass and the metakaolin to obtain slurry; adding the rice straw fiber into the slurry; performing further mixing to obtain slurry; transferring the slurry into a mold for extrusion forming; after the demolding, putting the materials under the natural conditions for curing curing, for 7 to 10 days. The fiber board prepared by the method has the advantages that the intensity is high; the hardening is fast; the anti-corrosion performance is realized; the water-resistant performance is good; the water absorption expansion rate is very low; the curing condition is simpleand convenient; the abrasion of the straw fiber raw material crushing process on the equipment is small; the problems that the cement-based plant fiber board production process is complicated, only the pulping fiber can be used, the production cost is high, and the like are solved; by the method, the utilization rate of agricultural and forest waste can be improved; economic and environment-friendly effects are achieved.

Owner:GUANGXI TEACHERS EDUCATION UNIV

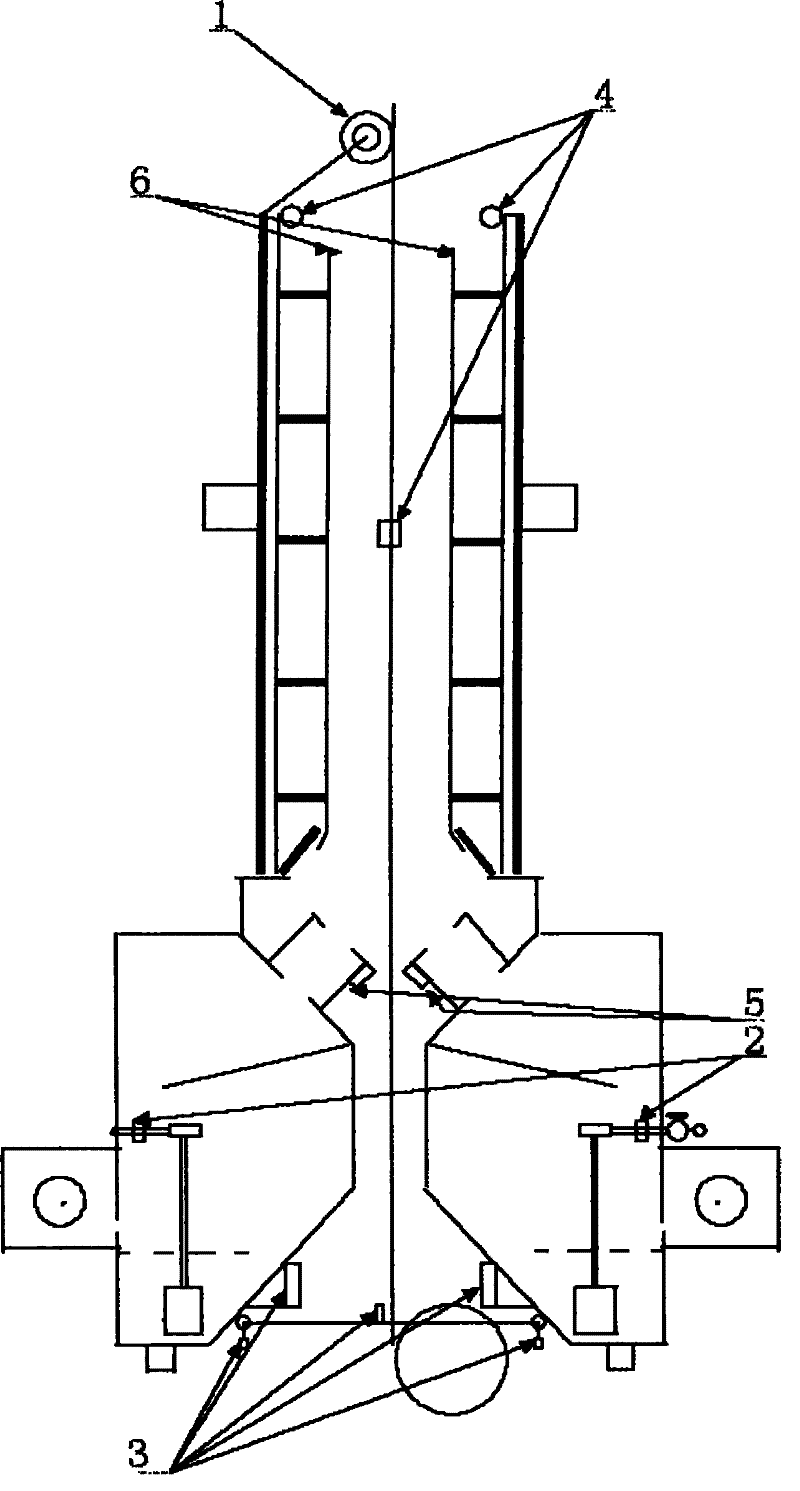

Sealing device for preventing flue gas from overflowing when tamping coke oven is charged with coal

InactiveCN102268268ASolve the spilloverSolve the problem that the external air is sucked into the coke ovenCharging devicesCoke oven doors/closuresFlue gasEmission standard

The invention discloses a sealing device for preventing flue gas from overflowing when a tamping coke oven is charged with coal, which comprises a shell with an open bottom; a flue gas buffer chamber inside the shell; , the front door is compatible with the door of the tamping coke oven, and the two sides and the upper edge are respectively provided with sealing knife edges, and the left and right edges and the upper edge of the rear door are respectively provided with high-temperature-resistant soft sealing strips; The middle parts of the outer sides of the left and right side walls of the gas buffer chamber are respectively equipped with guide wheels that match the guide rails on the coal loading car; rail wheel. The present invention effectively solves the problem that the flue gas in the coke oven overflows and the external air is sucked into the coke oven due to pressure fluctuations in the coke oven when charging coal into the tamping coke oven, and realizes that the furnace door does not emit smoke when charging coal The goal of achieving the environmental protection emission standard, there is a support and restriction relationship between the present invention and the coal loading vehicle, so the operation is reliable and stable, and it is not easy to tilt.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Lotus root slices with jujubes and glutinous rice and preparation method of lotus root slices

InactiveCN104872576ARuddy colorPleasant fragranceFood ingredient as antioxidantFood preparationHorticultureLotus root

The invention discloses lotus root slices with jujubes and glutinous rice and a preparation method of the lotus root slices. The preparation method of the lotus root slices comprises the following steps: washing and peeling fresh lotus roots, removing lotus root knots, cutting the lotus roots into lotus root segments, filling the glutinous rice into lotus root holes, putting the lotus root segments in boiled sugar water, and boiling the lotus root segments over high fire under the normal pressure, boiling the lotus root segments for 2-4 hours over medium fire after the sugar water is boiled, cooling and then slicing the lotus root segments, and canning the lotus root slices with the canned sugar water, then heating cans for 20-60 minutes at 90-110 DEG C, and finally vacuumizing, sealing and sterilizing to prepare canned lotus root slices with jujubes and glutinous rice. The lotus root slices with jujubes and glutinous rice is ruddy in color and luster, pleasant in fragrance and delicious in taste; the problem that the lotus root slices brown in the preservation process can be solved thoroughly.

Owner:JIANGSU HONEST FOOD

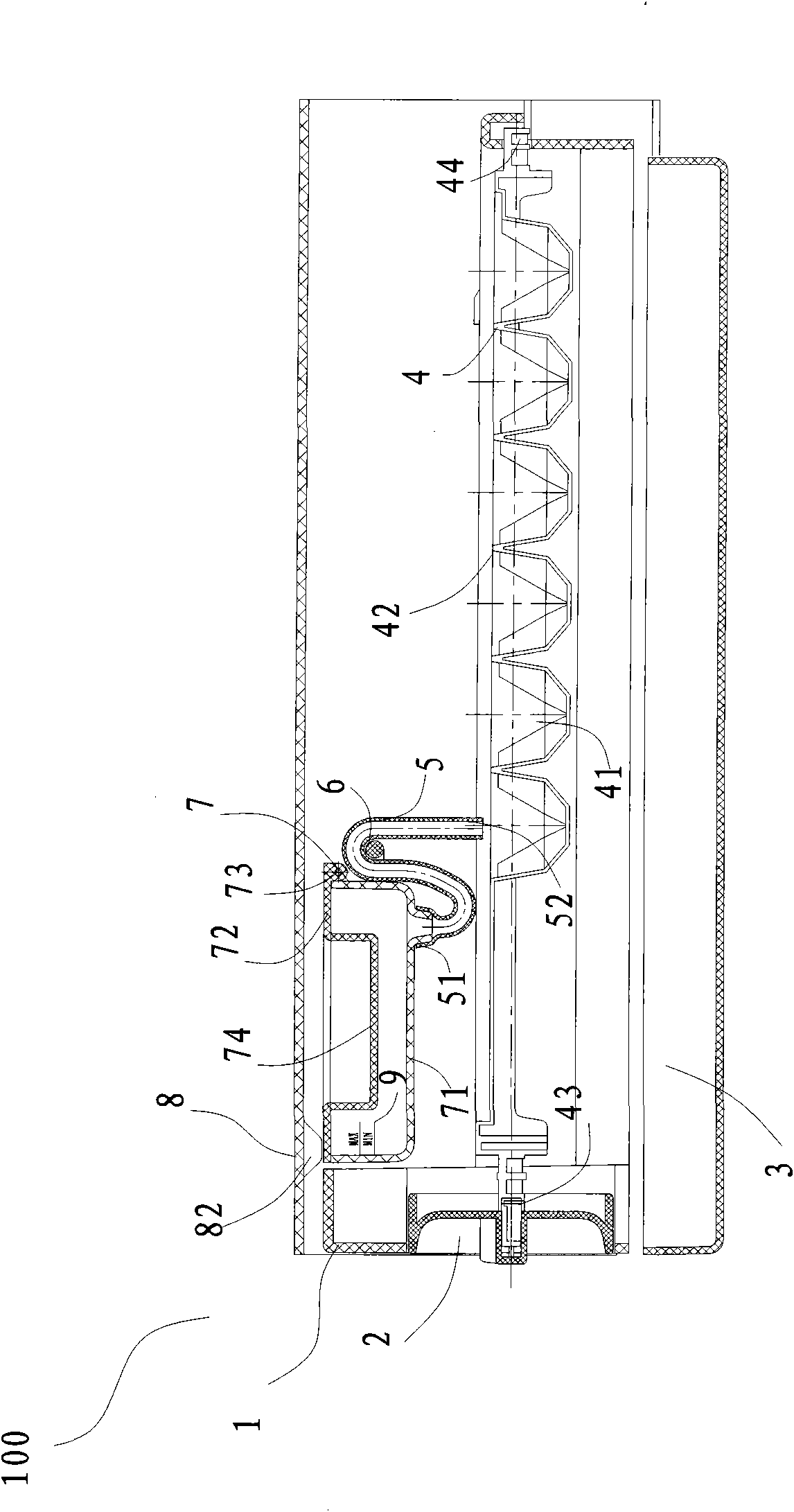

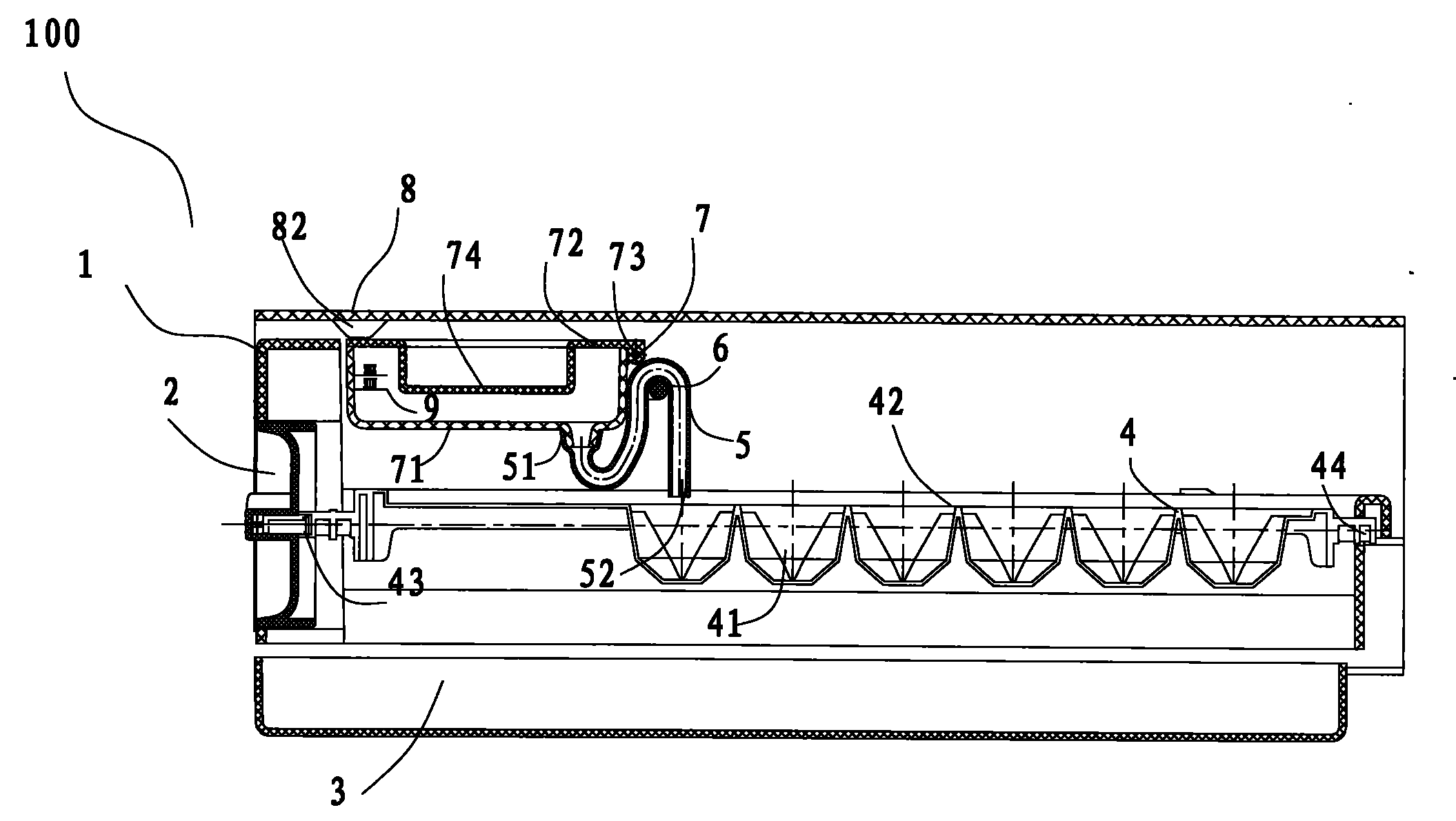

Ice machine and refrigerator having same

ActiveCN101915482ASolve the problem that water injection is not easy to controlSimple structureLighting and heating apparatusIce productionSiphonEngineering

The invention discloses an ice machine. The ice machine comprises an ice machine bracket, a knob part, an ice making grid, a water container, a siphon water pipe and an ice container, wherein one end of the ice making grid is connected to the knob part; the water container is arranged on the upper part of the ice making grid; the first end of the siphon water pipe is connected to the water container, while the second end is suspended above the ice making grid; the ice container is arranged below the ice making grid. The water container comprises a water container body and a water container cover, wherein the water container cover is rotationally connected to one end of the water container body by an elastic piece; and a depressed part is formed in the middle part of the water container cover. In the invention, automatic and accurate injection of water is realized on the basis of siphonage. In addition, the structural design of the water container makes the siphonage generate automatically. The invention further discloses a refrigerator having the ice machine.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

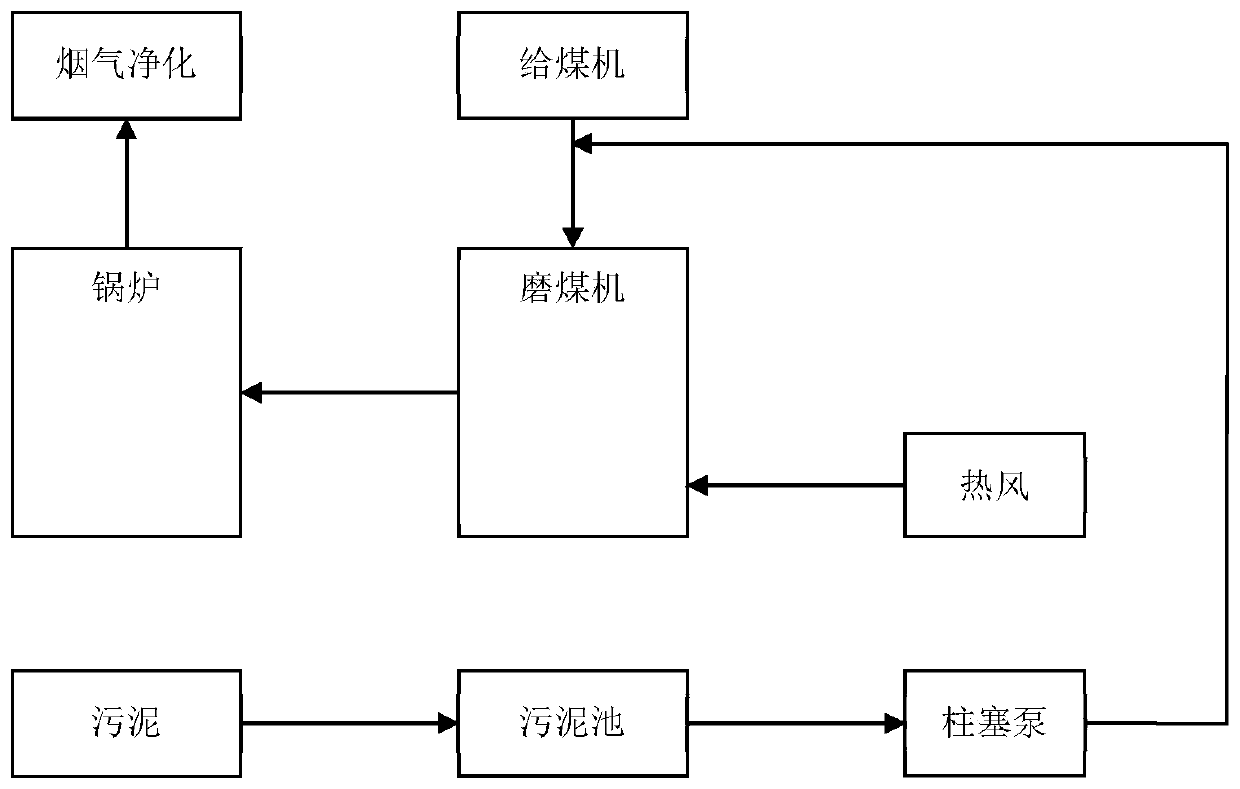

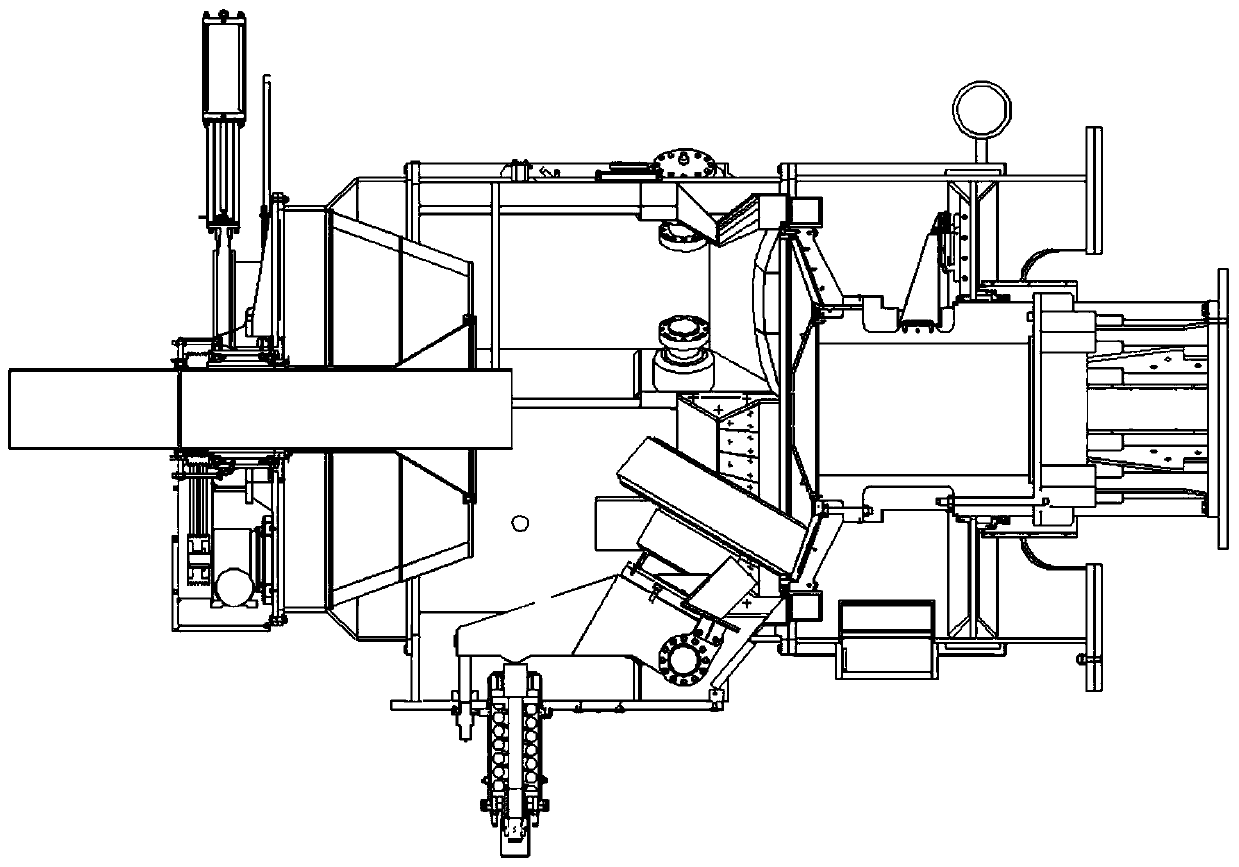

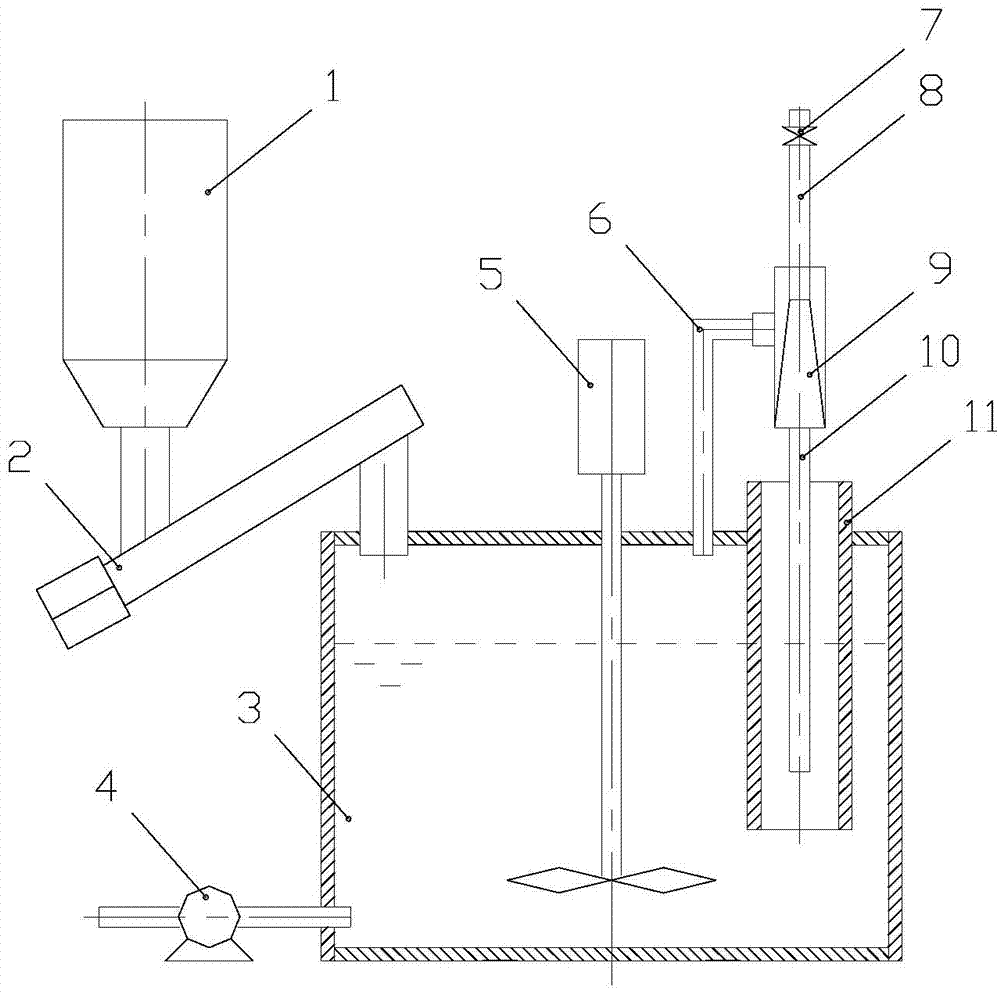

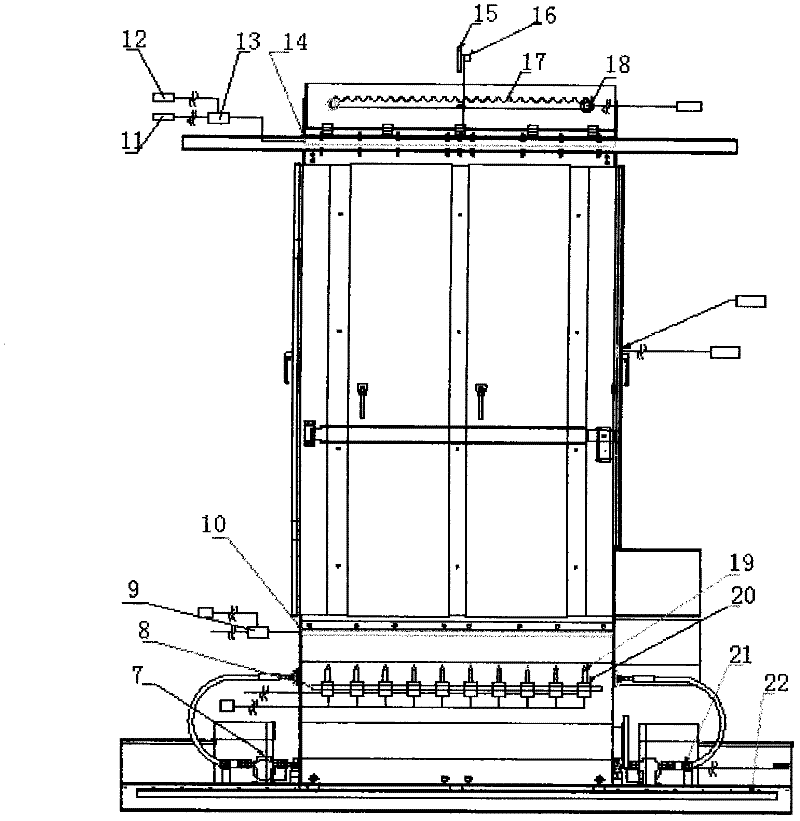

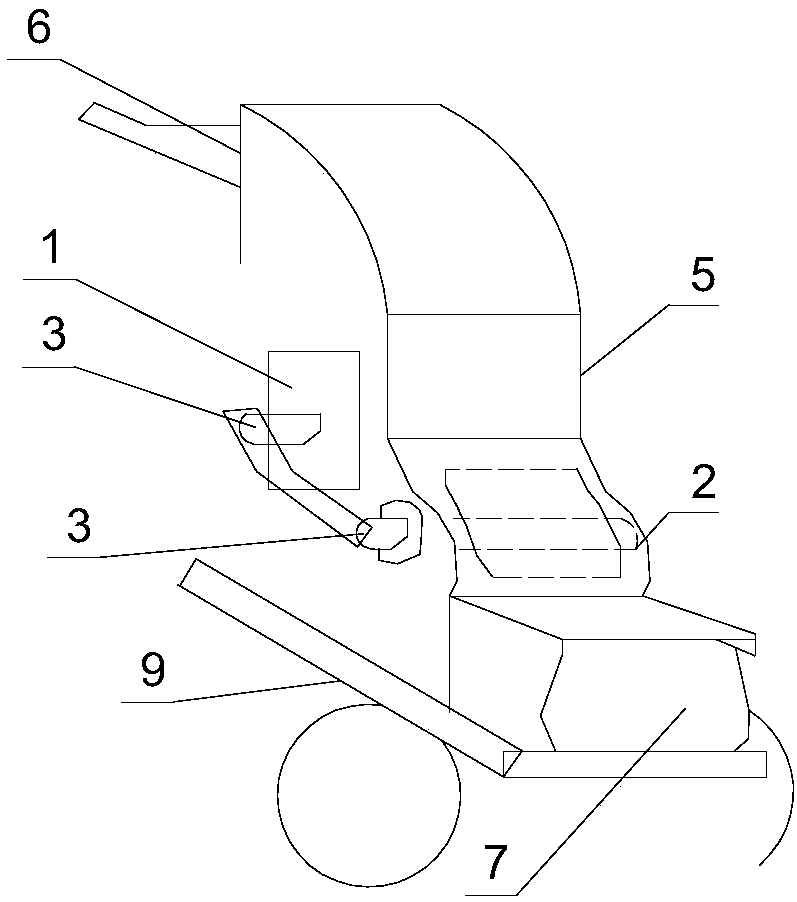

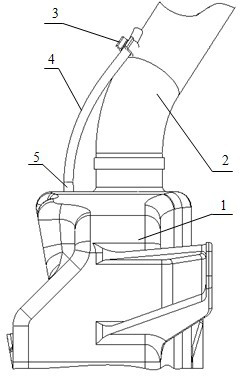

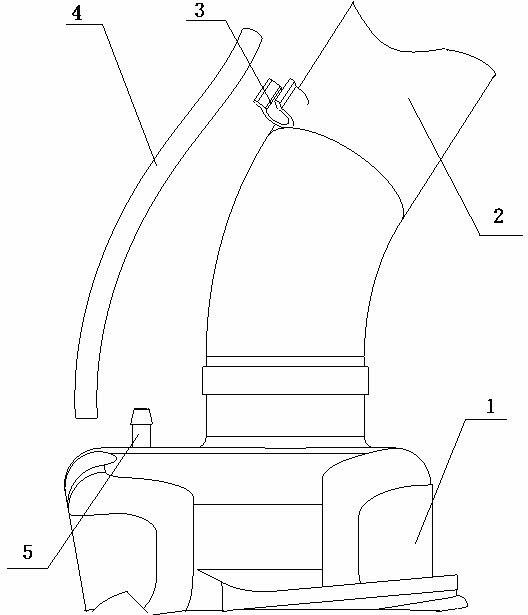

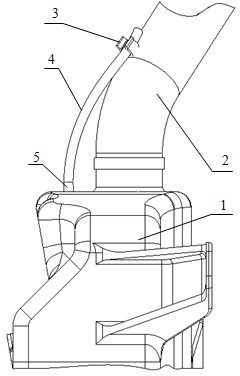

Device for blending combustion of sludge in medium-speed coal mill and method

PendingCN111237777ASolve the core problem of cloggingSolve the spilloverSludge treatment by de-watering/drying/thickeningIncinerator apparatusIsolation valveCombustion

The invention relates to a device for blending combustion of sludge in a medium-speed coal mill. The device comprises a sludge tank, a filter screen, a plunger pump, a coal mill sludge electric isolation valve, the medium-speed coal mill, a coal feeder, a coal feeder outlet electric valve, a coal falling pipe inner sleeve pipe, a related connecting pipeline and a circular sleeve pipe. The device for blending combustion of the sludge in the medium-speed coal mill has the beneficial effects that the core problem that a coal pulverizing system is prone to block due to direct blending combustion of the sludge in the coal pulverizing system is technically solved by combining the structural characteristics of a coal falling pipe on the medium-speed coal mill, the problem of odor overflow in thesludge conveying and drying process is solved, the coal mill is also used as sludge drying equipment, and special sludge drying equipment is not required to be added, so that the investment is saved;and according to a sludge blending combustion method, the original process of a boiler is fully utilized, the waste heat of flue gas and the heat value of the sludge are fully utilized, a heat sourceand equipment for drying the sludge do not need to be additionally arranged, and the method has the advantages of investment saving, high practicability, low operating cost, no secondary pollution andthe like.

Owner:ZHEJIANG ZHENENG TECHN RES INST

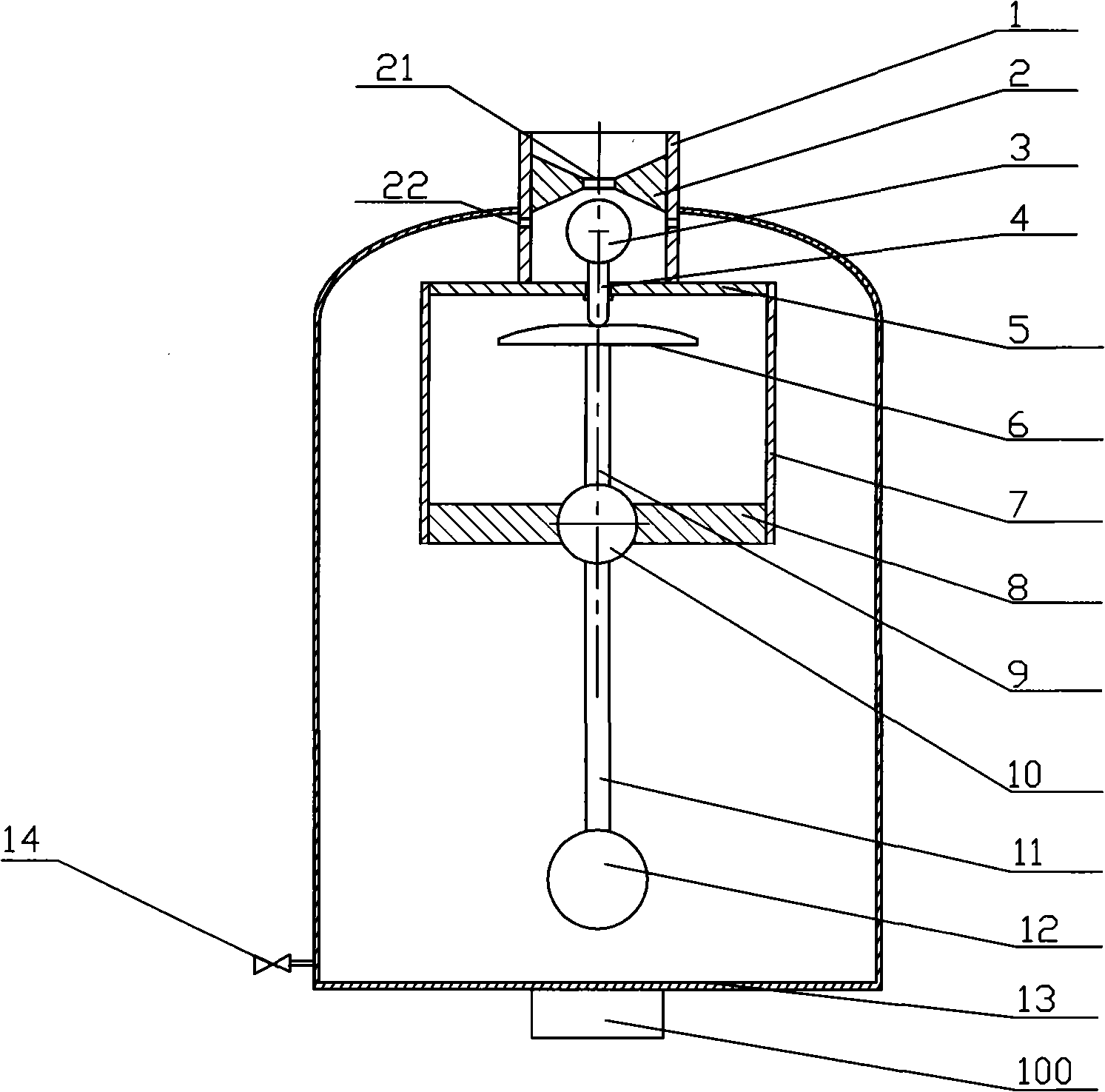

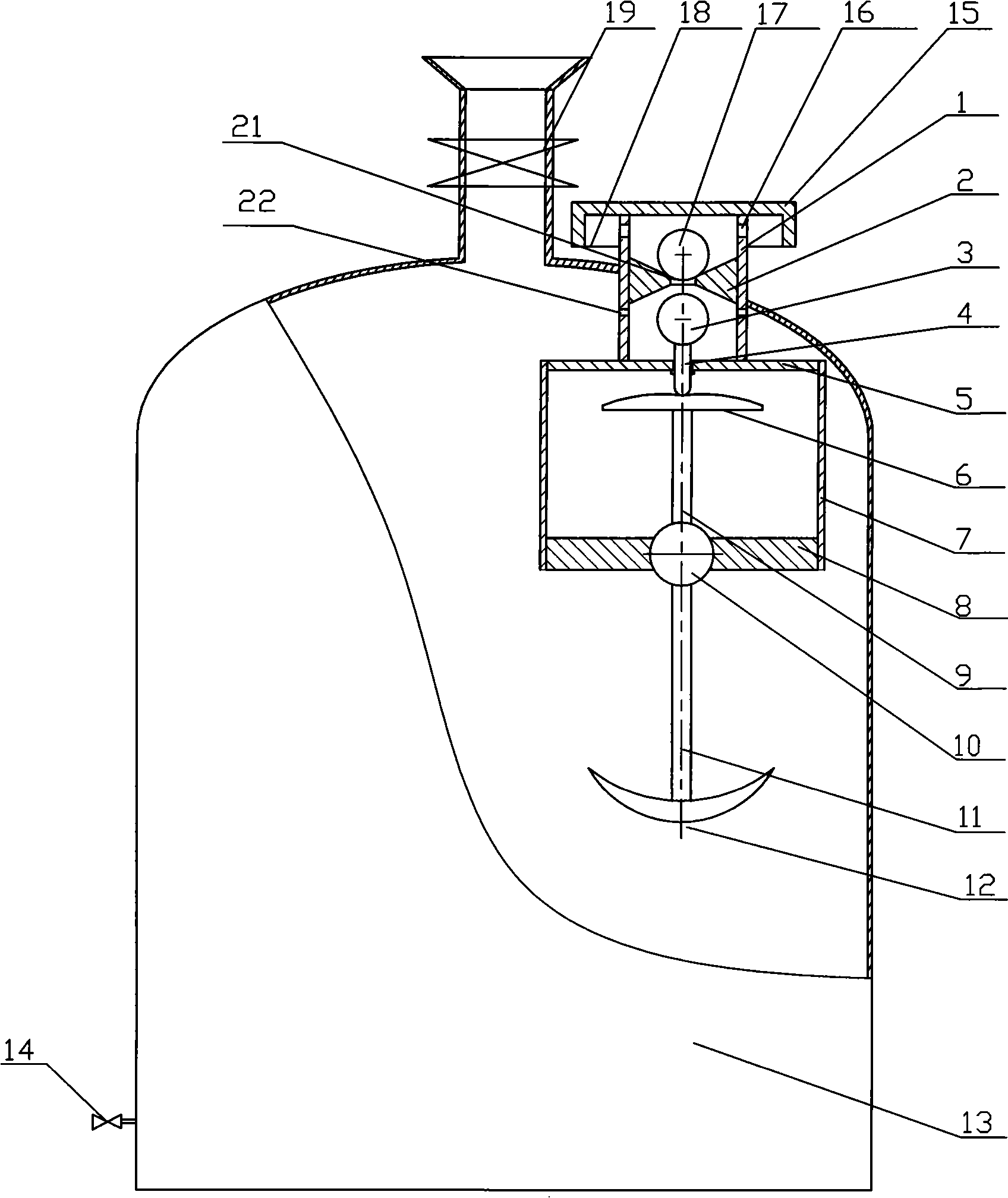

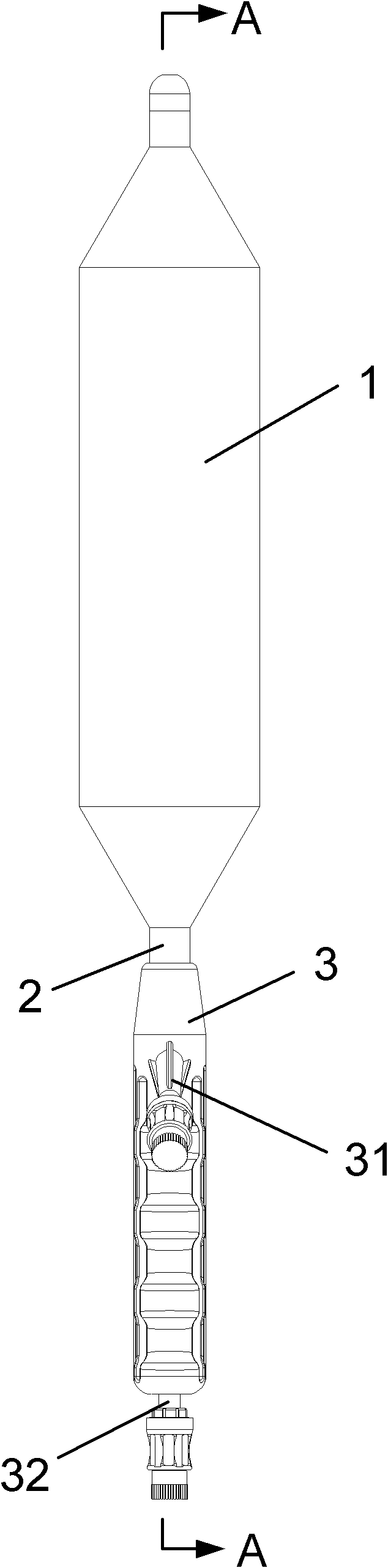

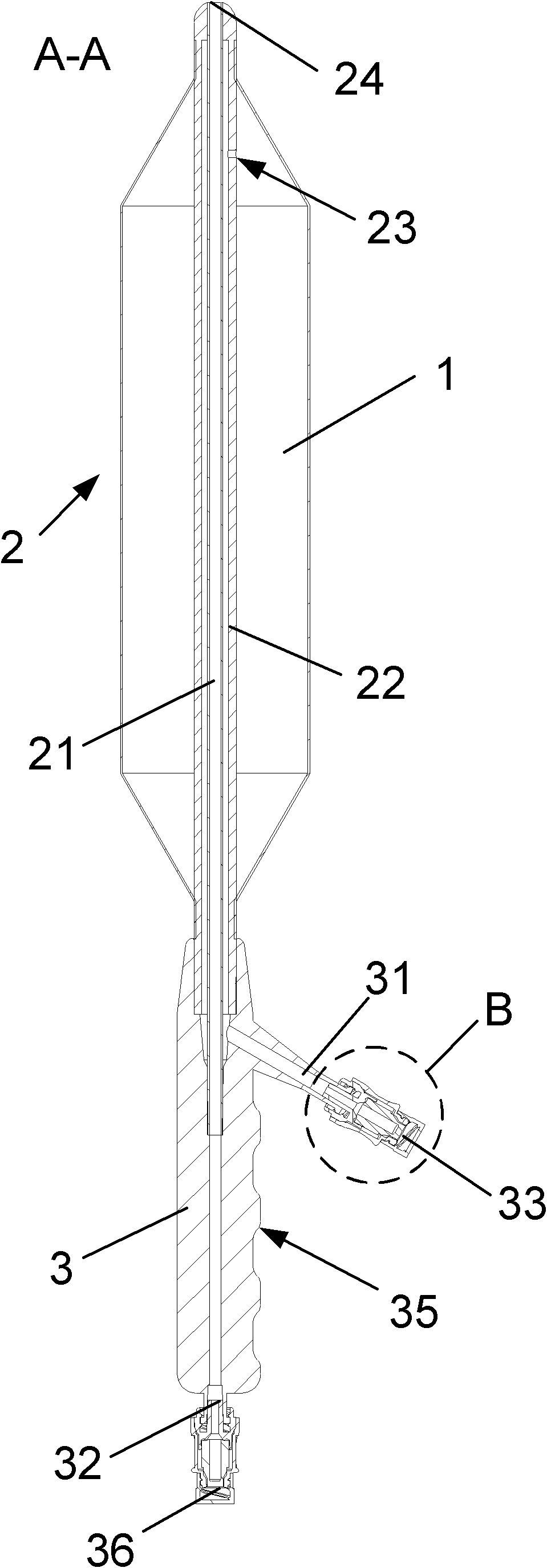

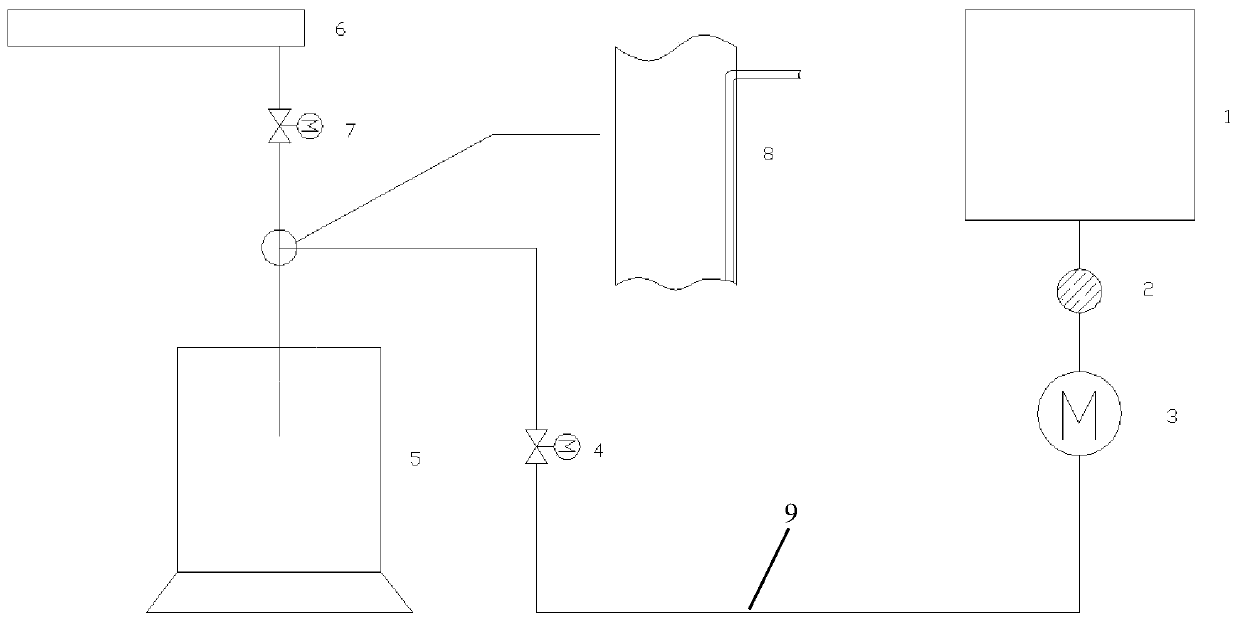

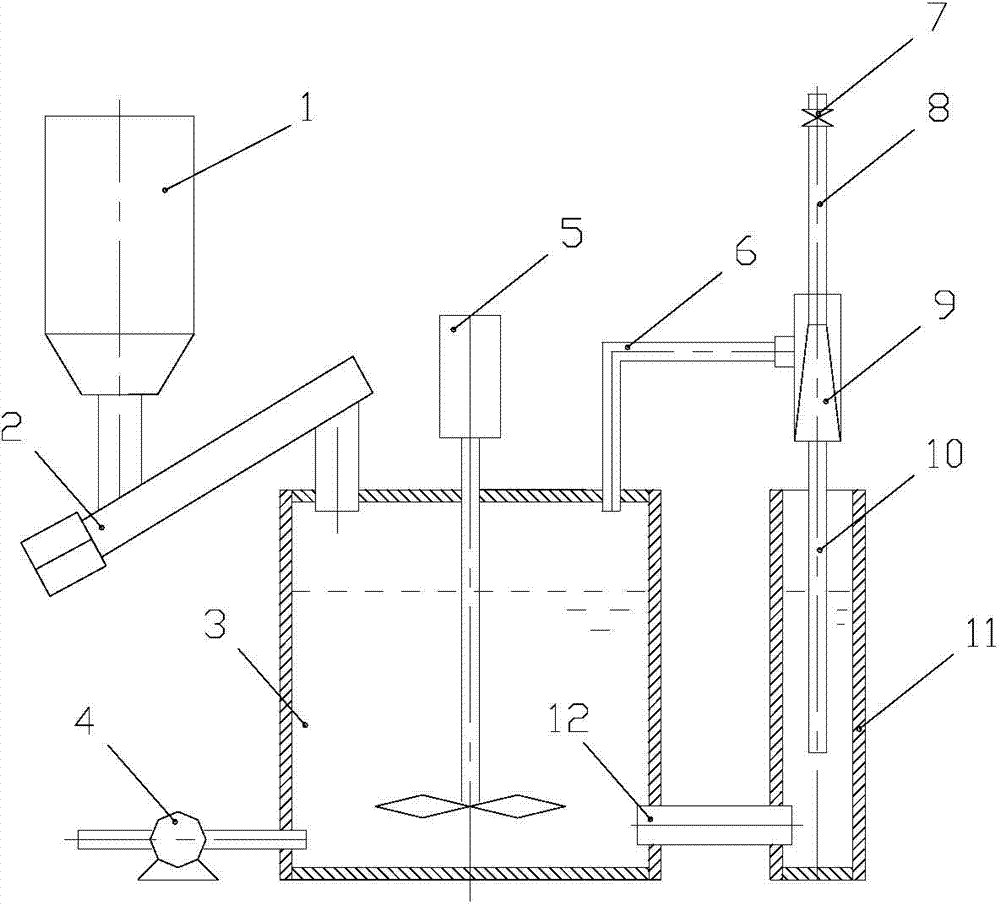

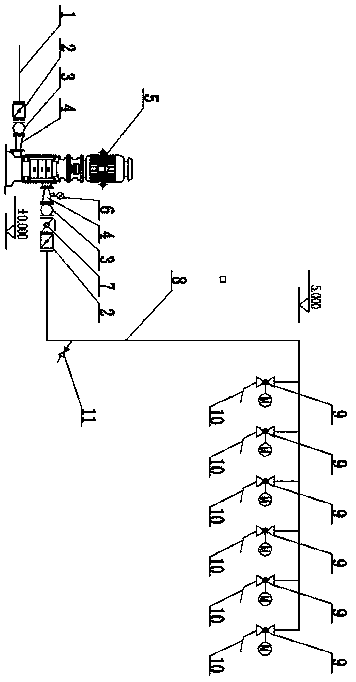

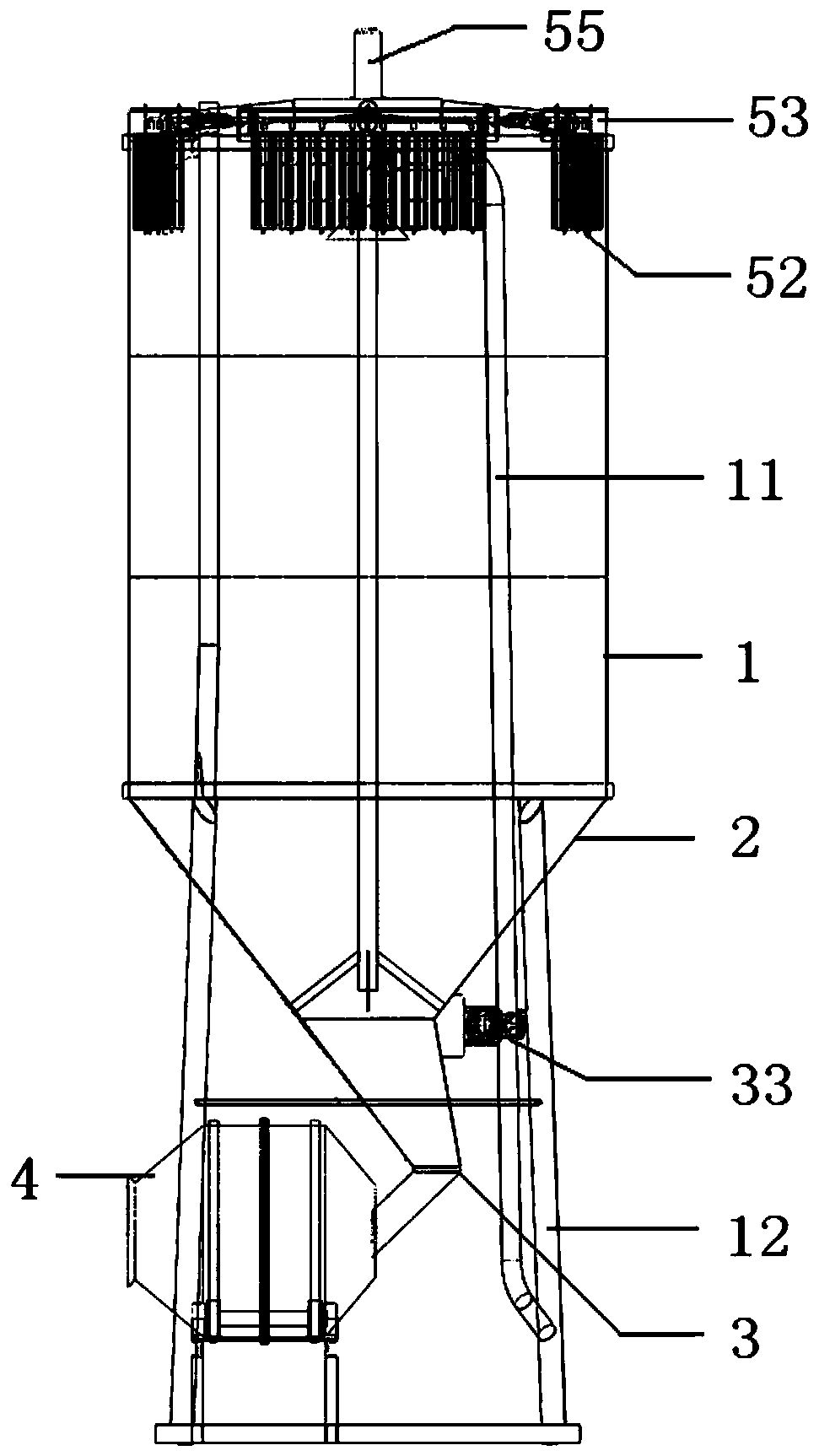

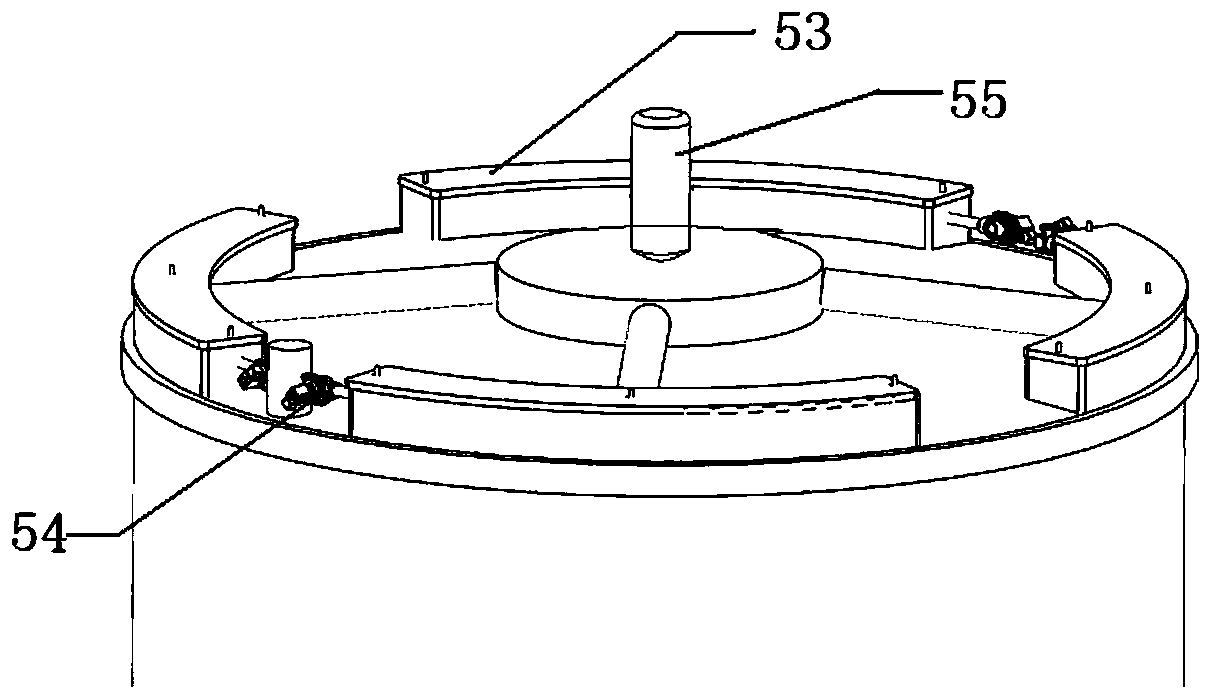

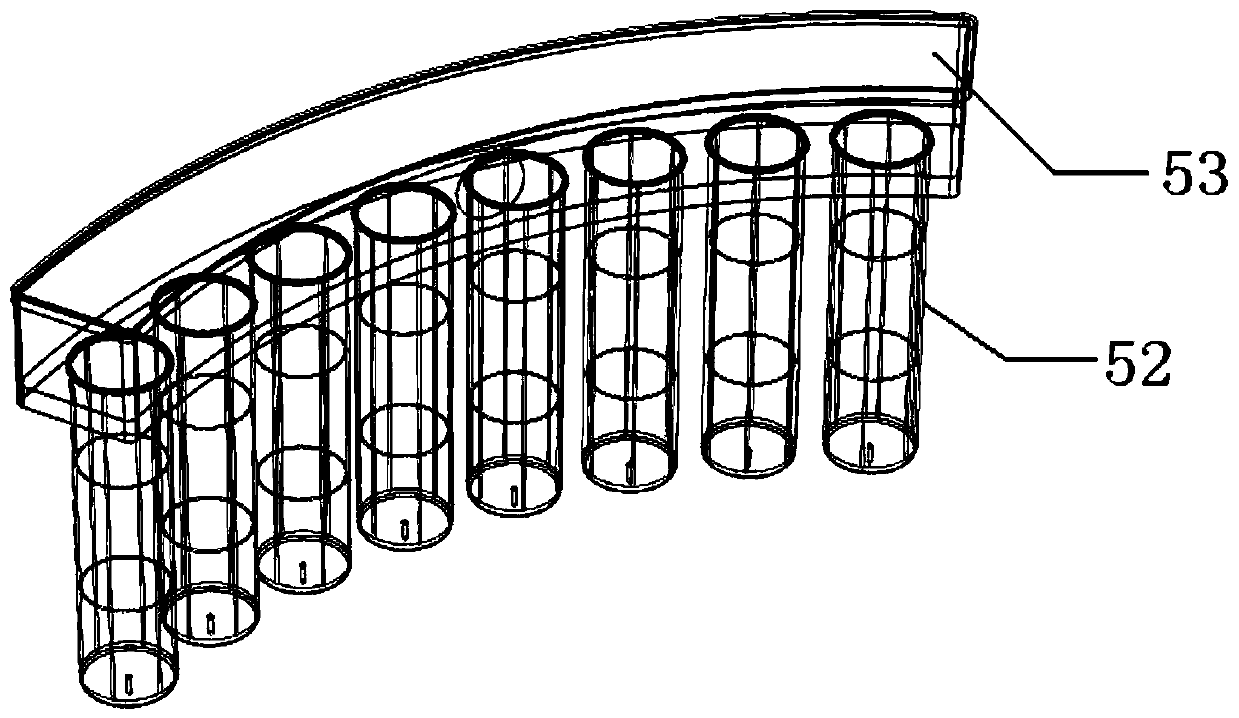

Activated carbon feeding device and activated carbon feeding method

ActiveCN104492331ASolve the spilloverChange workflowMixer accessoriesWater/sewage treatment by sorptionActivated carbonVapor–liquid separator

The invention discloses an activated carbon feeding device and activated carbon feeding method. The activated carbon feeding device comprises a slurry tank, a jet pump and a gas-liquid separator; a hopper is arranged outside the slurry tank and communicated with the interior of the slurry tank; the air suction opening of the jet pump is communicated with the top of the carbon slurry tank by use of a suction pipe; a water outlet pipe of the jet pump is inserted into the gas-liquid separator, and the water outlet pipe extends into the lower part of the gas-liquid separator; the gas-liquid separator is fixedly arranged on the carbon slurry tank; the bottom of the gas-liquid separator is located under the liquid level in the carbon slurry tank, while the top of the gas-liquid separator is located above the top cover of the carbon slurry tank and communicated with the atmosphere.

Owner:SHANDONG UNIV

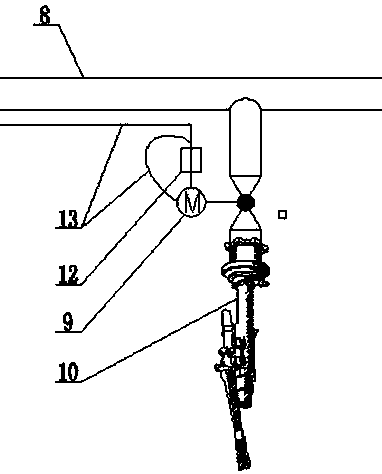

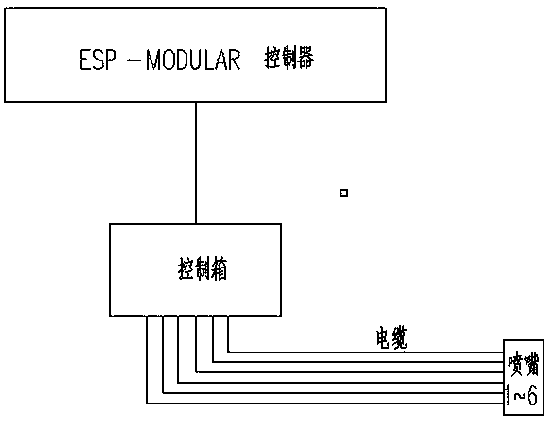

Electrostatic spraying equipment

ActiveCN102179327AImprove safety and reliabilityEliminate fire hazardsFire rescueSpray discharge apparatusSpray nozzleEngineering

The invention discloses electrostatic spraying equipment, which comprises a line speed detection system (1), an independent atomizing nozzle adjusting system (2), a plate and strip width detection system (3), an automatic flame detection and automatic fire distinguishing system (4), an unbalanced air pressure compensation and control system (5) and a serration plate electrode (6). The electrostatic spraying equipment solves an independent precision line speed detection problem, an independent atomizing nozzle adjusting problem, an independent precision width detection problem, an automatic detection and automatic fire distinguishing problem, an unbalanced air pressure compensation and control problem, and a coating material overflow problem caused by a planar electrode.

Owner:苏州必世洁机电有限公司

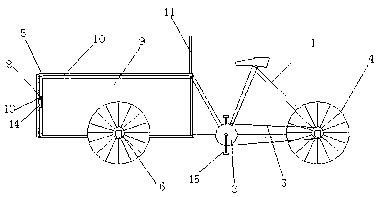

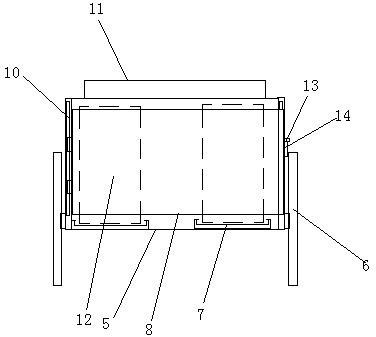

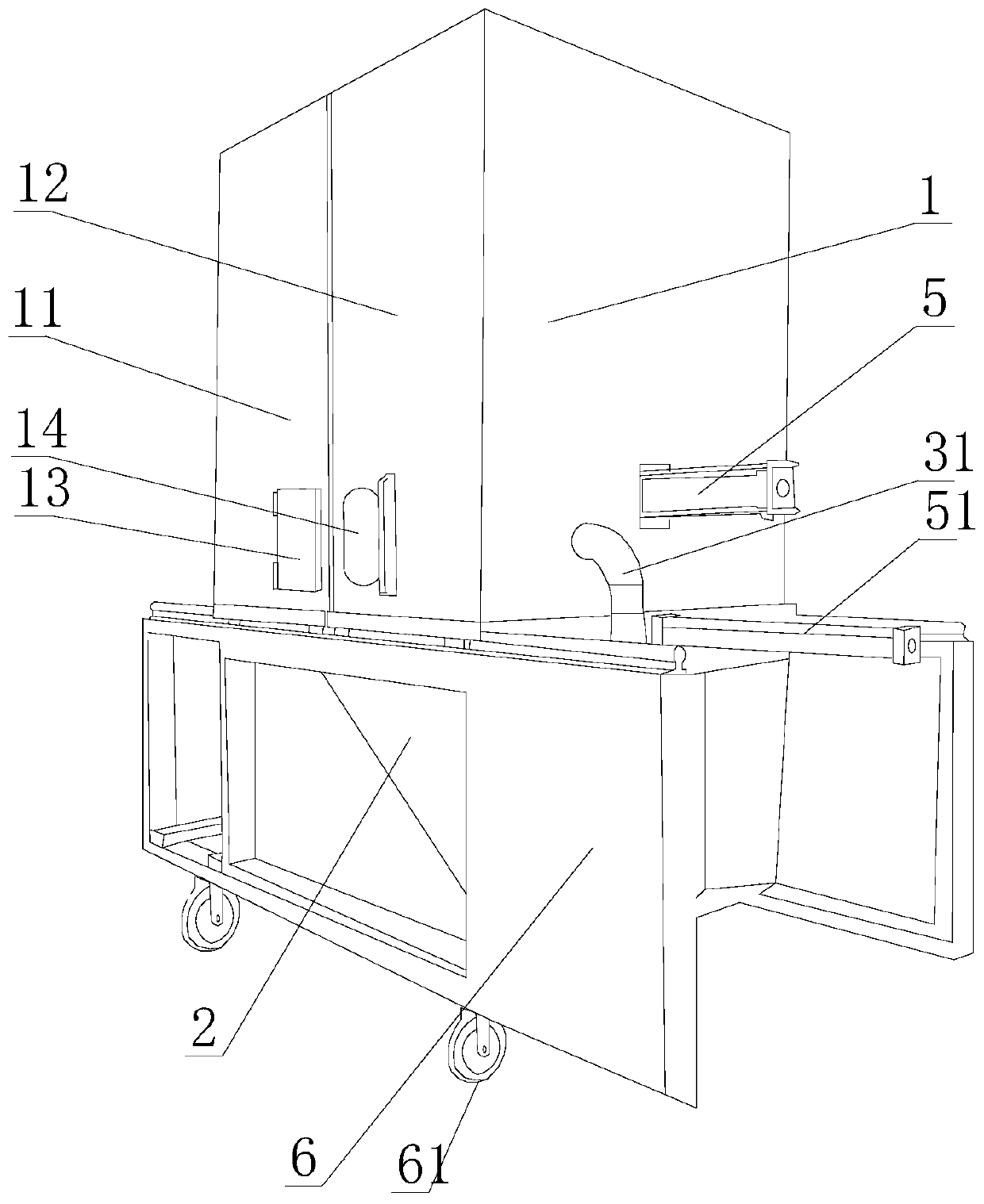

Garbage can transfer trolley

The invention discloses a garbage can transfer trolley which comprises a driving trolley body, a garbage can carrying device connected with the driving trolley body, and a frame, wherein the driving trolley body is a hand-driven trolley body; a transmission flywheel connected with pedals is arranged at the lower part of the frame; a transmission chain is arranged on the flywheel, and drives a driving wheel arranged at the rear part of the frame to move; the front part of the frame is connected with the garbage can carrying device; and a control head is arranged between the frame and the garbage can carrying device. Garbage cans are loaded in the transfer trolley directly, and then transported to a transfer station to pour, so that the problems that garbage drops and sewage overflows due to the fact that cleaners transfer the garbage to a garbage trolley, and then transfer the garbage to the transfer station are solved; the health of the cleaners is ensured; the labor intensity of the cleaners is reduced; and the garbage can transfer trolley is simple in structure and easy to achieve.

Owner:张凤平

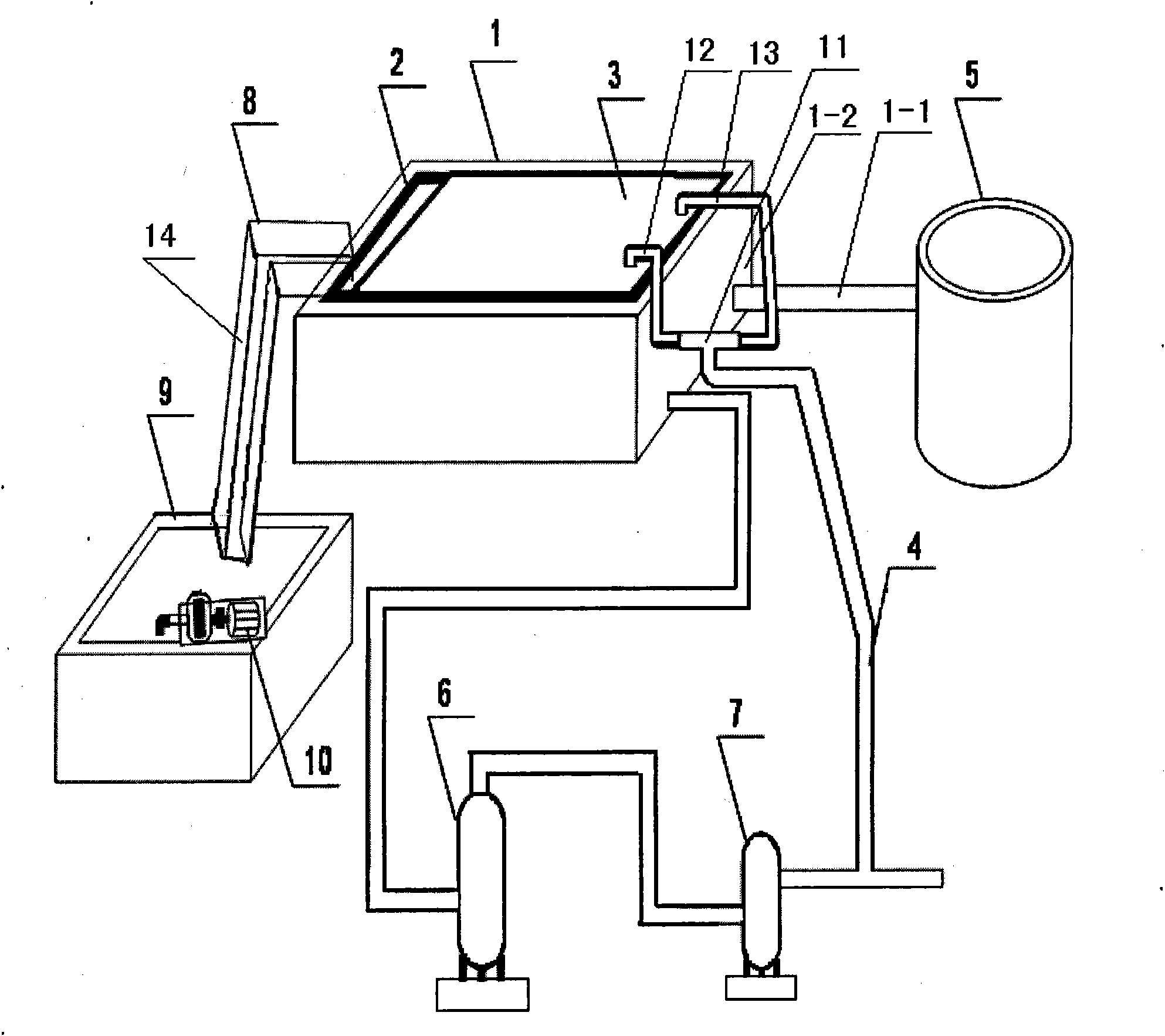

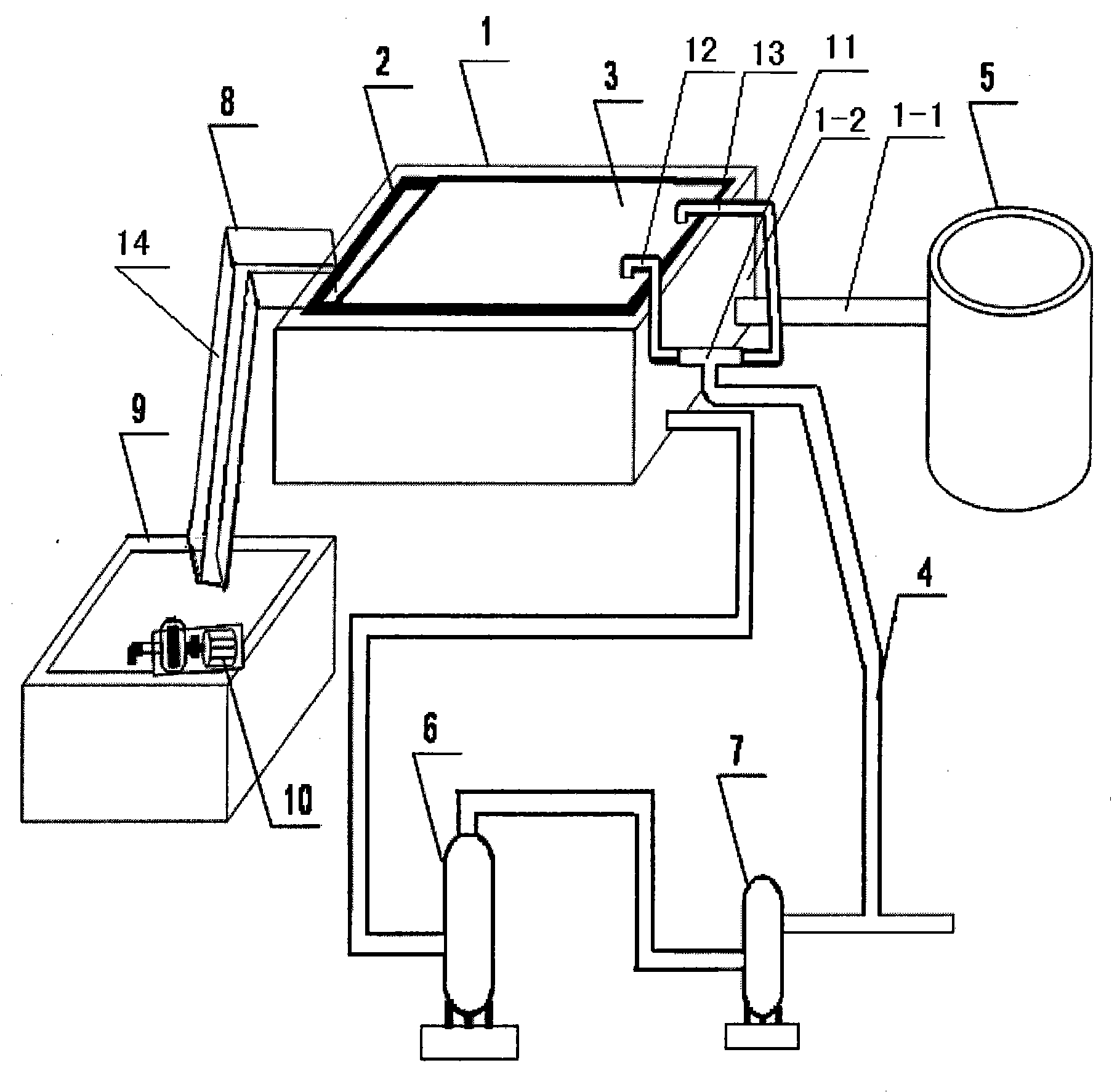

Closed flotation system with dross blowing device

InactiveCN101913672AOvercoming Scum SpillsOvercome the polluted environmentWater/sewage treatment by flotationDrossWastewater

The invention relates to a flotation device, in particular to a closed flotation system with a dross blowing device, which is used for blowing dross in the pretreatment stage of phenol-cyanogen wastewater treatment plants. The system solves the problem that dross scrapers in the existing floatation devices easily have failure. The system comprises a flotation tank, a compressed air pipe, a tee pipe coupling, a No.1 blowpipe, a No.2 blowpipe, a seal plate, a dross removal tank, a dross tank, a chute and a water pump, wherein one end of the compressed air pipe is communicated with one end of the tee pipe coupling; other two ends of the tee pipe coupling are respectively communicated with one end of the No.1 blowpipe and one end of the No.2 blowpipe; the other end of the No.1 blowpipe and the other end of the No.2 blowpipe are respectively inserted into the seal plate and are distributed along a side wall on which a wastewater inlet pipe of the flotation tank is positioned; the dross removal tank and the flotation tank are communicated; the upper and lower ends of the chute are respectively communicated with the dross removal tank and the dross tank; and a pumping pipe of the water pump is arranged in the dross tank. The system omits the dross scrapers, thus solving the problem that dross scrapers in the floatation devices easily have failure.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Molten steel flow divider bracket

ActiveCN103949625ASolve the spilloverNot easy to condenseMolten metal conveying equipmentsSteelmakingMetallurgy

The invention discloses a molten steel flow divider bracket, and belongs to the technical field of steelmaking equipment. The molten steel flow divider bracket is formed by connecting a bottom plate, and support posts which are respectively arranged at the four corners of the bottom plate, wherein a positioning plate which is parallel to the bottom plate is arranged at the middle upper part of the bracket; positioning holes for placing ingot molds are formed in the positioning plate; lock devices are respectively arranged on the opposite sides of the upper part of the bracket; each lock device consists of a steel angle, a bolt and a nut; the steel angle and the bolt are respectively arranged on two support posts on the same side surface of the bracket; one end of each steel angle is hinged to the corresponding support post; a gap is formed in the other end of the each steel angle; one end of the bolt is hinged to the corresponding support post; the other end of the bolt is connected and fixed to the gap of the corresponding steel angle through the corresponding nut. The molten steel flow divider bracket is simple and reasonable in structure and easy to produce and manufacture; the problem of overflow of molten steel is solved, and the ingot molds are not easily condensed with the bracket, so that the production efficiency is improved, the production cost is reduced, and the molten steel flow divider bracket has broad market space.

Owner:张家港市欧微自动化研发有限公司

Small filament rubbing machine device and method for treating farmland waste through aeration fermentation house

The invention provides a small filament rubbing machine device and a method for treating farmland waste through an aeration fermentation house. The small filament rubbing machine device comprises a power output device and a filament rubbing shaft. The aeration fermentation house is utilized to perform a fermentation treatment method on materials crushed by the filament rubbing machine, so that water of the materials can be reduced to be 30% or lower, and therefore, a treatment process is convenient to operate, and is simple and practical. Equipment integration of the crushing and filament-rubbing machine, the aeration fermentation house and a composite decomposing microbial inoculums can achieve upstream and downstream connection of filament rubbing machines of different models and the aeration fermentation house, and heat of all fermentation and dehydration processes is from biological heat energy and solar energy, so that the agricultural organic solid waste problem is radically solved, and therefore, the purposes of innocent treatment, reduction and reclamation are achieved, a drive and demonstration effect on industrial development of the solid waste is achieved, and the healthy industrial development is supported.

Owner:BEIJING SUNSHINE SPECTACLE ECOLOGICAL SCI&TECH

Converter flue gas cleaning and coal gas recovering RD valve dynamic control method

InactiveCN107794337AEliminate the effects of controlsHigh calorific valueManufacturing convertersFlue gasEngineering

The invention provides a converter flue gas cleaning and coal gas recovering RD valve dynamic control method. An RD valve dynamic control program is additionally arranged in a converter PLC; when a converter starts to blow oxygen, the converter PLC controls a valve plate to overturn to adjust the opening degree of an RD valve through an orma executor, the smoke amount of the RD valve is automatically increased to 20000 L / h on the basis of a conventional setting value, and the conventional setting value is recovered after 16 s to 17 s. when the coal gas recovering is started and a three-way valve starts to move, the converter PLC controls the valve plate to overturn to adjust the opening degree of the RD valve through the orma executor, the smoke amount of the RD valve is automatically increased to 20000 L / h on the basis of the conventional setting value, and the conventional setting value is recovered after 16 s to 17 s. By means of the converter flue gas cleaning and coal gas recovering RD valve dynamic control method, influences of adverse factors of adjusting time of the RD valve on control over the smoke amount are eliminated, the problems of smoke overflowing and coal gas recovering heat value losses caused by large-scope smoke reduction are solved, the production smoothness and the cost controllability are guaranteed.

Owner:ANGANG STEEL CO LTD

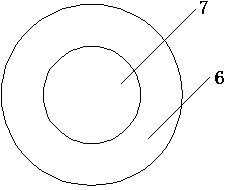

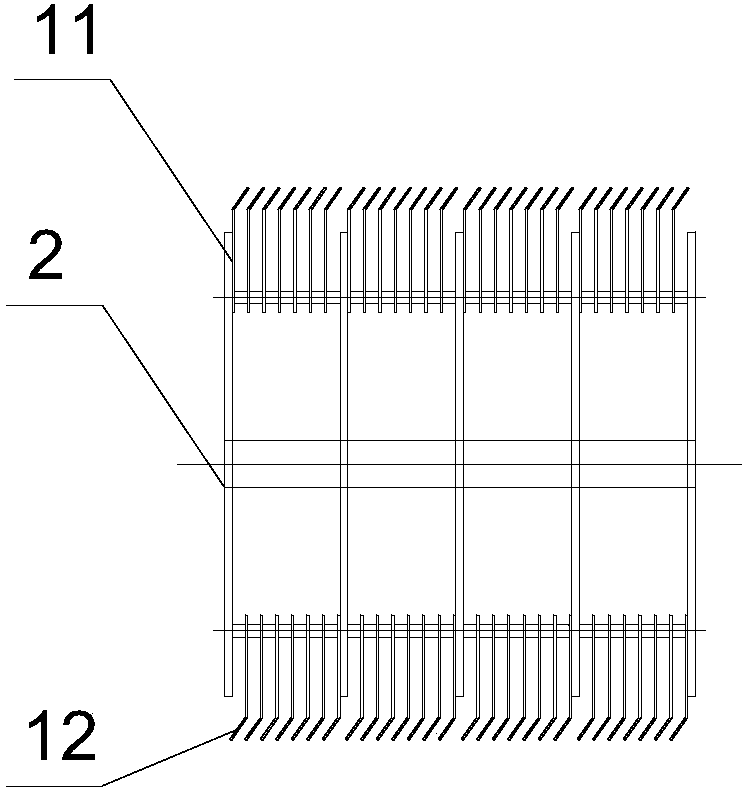

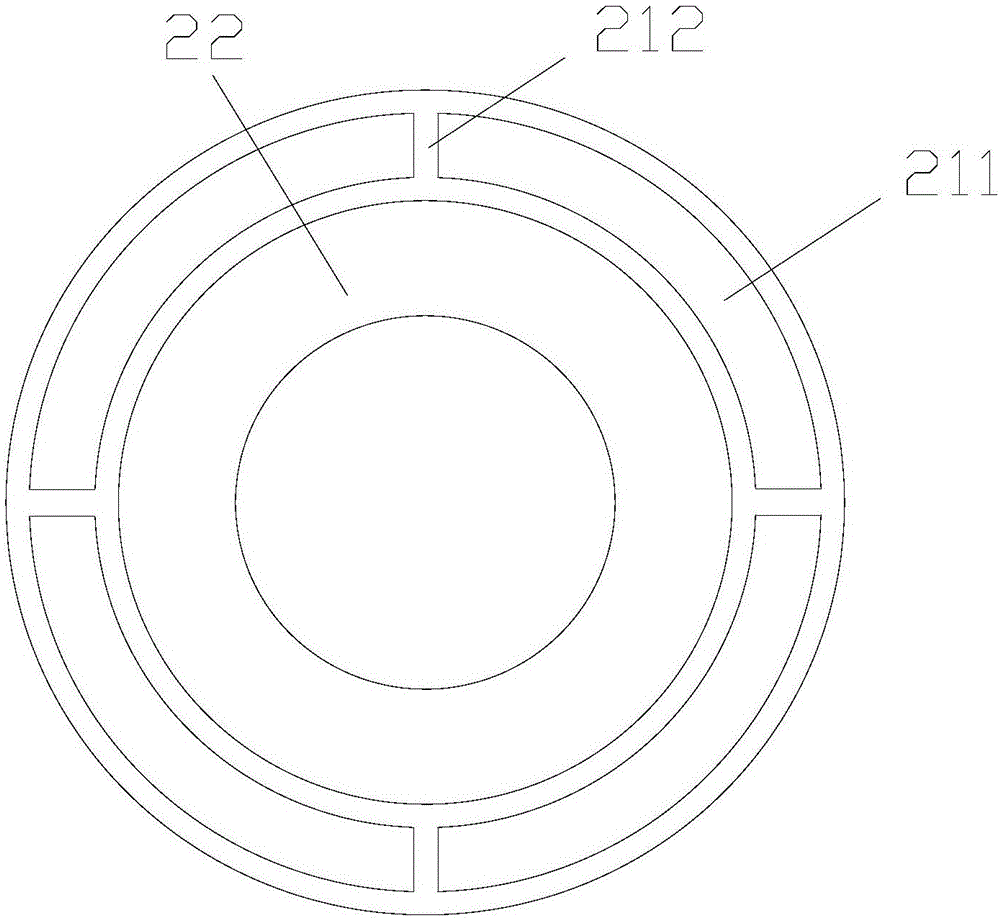

Damping ring for multi-section aluminum-casting rotor and processing method of aluminum-casting rotor

InactiveCN106712340AEven by forceImproving the Quality of Iron Core LaminationMagnetic circuit rotating partsManufacturing stator/rotor bodiesStatorAluminium

The invention discloses a damping ring for a multi-section aluminum-casting rotor. The damping ring comprises an outer-layer aluminum ring and an inner-layer silicon-steel ring, wherein the aluminum ring is provided with aluminum-casting through grooves which are distributed in a ring-shaped structure at equal intervals; a grooving rib is formed between two adjacent aluminum-casting through grooves; and the quantity of the grooving ribs is an approximate number of the quantity of rotor groove bodies. The invention also discloses a method for processing the multi-section aluminum-casting rotor by using the damping ring, and a stator. According to the damping ring, the method and the stator disclosed by the invention, the uniform stressing on a punching sheet with superimposed iron cores is guaranteed, the superimposition quality of the iron cores is improved, the overflowing and the bubbles of aluminum are solved, and the quality and the reliability of the aluminum-casting rotor are improved.

Owner:HEFEI UNIV OF TECH

Clean production process for wettable powder of pesticide

InactiveCN107258775AEfficient clean production processClean production process saves energyBiocideFungicidesActive componentMaterials science

The invention discloses a clean production process for a wettable powder of a pesticide. The clean production process comprises the following steps: (1) subjecting raw materials of the wettable powder, including active components of the pesticide, a dispersant, a wetting agent and a filling material, to pre-dispersion in water so as to form a suspension with a particle size of no more than 20 [mu]m; (2) subjecting the suspension to sand milling with a sand mill so as to obtain a suspension with a particle size D90 of no more than 8 [mu]m and a particle size D50 of no more than 5 [mu]m; and (3) subjecting the suspension to spray drying with a centrifugal spray dryer so as to obtain a wettable powder product.

Owner:无锡华格新材料有限公司

A chute low noise motor

ActiveCN103501065BSolve the spilloverSolve the bubblesMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to a motor, in particular to a chute low-noise motor, which includes a machine base, a stator arranged on the machine base, a rotor and a rotating shaft; the rotor includes at least two sections of rotor cores, and the rotor cores The oblique key method of false shaft inclination is used to laminate the punched sheets to form a chute core; the chute of adjacent chute cores is in the opposite direction and the angle is staggered? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? set up. Therefore, the present invention has the following advantages: 1. The vibration and noise, the quality of iron core lamination, the quality of cast aluminum, and the structure of the cast aluminum rotor with inclined slots for high-power motors are all optimized to a large extent, and are suitable for vibration and noise requirements. High, the motor type is a small and medium-sized cast aluminum rotor structure AC motor; 2. It fundamentally ensures the force uniformity and rigidity of the iron core laminated sheet, improves the quality of the iron core laminate, and reduces the deformation and vibration noise The impact of aluminum spillage and air bubbles is solved, and the quality of the cast aluminum rotor and the reliability of the motor performance are improved.

Owner:中国船舶重工集团公司第七一二研究所

Furnace body of cupola furnace

InactiveCN103292594AMeet the requirements of safe productionSimple structureVertical furnacesCombustion chamberProtection ring

The invention discloses a furnace body of a cupola furnace. Materials are fed into the furnace body laterally. The furnace body sequentially comprises a hearth, a crucible, a stack and a chimney from bottom to top. The furnace body is basically in the shape of a circular column and is positioned on a hearth plate of a cupola furnace supporting portion of the cupola furnace, and a feed inlet of the furnace body is positioned on the lower portion of the chimney. The furnace body mainly comprises a cylindrical shell and a furnace lining, the cylindrical shell is made of steel plates, and the furnace lining made of refractory materials is fixed onto the inner wall of the shell. A combustion chamber is arranged on a part, which is positioned from the hearth plate to the lower edge of the feed inlet, of the furnace lining. The furnace body further comprises a collision protection ring. The furnace body is structurally characterized in that the height of the feed inlet of the furnace body ranges from 400 millimeters to 1500 millimeters, and the width of the feed inlet ranges from 80% to 100% of the inner diameter of the combustion chamber of the furnace body. The collision protection ring is provided with a feeding notch, the feeding notch is positioned at the front of the upper portion of the collision protection ring, and the shape of the feeding notch corresponds to that of the rear of a guide groove of a guide device used with the feeding notch.

Owner:姚立猛 +1

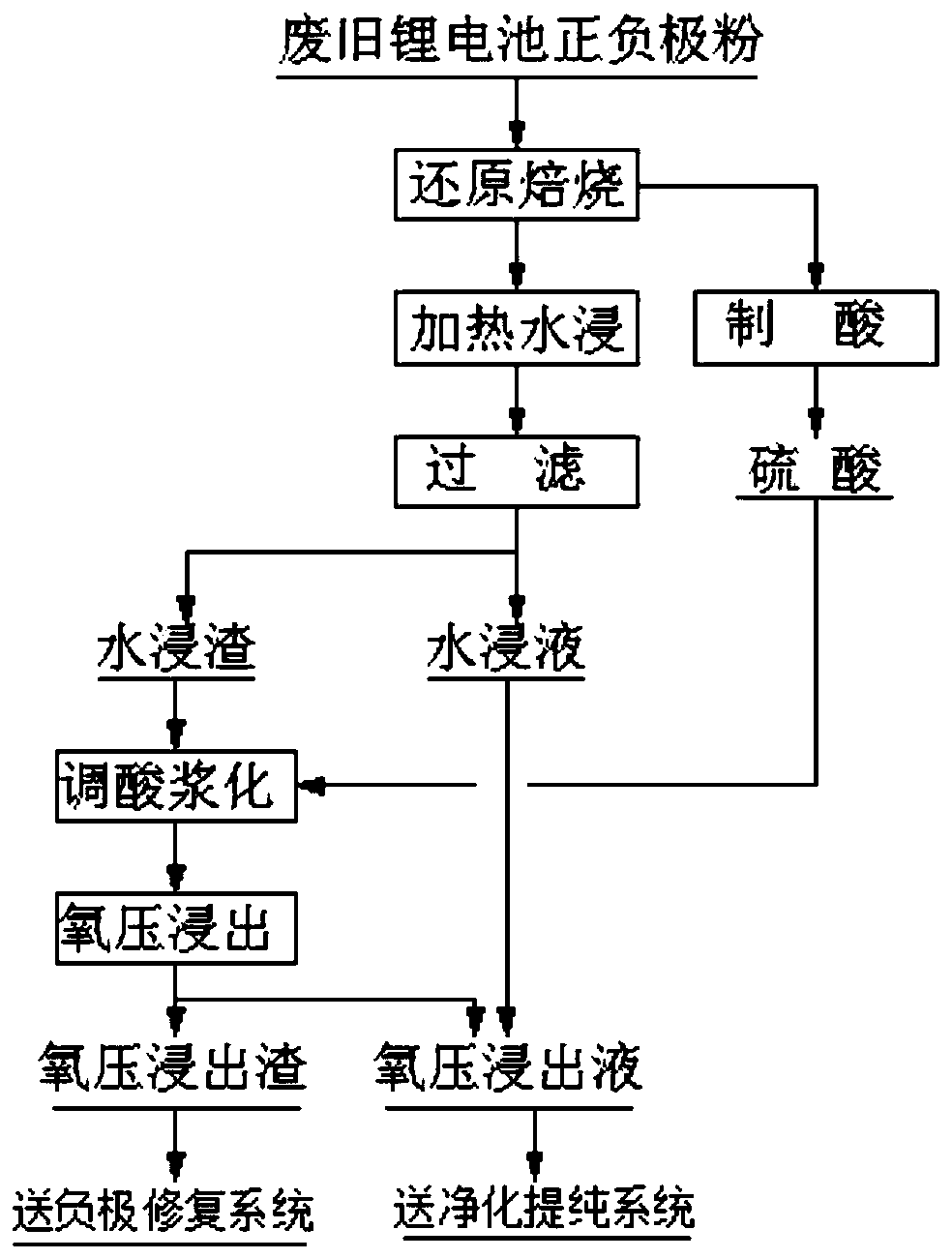

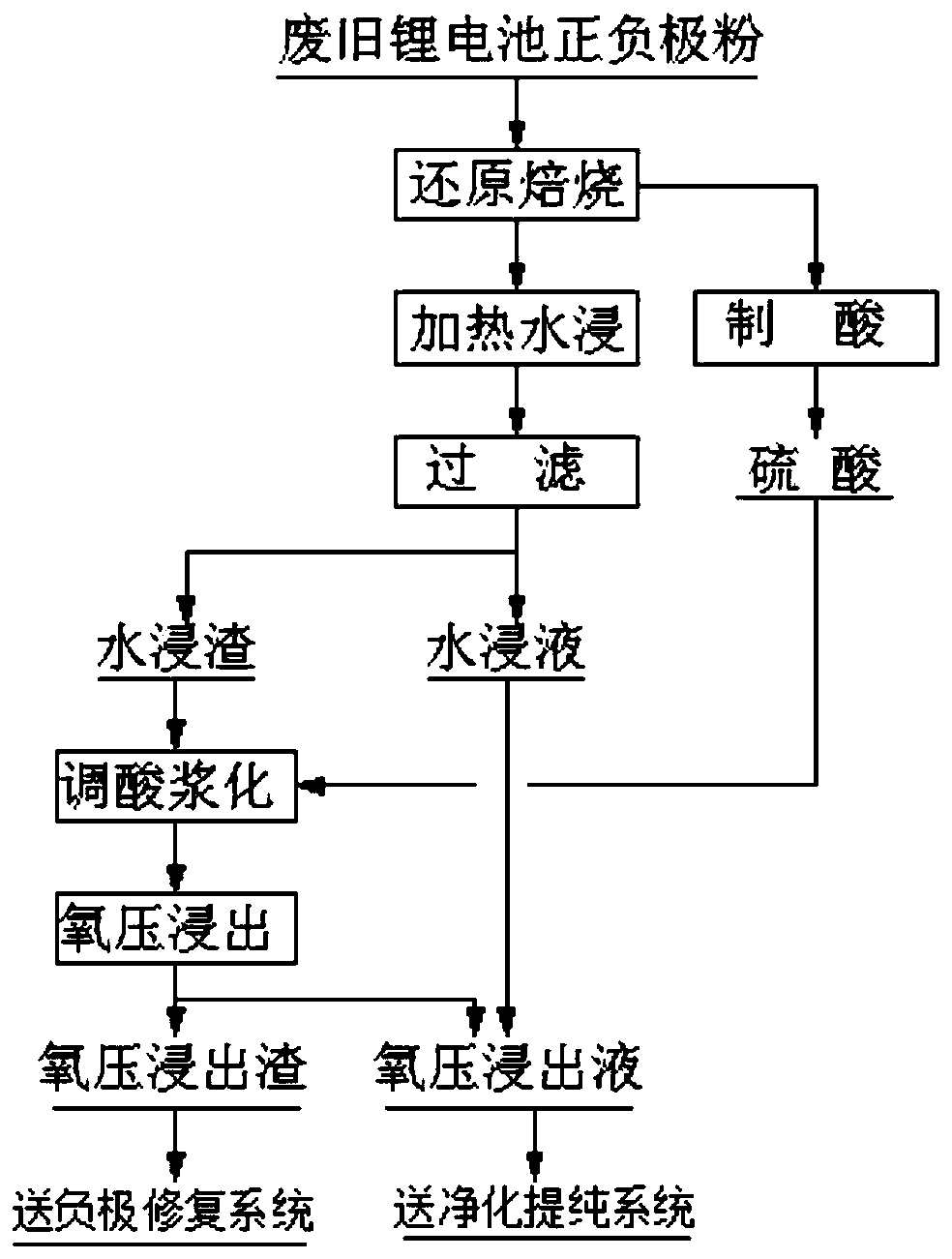

Method for recovering metal elements in lithium battery anode and cathode materials

PendingCN111172396AImprove leaching rateHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementMetallurgyPartial pressure

The invention provides a method for recovering metal elements in lithium battery anode and cathode materials. The method comprises the following steps of carrying out reduction roasting on the lithiumbattery anode and cathode materials and a reducing agent to obtain a reduction roasting product, wherein the reduction roasting temperature is 300-800 DEG C; carrying out heating and water leaching on the reduction roasting product and water to obtain water leached residues and water leached liquid, wherein the weight ratio of the reduction roasting product to the water is 1:(3-6), and the waterbath temperature is 60-90 DEG C; carrying out oxygen pressure leaching on the water leached residues to obtain oxygen pressure leached residues and oxygen pressure leached liquid, wherein the weight ratio of the water leached residues to the water is 1:(3-6), the reaction temperature is 130-180 DEG C, the reaction pressure is 1.2-1.7 MPa, and the oxygen partial pressure is 0.3-0.5 MPa; and mixingthe water leached liquid and the oxygen pressure leached liquid, and performing purifying to recover the valuable metal elements in a closed environment. By adopting the recovering method, the leaching rate of the metal elements in the lithium battery anode and cathode materials can be greatly improved, and the recovery period is shortened.

Owner:YINLONG ENERGY CO LTD

Fully sealed coal cabin vehicle access water curtain device

InactiveCN108261871AStop SpillSolve the spilloverUsing liquid separation agentControl systemSpray nozzle

The invention discloses a device arranged at a fully sealed coal cabin access for preventing coal dust from outwards flowing. The device is arranged at the upper part of the fully sealed coal cabin access. The device comprises a water pump, a water conveying pipe, a spray nozzle, electric equipment and a control system. The device sprays water mist from top to bottom to form a water curtain; the outward flowing of coal dust in the cabin can be effectively prevented; no influence is caused on access of vehicles into or out from the coal cabin.

Owner:SHANXI SHANGFENG TECH

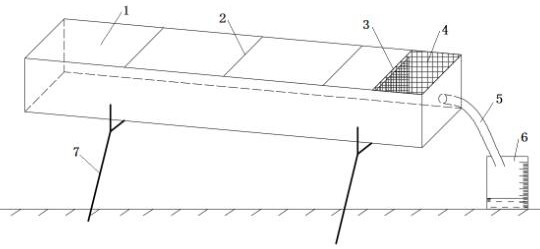

Simple and convenient under-forest vegetation rainfall runoff collecting and measuring device and mounting method

PendingCN112255052AReduce distractionsSolve the spilloverWithdrawing sample devicesRainfall runoffMeasurement device

The invention relates to a simple and convenient under-forest vegetation rainfall runoff collecting and measuring device and a mounting method. The simple and convenient under-forest vegetation rainfall runoff collecting and measuring device comprises a runoff collector and a runoff interception groove with an open top, an inner cavity of the runoff interception groove is divided into a first interception cavity and a second interception cavity through a vertical filter screen, the second interception cavity is communicated with the runoff collector through a water guide pipe, and the top of the second interception cavity is covered with a transverse filter screen. By arranging the vertical filter screen and the transverse filter screen, interference of foreign factors such as litters andinsects can be reduced, and the problem that rainwater overflows when the precipitation amount is large is solved; the water outlet of the rectangular runoff interception groove for collecting water is connected with the runoff collector for collecting water through a water guide pipe, so that the evaporation of the collected rainwater can be greatly reduced due to the factors; the rectangular runoff interception tank for collecting water and the runoff collector for collecting water are relatively independent, and sampling is convenient.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Semiautomatic feeding device

The invention provides a semiautomatic feeding device. The device comprises an open-close type sealed cabin, a discharging hopper, an electric dust collector and an electric dredging screw set, wherein the discharging hopper is arranged below the open-close type sealed cabin; the electric dust collector is used for dust collection of the open-close type sealed cabin; the electric dust collector iscommunicated with the open-close type sealed cabin through a first dust collecting pipe; the electric dredging screw set is arranged in the discharging hopper. The open-close type sealed cabin is conveniently used for putting materials, opening bags and discharging; for preventing dust from overflowing, the open-close type sealed cabin is sealed in the bag opening process and the electric dust collector is opened for collecting dust; under the caking condition of the materials, the electric dredging screw set smashes cakes, so that the problems of overflowing and caking of dust are solved. The device has the advantages of environmental protection, safety, small size, convenience in moving, low cost and simple operation.

Owner:吴朋钱

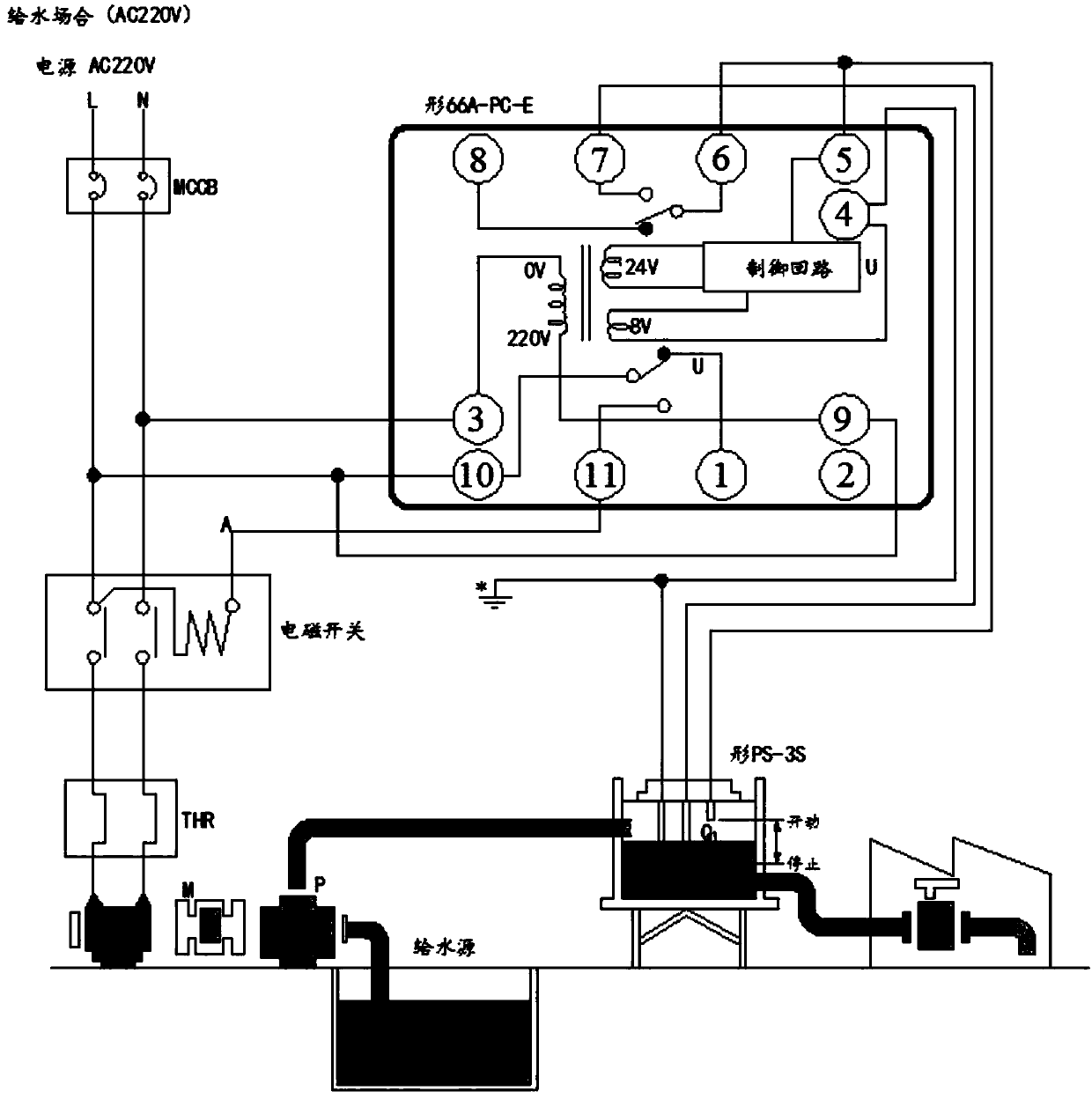

Intelligent control device for water pump motor

PendingCN108021151ANo overflowSolve the spilloverLevel controlElectric switchesAutomatic controlEngineering

The invention discloses an intelligent control device for a water pump motor, and relates to the field of automatic control. The device comprises water pump, a common electrode, a first electrode, a second electric, and a liquid container. The common electrode, the first electrode and the second electrode are disposed at the top of the liquid container. One end of the common electrode is connectedwith the grounding end of the water pump, and the other end extends to a first water level point of the liquid container. One end of the first electrode is connected with the fire wire end of the water pump, and the other end extends to a second water point of the liquid container. One end of the second electrode is connected with the zero line of the water pump, and the other end extends to a third water point of the liquid container. The distance between the first water level point and the bottom of the liquid container is less than the distance between the second water level point and thebottom of the liquid container, and the distance between the second water level point and the bottom of the liquid container is less than the distance between the third water level point and the bottom of the liquid container.

Owner:GUANGZHOU AUTOFOR ENERGY SAVING TECH CO LTD

Method for cladding watch bezel with gold

The invention discloses a method for cladding a watch bezel with gold. The method comprises the following steps: (1) machining a gold plate to obtain a thin gold sheet for later use; (2) using an oilpressure die to make the thin gold sheet into a semi-finished gold ring matching a workpiece to be cladded with gold in shape; (3) using a laser machine to sweep the outer surface of the workpiece tobe cladded with gold to engrave reticular grooves and filling the grooves with silver solder paste; (4) using the semi-finished gold ring to sleeve the workpiece to be cladded with gold and performingpre-press forming; (5) placing the pre-pressed product in a pressure die and putting the pressure die into a nitriding furnace for welding; and (6) subjecting the product treated by the nitriding furnace to natural cooling, taking out the product and performing finish turning, polishing and cleaning to obtain a watch bezel cladded with gold. By designing the reticular grooves on the surface of the workpiece to be machined as well as using the silver solder paste for filling and then welding, the method can effectively avoid phenomena such as silver spillover, pseudo soldering and unsolderingand no new concave positions can appear during the post machining.

Owner:广州市飞时达钟表有限公司

Mortar tank with automatic dust-collecting function

ActiveCN109693313AAvoid pollutionSolve the spilloverMixing operation control apparatusPretreatment controlAir pollutionWaste management

The invention discloses a mortar tank with an automatic dust-collecting function. The mortar tank with the automatic dust-collecting function comprises a tank body, a feeding pipe and a supporting rack. The feeding pipe extends into the tank body, the supporting rack is arranged on the lower part of the tank body, the lower part of the tank body is a tapered part, a discharging port is formed on the bottom of the mortar tank, and the discharging port communicates with a blending machine; a plurality of dust-removing filtering bags are arranged at the position, close to the top, of the tank body, and the dust-removing filtering bags are gathered through one or more dust-removing tanks and communicate with an air vent arranged at the top of the tank body. According to the mortar tank with the automatic dust-collecting function, when mortar materials are conveyed to the mortar tank by mortar through the feeding pipe, in the action of the dust-removing filtering bags, powder can be blockedin the tank body, and thus air pollution is avoided.

Owner:ZHEJIANG UNIV

Washing pot with ventilating structure

The invention discloses a washing pot with a ventilating structure, comprising a washing pot body and a flow guide tube arranged on the washing pot body, wherein a ventilating hole is arranged in the top of the washing pot body; a ventilating pipe is connected on the ventilating hole; and the other end of the ventilating pipe is fixed on the outer wall of the flow guide tube. The washing pot with the ventilating structure, disclosed by the invention, is simple in structure and obvious in effect and has the advantages that: on the base of not changing size structures of the flow guide tube and the washing pot body, the ventilating hole and the ventilating pipe are additionally arranged on the top of the washing pot body to ensure that the air therein can be timely discharged from the ventilating hole when washing liquid is injected into the washing pot, therefore, problems that the washing liquid overflows and splashes are effectively solved and the assembling efficiency is improved; and in the meantime, the ventilating pipe is arranged to guarantee that even if a car runs on a bumpy road surface, the washing liquid does not overflow from the ventilating hole.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com