Self-closing valve for preventing liquid overflowing when container is dumped

A self-closing valve and container technology, which is applied to devices, containers, and large containers that prevent repeated filling of containers, and can solve problems such as polluting the environment, aggravating, and hurting people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

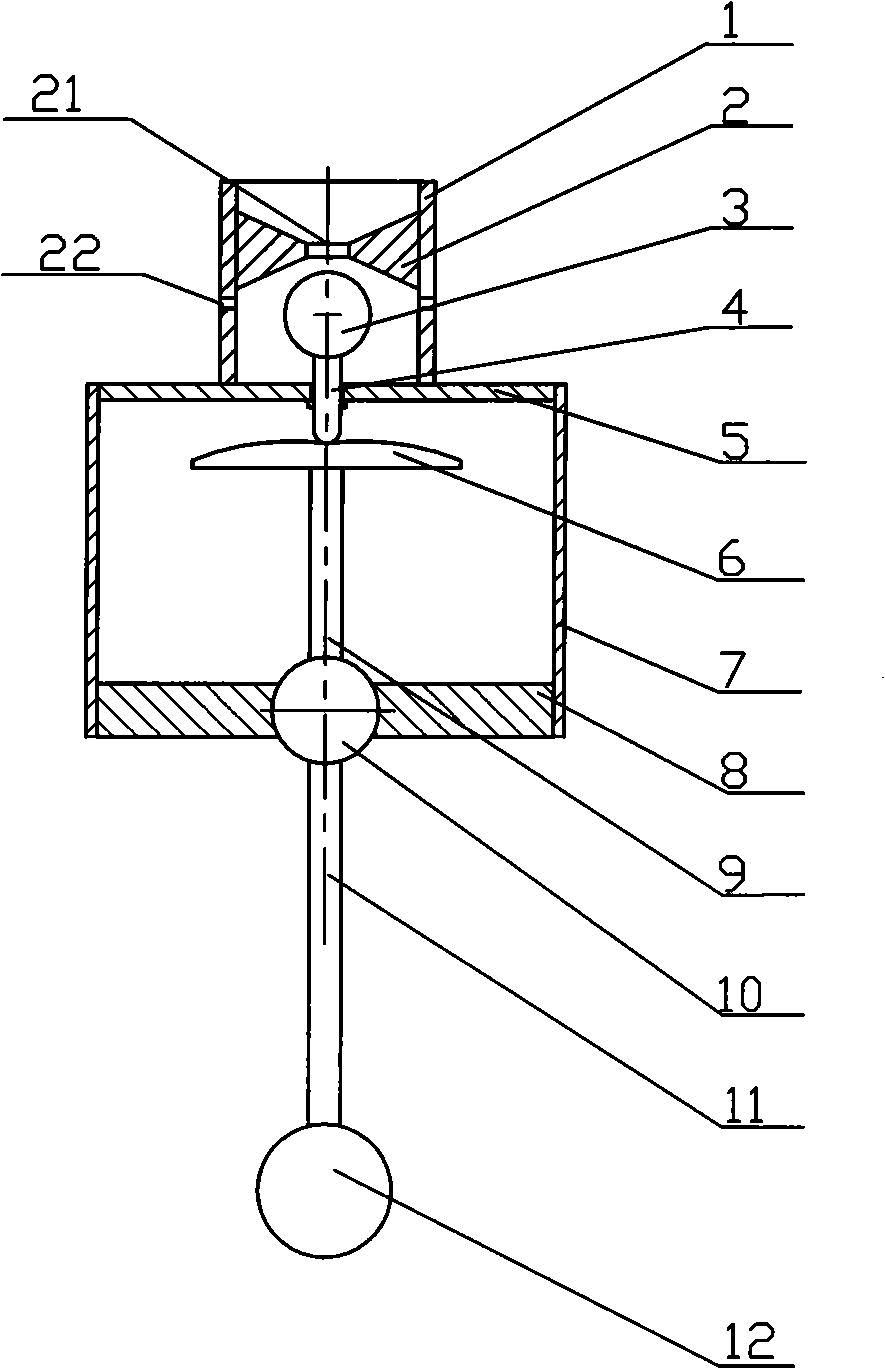

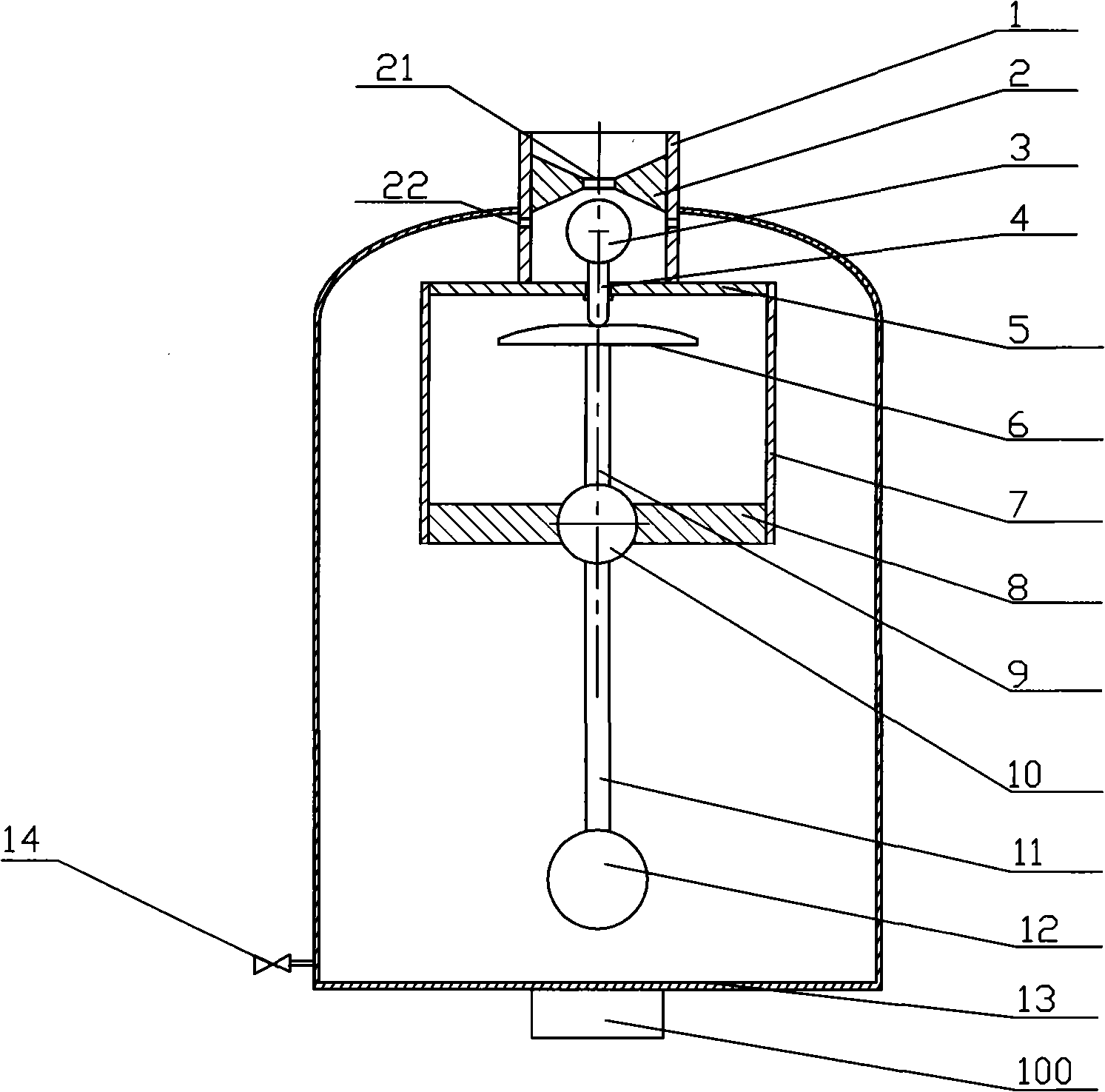

[0025] The self-closing valve for preventing liquid from overflowing when the container is toppled over includes a valve body 1, a valve seat 2, a spherical disc 3, a valve stem 4, a valve stem sleeve 5, a universal three-dimensional cam 6, a bearing frame 7, and a bearing sleeve 8 , universal cam connecting rod 9, ball bearing 10, weight connecting rod 11, spherical weight 12, the above structure has the same central axis from top to bottom, as figure 1 and figure 2 As shown, the valve body 1 and the valve seat 2 are an integral structure, the center of the valve seat 2 has an inlet and outlet 21, its upper and lower end surfaces are both inner conical surfaces, and its lower end surface can form a linear contact seal with the spherical valve disc 3 ; On the valve body 1, the part below the valve seat 2 and installed in the container 13 has more than one inlet and outlet 22, such as figure 2 As shown, the valve disc 3 is fixedly connected with the valve stem 4, the lower e...

Embodiment 2

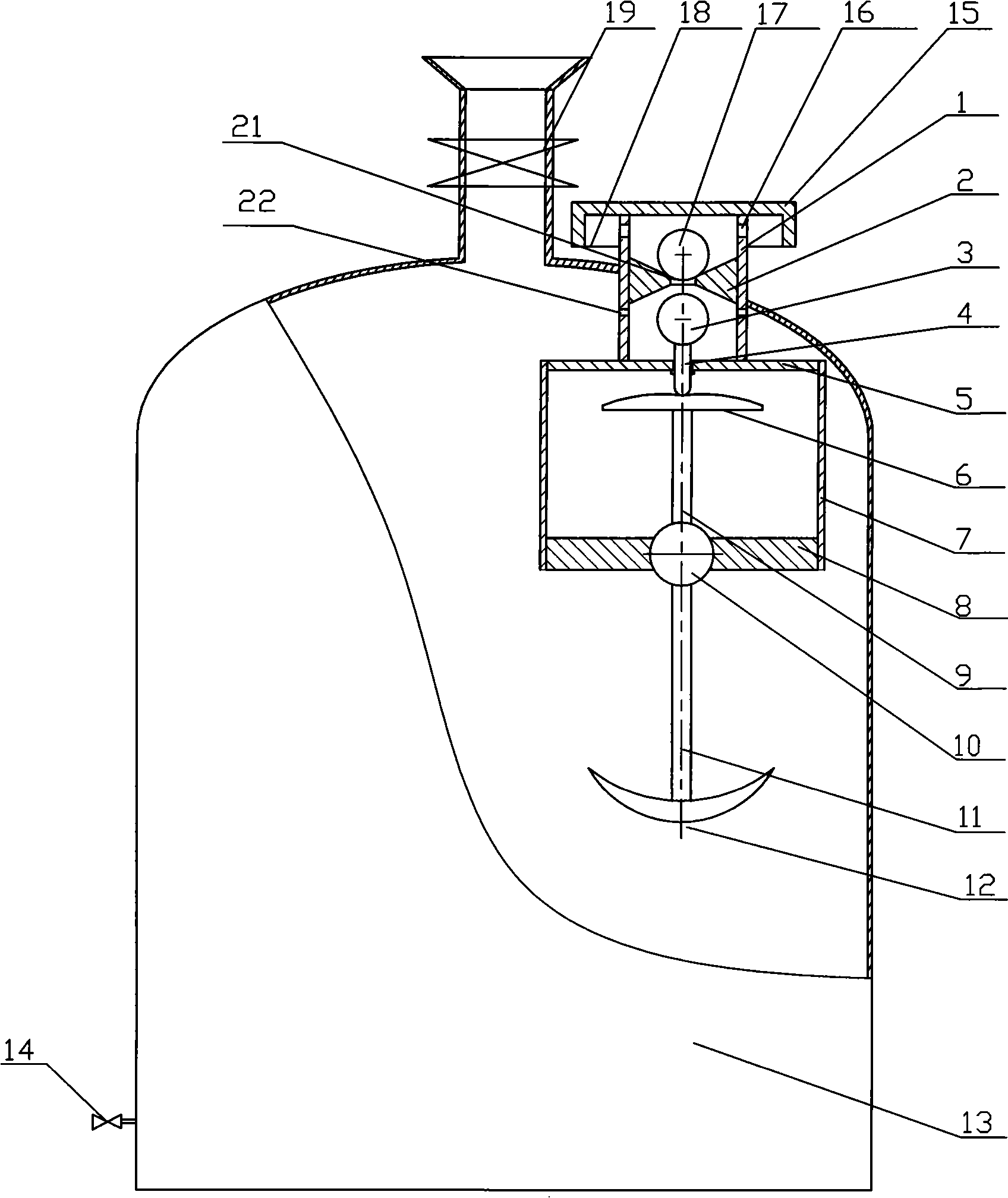

[0031] This embodiment is a self-closing valve with an exhaust valve, that is, on the basis of the structure of Embodiment 1, an exhaust valve is added, and the exhaust valve falls on the inlet and outlet 21 of the upper end surface of the valve seat 2. The sealing ball 17 is in close linear contact with the upper end surface of the valve seat 2; in order to prevent external pollution, the device also includes a cover body 15 and a silk screen 18, and is located on the valve body 1 above the valve seat 2. There is an air outlet 16; the cover body 15 is installed and fixed on the upper part of the valve body 1, and the silk screen 18 is sealed on the lower part of the cover body 15, forming a breathable protective cover together with the cover plate, and the air outlet hole 16 is sealed therein.

[0032] Install the device on containers containing volatile liquids, such as image 3 and shown in Figure 4. After pouring into the volatile liquid, close the valve 19 on the top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com