Mortar tank with automatic dust-collecting function

A mortar tank and automatic technology, applied in the directions of batch storage, clay preparation device, mixing operation control device, etc., can solve the problems of inability to collect dust and occupy operating space, and achieve the solution of dust overflow, uniform discharge, and prevention of mortar segregation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

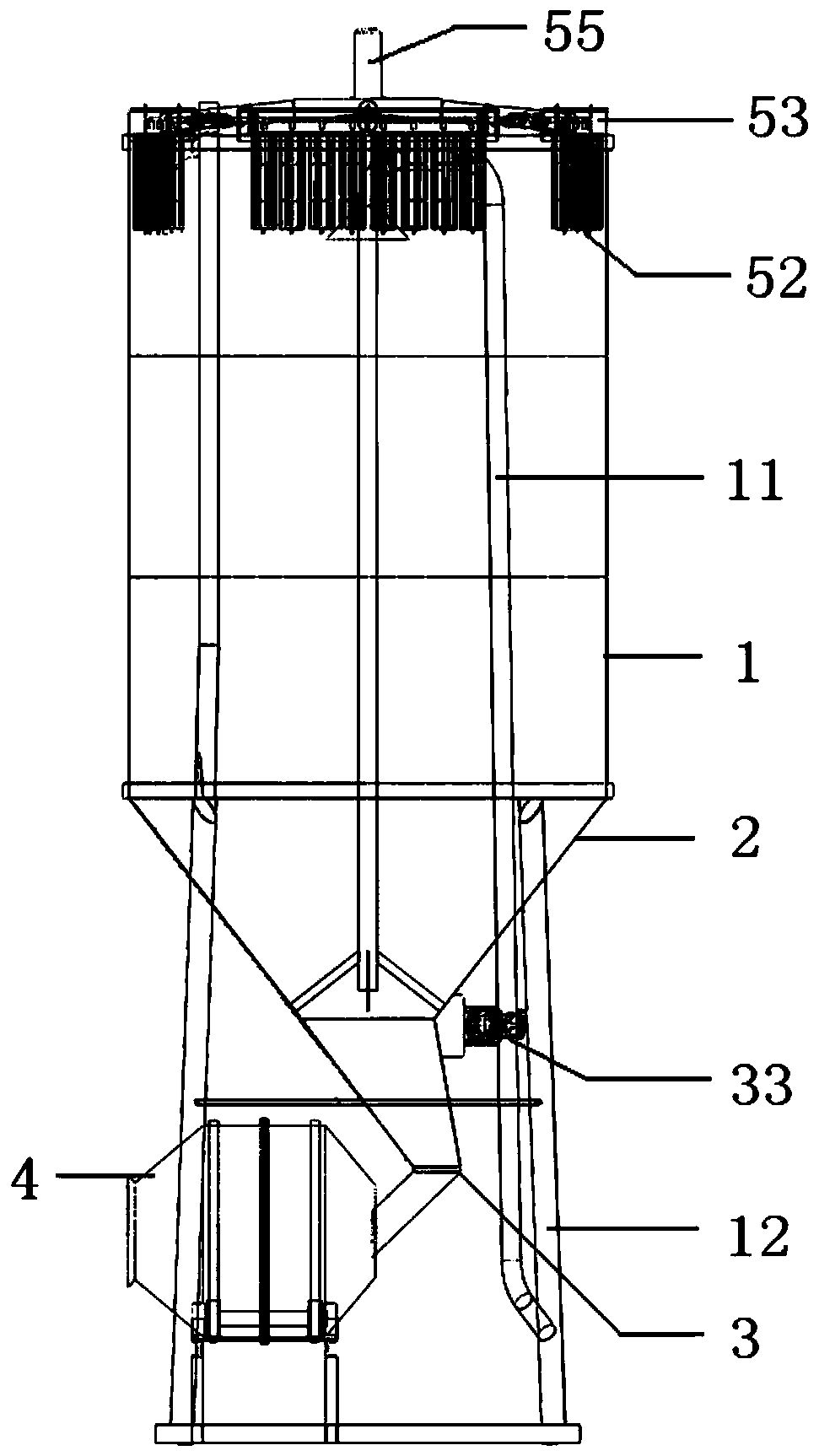

[0036] Such as Figure 1-Figure 3 As shown, a mortar tank with automatic dust collection function includes a tank body 1, a feed pipe 11 extending into the inside of the tank body 1, and a support frame composed of four supporting legs 12 arranged under the tank body 1. The tank body 1. The lower part is a cone part 2, and the bottom of the tank is provided with a discharge port 3, which communicates with the mixer 4.

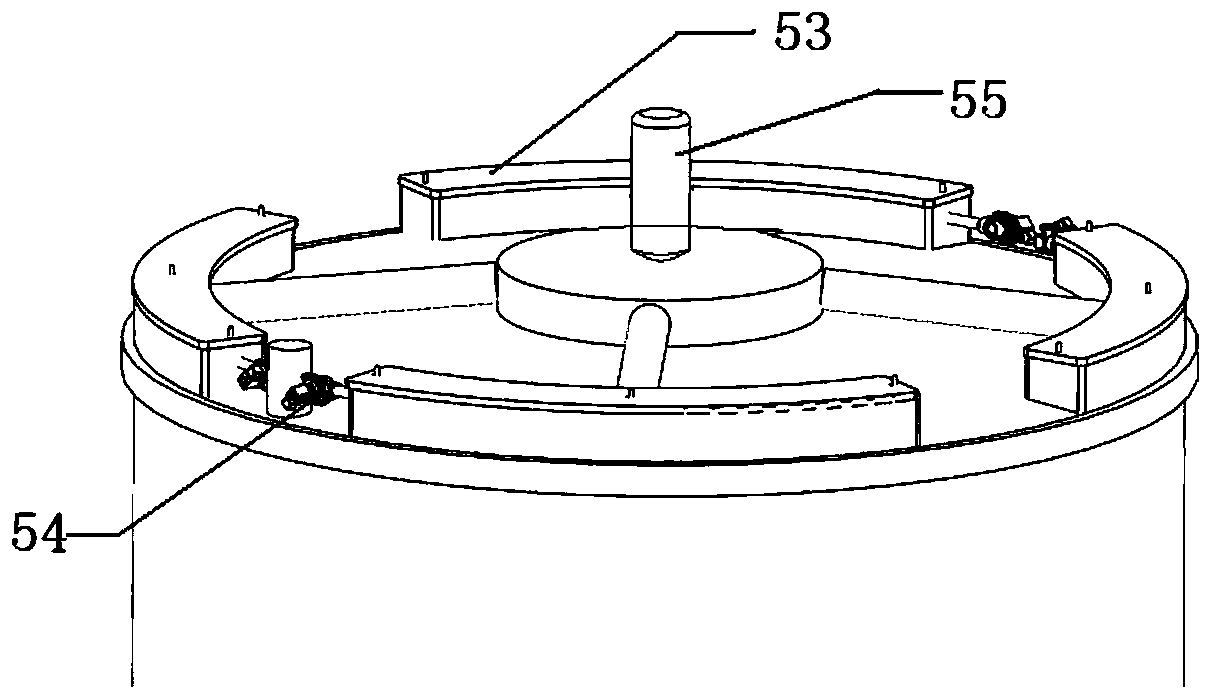

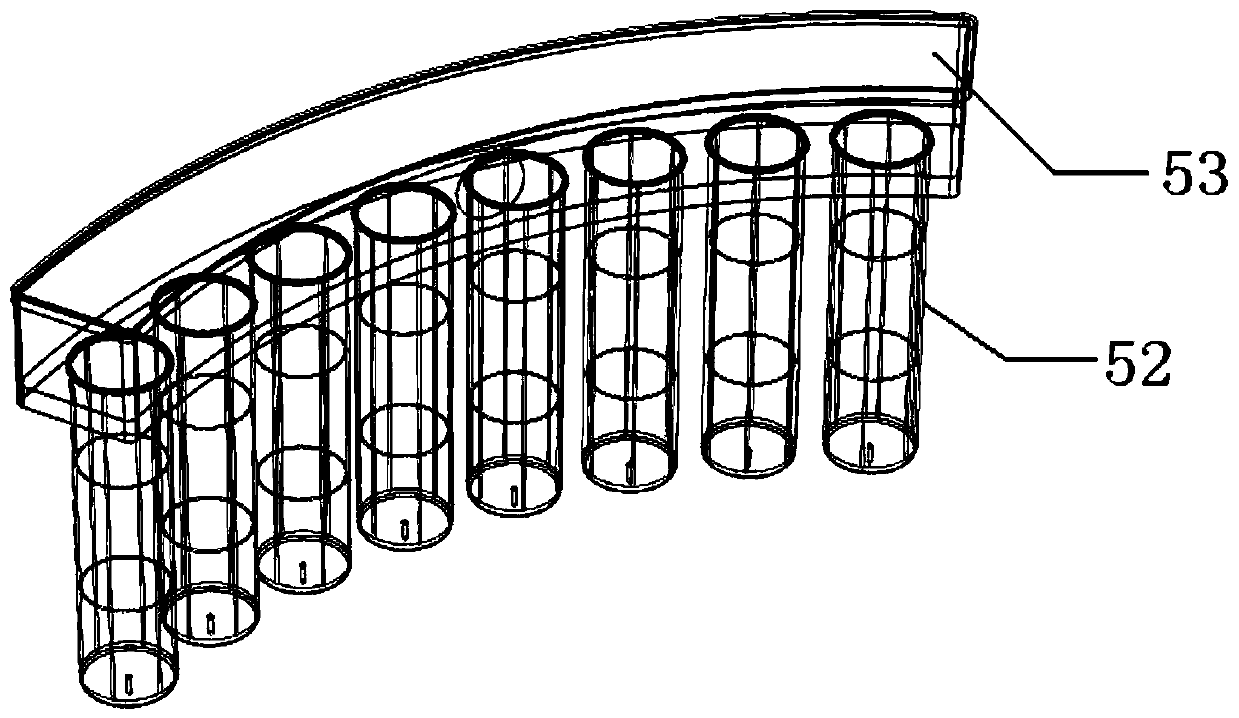

[0037] The top of the tank body 1 is provided with a ventilation opening 55, and the four dust removal boxes 53 communicate with the ventilation openings 55 through pipes, and each dust removal box 53 is provided with several dust removal filter bags 52. Also be provided with the dedusting nozzle of the second electromagnetic pulse valve 54 in each dedusting box 53, the air inlet pipe of dedusting nozzle is the support leg 12 of hollow, totally 4 support legs, and support leg 12 is interconnected by hollow pipe, unified As an air storage chamber for compressed...

Embodiment 2

[0044] As a description of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below.

[0045] Such as Figure 4 As shown, the cone part 2 of the mortar tank is also provided with four air nozzles 32 facing the conical inner wall, each air nozzle 32 is provided with a first electromagnetic pulse valve 31, and each supporting leg 12 is correspondingly provided with an air nozzle 32. The air nozzles 32 are evenly distributed along the radial direction of the cone. Air compressed by the air compressor 33 is stored in the support leg 12 to supply air to the air nozzle 32 .

[0046] The discharge port 3 is provided with a butterfly valve with a position detection switch, the position detection switch is connected to a solenoid valve controller, and the solenoid valve controller drives the first electromagnetic pulse valve 31 to control the opening and closing of the air nozzle 32 .

[0047] In this embodiment, there are 4 support ...

Embodiment 3

[0054] As an explanation of Embodiment 3 of the present invention, only the differences from Embodiment 1 above will be described below.

[0055] In this embodiment, on the basis of Embodiment 1, the dust suction pipe 6 and the dust removal fan 51 are added. Such as Figure 5 As shown, one end of the ash suction pipe 6 extends into the tank body of the mixer, the opening is located near the dustproof filter bag 52 , and the opening at the other end is located at the entrance of the mixer 4 . The part of the ash suction pipe 6 in the tank body is a metal hard tube, and the part extending out of the tank body is a plastic tube.

[0056] Such as Figure 6 As shown, the vent 55 at the top of the tank body is equipped with a dust removal fan 51, and the four dust removal boxes are connected with the dust removal fan 51 after being collected through pipelines.

[0057] The structure of the mortar mixer adopts the way of front and rear through holes to enter the feeding and discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com