Electrostatic spraying equipment

An electrostatic spraying and equipment technology, which is applied in the field of fully automatic PLC-controlled air-driven electrostatic spraying equipment, can solve problems such as failure to alarm, insufficient ionization, and failure to deliver mist coating materials, so as to improve safety and reliability. The effect of eliminating fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

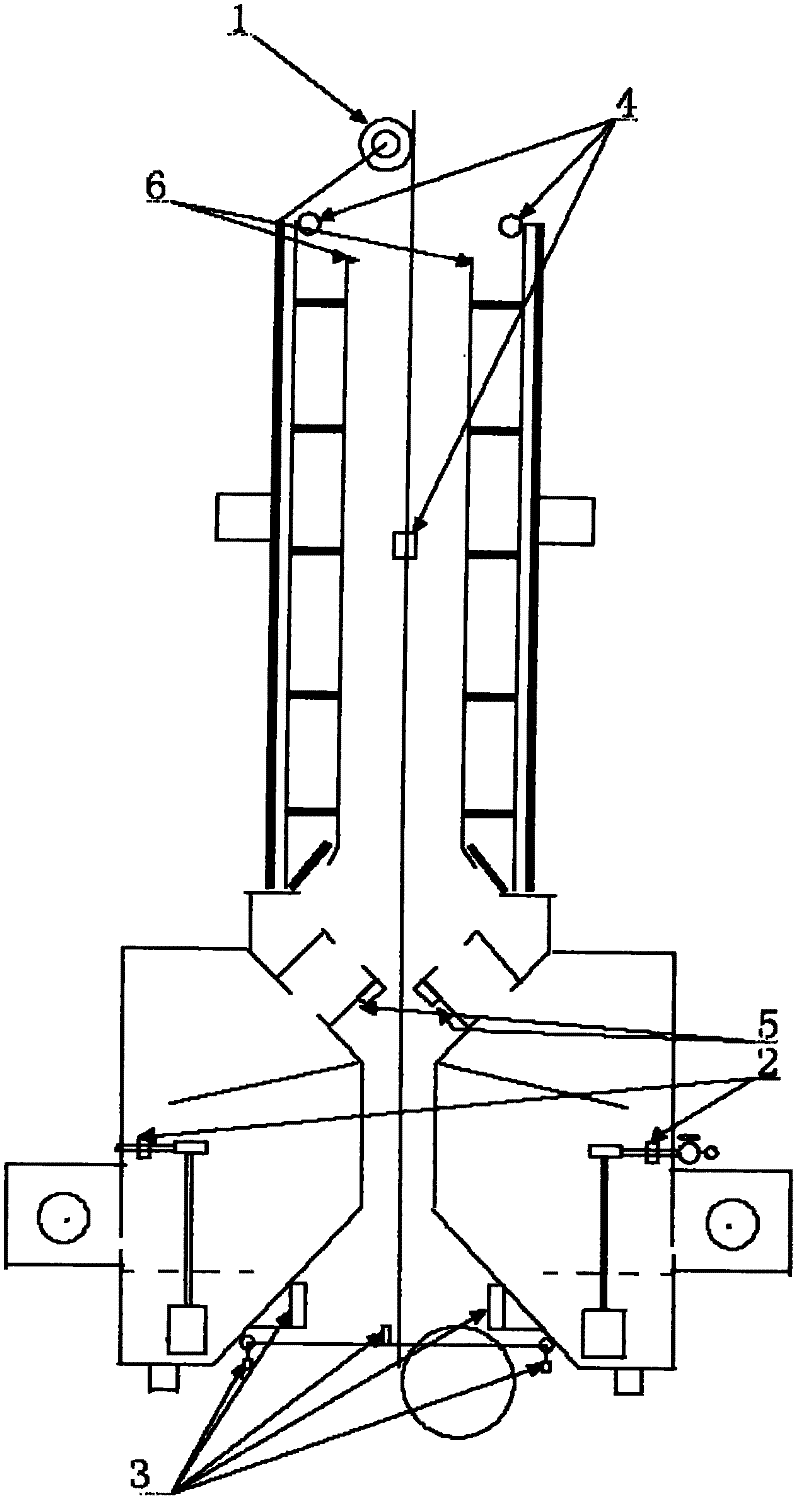

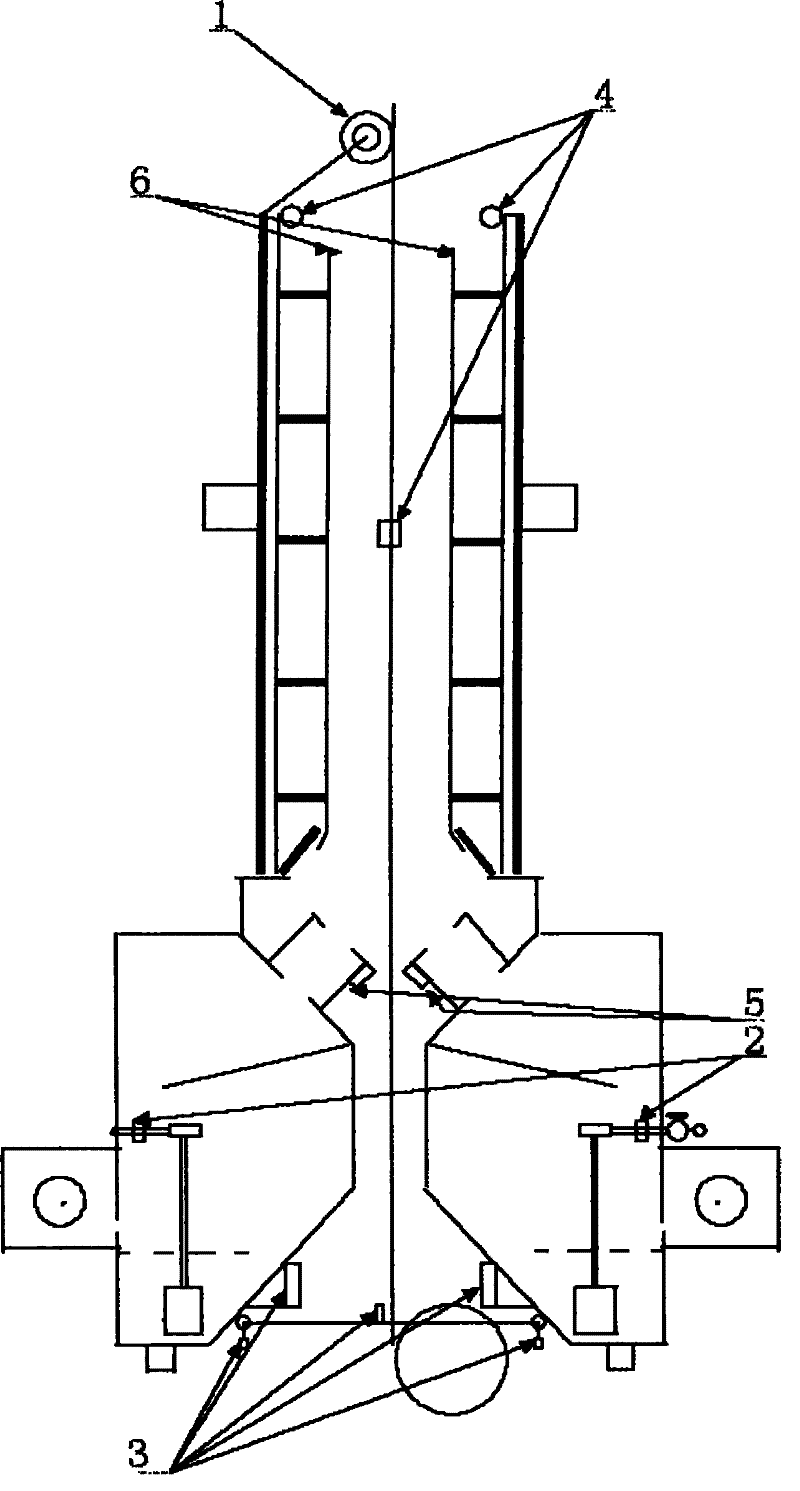

[0029] An electrostatic spraying equipment, including: line speed detection system 1, independent atomizing nozzle adjustment system 2, strip width detection system 3, automatic flame detection and automatic fire extinguishing system 4, unbalanced air pressure compensation and control system 5 and sawtooth electrodes 6.

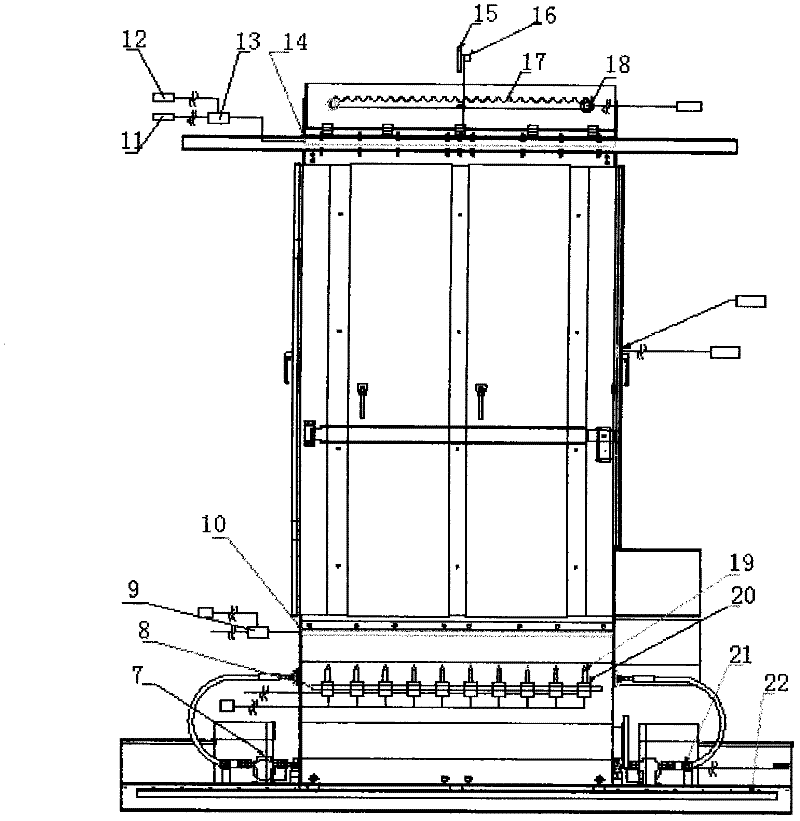

[0030] Linear speed detection device: The linear speed detection device is composed of connecting rod, cylinder, spring, follower wheel 15, and encoder 16. The lower part of the connecting rod is fixed at the middle position of the top of the equipment with a hinge, and the lower part of the cylinder is also fixed at the middle position of the top of the device. The upper part of the cylinder is connected to the spring, and the spring is connected to the middle of the connecting rod. The follower wheel 15 and the encoder 16 are coaxially installed on the top of the connecting rod. During operation, the cylinder moves to make the connecting rod lean against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com