Patents

Literature

87results about How to "Improve coating accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

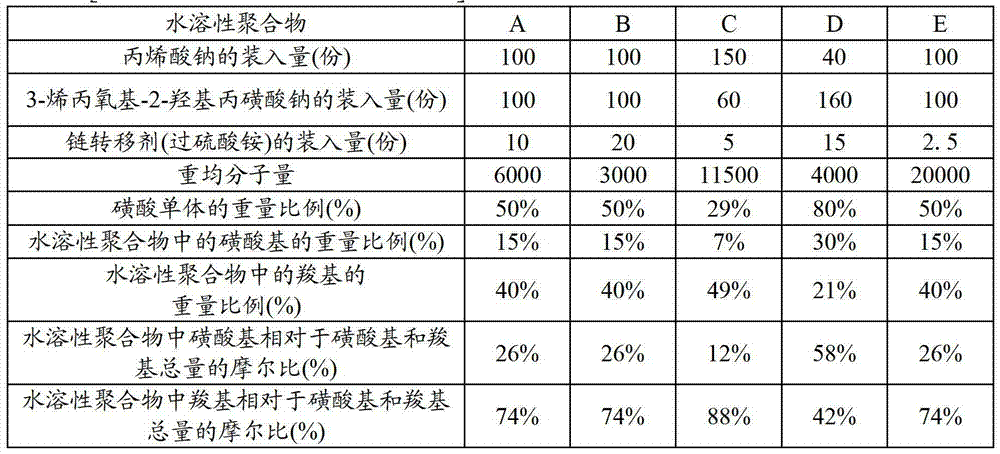

Slurry composition for porous film in battery, method for manufacturing porous film for secondary battery, porous film for secondary battery, electrode for secondary battery, separator for secondary battery, and secondary battery

ActiveCN103081181AGood dispersionEfficient preparationElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesParticulatesWater insoluble

Provided is a slurry composition for a porous film in a battery, the composition containing: 70-99 parts by weight of non-electroconductive particles, 0.1-4 parts by weight of a water-soluble polymer having a sulfonic acid group and a weight-average molecular weight of 1000-15000, 0.1-10 parts by weight of a water-insoluble particulate polymer, and water. Also provided are a method for manufacturing a porous film for a secondary battery, a porous film for a secondary battery, an electrode for a secondary battery, a separator for a secondary battery, and a secondary battery in which the slurry composition is used.

Owner:ZEON CORP

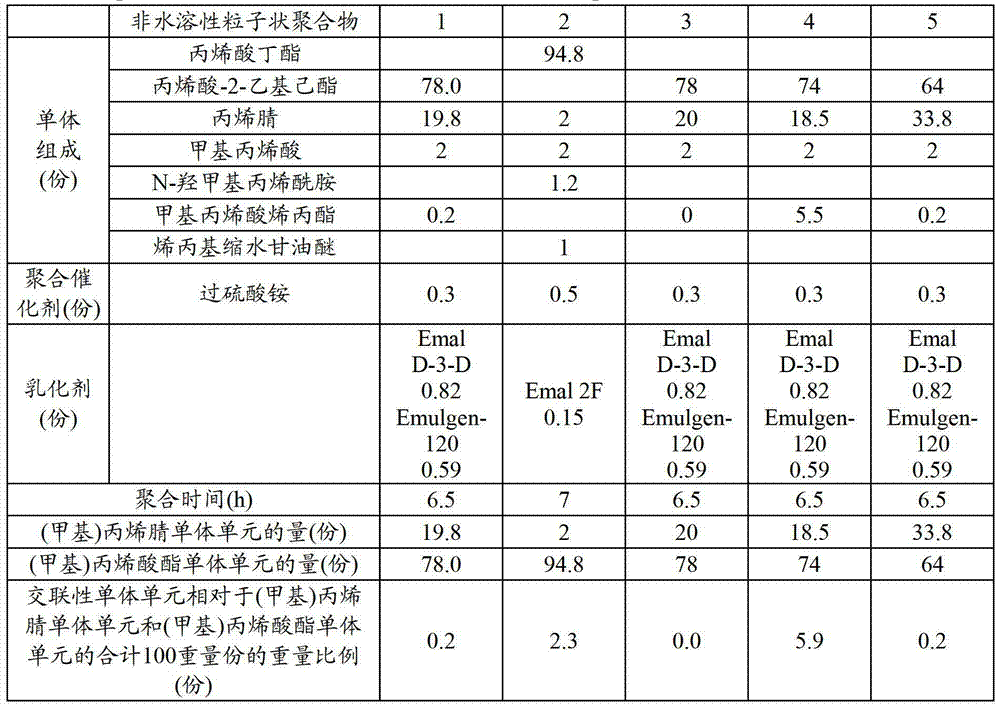

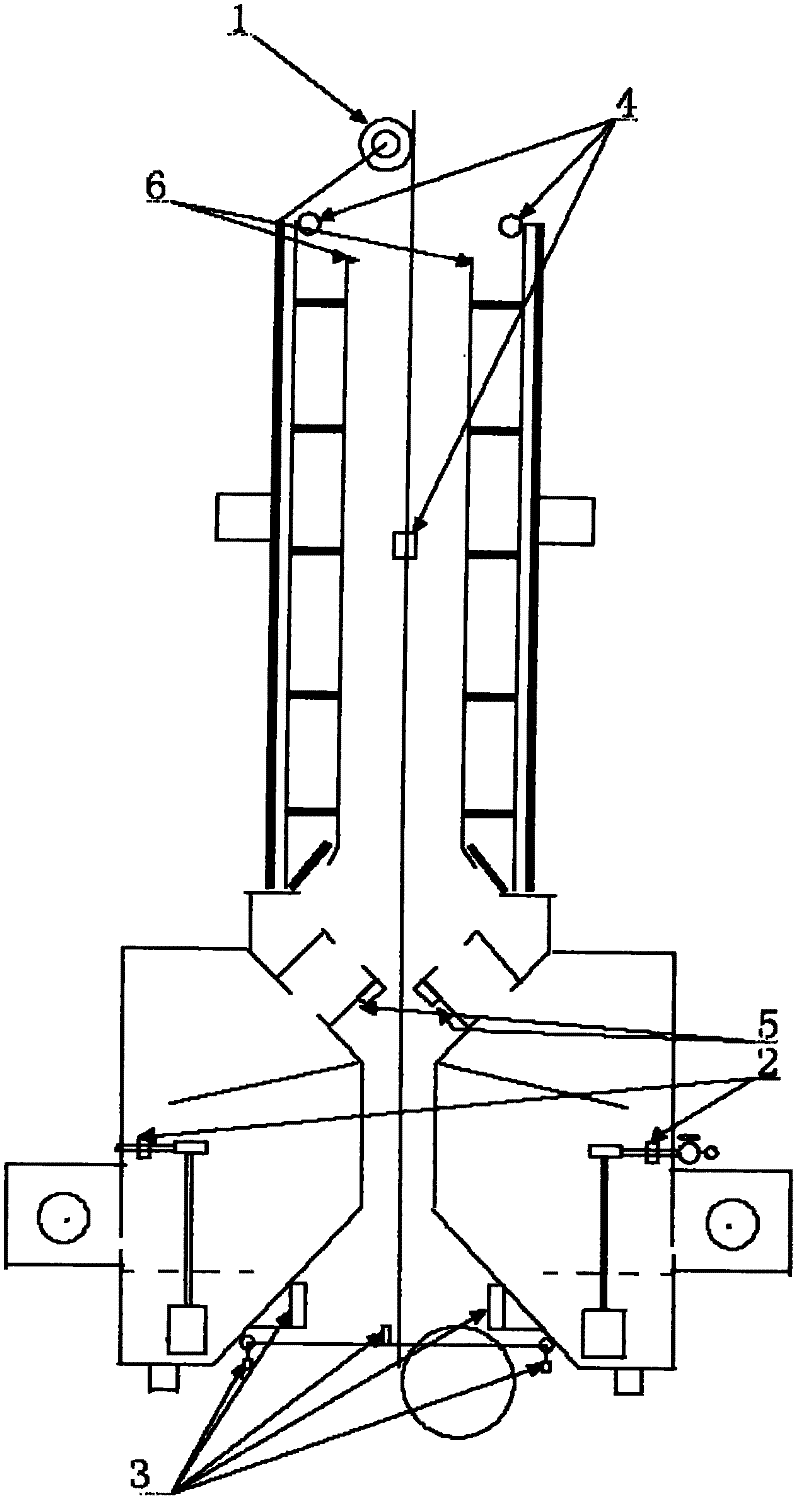

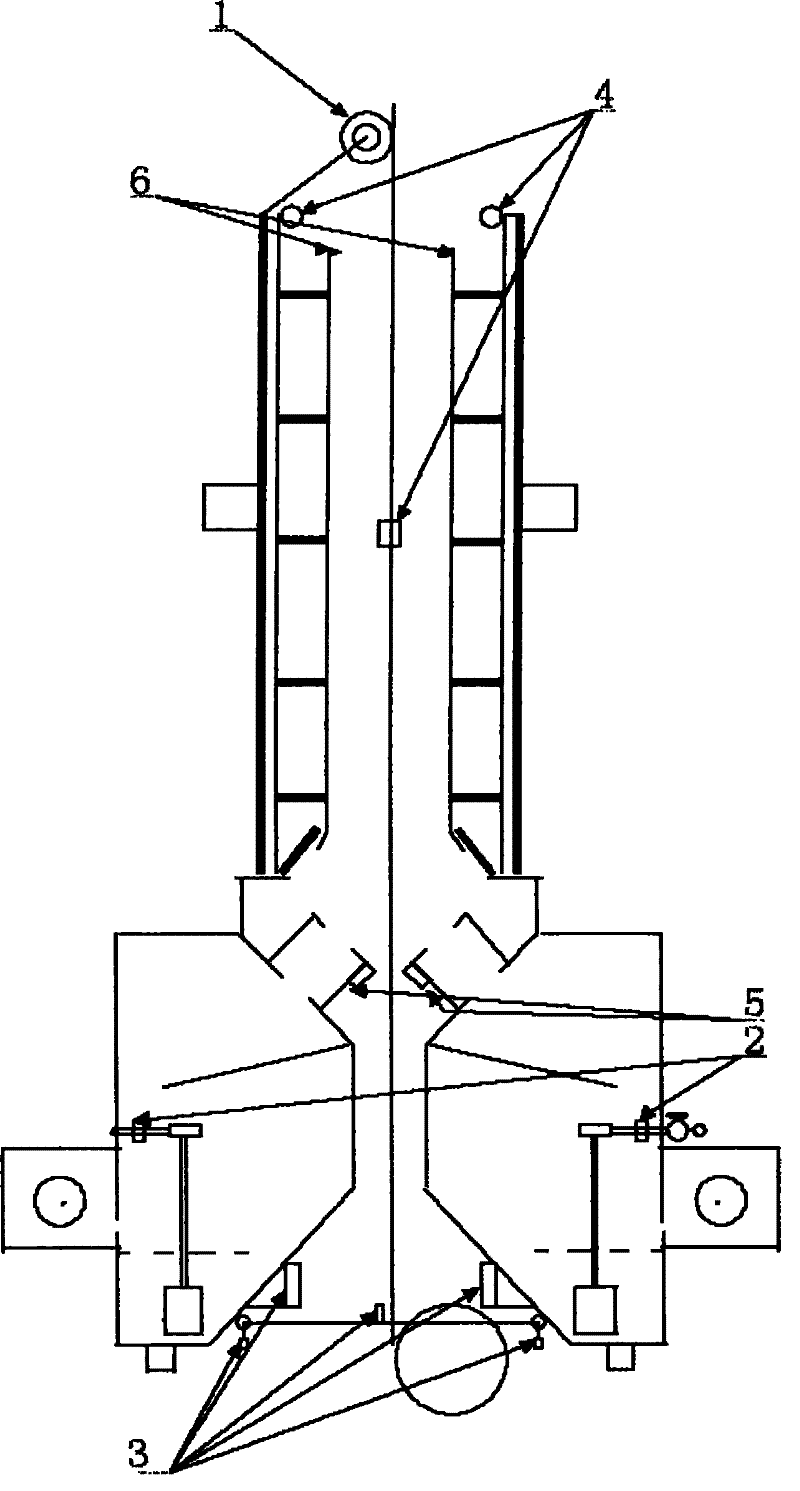

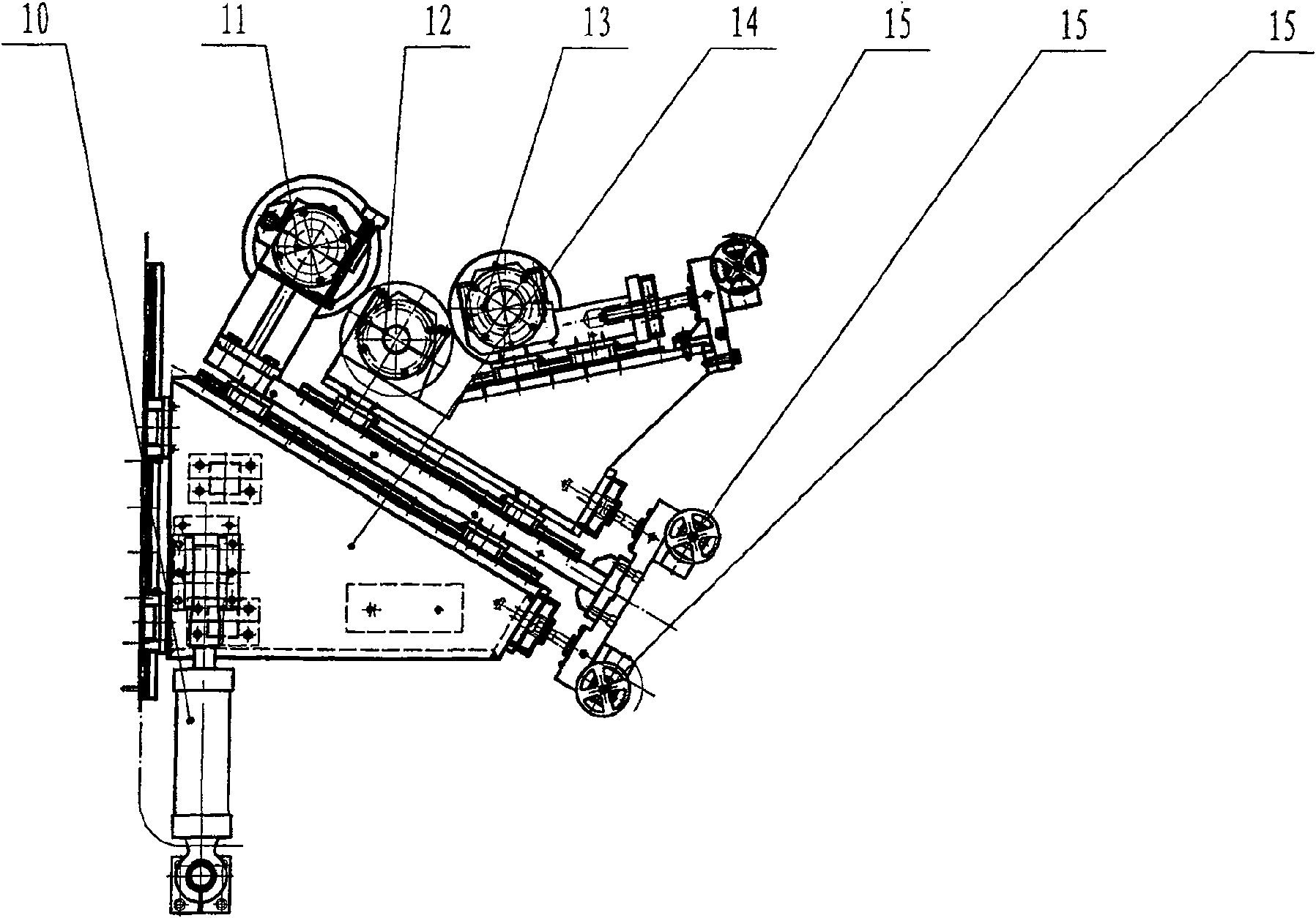

Roller coater

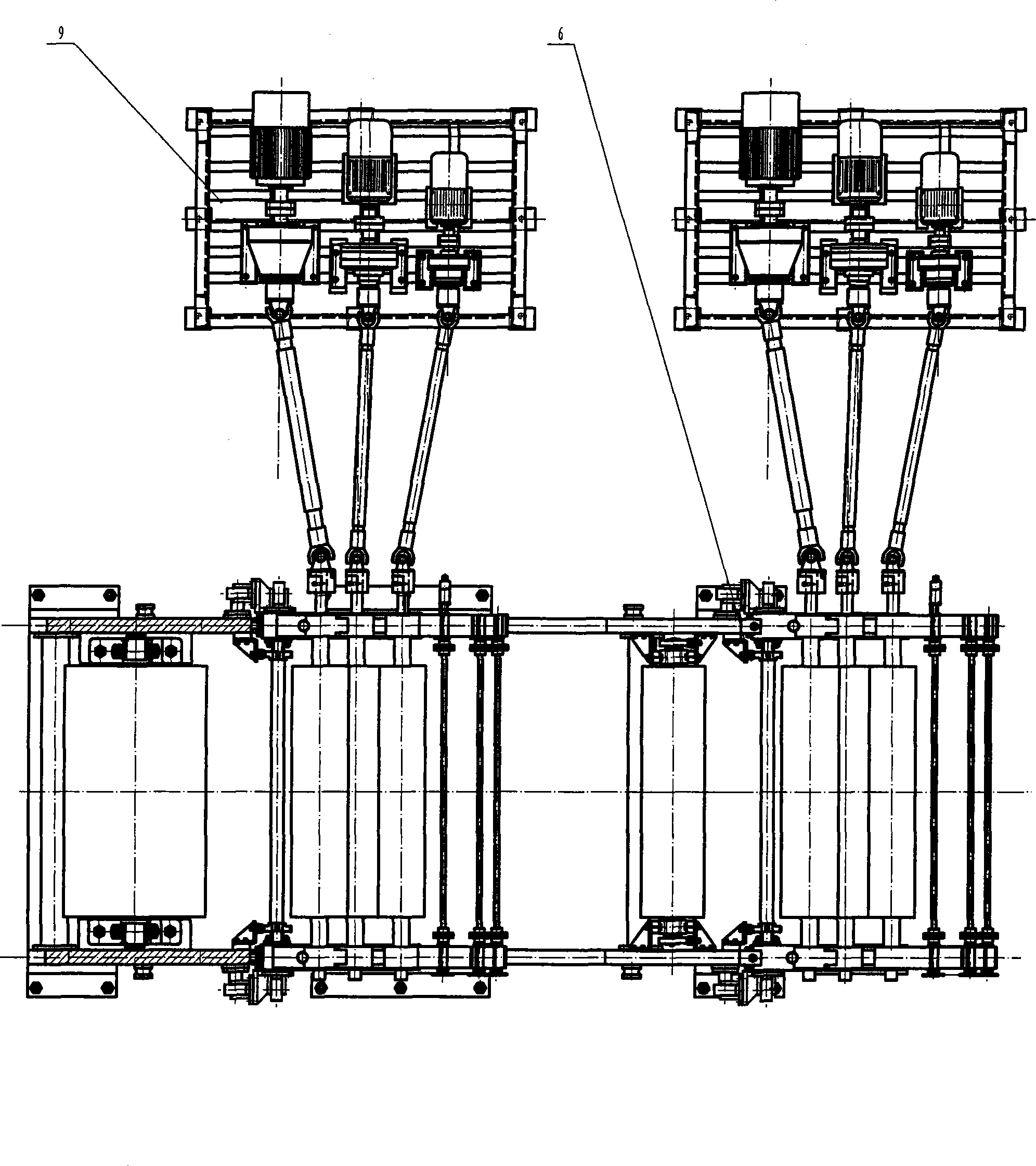

ActiveCN101244413ASolve the problem of coating qualityRealize online maintenance and color changeLiquid surface applicatorsCoatingsLacquerEngineering

The invention provides a roller machine suitable for coating chemical coating, which is characterized in that the roller machine comprises two sets of coating mechanism arranged top to top, a support roller mechanism, a turning roller component, a frame, a synchronous mechanism, a shower, a back-coated lifting device and a transmission mechanism. Back coating frames of a coating roller device, a reclaiming roller device and a regulating roller device fitted with specially made polyurethane material are driven by an oil cylinder and synchronous lifting at both sides is assured by the synchronous mechanism in the coating mechanism; clearance among the coating roller device, the reclaiming roller device and the regulating roller device is regulated by the regulating mechanism to regulate coating thickness. The shower line is in a lacquer tray of a front coating mechanism and a flat mouth shower with a valve is arranged on the shower line; flow rate of the paint is controlled and coating thickness is adjusted by regulating the valve. Jet tube mode is adopted in the lacquer tray of a bottom roller in the back coating mechanism; paint is agitated to prevent from deposition. The roller machine has the advantages that double-roller coating structure is adopted and one is used and the other is standby, maintenance and exchanging color are carried out online, time is saved and productivity is improved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

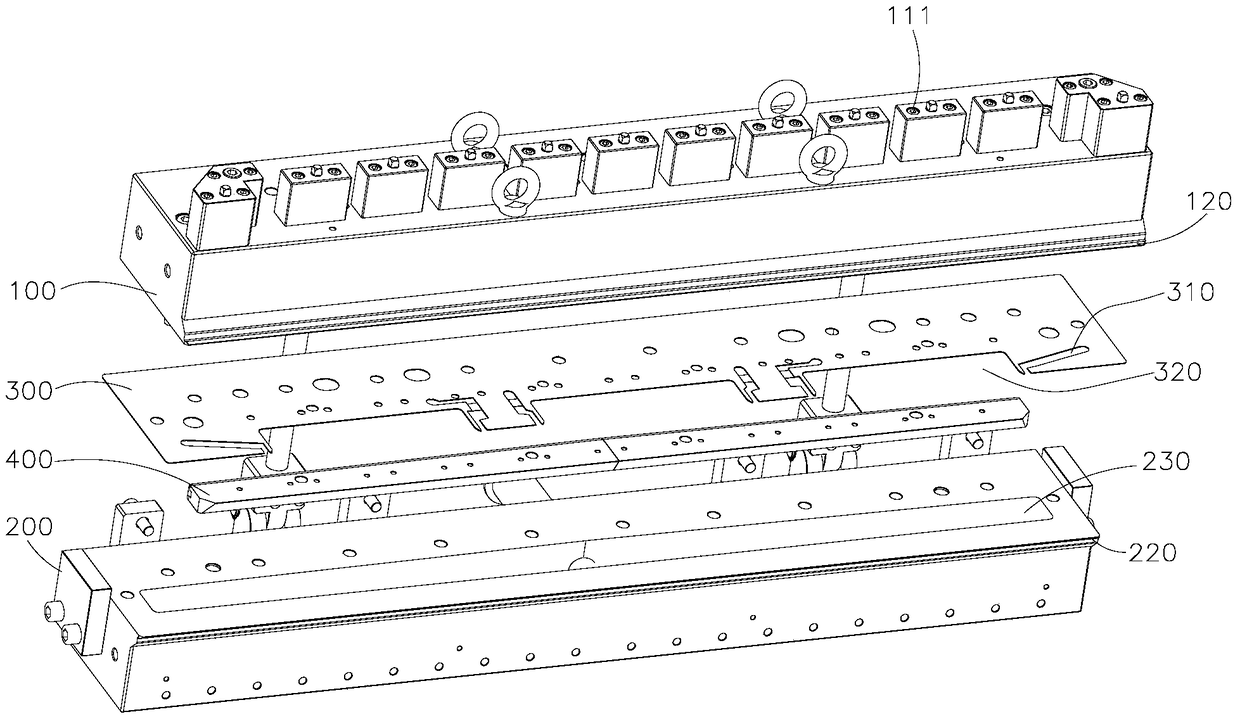

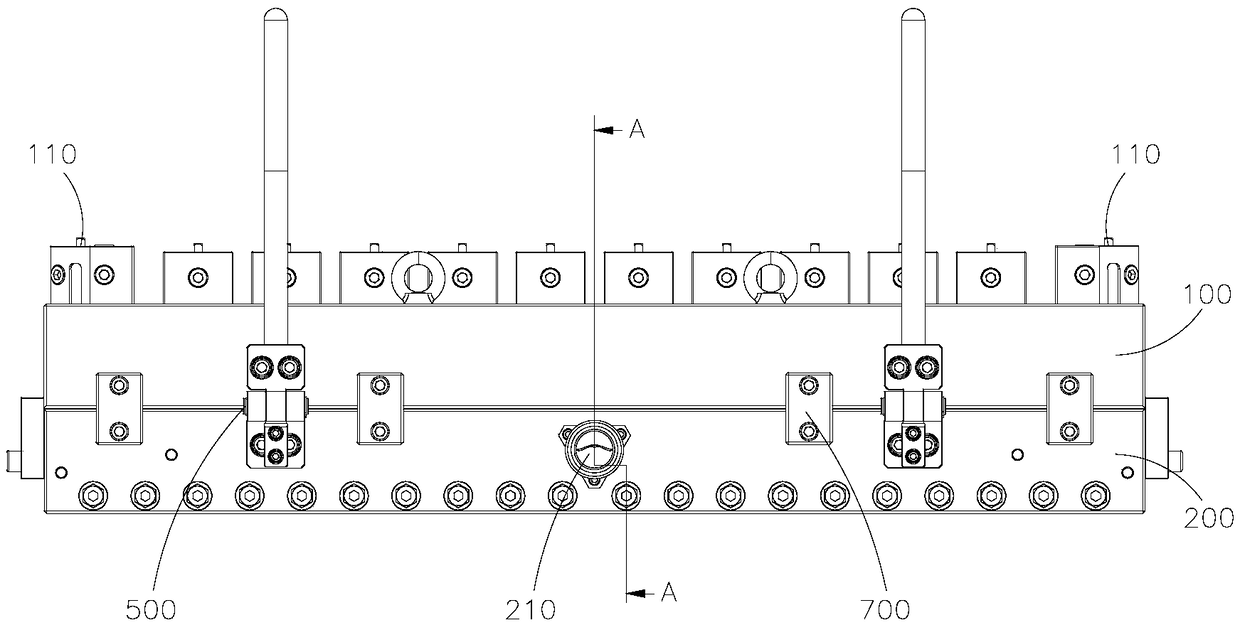

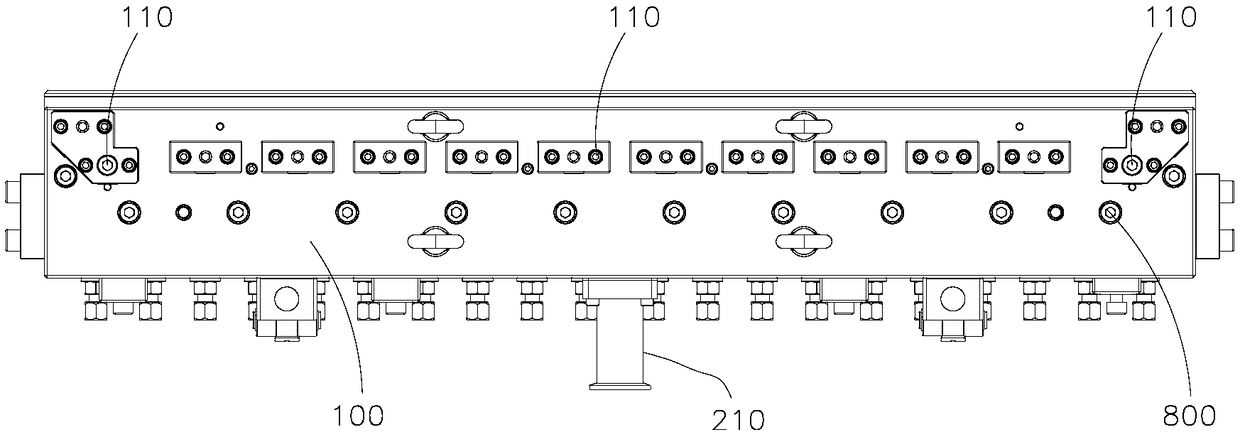

Coating die head for single or multiple lithium battery pole pieces

PendingCN110302942ARealize online adjustmentAvoid cleaningLiquid surface applicatorsElectrode manufacturing processesSlurryEngineering

The invention discloses a coating die head for single or multiple lithium battery pole pieces. The coating die head comprises an upper die head and a lower die head. A feed inlet is formed in the upper die head or the lower die head, and a trough for accommodating coating slurry is formed in the lower die head, the feed inlet communicates to the trough, and the front sides of the upper die head and the lower die head are matched to form a die nozzle. The upper die head and the lower die head define a die cavity for accommodating the coating slurry, and the front side of the die cavity is isolated by the upper die head and the lower die head to form a silt of the die nozzle; the trough stretches along the length direction of the lower die head, a plurality of adjusting slide blocks are distributed vertical to the coating direction between the upper die head and the lower die head, the adjusting slide blocks slide along the surface of the lower die head, and the adjusting slide blocks are matched on the side of the die nozzle to form a discharge port with variable width for coating slurry. The dimension of the die cavity is adjusted by controlling the slide blocks, so that the coating width of the coating die is adjusted online. The die cavity is not opened in the adjusting process, so that the production efficiency is improved and consistent production of products is facilitated.

Owner:NINGBO VEKEN BATTERY

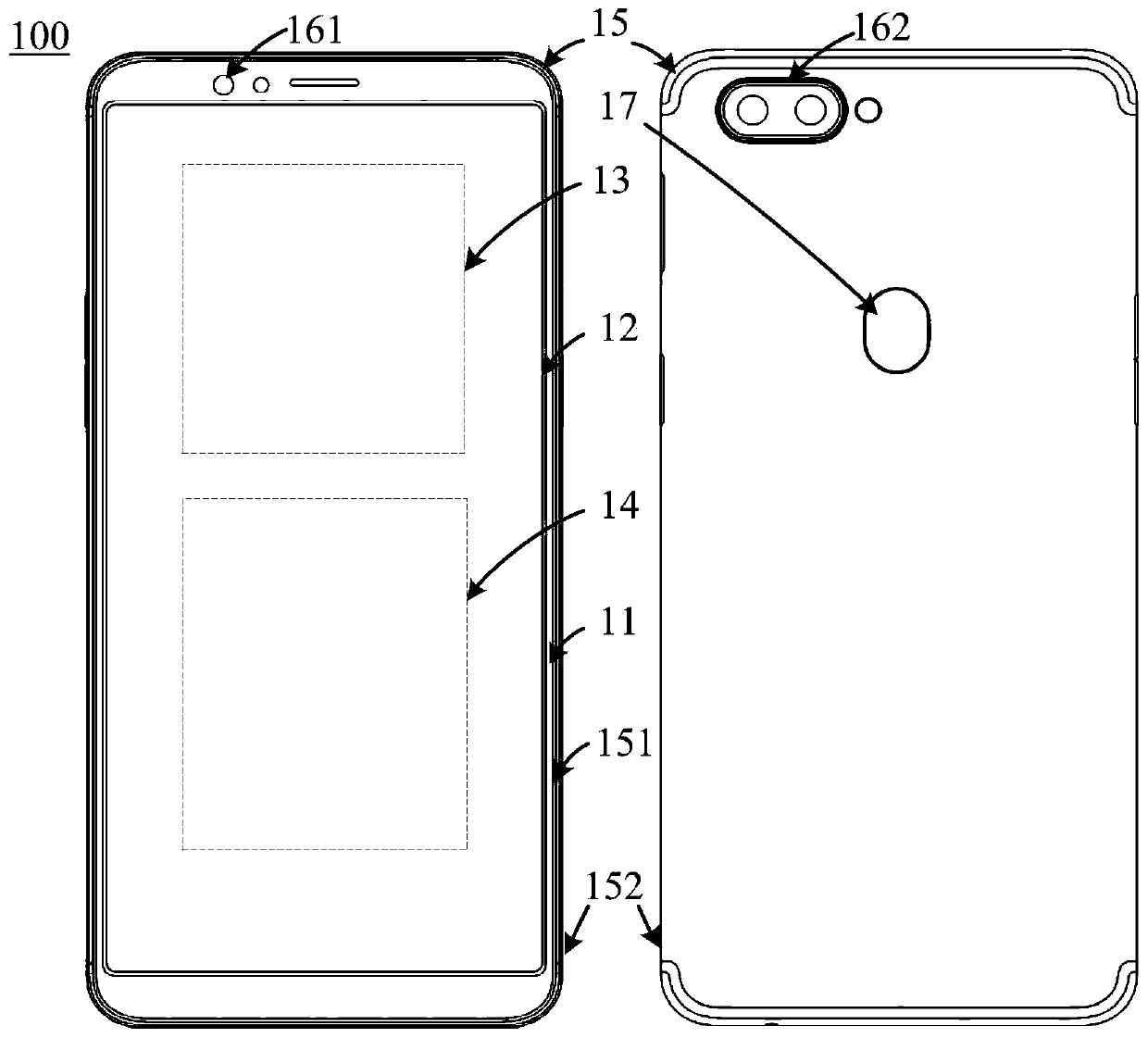

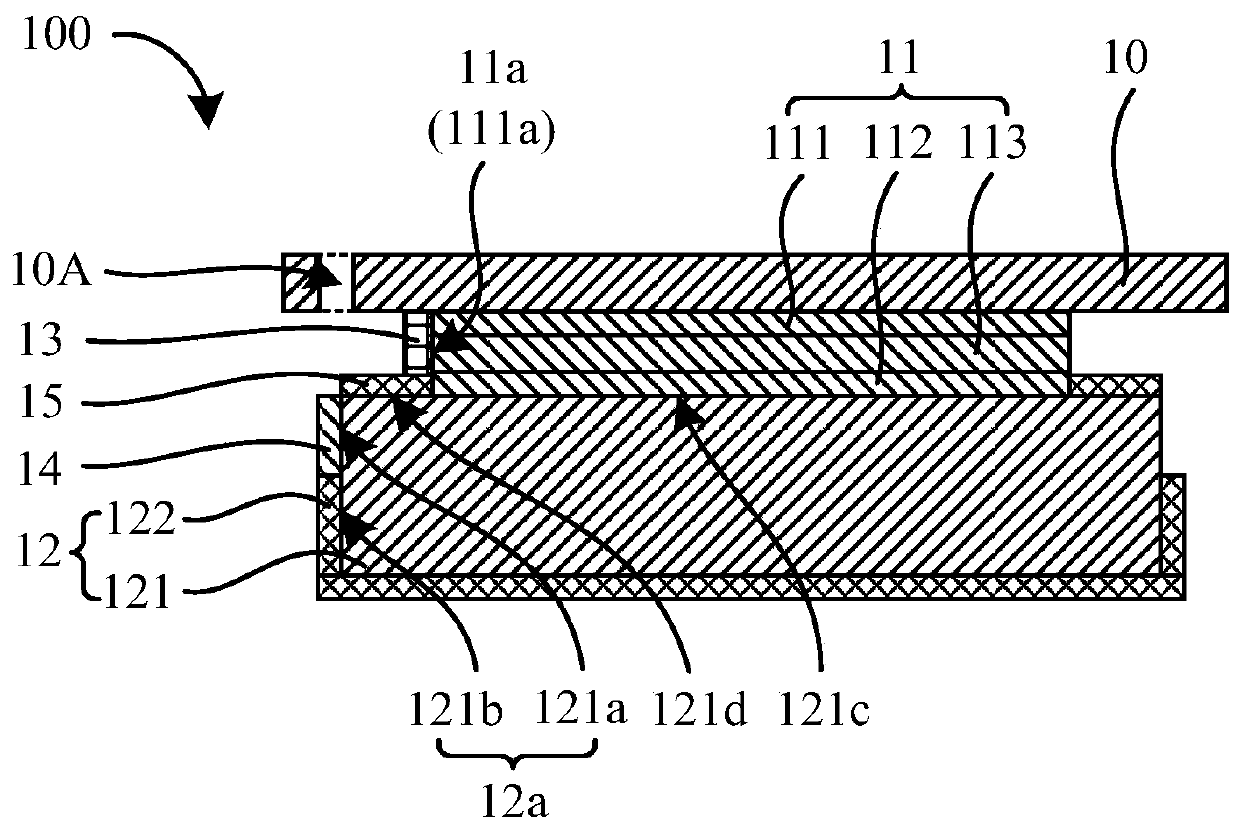

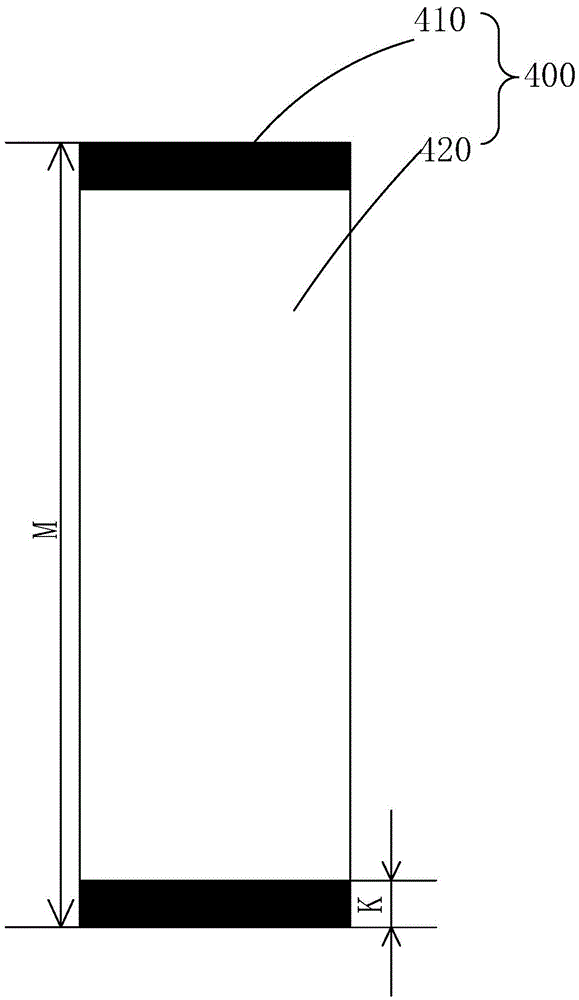

Display device, electronic equipment and manufacturing method of display device

InactiveCN110716340AReduce the number of dispensingImprove coating accuracySubstation equipmentNon-linear opticsDisplay devicePolarizer

Embodiments of the invention disclose a display device, electronic equipment and a manufacturing method of the display device. The display device comprises a display panel, a polarizer, a backlight module and shading glue, wherein the display panel is provided with a light-transmitting area and a shading area, and the shading area is arranged around the periphery of the light-transmitting area; the polarizer is arranged on the display panel, a first through hole is formed in the polarizer, and the first through hole is arranged to correspond to the light-transmitting area; the backlight moduleis arranged on the polarizer, a second through hole is formed in the backlight module, and the second through hole is arranged to correspond to the light-transmitting area; and the shading glue is arranged on the periphery of the hole wall of the second through hole and extends to the periphery of the hole wall of the first through hole. According to the scheme, the glue dispensing frequency during assembly of the display device is reduced and the coating precision of the periphery of the light-transmitting area is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Slit type coating head

PendingCN109482428AImprove coating efficiencyImprove coating accuracyLiquid surface applicatorsCoatingsEngineeringElectrical and Electronics engineering

The invention provides a slit type coating head. The coating head comprises an upper die, a lower die and a spacer clamped between the upper die and the lower die; the lower die is provided with a first lip edge portion, the upper die is provided with a second lip edge portion opposite to the first lip edge portion, the lower die is provided with at least one first feeding channel, the upper die is provided with at least one second feeding channel, and the spacer is provided with at least one opening and at least one groove; and a first slit channel is formed among the upper die, the opening and the lower die, a second slit channel is formed between the groove and the upper die, a first discharge port is formed among the first lip edge portion, the opening, and the second lip edge portion,a second discharge port is formed among the first lip edge portion, a notch of the groove, and the second lip edge portion, wherein the first feeding channel, the first slit channel and the first discharge port communicate in sequence to form a first flow channel, and the second feeding channel, the second slit channel and the second discharge port communicate in sequence to form a second flow channel which is isolated from the first flow channel. According to the slit type coating head, at least two kinds of thick liquids can be coated at the same time, and thus the coating efficiency and precision are improved.

Owner:SHENZHEN MANST TECH CO LTD

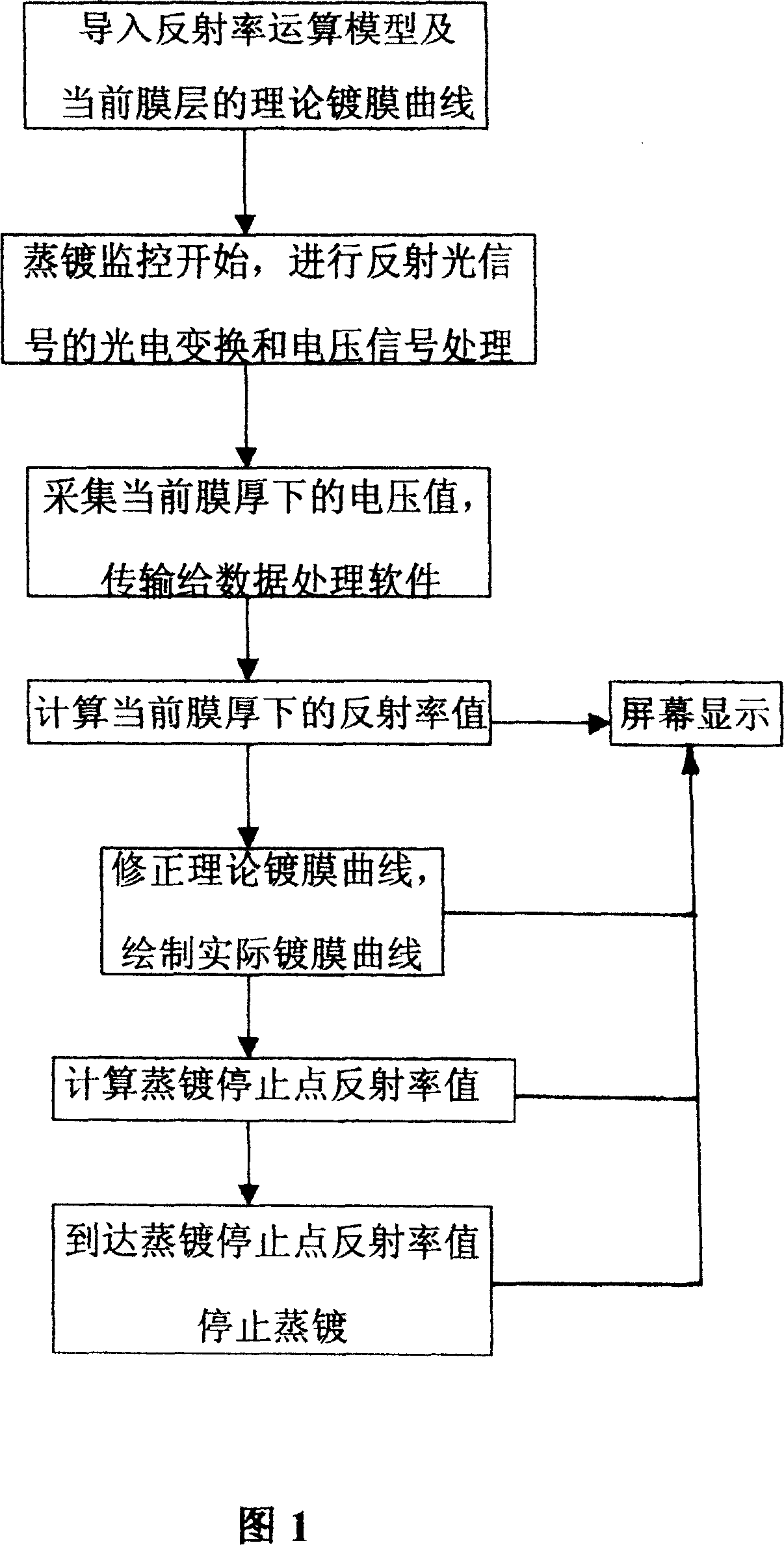

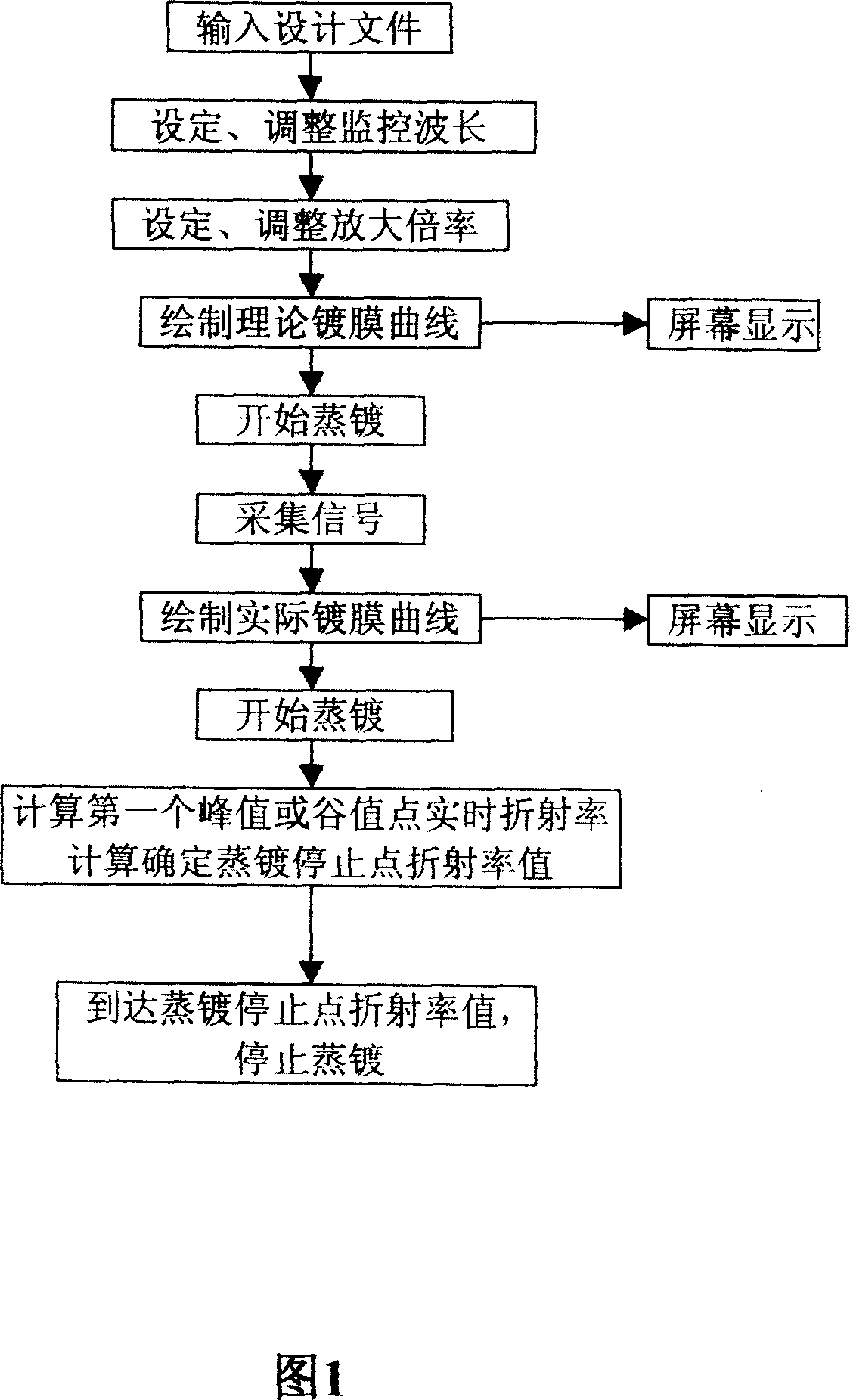

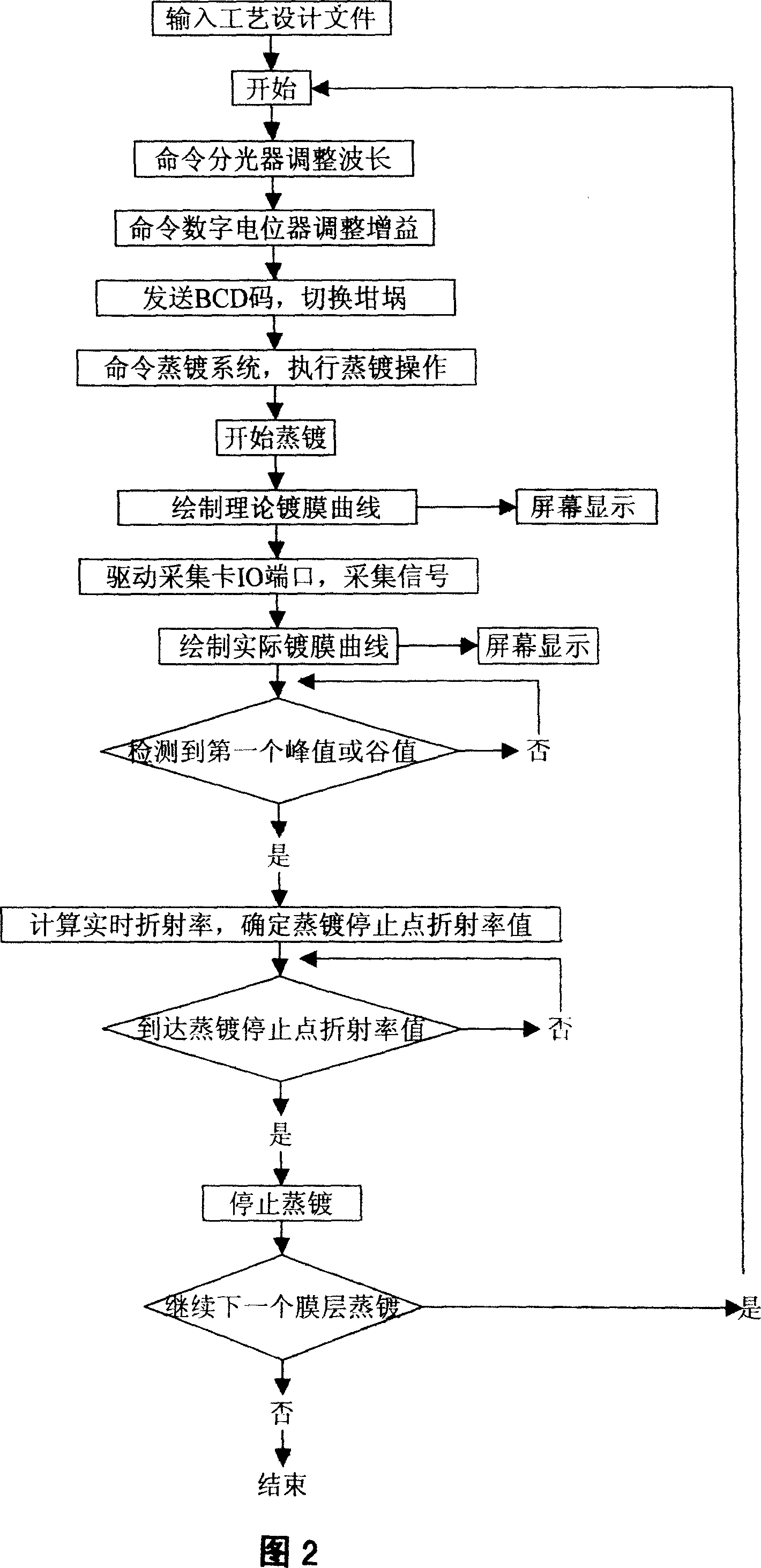

Measurement and display method for film thickness reflectivity of optical coated film

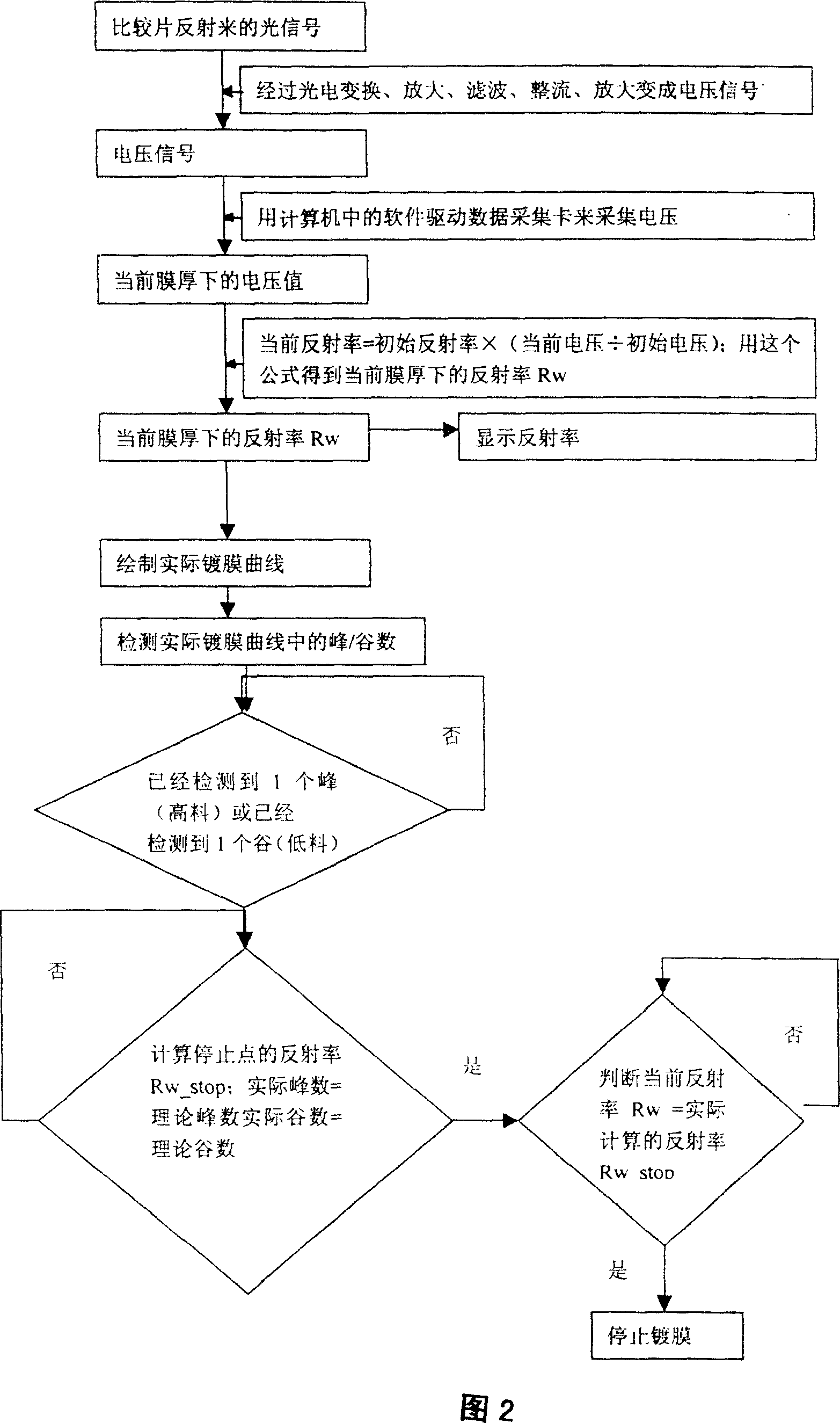

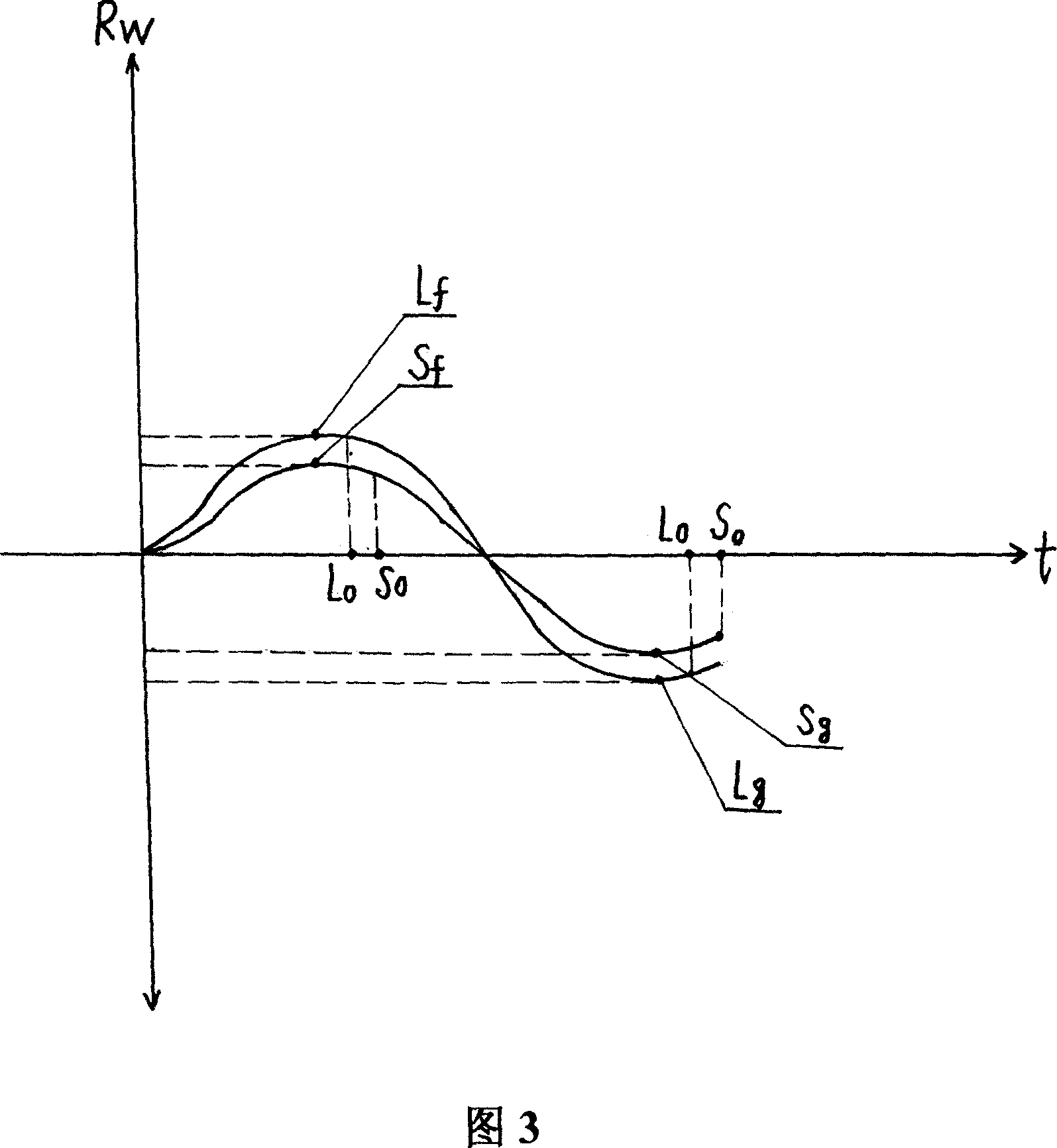

ActiveCN101017211AObserve intuitivelyAccurate observationScattering properties measurementsTesting optical propertiesProcess functionRefractive index

This invention relates to one optical coat film reflection rate measurement and display method for optical film monitor, which uses computer for rapid data process function and processes online measurement and real time display in the coating process and determines the coat terminate point according to the coat film curve peak or trough point reflection value.

Owner:HENAN COSTAR GRP CO LTD +1

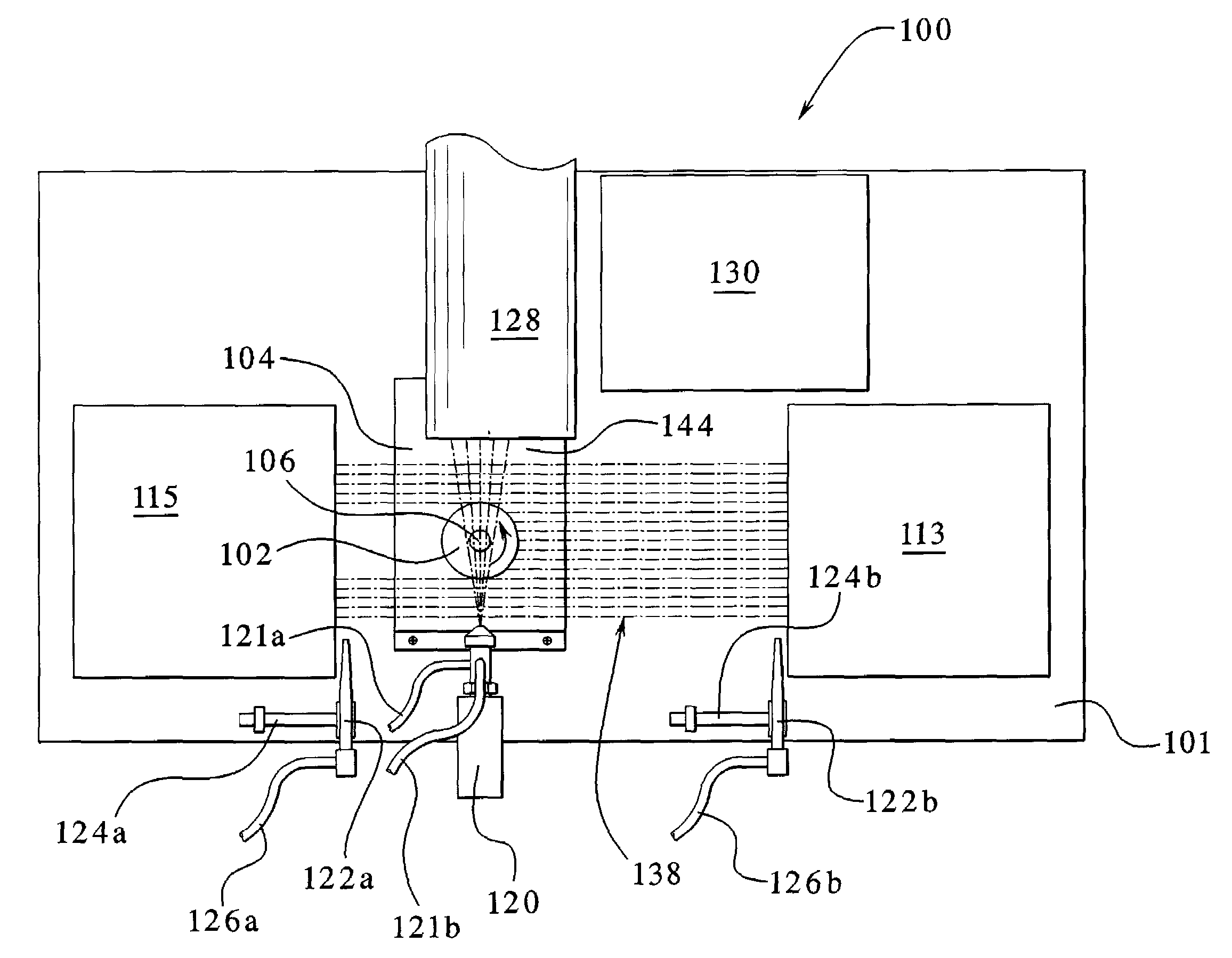

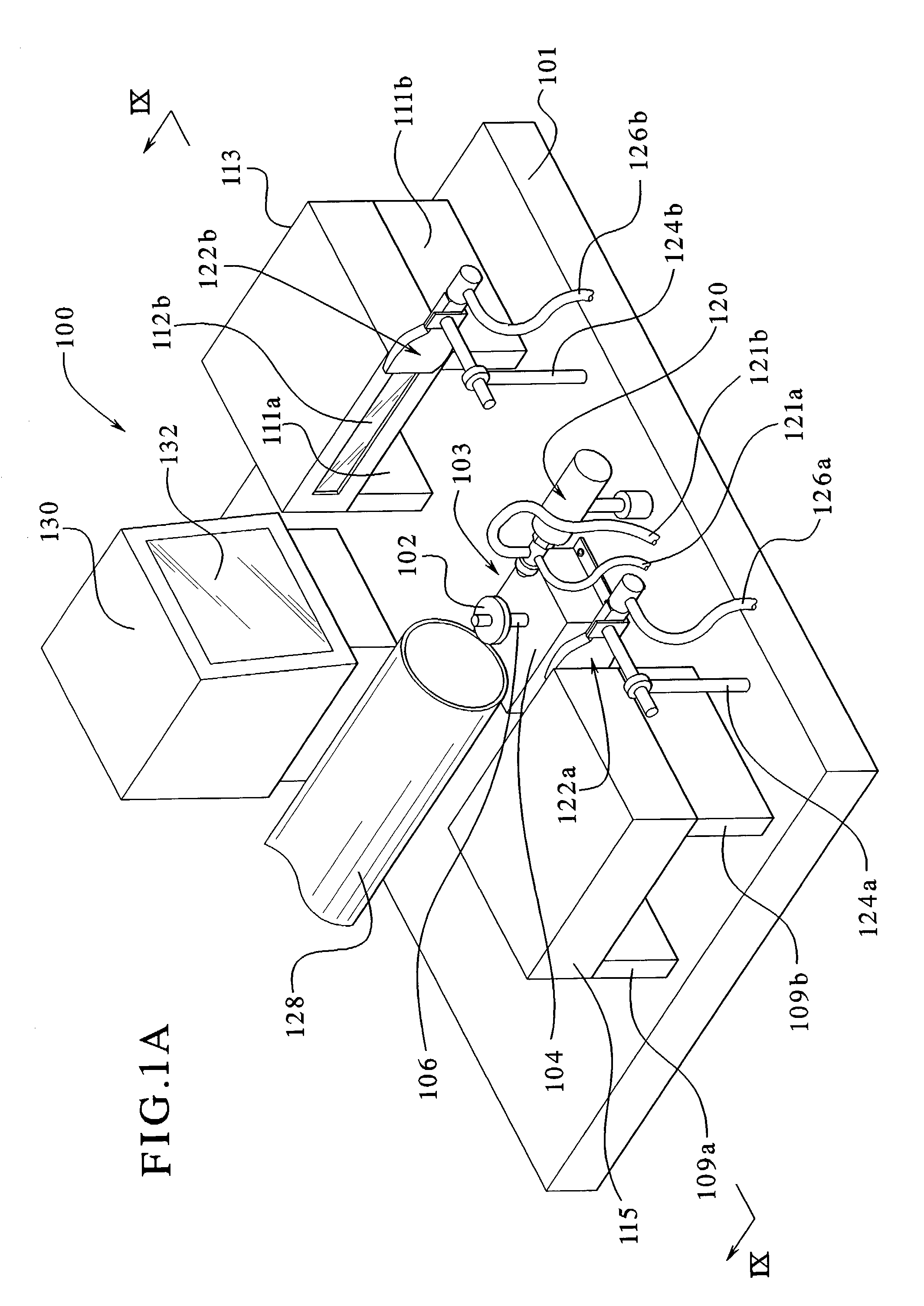

Method for simultaneously coating and measuring parts

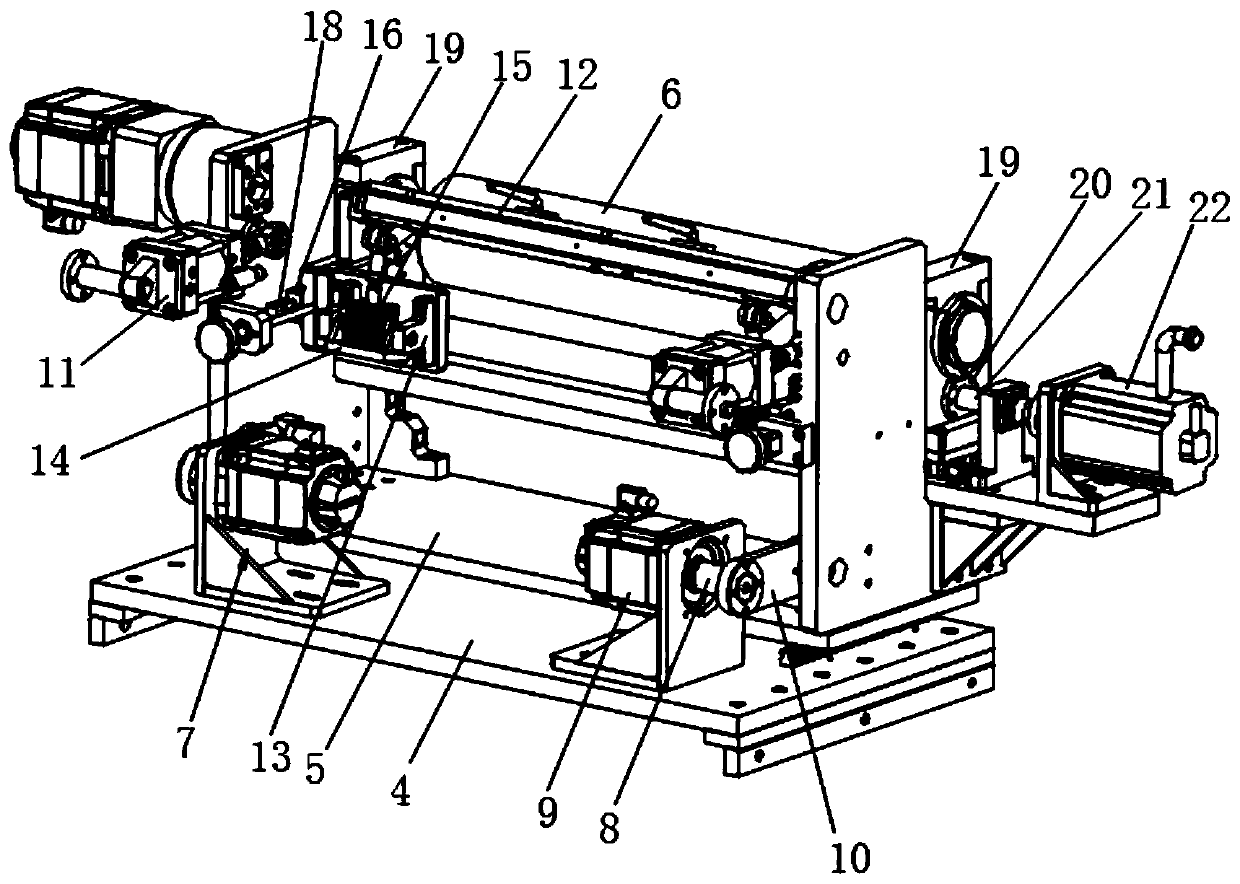

InactiveUS6998147B2Enhance accuracyIncrease coating efficiencyElectric discharge heatingSpraying apparatusContinuous measurementInjector

A method and apparatus for simultaneously coating and measuring a part. The apparatus includes a part support, a sprayer and a part measurer positioned adjacent to the part support and a display device positioned adjacent to the part support. The sprayer applies a coating to a section of the part while the part measurer continuously measures a dimension of the section of the part being coated. In one embodiment, an initial amount of coating and a final amount of coating are applied to the section of the part based on the dimension measurements and desired dimension of the part. In another embodiment, the amount of coating applied to the part is based on the desired coating thickness. As a result, the apparatus and method of the present invention significantly reduces the margin of error related to the application of coatings to parts.

Owner:DIMENSION BOND CORP

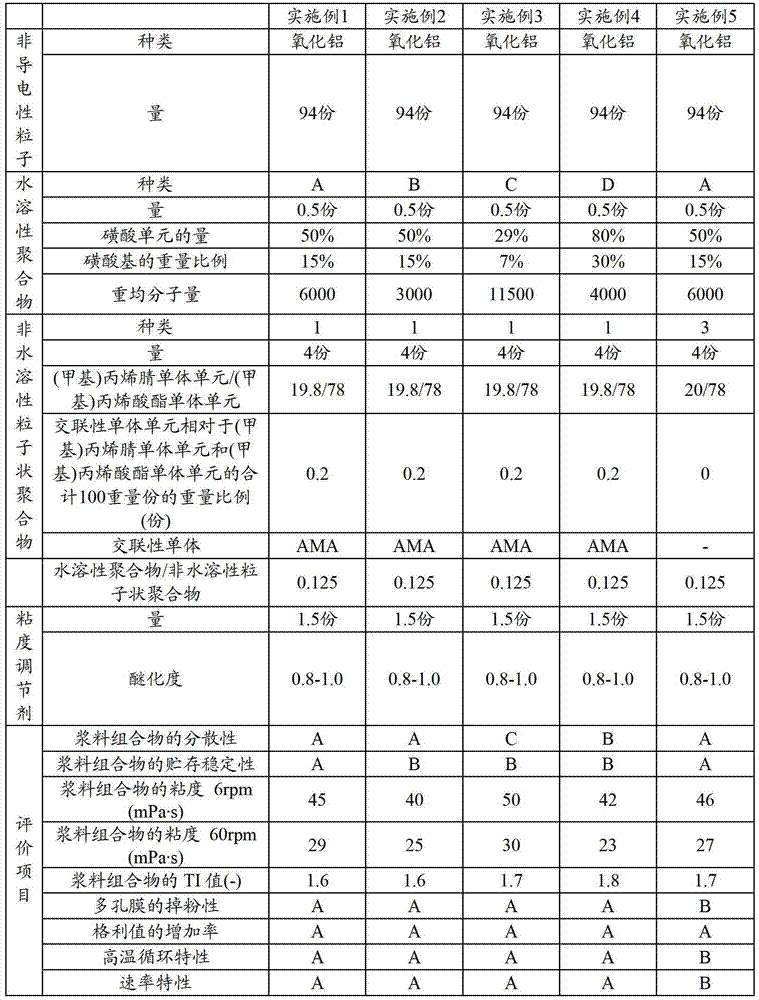

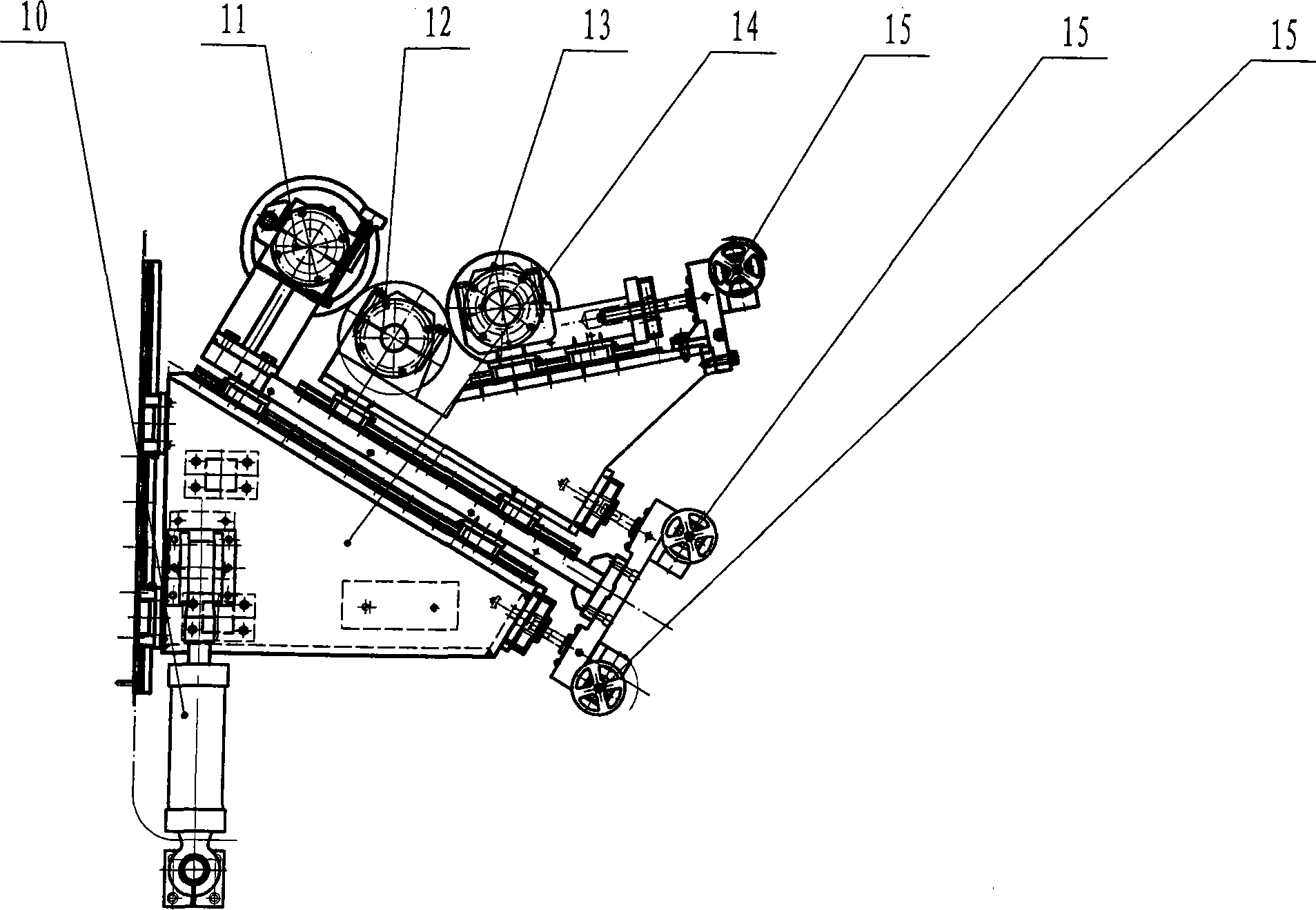

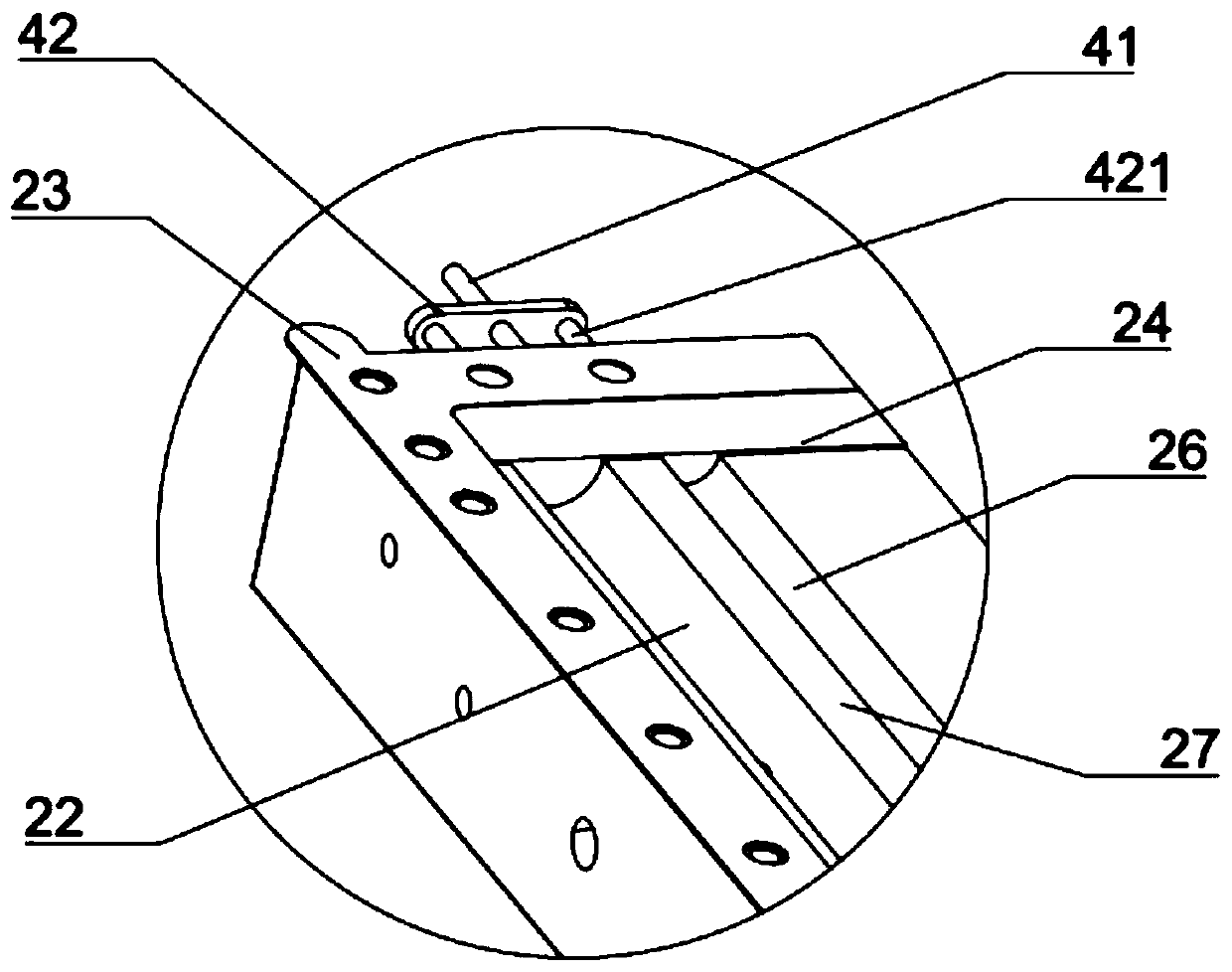

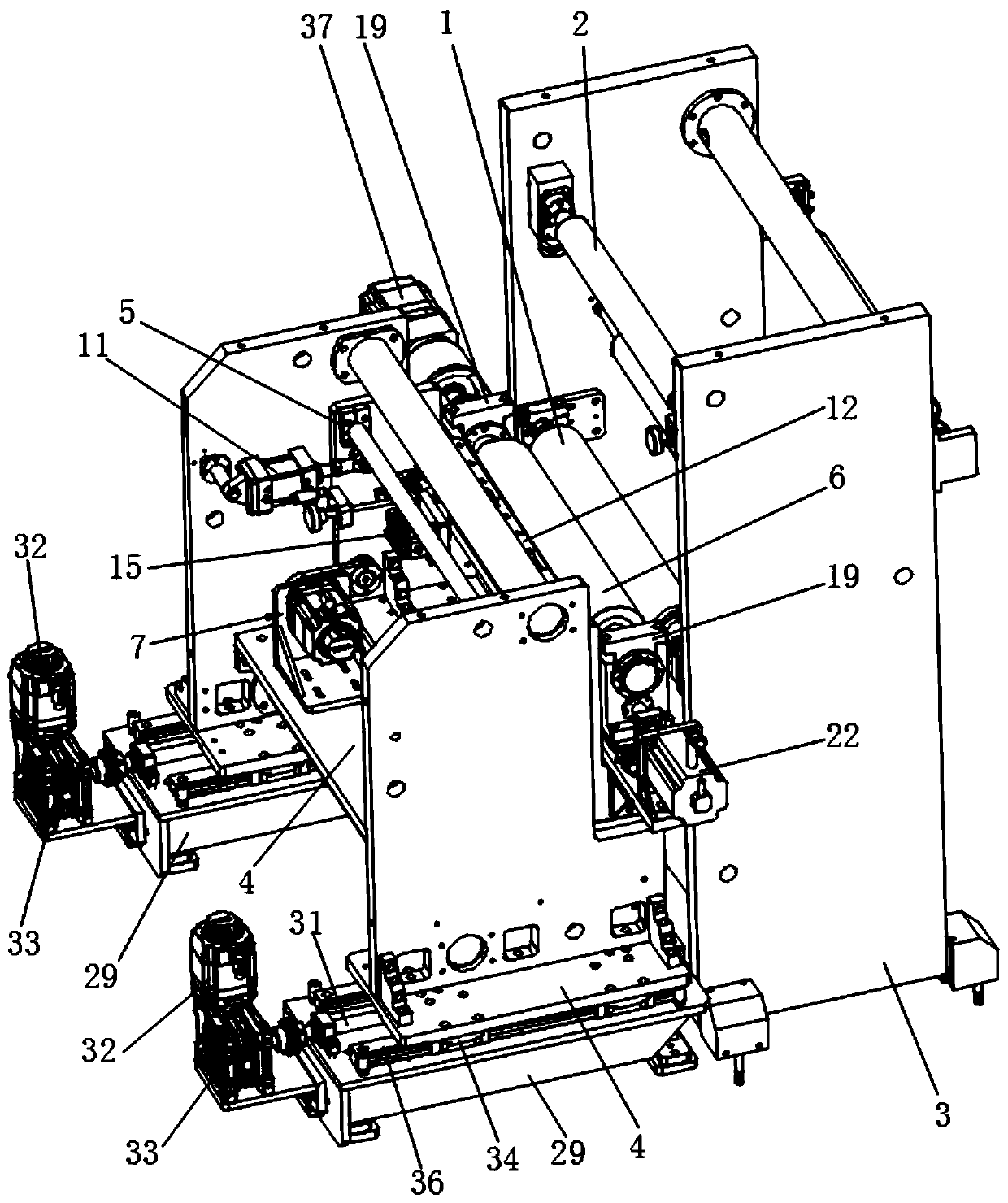

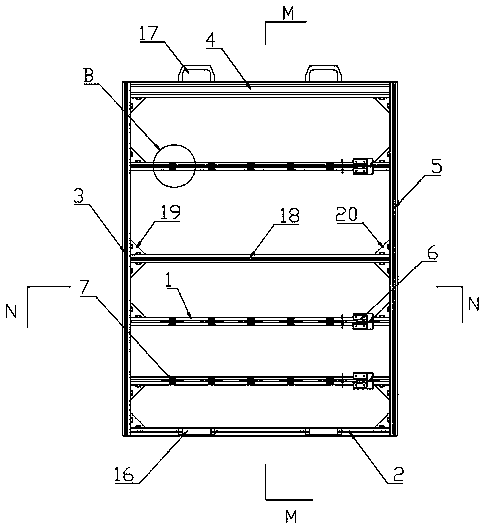

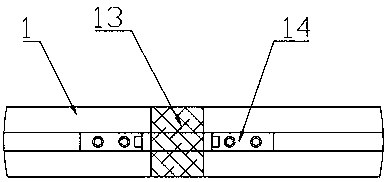

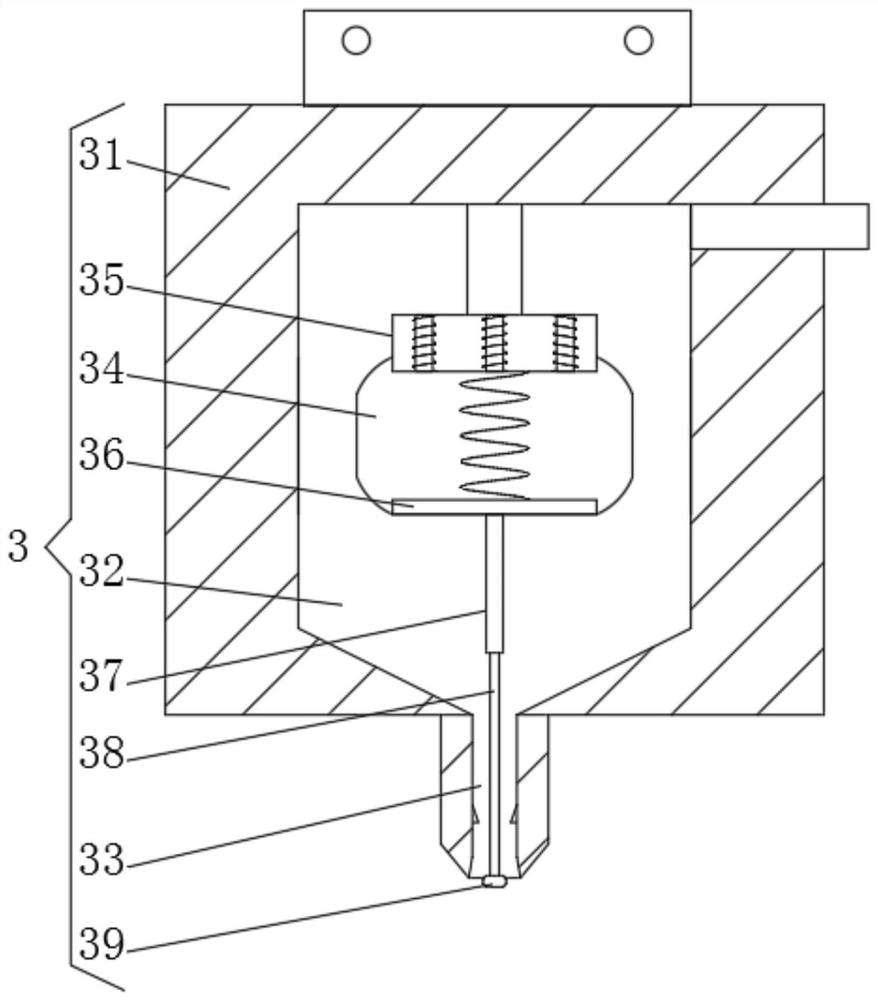

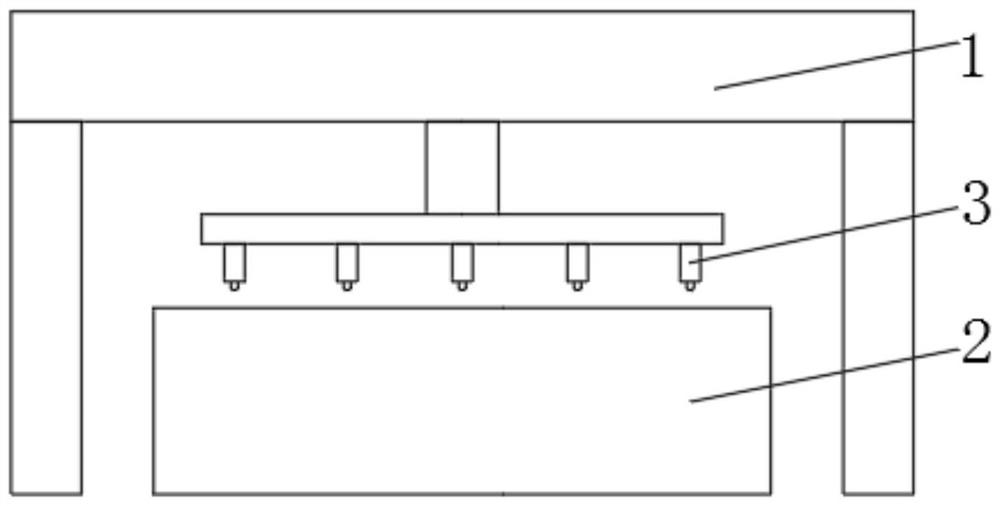

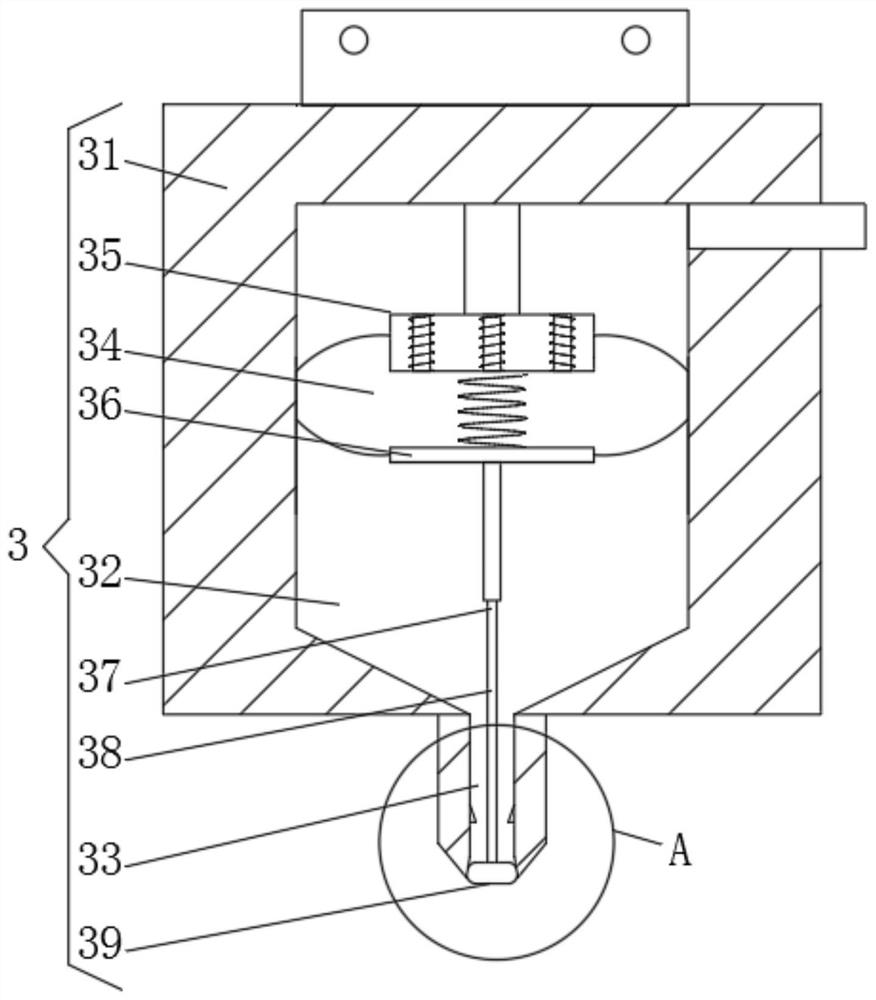

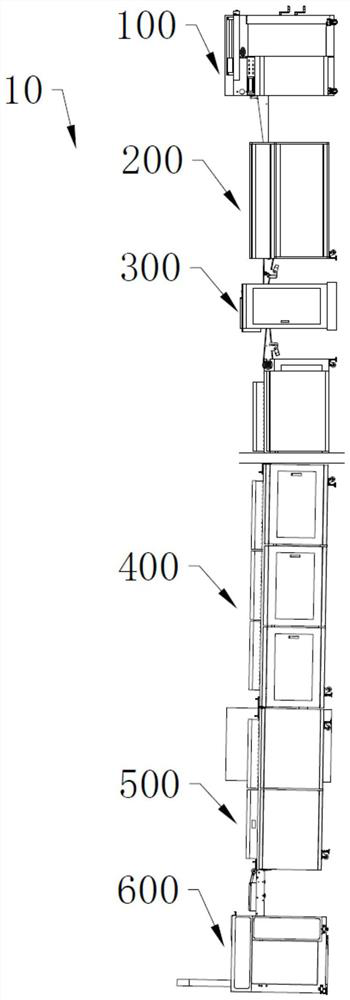

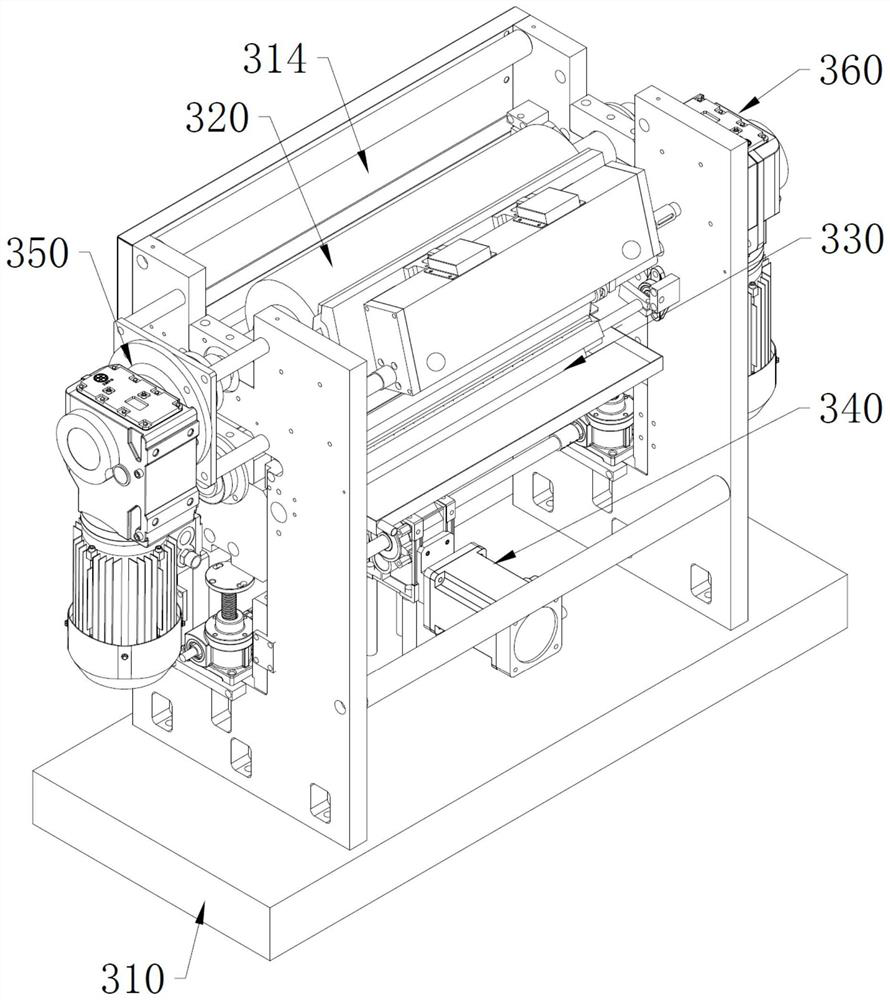

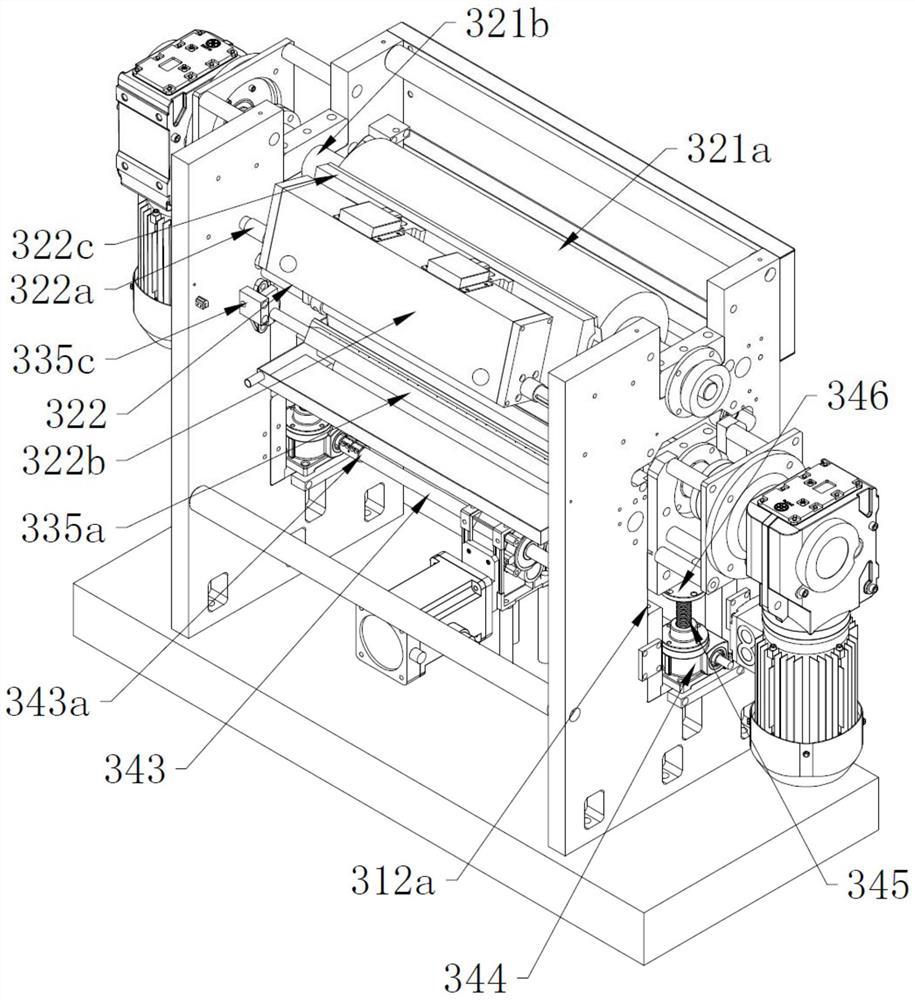

Plate roller movement intermittent coating mechanism

PendingCN110237983ATo achieve the purpose of intermittent coatingImprove coating accuracyLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention relates to the technical field of coating machines, in particular to a plate roller movement intermittent coating mechanism. The plate roller movement intermittent coating mechanism comprises a coating device for coating the surface of a substrate with an adhesive and a conveying device for conveying the substrate to the coating device. The conveying device comprises a rotationally-arranged rubber roller and a plurality of conveying rollers, the coating device comprises a base, a connecting seat arranged on the base in a sliding manner, a plate roller rotationally arranged on the connecting seat and a first driving assembly used for driving the connecting seat to move in the direction getting close to or being away from the rubber roller, the plate roller is arranged on the side close to the rubber roller, the first driving assembly comprises a cam, a first driving member for driving the cam to rotate and a connecting rod eccentrically connected to the side, far away from the first driving member, of the cam, the connecting rod is rotatably connected with the cam, and the end, far away from the cam, of the connecting rod is rotatably connected with the connecting seat. The plate roller movement intermittent coating mechanism has the advantages of high coating accuracy and high coating speed.

Owner:SHENZHEN NEW KATOP AUTOMATION TECH

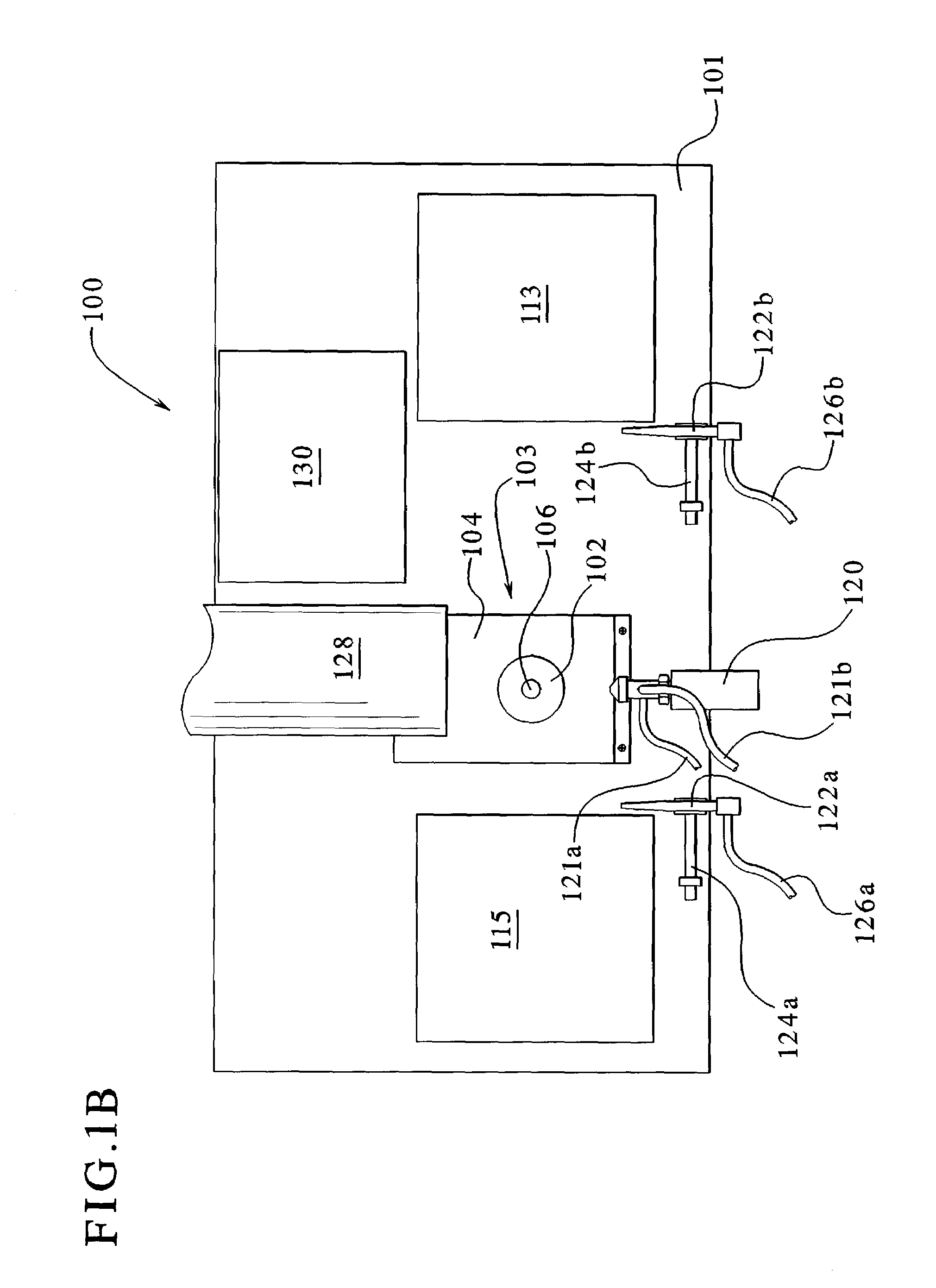

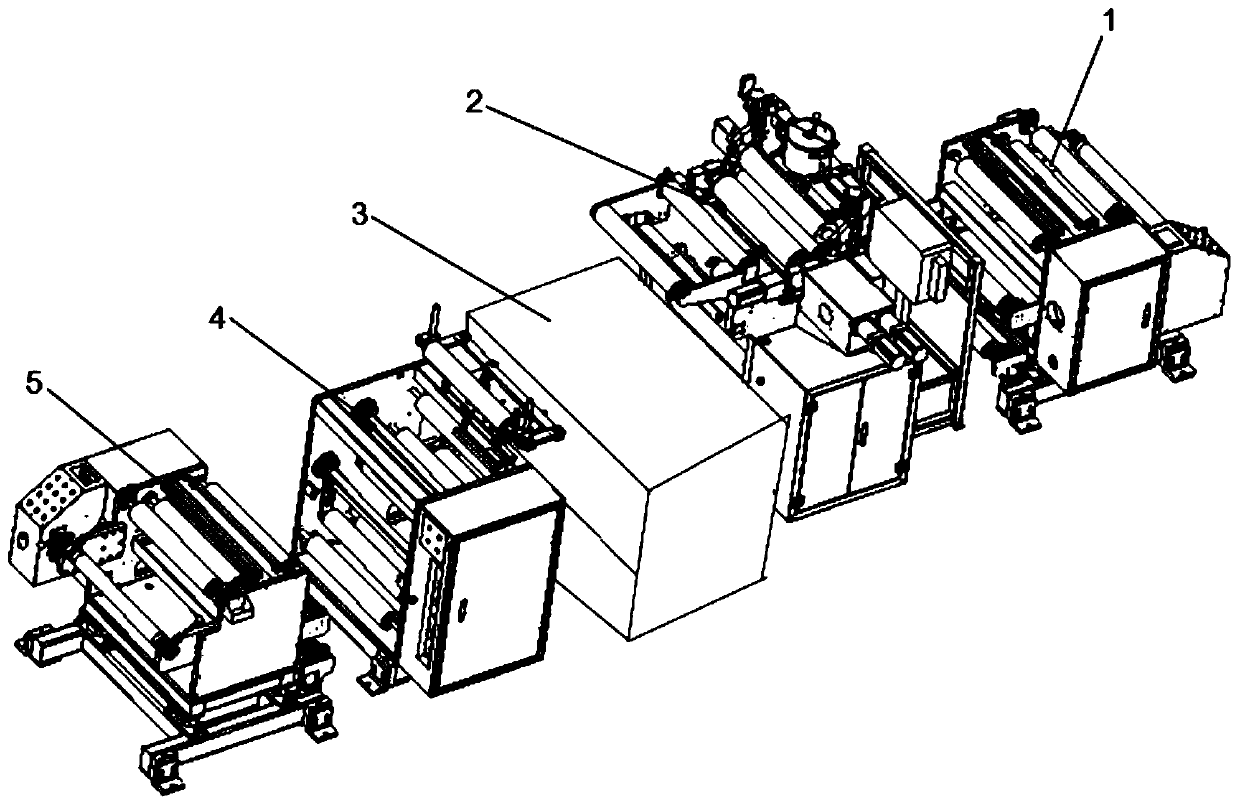

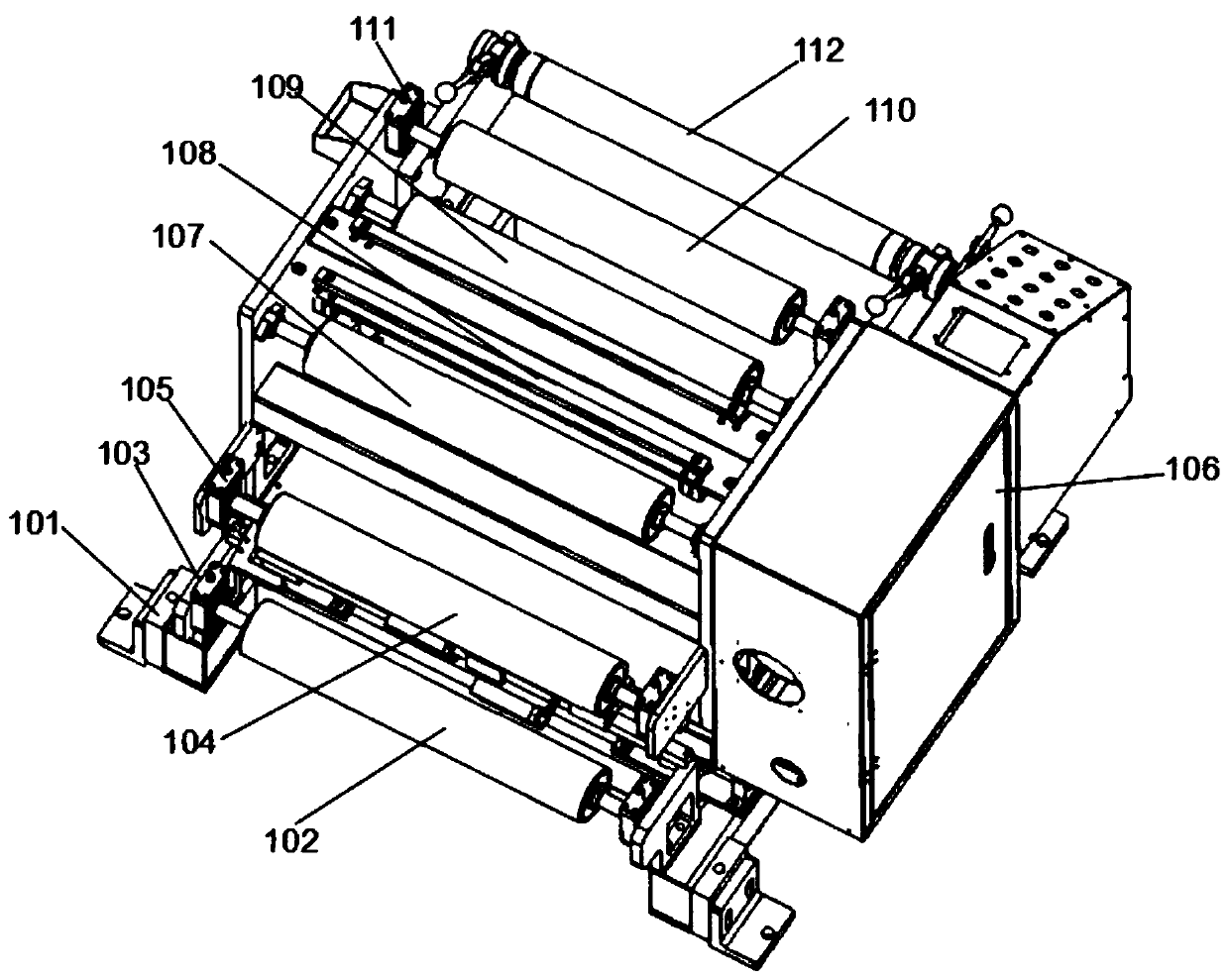

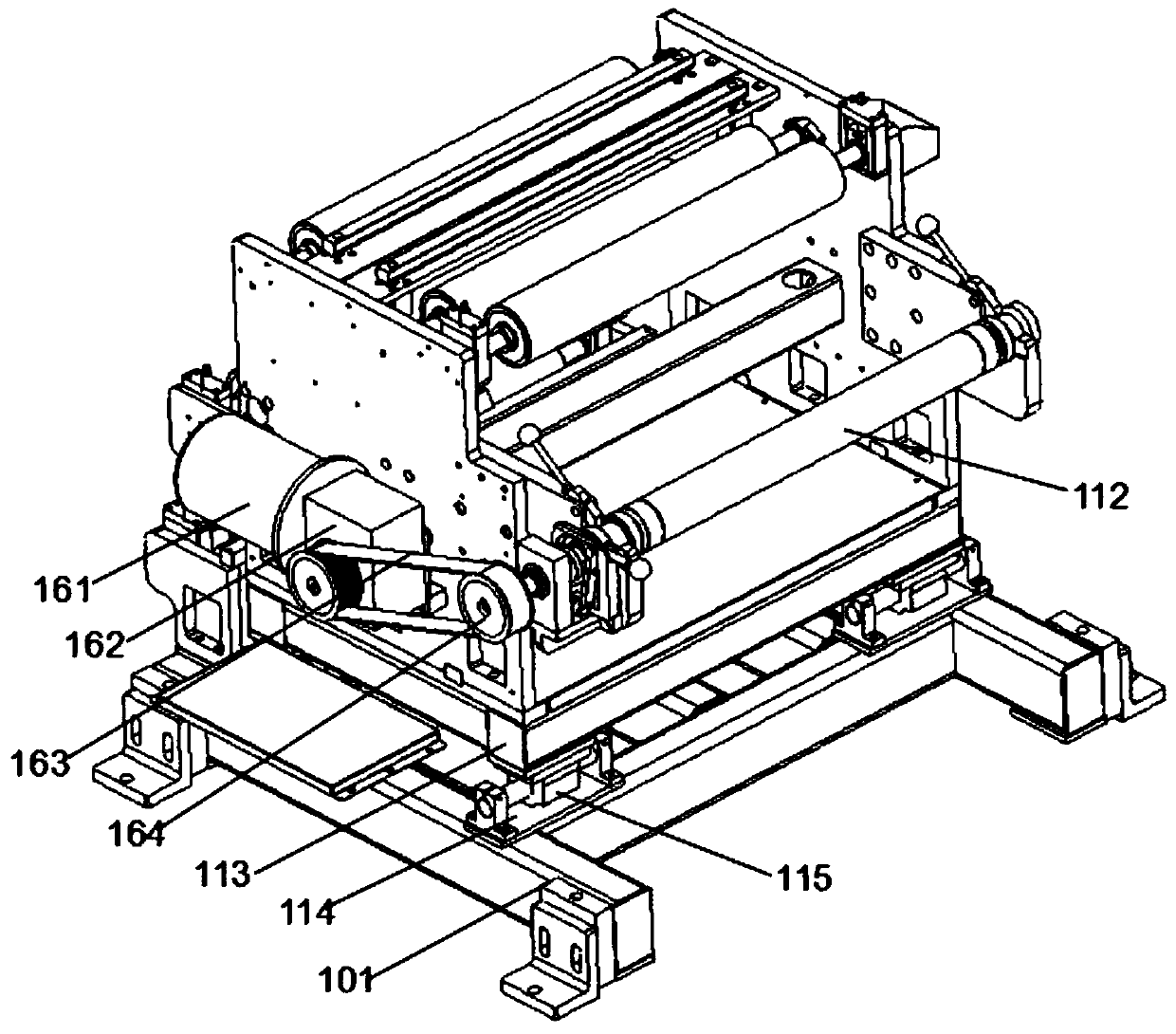

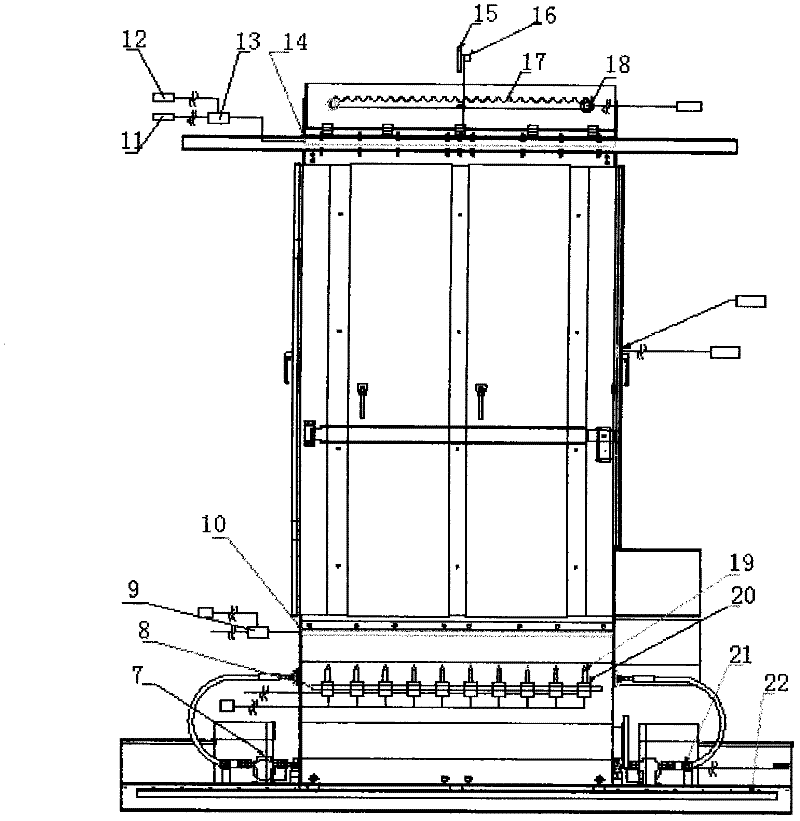

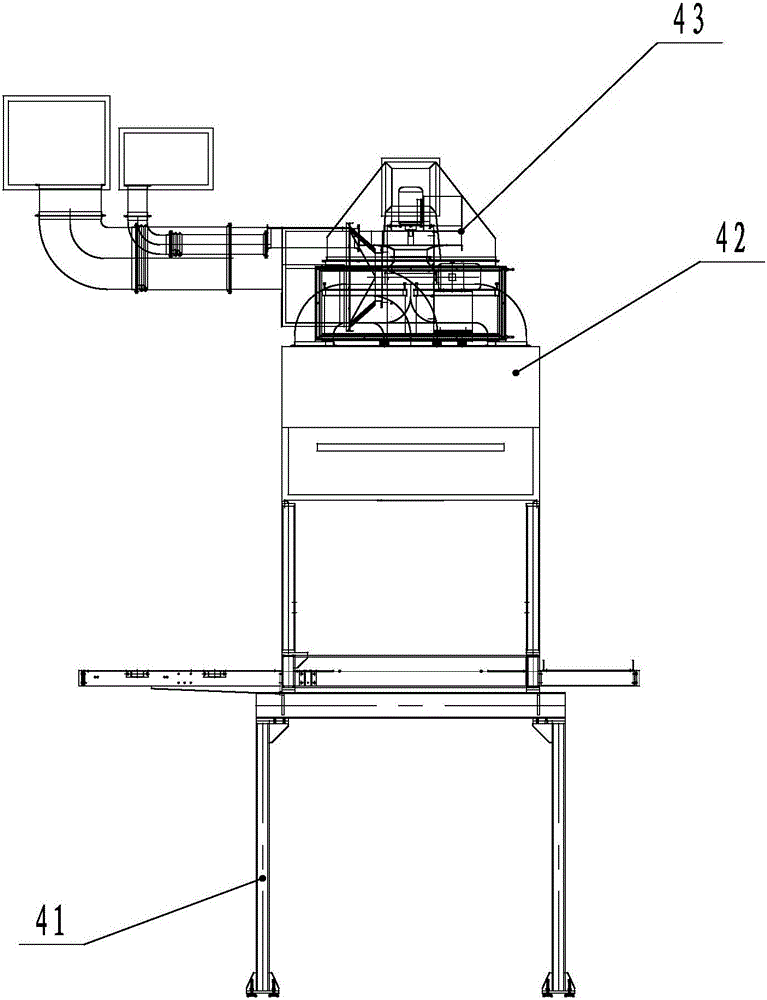

Full-automatic coating machine

PendingCN110605217AIncrease productivityImprove coating qualityLiquid surface applicatorsShaking/oscillating/vibrating mixersAgricultural engineeringCoating

The invention provides a full-automatic coating machine. The full-automatic coating machine comprises an uncoiling device, a coating device mounted behind the uncoiling device, an oven mounted behindthe coating device, a traction device mounted behind the oven, and a coiling device mounted behind the traction device. The uncoiling device in the coating machine is reasonable in structure arrangement; a frame is totally adjusted in a moving mode to achieve high adaptability; and through arrangement of multiple adjustable guide rollers and tensioning rollers, the coiling / uncoiling effect is excellent. The coating device in the coating machine is reasonable in structural design, not easy to generate precipitations in a trough, high in loading uniformity and easy to control a gap between a coating roller and a transfer glue roller. The traction device of the coating machine is provided with a feed adjusting mechanism to achieve excellent rectifying and tension adjusting effects; and through cooperation between a first tensioning adjustment mechanism and a second tensioning adjustment mechanism, the precise tension adjustment of a coating basal body in the traction conveying process canbe realized.

Owner:河南壮凌智能设备有限公司

Method for on-line measuring refractive index of blooming

ActiveCN101017085AAccurate calculationAccurate Calculation ControlPhase-affecting property measurementsUsing optical meansOnline testRefractive index

This invention relates to one optical film thickness online measurement reflection method, which uses computer for online test on film layer real time reflection rate test and uses real time reflection rate value to correct the monitor voltage signal theory change curve; when the coating film curve processed peak value point and trough point to compute real time reflection rate to stop to correct stop point voltage value and theory curve to display the reflection rate onto screen.

Owner:HENAN COSTAR GRP CO LTD +1

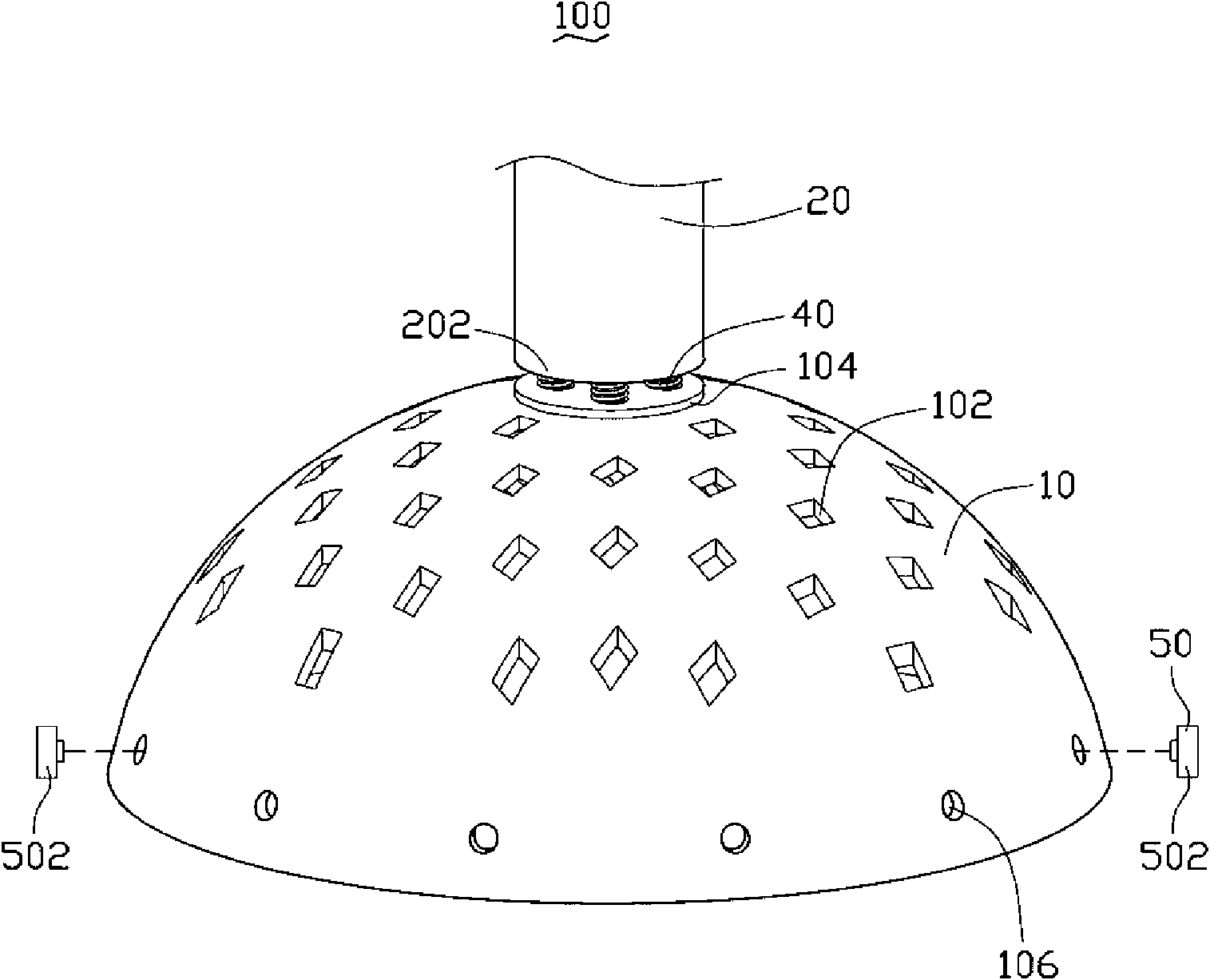

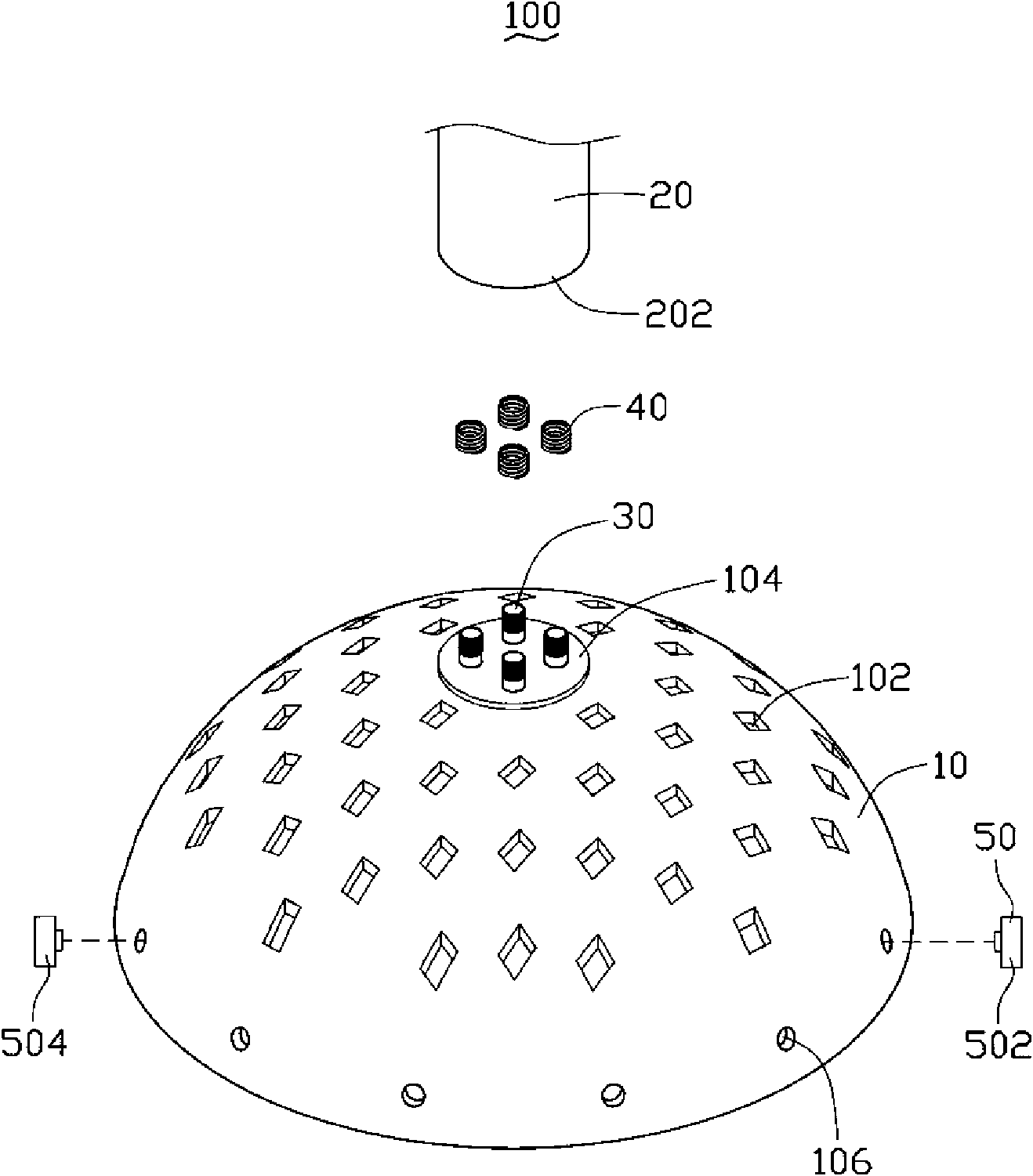

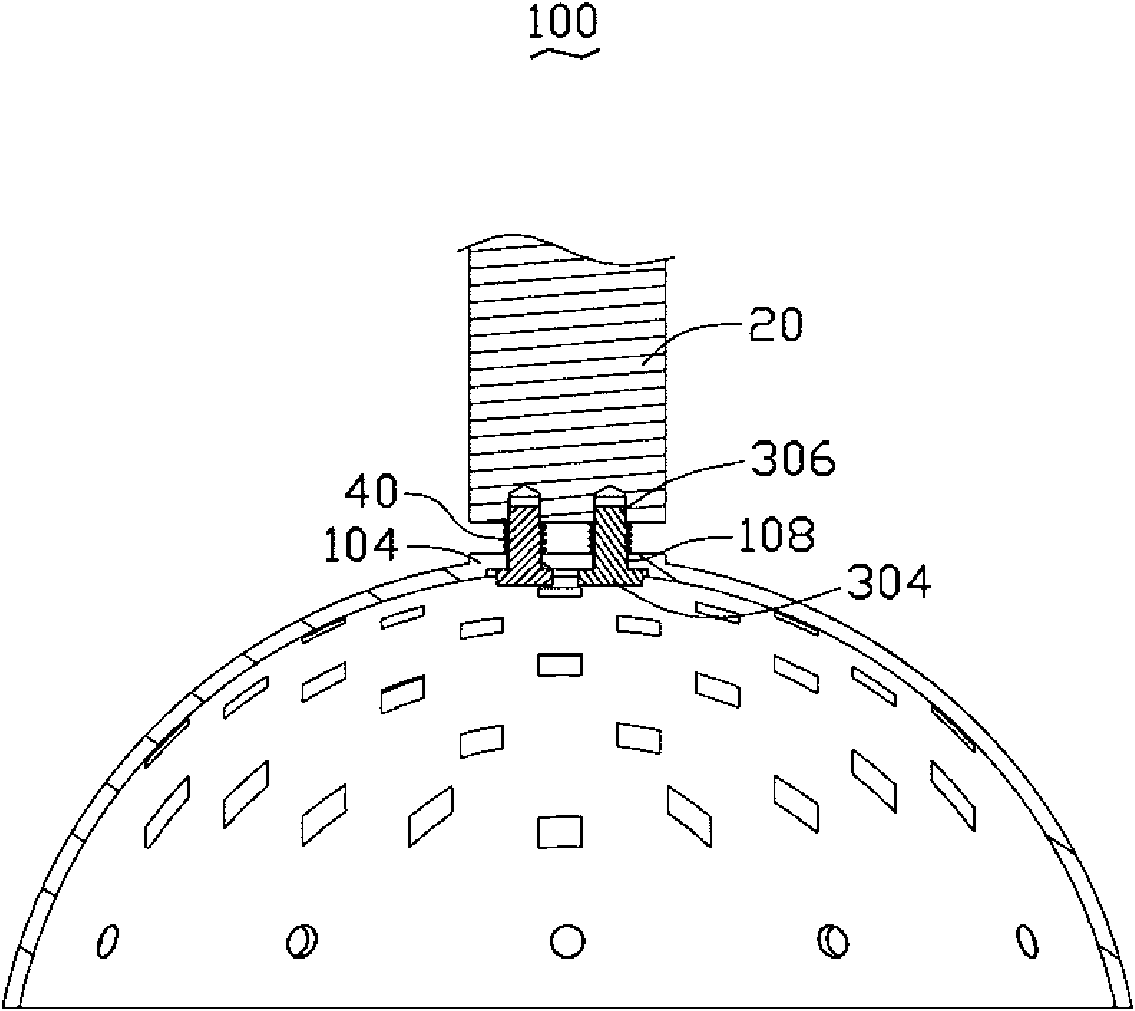

Film plating device

InactiveCN101603169AAvoid Variations in Coating ThicknessAvoid thickness differencesVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

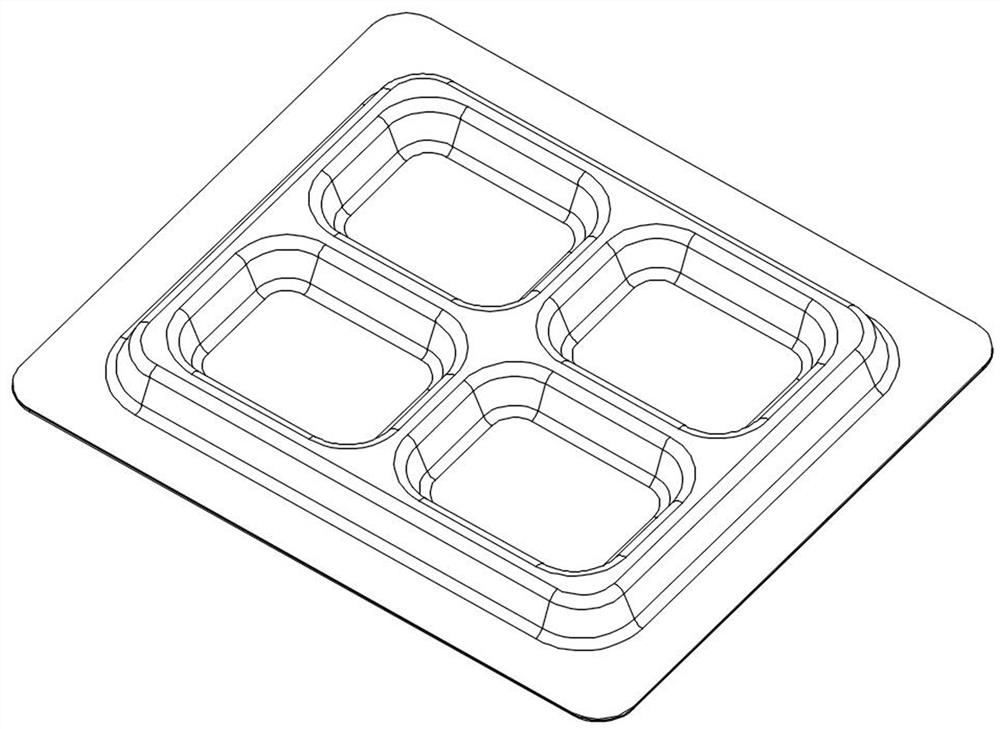

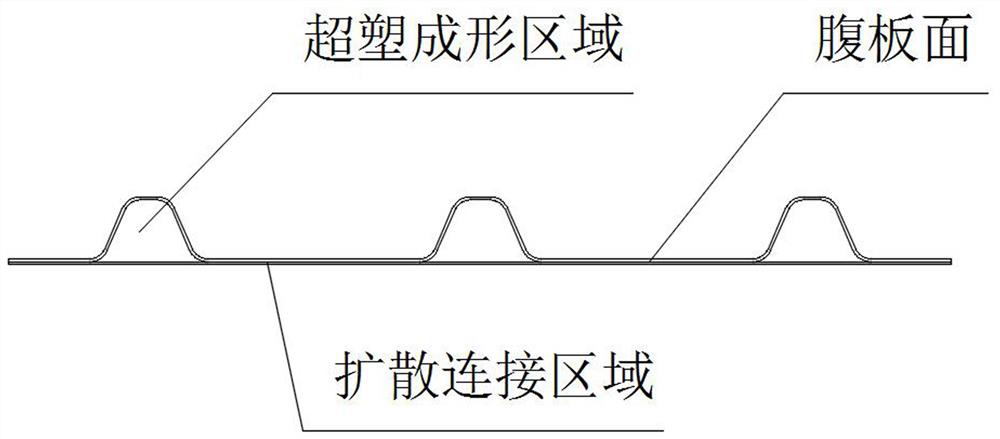

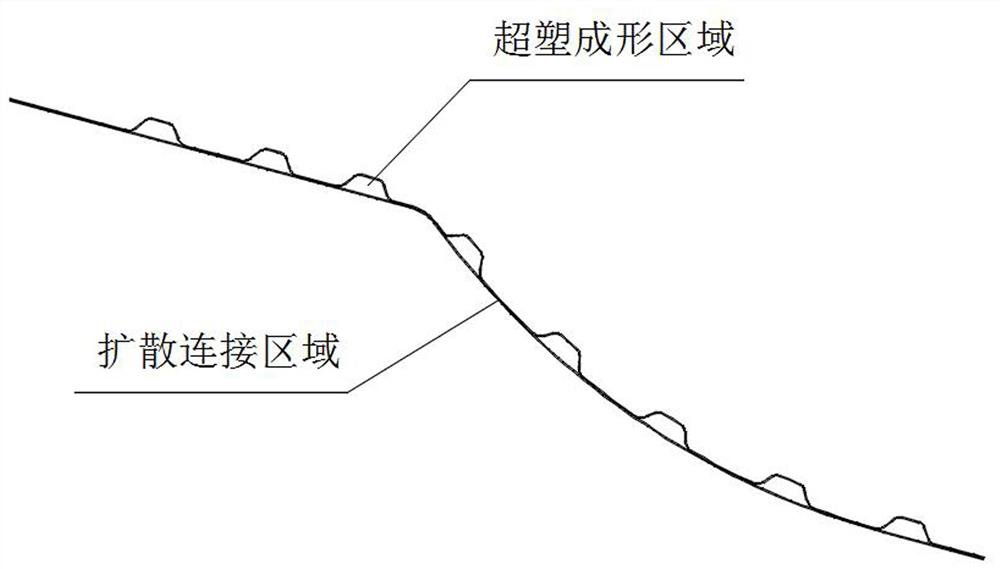

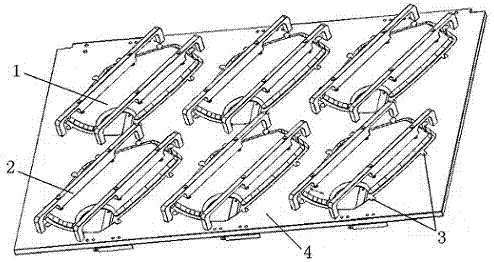

Preparation method of curved web surface titanium alloy superplastic forming-diffusion bonding blank

InactiveCN113333935AImprove coating accuracyReduce wearShaping toolsNon-electric welding apparatusTitanium alloyMoulding device

The invention discloses a preparation method of a curved web surface titanium alloy superplastic forming-diffusion bonding blank. The blank is a titanium alloy plate containing n layers, and n is larger than or equal to 2. The preparation method comprises the following steps that S1, a process model of a formed part is designed; S2, a forming device for preparing a blank is prepared according to the process model for designing the formed part; and S3, an overall blank is prepared through the forming device for preparing the blank, and the upper surface and the lower surface of the overall blank are evenly coated with welding stopping agents. According to the method, the shapes of the web faces of parts are formed through a pre-forming hot-pressing die, the bonding faces between blanks are coated with the welding stopping agents, a welding stopping agent coating area does not participate in material flowing before follow-up superplastic forming / diffusion bonding forming, the welding stopping agent coating precision is improved, a lineation sample plate is only used for lineation and does not directly participate in welding stopping agent coating, the abrasion of the sample plate is small, in addition, operation is convenient, the requirement for high-quality forming of parts is met, and the method is suitable for wide application and popularization.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Process for coating strip with fully-closed outer edge by utilizing magnetron sputtering coating machine

ActiveCN103114273AImprove coating accuracyHigh precisionVacuum evaporation coatingSputtering coatingNumerical controlEngineering

The invention relates to a process for coating a strip with a fully-closed outer edge and is mainly applied to the technical field of physical vapor deposition (PVD) coating. The process comprises the following steps: performing computerized numerical control (CNC) machining on the coated film, wherein the profile tolerance is controlled to be 0.1, Cpk is controlled to be more than 1.33 through the SPC control means, and the no-return gauge inspection accords with +0.1 / -0.15; coating and cleaning the coated film; putting the coated film into a coating tool, and blocking a non-coated part on the coated film, so that the coated part on the coated film is exposed outside; putting the coating tool in a coating cavity of the magnetron sputtering coating machine, wherein the coating surface is arranged on one side at which a target is positioned; setting the coating process parameters according to the standard; and coating to obtain the coating film with the strip of which the outer edge is fully closed. According to the process, the strip with the fully closed outer edge can be coated, the coating accuracy is high, the film forming position is accurate, the edge is clean and is not shaded, and the cost is low.

Owner:ZHEJIANG LANTE OPTICS

Encapsulation method for dye sensitization solar cell

InactiveCN101373668AImprove coating accuracySimple processLight-sensitive devicesCapacitor electrodesDye-sensitized solar cellTitanium dioxide thin film

The invention discloses an encapsulation method of a dye-sensitized solar cell, which comprises the following steps: making through holes on a piece of FTO conductive glass to be used as a platinum electrode substrate, wherein the through hole is perpendicular to the surface of the conductive glass; utilizing the screen printing technology to print titanium dioxide on the FTO conductive glass, on which a photo anode is manufactured; sintering well-printed titanium dioxide films; after the sintering, adopting the screen printing technology to print a UV curing glue in a clearance position between the thin films; the platinum electrode substrate is covered and then conducting UV curing so as to encapsulating each block of titanium dioxide; injecting electrolyte in the through holes on the FTO glass serving as the platinum electrode substrate; and utilizing the UV glue to encapsulate all through holes. The encapsulation method has the advantages of having relatively high coating precision and simple process, greatly shortens the encapsulation time and improves the production efficiency.

Owner:IRICO

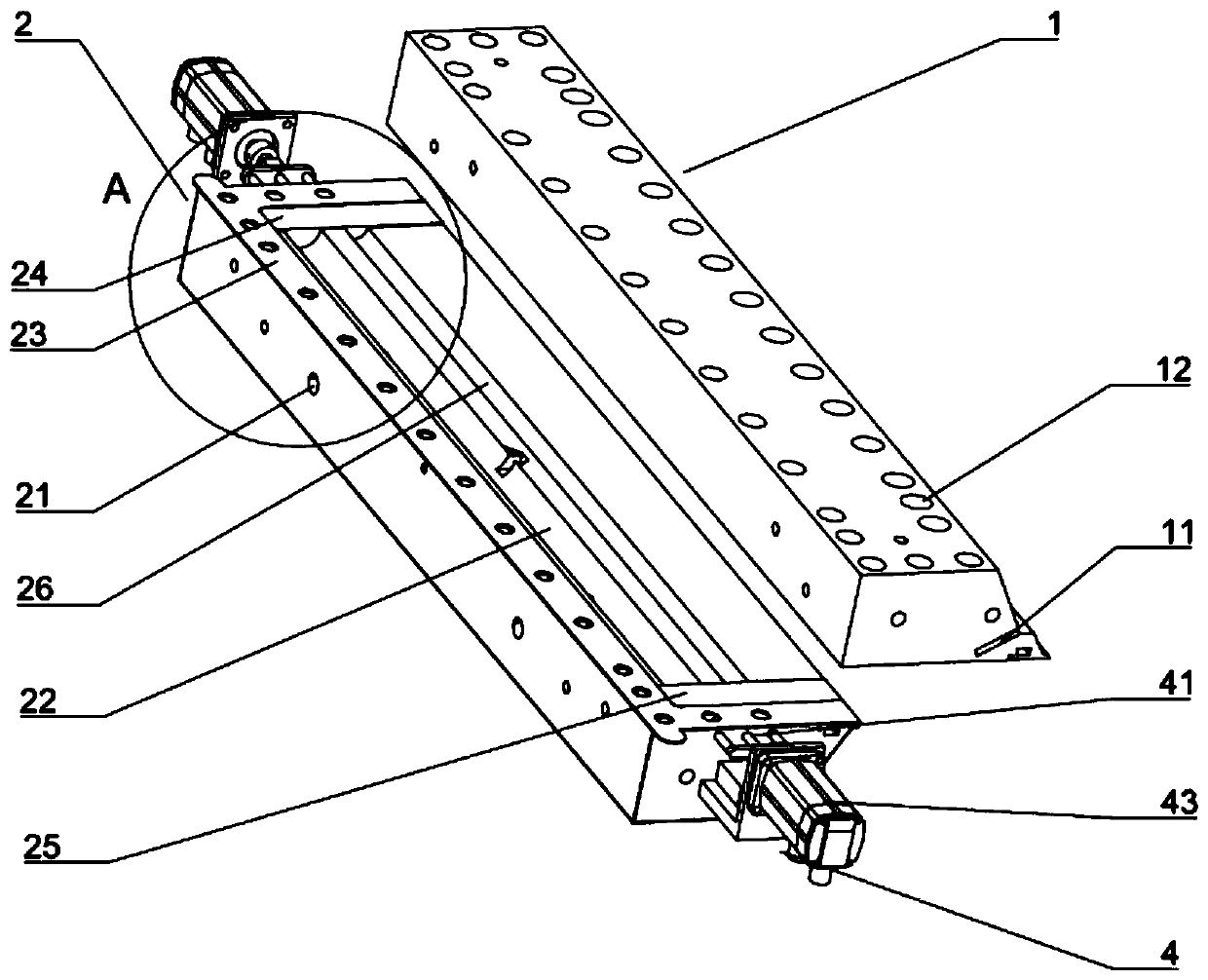

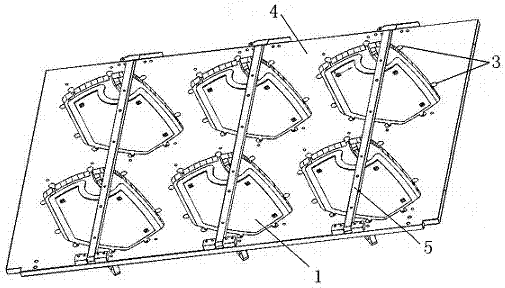

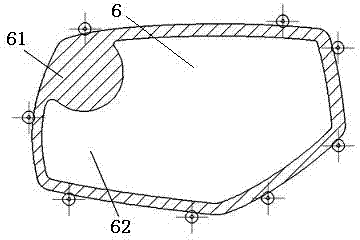

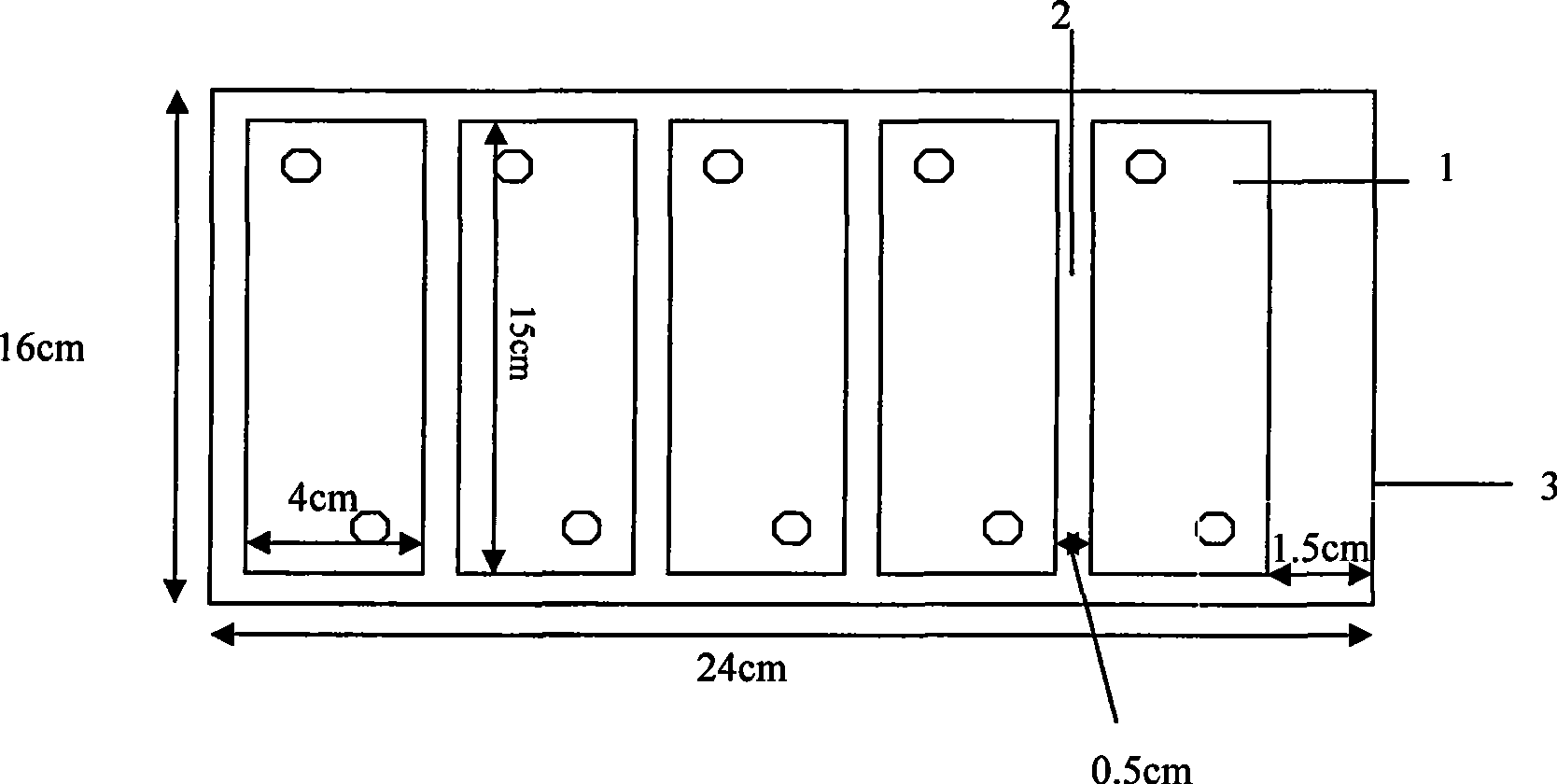

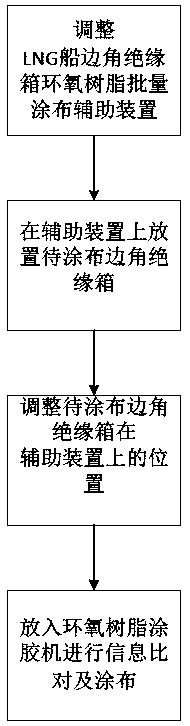

Method for batch-coating epoxy resin on corner insulation box of LNG (Liquefied Natural Gas) ship liquid cargo tank

The invention discloses a method for batch-coating an epoxy resin on a corner insulation box of an LNG (Liquefied Natural Gas) ship liquid cargo tank, and belongs to the technical field of ship construction. The method comprises the steps of (1) adjusting a position of a sliding cross beam of an auxiliary device according to a size of the corner insulation box to be coated; (2) placing the cornerinsulation box to be coated on the auxiliary device; (3) adjusting a position of the corner insulation box to be coated on the auxiliary device, and locking and positioning the corner insulation box to be coated; and (4) placing the auxiliary device and the corner insulation box to be coated on an epoxy resin coating machine, comparing information, and coating. The method provided by the inventionis simple and convenient in operation steps and easy to grasp; by utilizing the steps of the method, multiple corner insulation boxes to be coated can be coated at the same time, so that the coatingefficiency is higher; the multiple corner insulation boxes to be coated are placed on the auxiliary device in parallel, so that the coating accuracy is higher; and operating personnel can carry the multiple corner insulation boxes at the same time, so that the labor intensity is reduced, and the labor efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

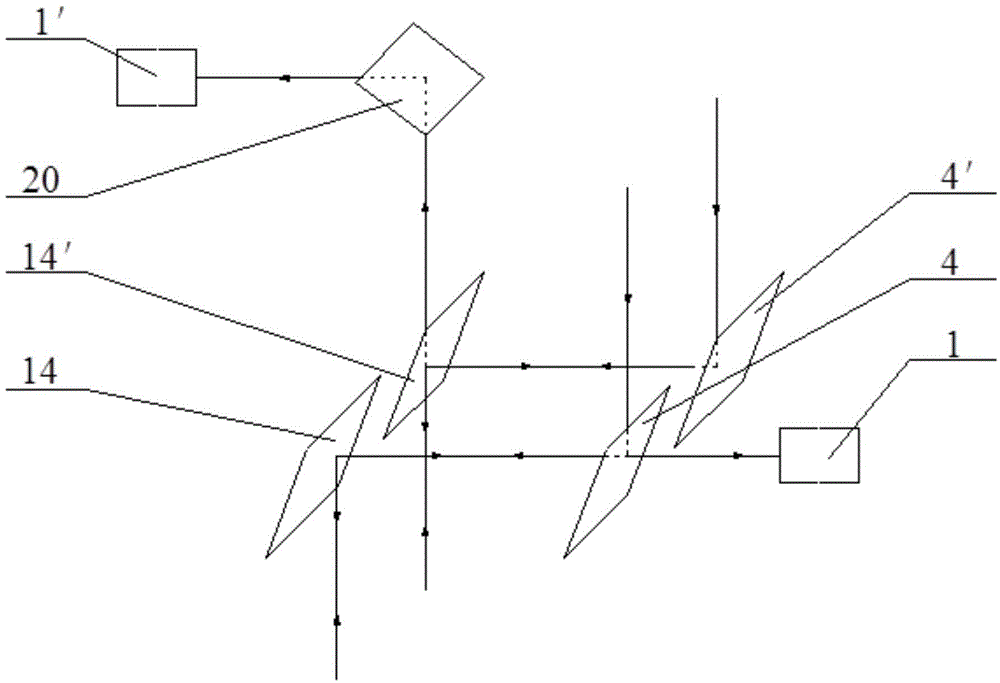

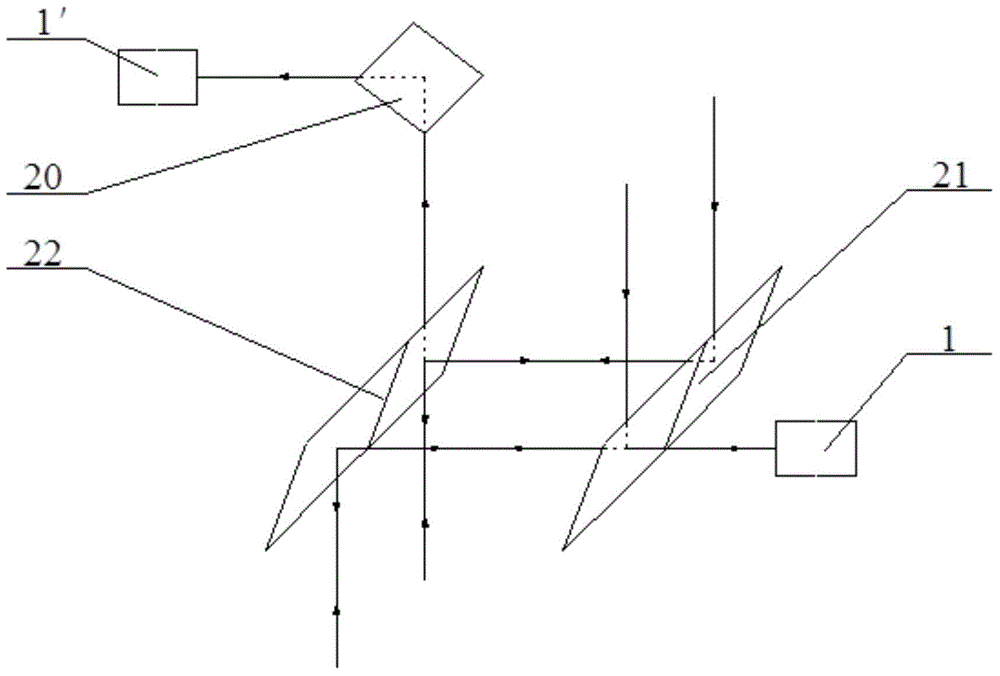

Electrostatic spraying equipment

ActiveCN102179327AImprove safety and reliabilityEliminate fire hazardsFire rescueSpray discharge apparatusSpray nozzleEngineering

The invention discloses electrostatic spraying equipment, which comprises a line speed detection system (1), an independent atomizing nozzle adjusting system (2), a plate and strip width detection system (3), an automatic flame detection and automatic fire distinguishing system (4), an unbalanced air pressure compensation and control system (5) and a serration plate electrode (6). The electrostatic spraying equipment solves an independent precision line speed detection problem, an independent atomizing nozzle adjusting problem, an independent precision width detection problem, an automatic detection and automatic fire distinguishing problem, an unbalanced air pressure compensation and control problem, and a coating material overflow problem caused by a planar electrode.

Owner:苏州必世洁机电有限公司

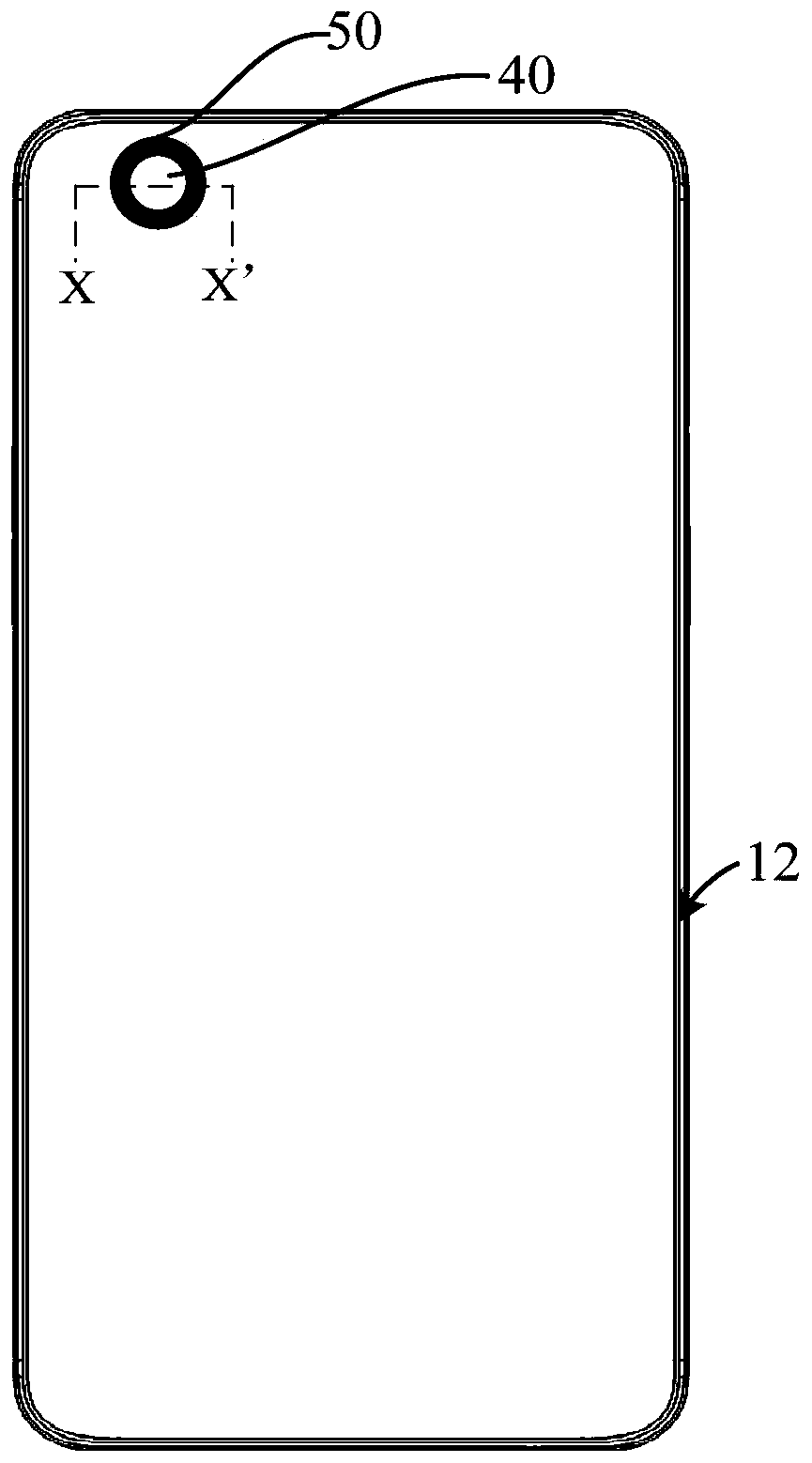

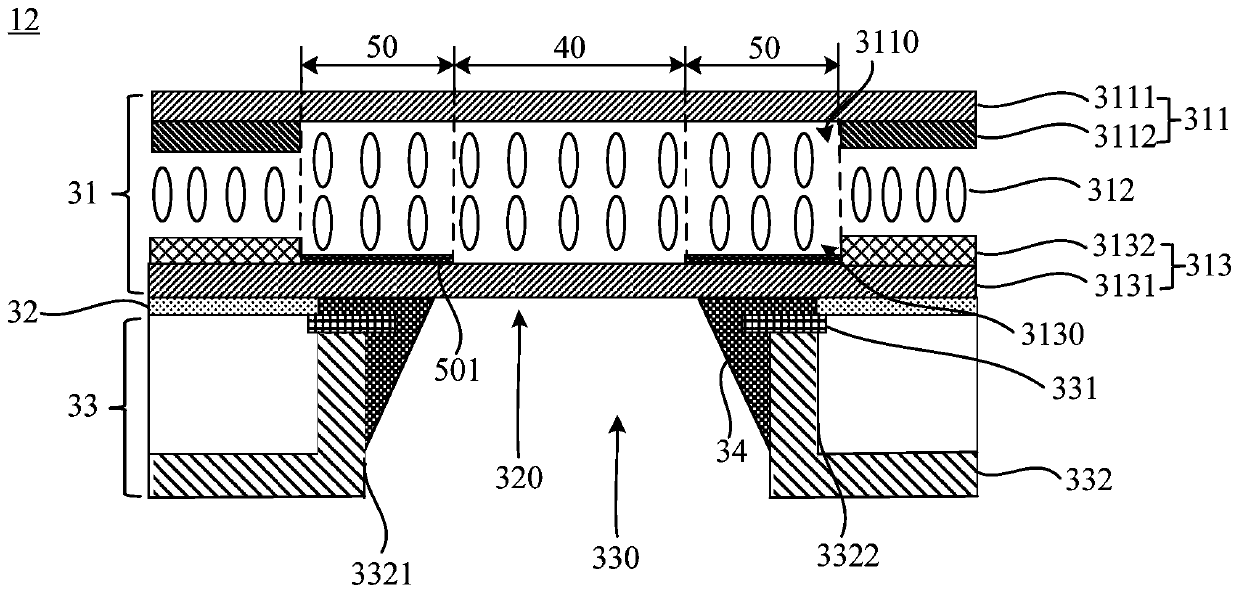

Display device and electronic apparatus

InactiveCN111045244AImprove coating accuracyAvoid enteringNon-linear opticsDisplay deviceEngineering

The invention provides a display device and electronic equipment, the display device comprises a cover plate, a liquid crystal box, a backlight module, a first shading body and a second shading body,the end part of the cover plate is provided with a through hole, and the through hole is used for light required by a photosensitive device to pass through; the liquid crystal box is arranged on the cover plate and located at the outer side of the through hole, and the liquid crystal box comprises a first side face; the backlight module is arranged at the side, away from the cover plate, of the liquid crystal box, the backlight module comprises a second side face, and the first side face and the second side face are close to the through hole; the first shading body is arranged on the first side face and used for preventing light emitted by the liquid crystal box from entering the through hole. The second shading body is arranged in the second side face and used for preventing light emittedby the backlight module from entering the through hole. The light transmission effect of a photosensitive hole is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

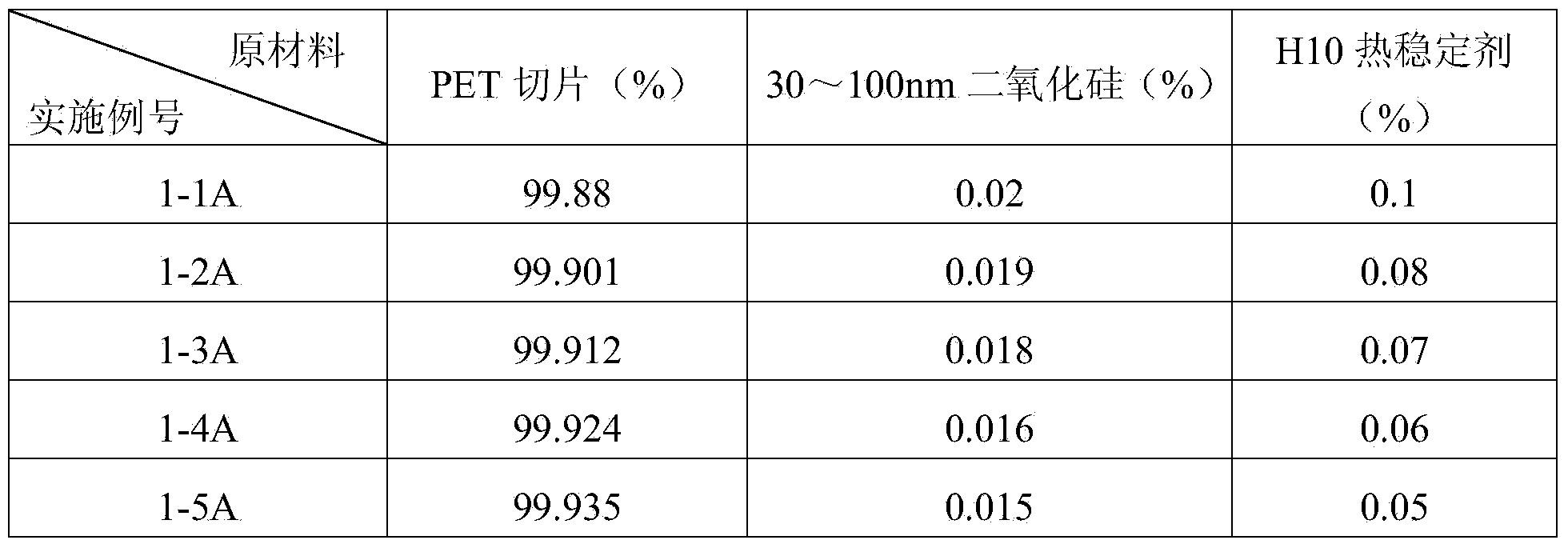

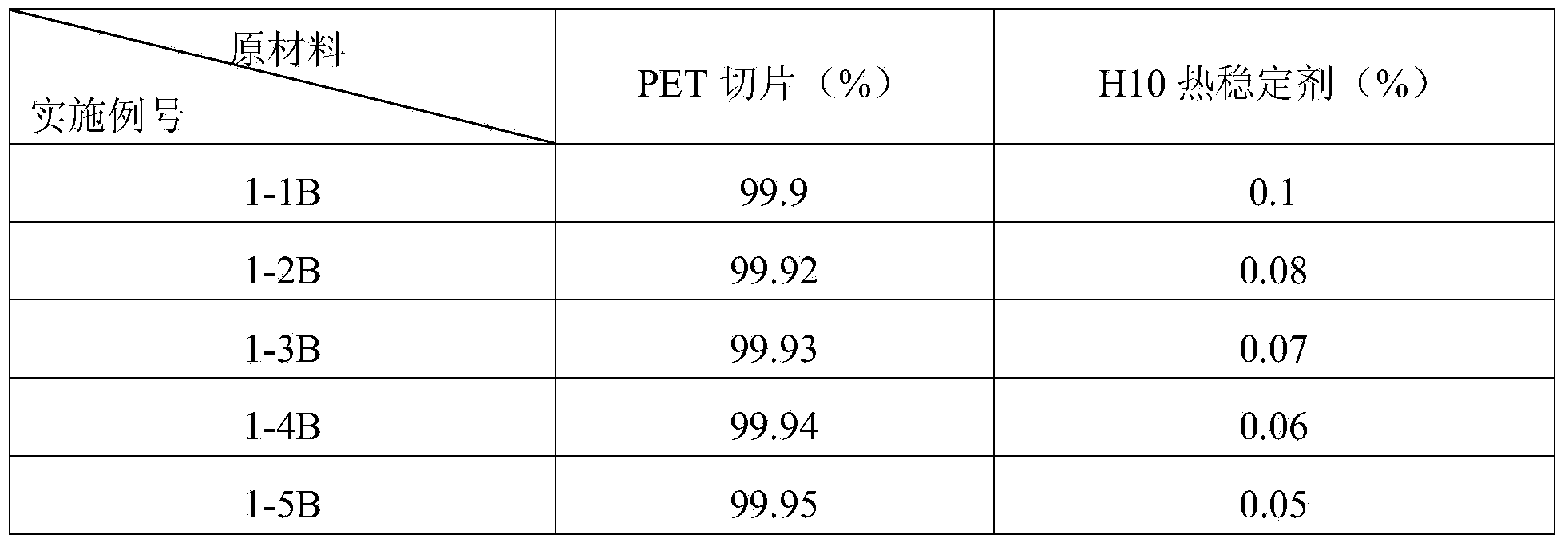

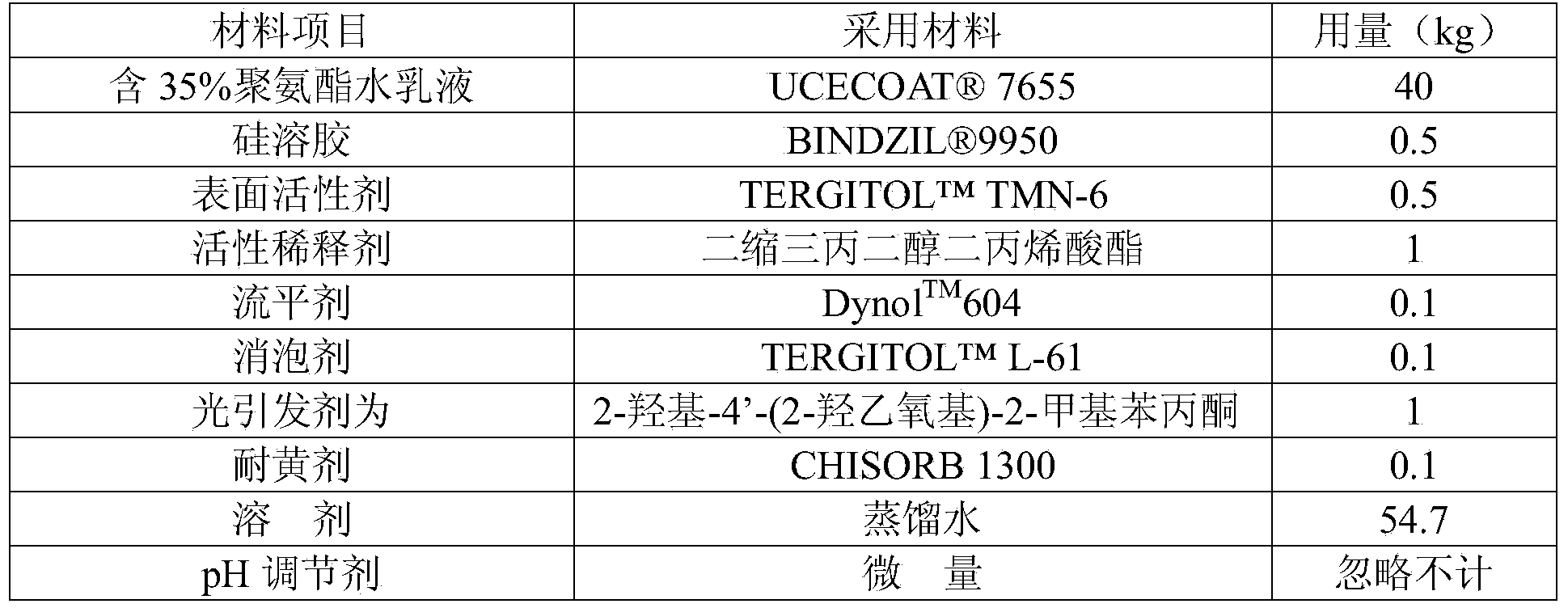

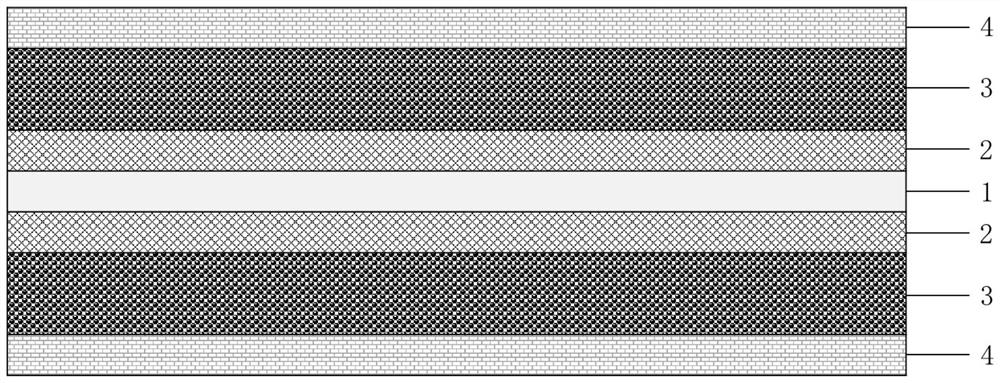

Single-face or double-face optical hardening composite membrane and preparation method thereof

ActiveCN104228257AReduce interference rainbow patternLess crystal pointLamination ancillary operationsSynthetic resin layered productsActive agentUltraviolet lights

The invention discloses a single-face or double-face optical hardening composite membrane. The single-face or double-face optical hardening composite membrane is characterized by being composed of a base membrane and hardening resin coatings, wherein the hardening resin coatings are applied and solidified to single face or double faces of the base membrane, the base membrane is a two-way-stretched optical A-layer and B-layer composite membrane or A-layer B-layer and A-layer composite membrane, the thickness of the base membrane is 100 to 250 microns, and the thickness of each coating is 1 to 10 microns. A preparation method comprises the steps of performing melting casting and longitudinal drawing on polyester chips respectively by a No.1 extruder and a No.2 extruder so as to form blank sheets, then applying hardening resin coating liquid to the surfaces of the blank sheets, drying, horizontally drawing, performing heat setting, and solidifying by ultraviolet light so as to obtain the single-face or double-face optical hardening composite membrane, wherein the hardening resin coating liquid is composed of an aqueous emulsion containing 35% of polyurethane, nano-silica sol, a surface active agent, a flatting agent, a defoaming agent, a photoinitiator and an anti-yellowing agent. According to the single-face or double-face optical hardening composite membrane, one-step processing is adopted, and the prepared single-face or double-face optical hardening composite membrane is suitable for the field of touch displays.

Owner:四川东方绝缘材料股份有限公司

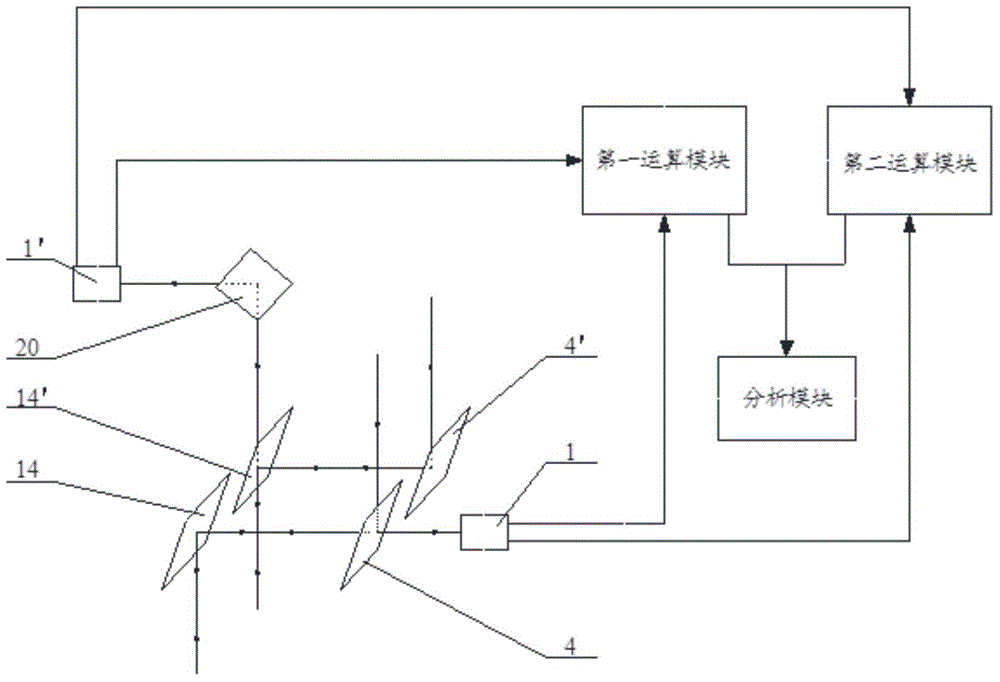

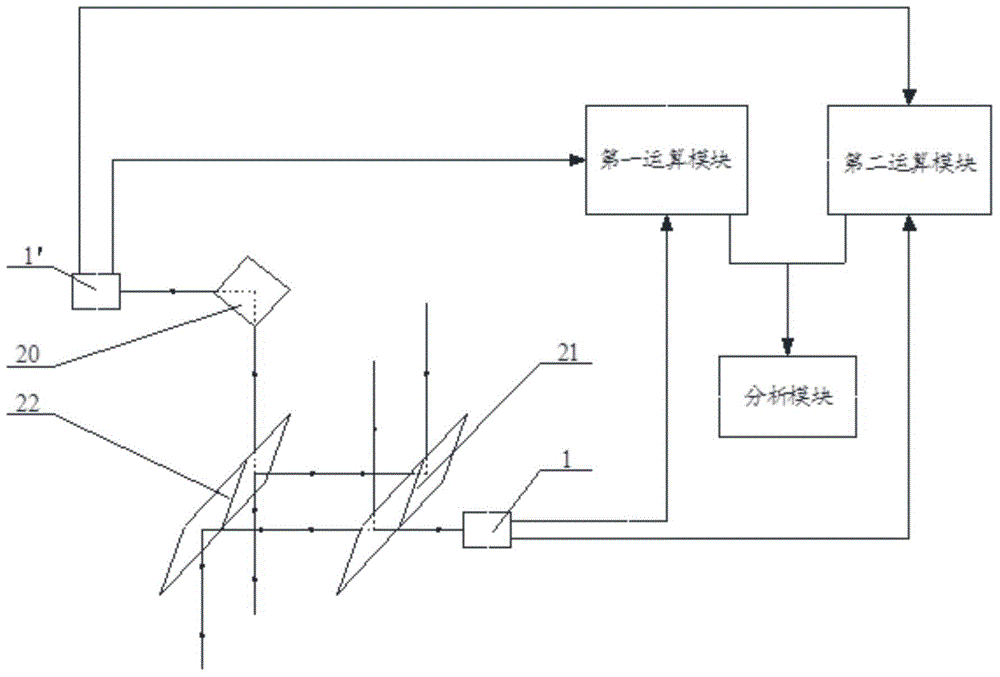

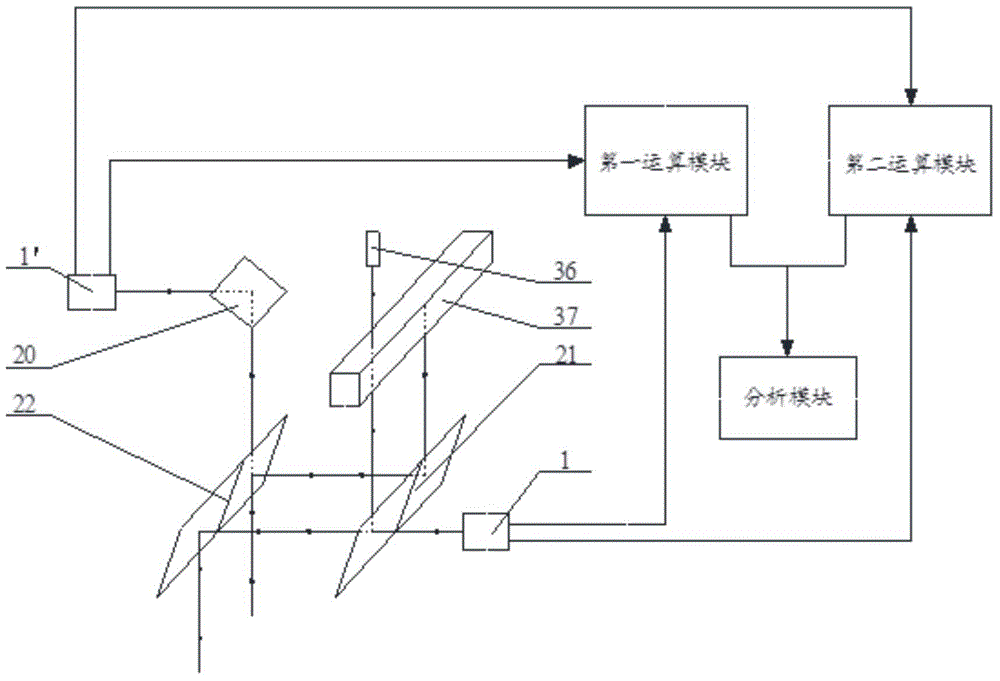

Device for automatically detecting two-dimensional morphology of wafer substrate

Disclosed is a device for automatically detecting the two-dimensional morphology of a wafer substrate. Through a first operation module and a second operation module of the device, the curvature CX of any two incident points on a wafer substrate in the radial direction of a to-be-detected substrate (namely, the X direction) and the curvature CY of any one incident point on the wafer substrate in the moving direction of the to-be-detected substrate (namely, the Y direction) can be obtained. Through an analysis module, the two-dimensional morphology of the wafer substrate can be obtained based on the calculation result of CX and CY. Thus, detection of the two-dimensional morphology of the wafer substrate is completed automatically. Moreover, N first beam splitters in one-to-one correspondence with N laser beams and N second beam splitters in one-to-one correspondence with N laser beams are provided with coating areas, and the reflectance and transmittance properties of each coating area are determined by the propagation direction of corresponding first-type reflected light beams. As the N first beam splitters and the N second beam splitters are of a simple structure and very high coating precision, the consistency of light received by PSDs in different propagation directions is ensured.

Owner:北京艾瑞豪泰信息技术有限公司

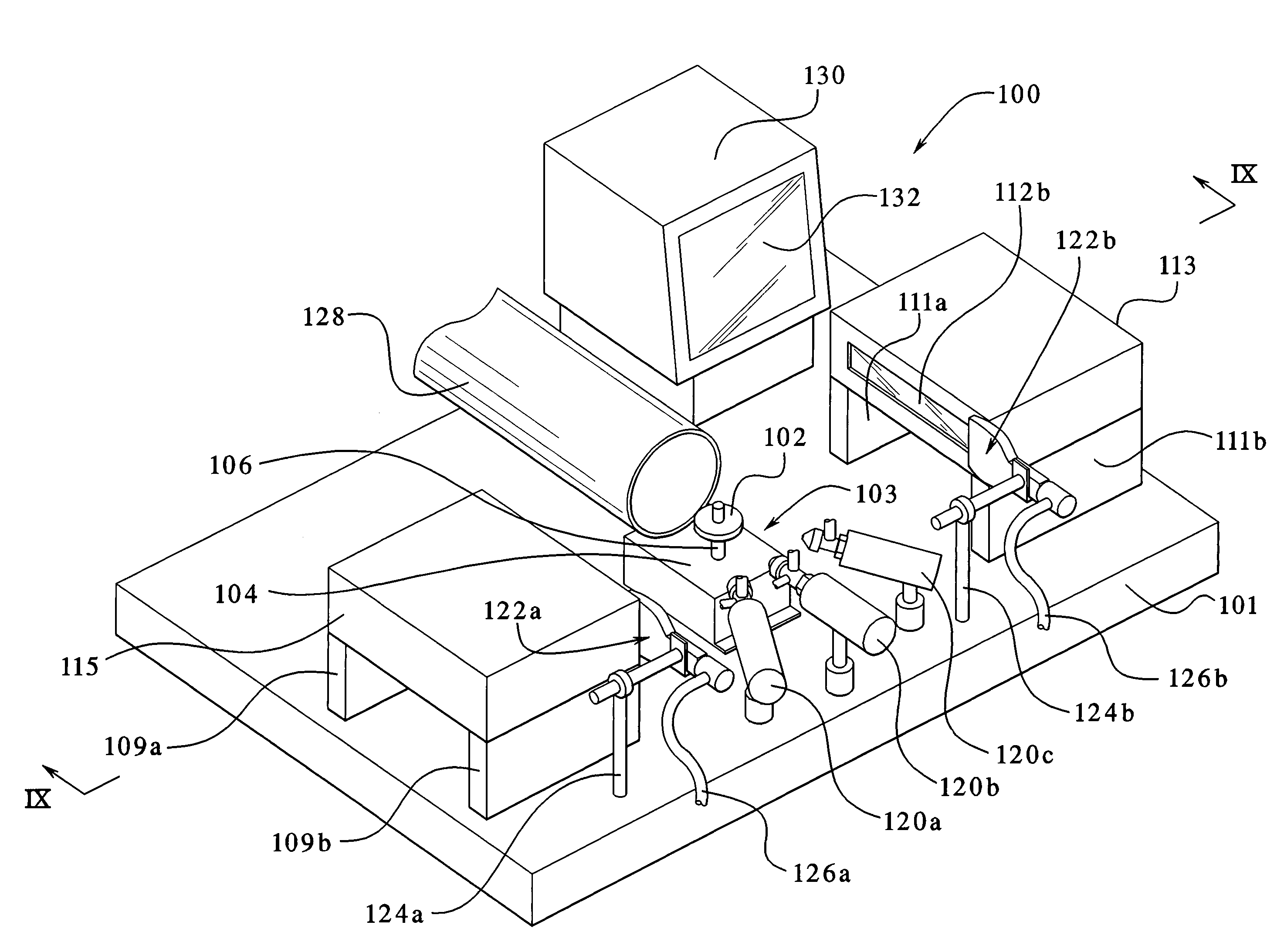

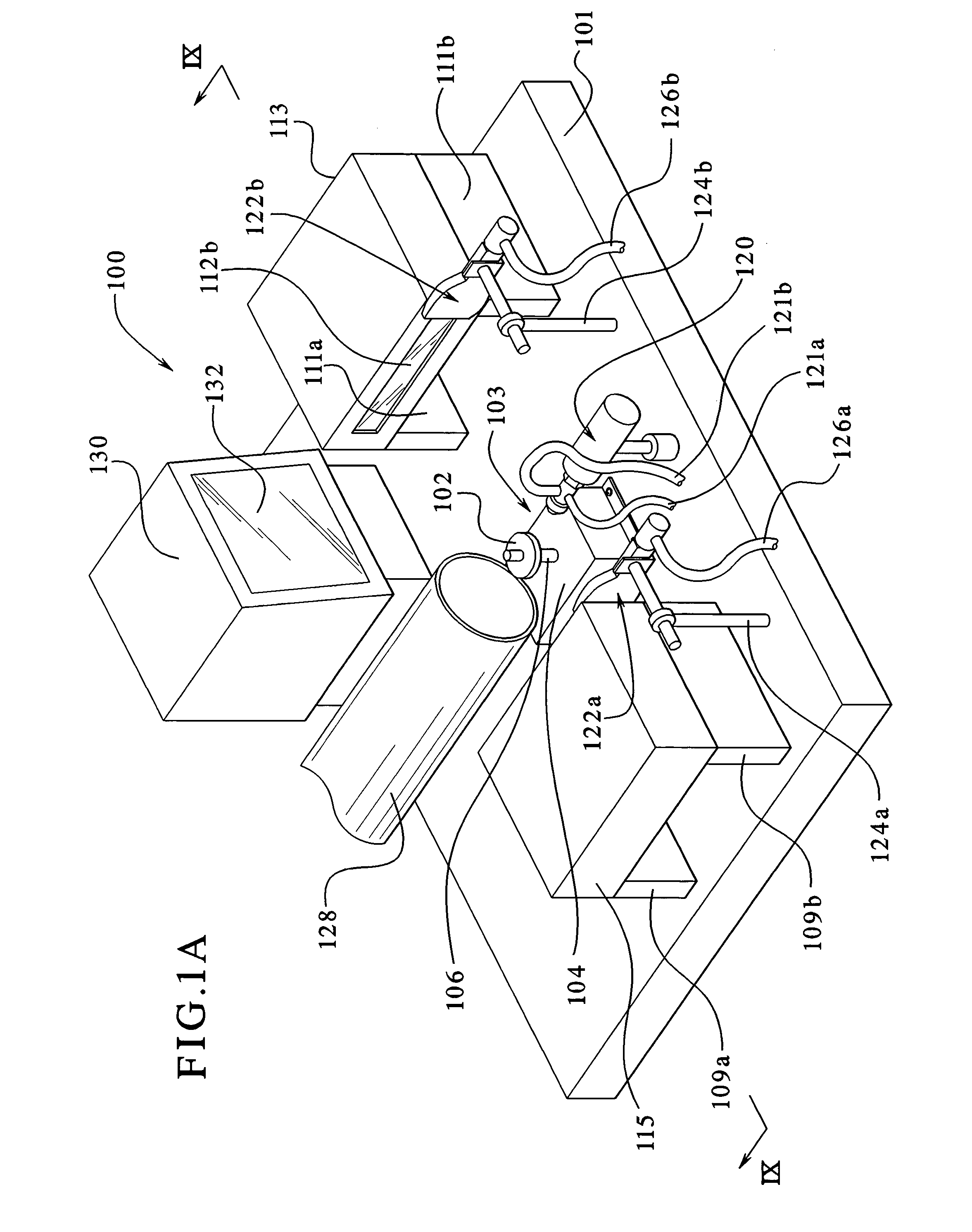

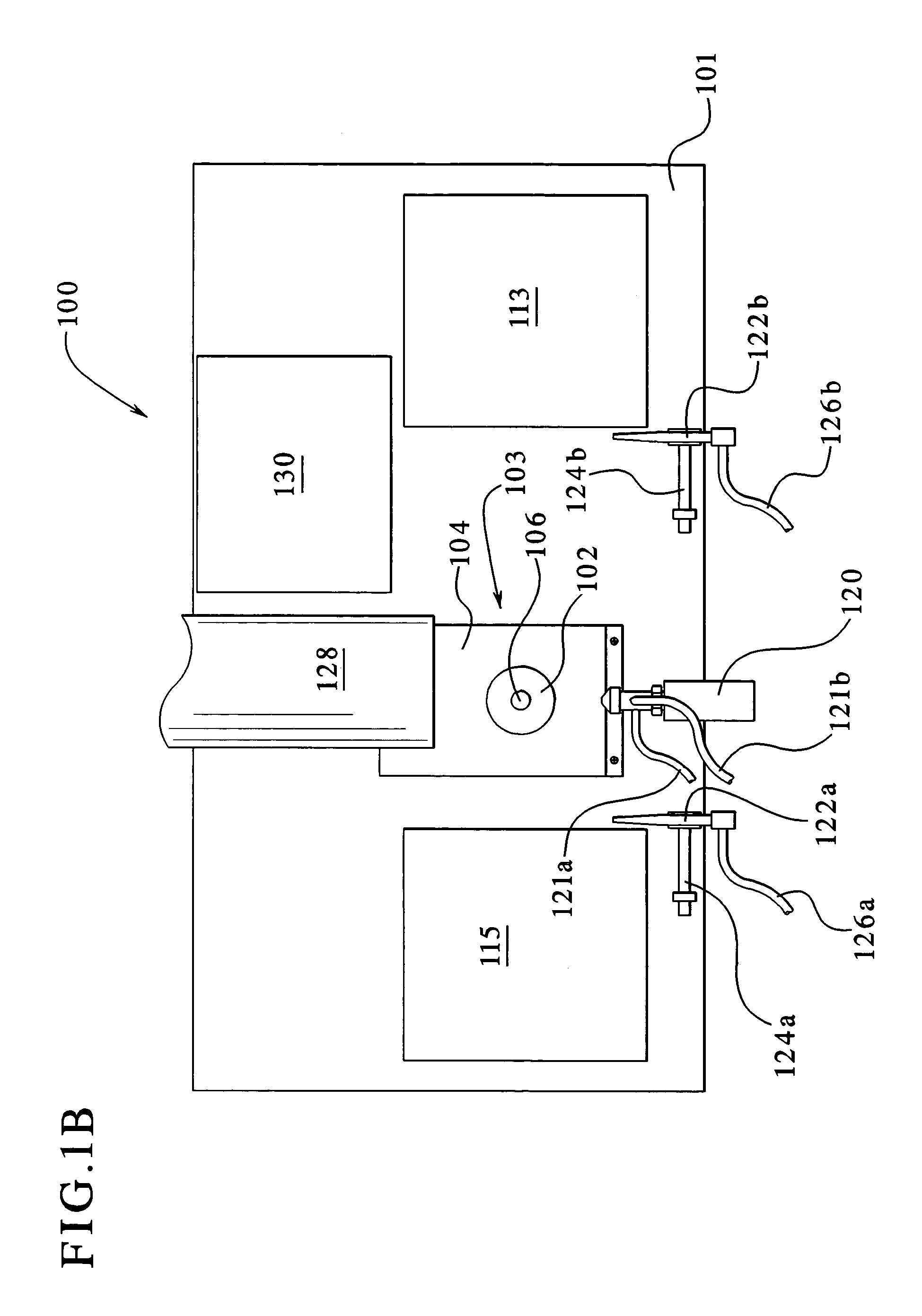

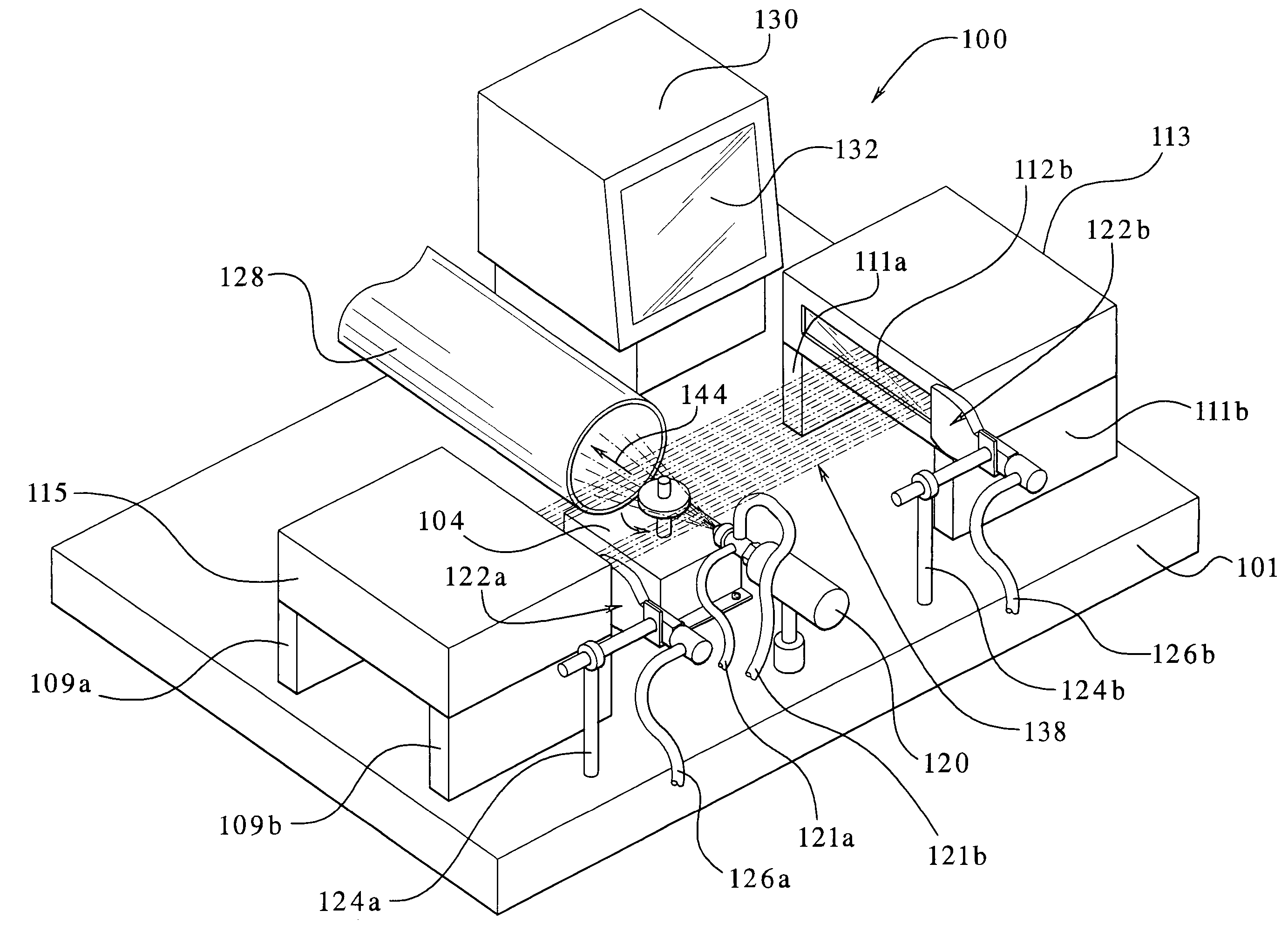

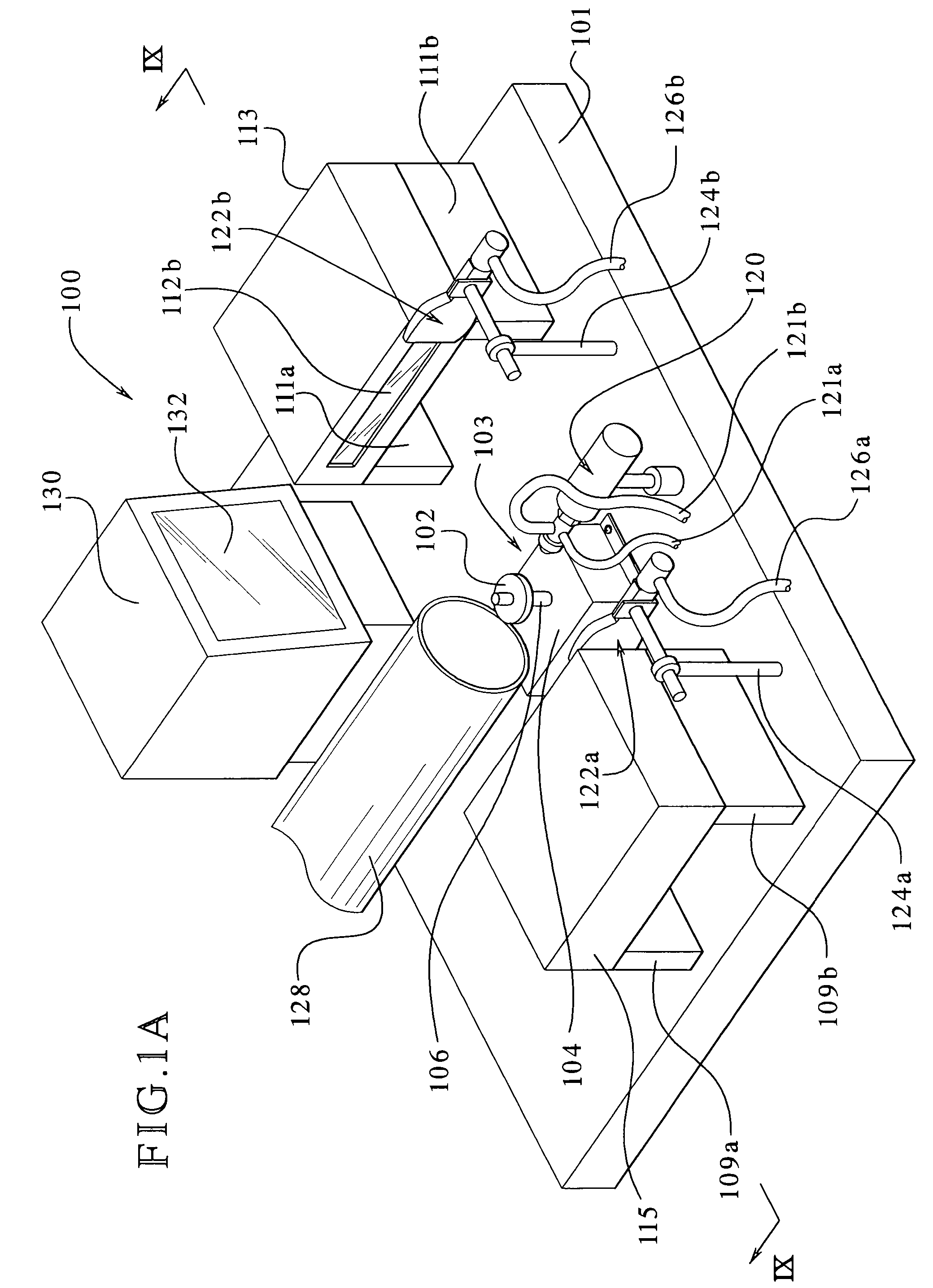

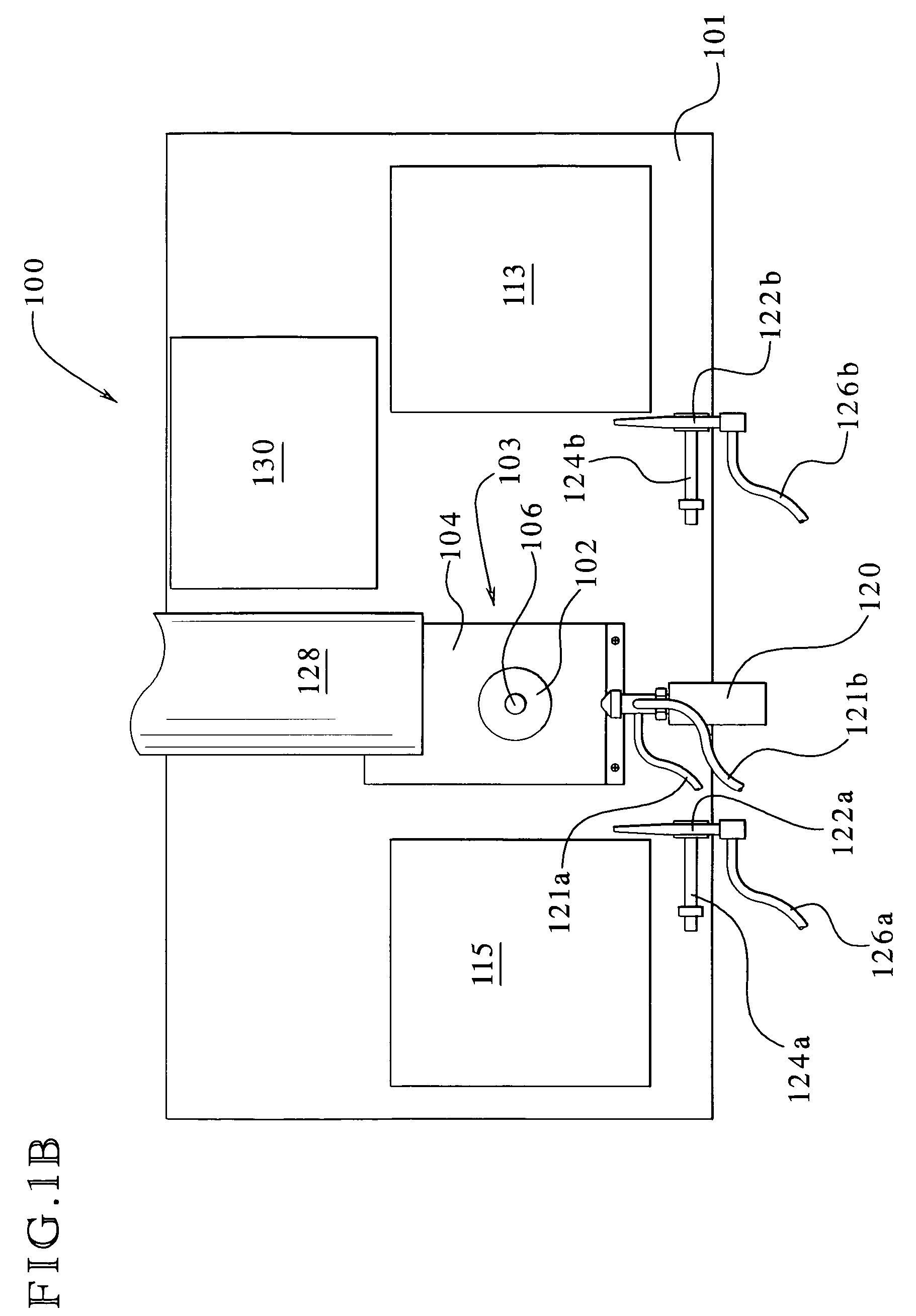

Apparatus for simultaneously coating and measuring parts

InactiveUS6991683B2Improve coating accuracyImprove coating efficiencyLiquid surface applicatorsInvestigating moving sheetsContinuous measurementSprayer

Owner:DIMENSION BOND CORP

Coating equipment and coating system applying same

InactiveCN114713438AAbsorb moreImprove transfer abilityLiquid surface applicatorsCoatingsCoating systemMechanical engineering

The invention discloses coating equipment and a coating system applying the coating equipment, the coating equipment comprises a rack, the rack is provided with a feeding roller, a discharging roller, a pressure roller, a coating roller and a trough, the peripheral surface of the coating roller is provided with a recess, part of the coating roller is immersed in coating liquid in the trough, the pressure roller is located above the coating roller, and the pressure roller is located above the coating roller. After a base material enters the coating equipment through the feeding roller, the upper surface of the base material abuts against the bottom of the pressure roller, the lower surface of the base material abuts against the top of the coating roller to complete coating, finally the base material enters the next procedure through the discharging roller, the running direction of the coating roller is opposite to the moving direction of the base material, and the movement of the base material drives the pressure roller to rotate. According to the coating equipment, the capacity of transferring the coating liquid from the coating roller is improved, so that the coating precision and the coating effect on a base material are improved.

Owner:浙江庞度环保科技股份有限公司

Roller coater

ActiveCN100591426CSolve the problem of coating qualityRealize online maintenance and color changeLiquid surface applicatorsCoatingsLacquerMechanical engineering

The invention provides a roller machine suitable for coating chemical coating, which is characterized in that the roller machine comprises two sets of coating mechanism arranged top to top, a supportroller mechanism, a turning roller component, a frame, a synchronous mechanism, a shower, a back-coated lifting device and a transmission mechanism. Back coating frames of a coating roller device, a reclaiming roller device and a regulating roller device fitted with specially made polyurethane material are driven by an oil cylinder and synchronous lifting at both sides is assured by the synchronous mechanism in the coating mechanism; clearance among the coating roller device, the reclaiming roller device and the regulating roller device is regulated by the regulating mechanism to regulate coating thickness. The shower line is in a lacquer tray of a front coating mechanism and a flat mouth shower with a valve is arranged on the shower line; flow rate of the paint is controlled and coating thickness is adjusted by regulating the valve. Jet tube mode is adopted in the lacquer tray of a bottom roller in the back coating mechanism; paint is agitated to prevent from deposition. The roller machine has the advantages that double-roller coating structure is adopted and one is used and the other is standby, maintenance and exchanging color are carried out online, time is saved and productivity is improved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

Device for detecting two-dimensional morphology of wafer substrate

ActiveCN105698705ASimple structureImprove coating accuracyUsing optical meansOptical pathTransmittance

The invention provides a device for detecting the two-dimensional morphology of a wafer substrate, and belongs to the technical field of semiconductor material nondestructive testing. The device for detecting the two-dimensional morphology of a wafer substrate comprises N first beam splitters in one-to-one correspondence with N laser beams and N second beam splitters in one-to-one correspondence with N laser beams. The N first beam splitters and the N second beam splitters are provided with coating areas, the coating areas make the beam splitters different in reflectance and transmittance, so that N beams of light incident on a sample and then returned can be divided into two directions through the first beam splitters and the second beam splitters and detected separately. The reflectance and transmittance properties of each coating area are determined by the propagation direction of corresponding first-type reflected light beams. By coating different areas of the beam splitters with films of different properties, the requirement of the device for detecting the two-dimensional morphology of a wafer substrate for light path transmission is met. As the coating precision is extremely high, the consistency of light received by PSDs in different propagation directions is ensured.

Owner:NANCHANG ANGKUN CO LTD

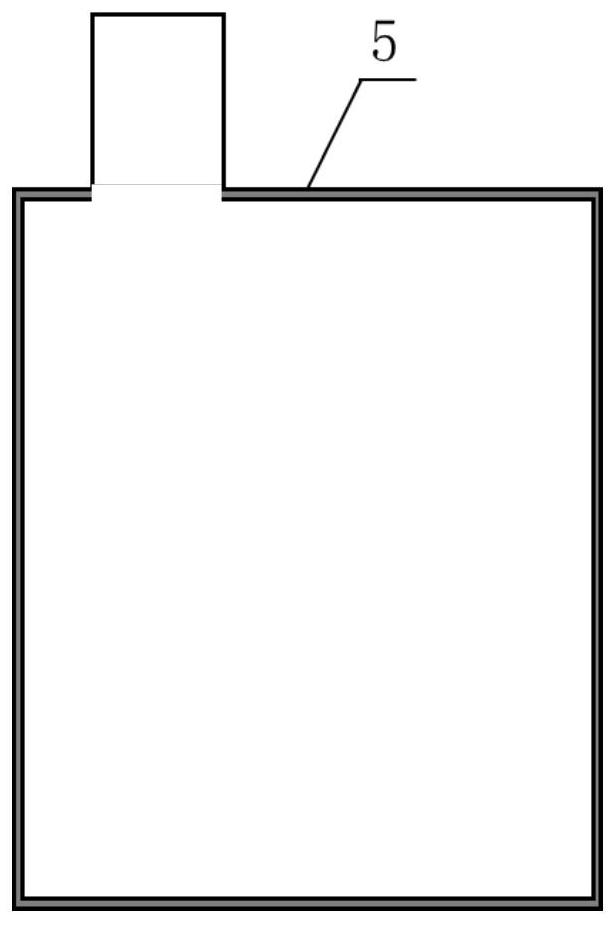

Positive pole piece for high-safety lithium ion battery as well as preparation method and application of positive pole piece

PendingCN114267821AIncrease resistanceGuaranteed electrical performanceElectrode manufacturing processesElectrode carriers/collectorsElectrical batteryEngineering

The positive pole piece comprises a current collector and first safety coatings correspondingly arranged on the two outer side surfaces of the current collector, positive active layers are arranged on the two outer side surfaces of the first safety coatings, and the positive active layers are made of ternary positive materials. Second safety coatings are arranged on the two outer side surfaces of the positive electrode active layer, and end face safety coatings are arranged on the side edge end faces, except the tab position, of the positive electrode piece. The invention also discloses a preparation method of the positive pole piece, which comprises the following steps: uniformly stirring the raw materials to prepare each layer of slurry, sequentially coating the slurry on the current collector, and then stamping and coating the end surface; the invention also discloses an application of the positive pole piece in a lithium ion battery. Through the three-layer coating structure of the positive pole piece, the electrical performance and the safety performance of the lithium ion battery are ensured at the same time; the multi-layer coating method is adopted, so that the preparation efficiency is high; the positive pole piece is used as a composition structure of the lithium ion battery, so that the needling safety performance of the lithium ion battery is improved.

Owner:XIAN SAFTY ENERGY TECH

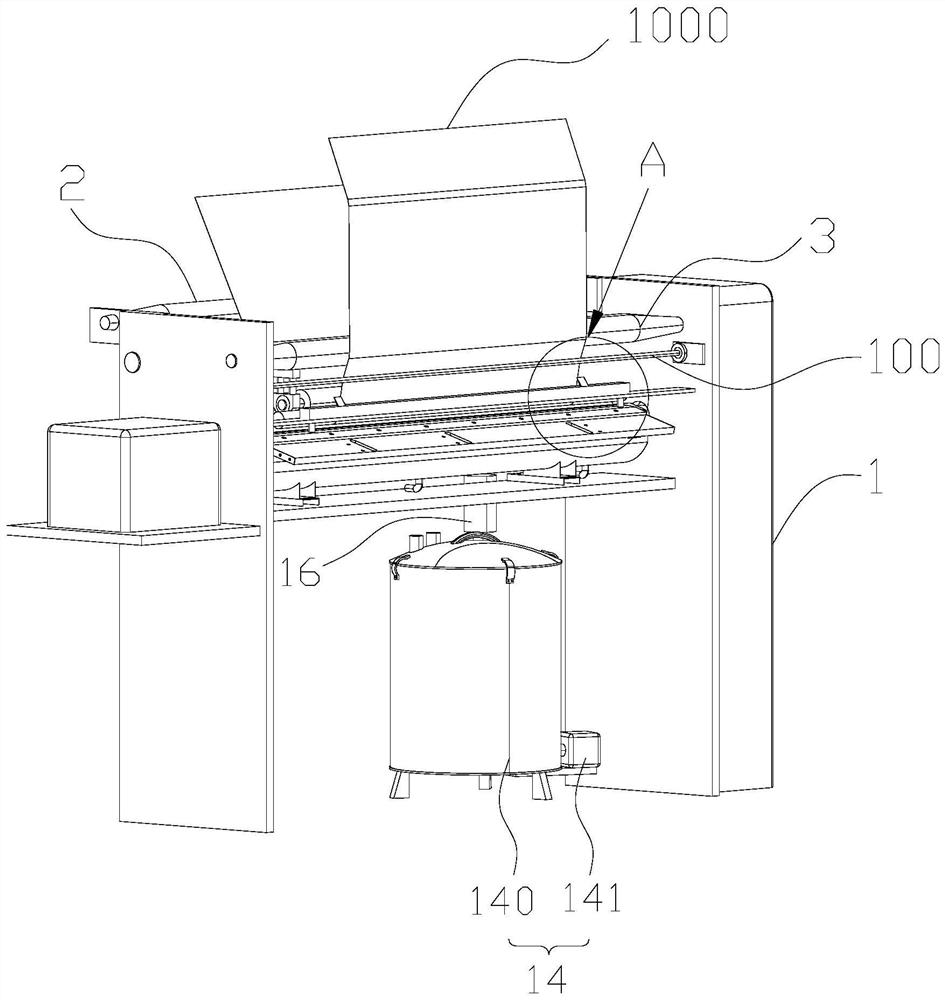

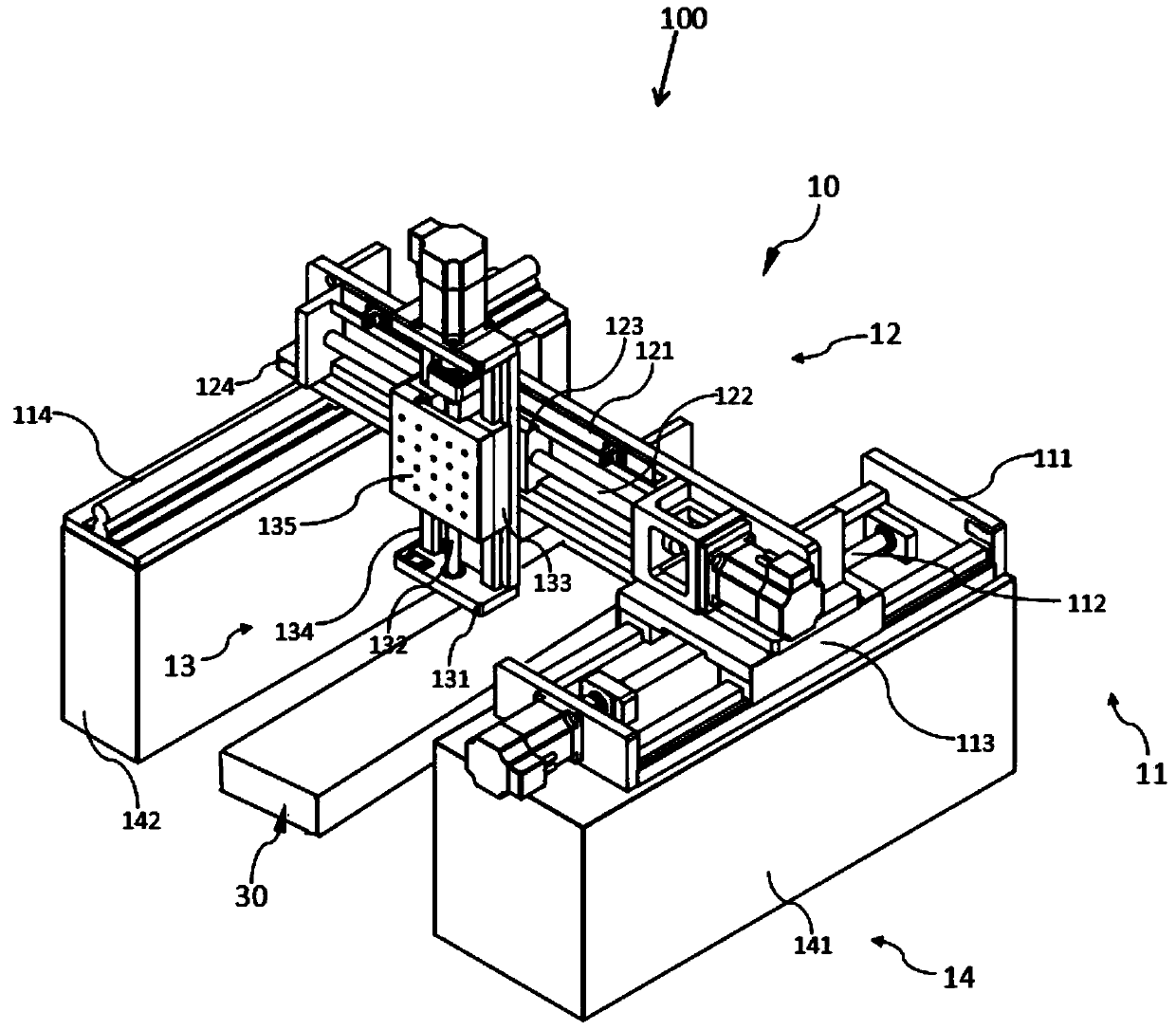

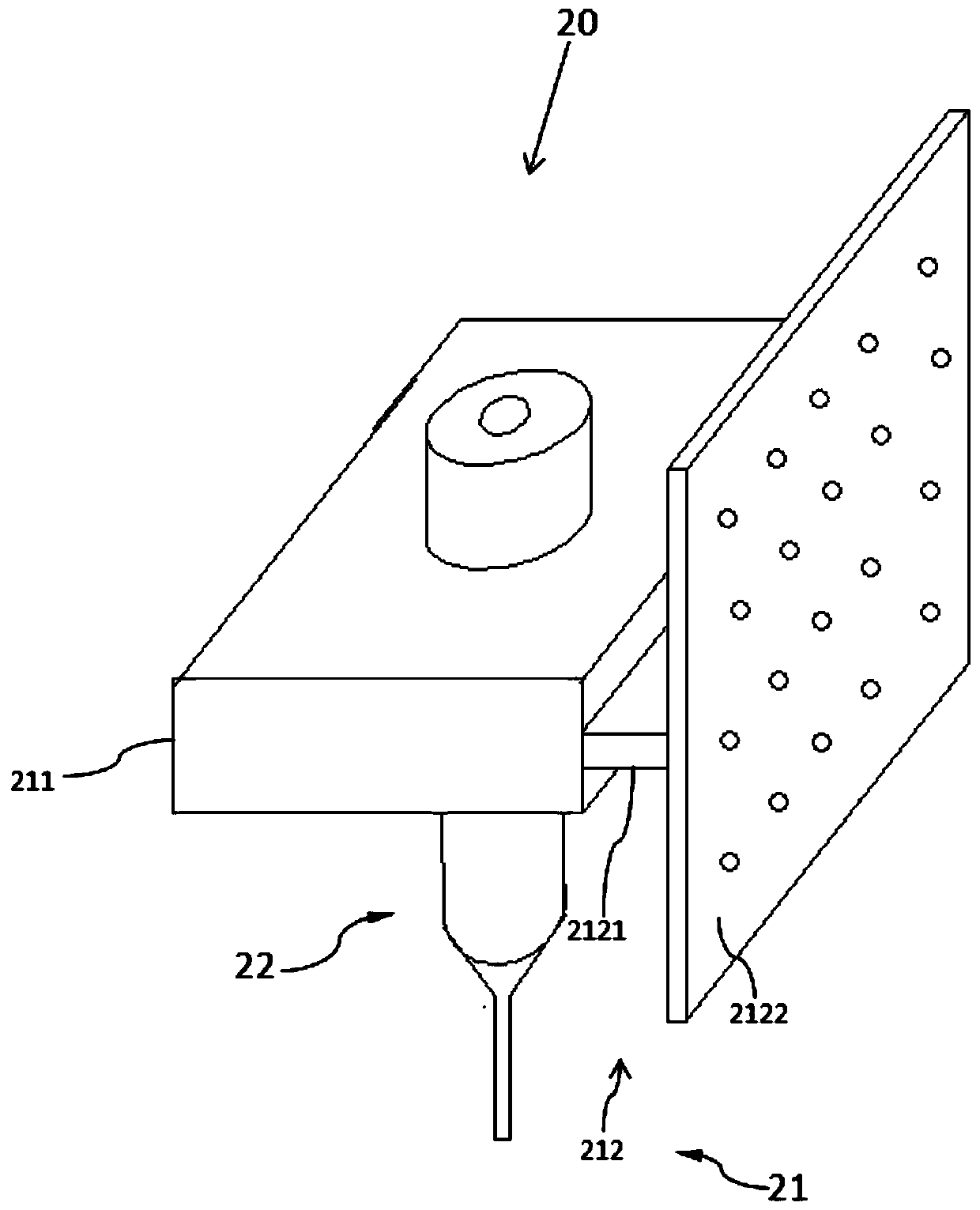

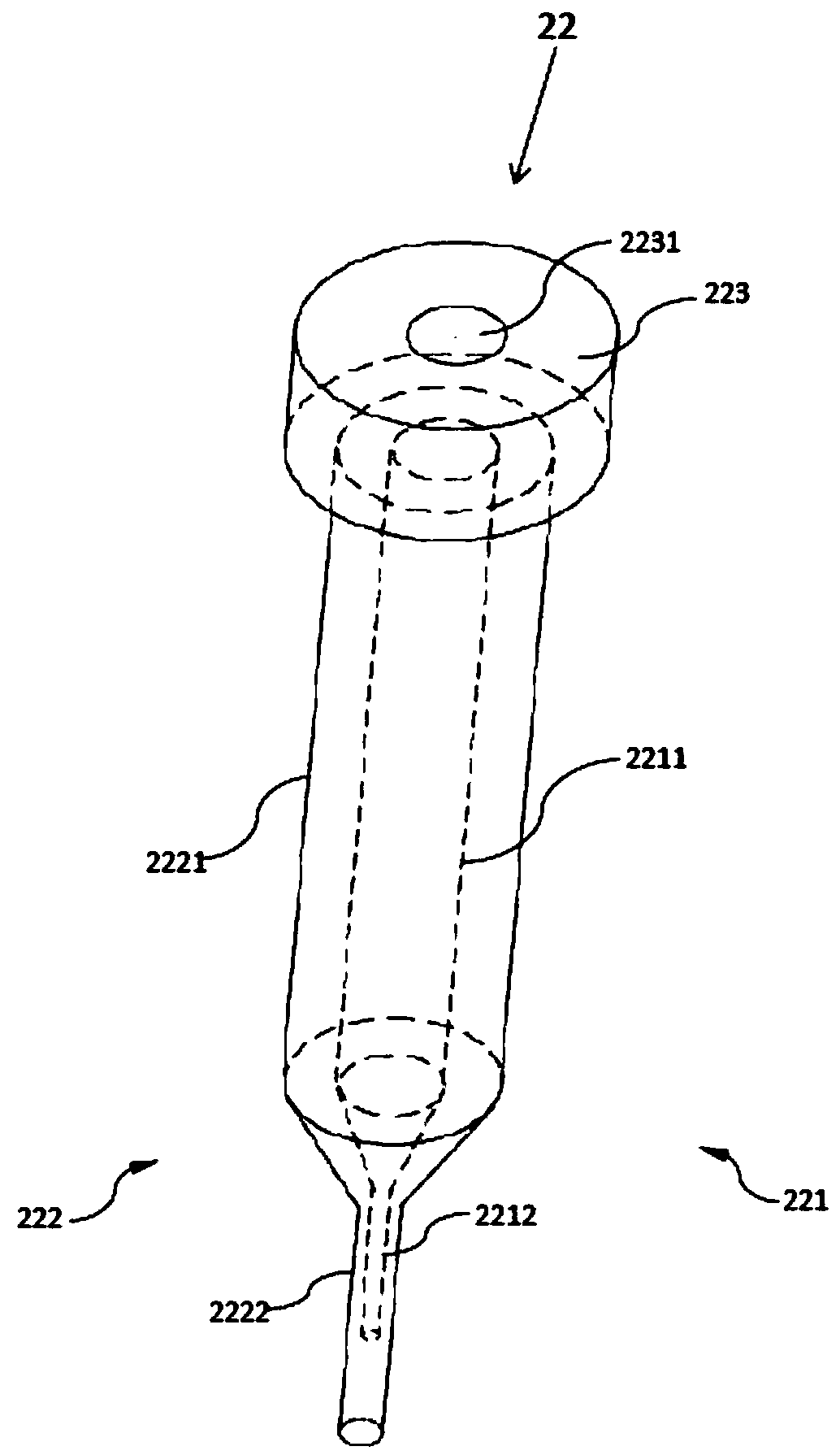

Skin in-situ printing equipment

PendingCN110870804AGood spreadabilityEasy to adjust speedSkin implantsOperating tablesCross linkerPower apparatus

The invention provides skin in-situ printing equipment, which is used for coating biological glue and a cross-linking agent on a preset part of a patient, and is characterized by comprising a platformdevice, a printing head device, a coating power device, a three-axis moving device and a control device, wherein the platform device is used for bearing and transporting a patient; the printing headdevice is used for coating biological glue and a cross-linking agent on a preset part and is provided with a support unit and a sprayer unit arranged on the support unit; the coating power device is used for extruding the biological glue and the cross-linking agent out of the sprayer unit during coating; the three-axis moving device is used for driving the printing head device to move to the preset part; the control device is used for controlling the above devices; the sprayer unit is provided with a first sprayer assembly comprising a first barrel and a first needle head, and a second sprayerassembly comprising a second barrel and a second needle head; the second barrel and the second needle head surround the first barrel and the first needle head respectively and are provided with a first gap and a second gap; the first gap is communicated with the second gap; and the lower end of the second needle head is lower than the lower end of the first needle head.

Owner:上海叁钛生物科技有限公司

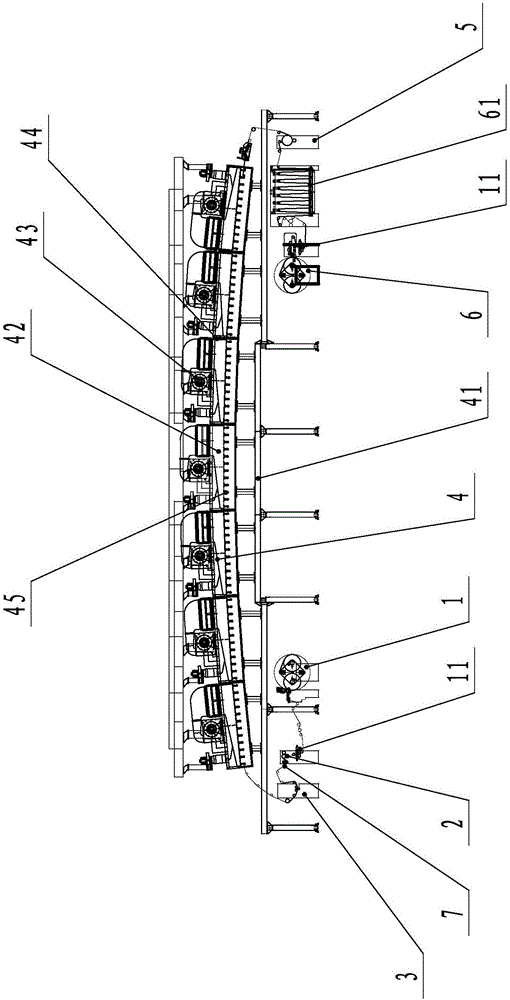

Coating production line for release films

InactiveCN106000786AReduce wind resistanceShorten the film lengthPretreated surfacesCoatingsProduction lineBiochemical engineering

The invention discloses a coating production line for release films. The coating production line comprises an unrolling unit, a corona unit, a feeding traction unit, a coating unit, a heating system, a cooling traction unit and a rolling unit, wherein the unrolling unit, the corona unit, the feeding traction unit, the coating unit, the heating system, the cooling traction unit and the rolling unit are sequentially connected; the heating system is provided with a machine frame, and a plurality of drying ovens are installed on the machine frame and are provided with fans; the unrolling unit, the corona unit, the feeding traction unit, the coating unit, the cooling traction unit and the rolling unit are arranged below the machine frame, and the unrolling unit and the rolling unit are provided with dust removal devices. According to the coating production line, the film moving length is reduced, the film moving path is simpler, the distance from moving films to the ground is increased, and the surface cleanliness of base material is high; the machine frame is separated from the coating unit, the feeding traction unit and the cooling traction unit through wallboards, and vibration of the machine frame is prevented from causing adverse effect on the units. The coating production line has the advantages that the film moving length is small, the coating accuracy is high, the product quality is high and the practicality is high.

Owner:ZHONGSHAN SONGDE NEW MATERIAL EQUIP CO LTD

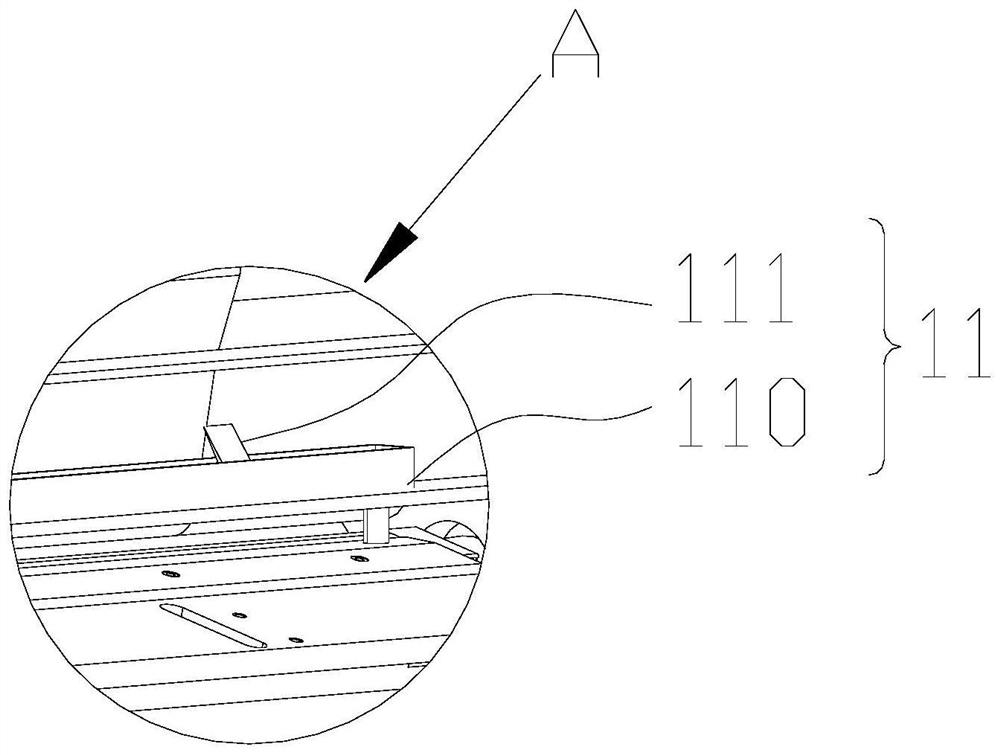

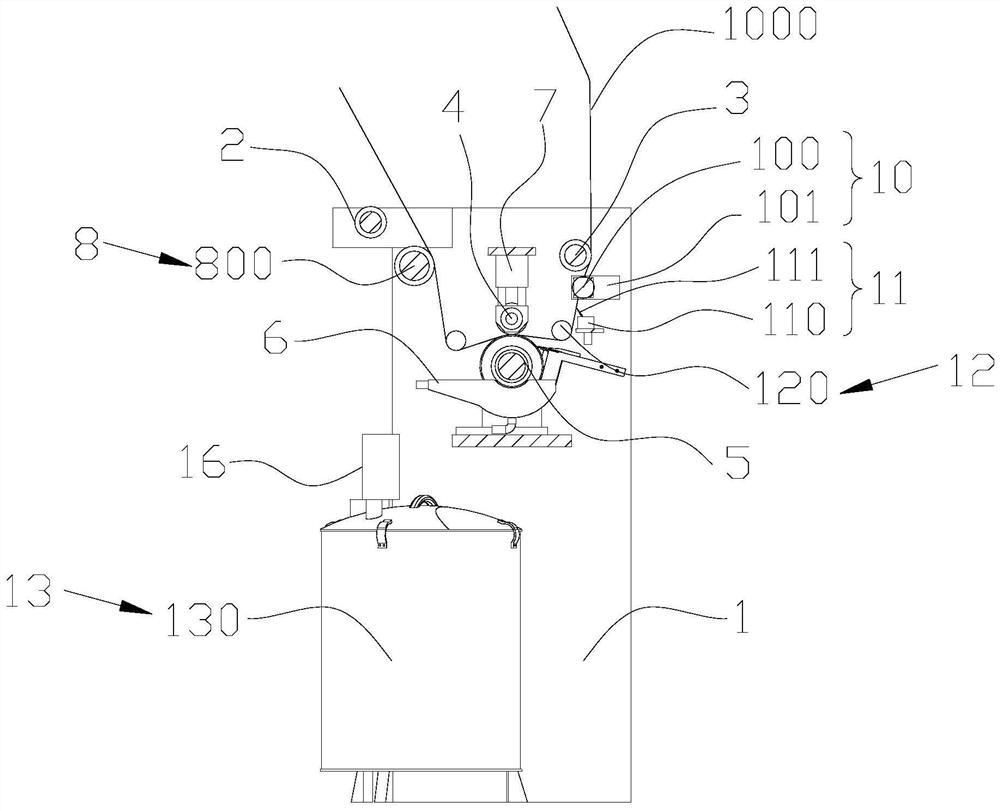

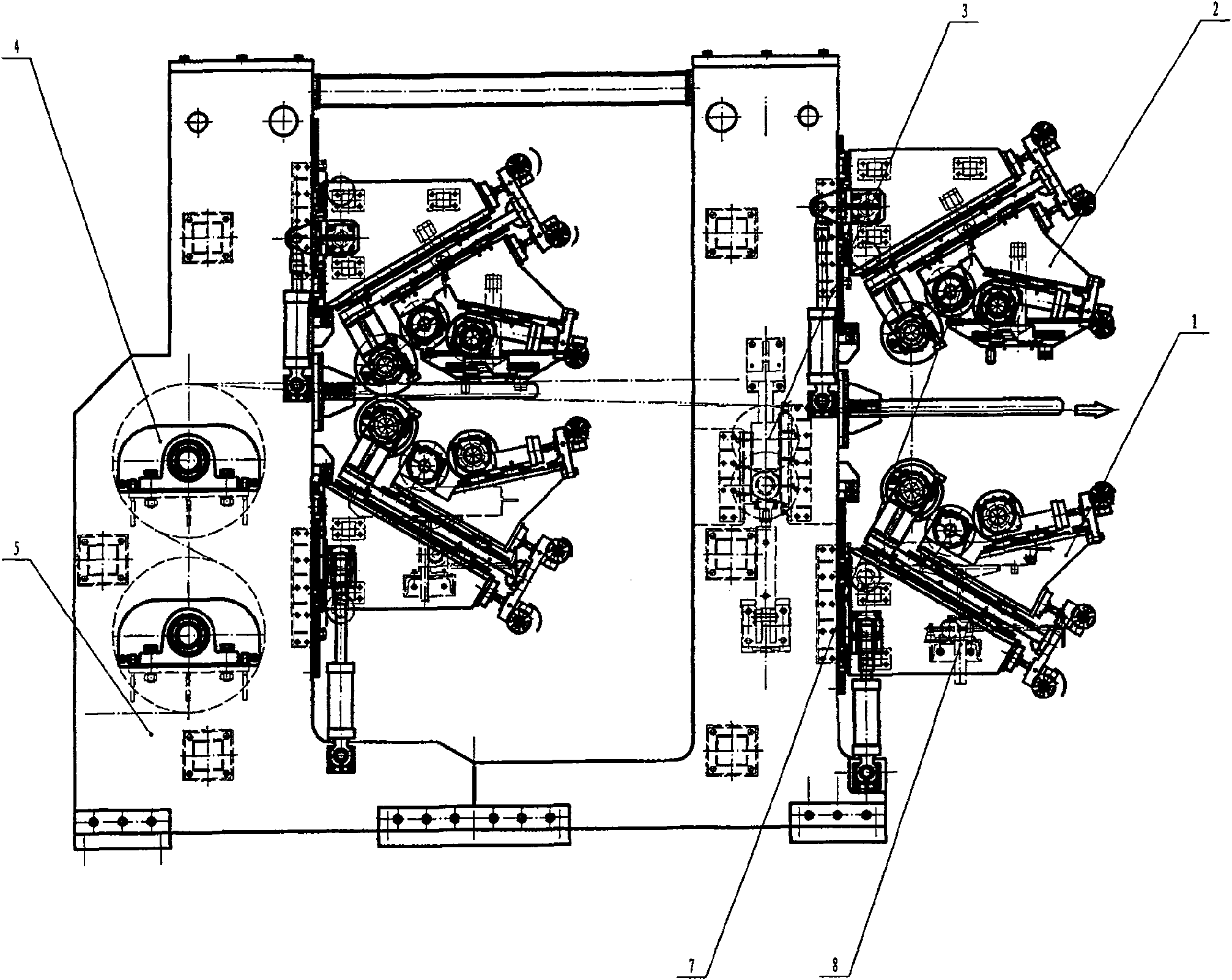

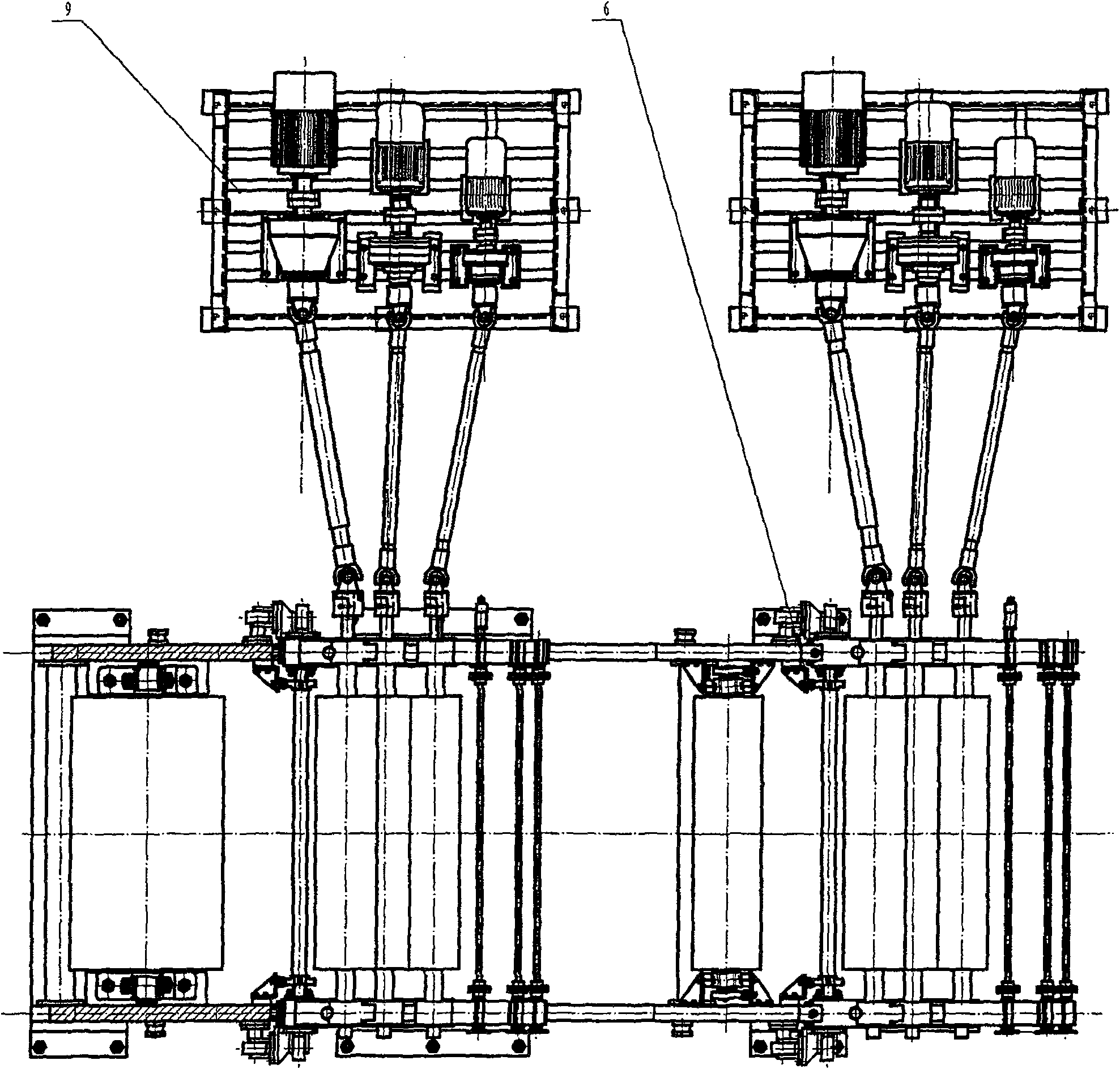

A stringer for semiconductor cell processing

ActiveCN111940864BImprove identityConvenience to maintain identityFinal product manufactureMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of semiconductor processing equipment, and discloses a stringer for processing semiconductor cells, comprising a stringer body and a conveyor belt for transporting materials. The stringer body is connected with a nozzle through a manipulator. The air pressure is used to control the open state of the cut-off airbag and the blocked airbag. Its expansion and contraction will not be affected by external solutions. After a long time of use, its resistance will basically not change, and the response time of its opening and closing is relatively constant. , it is convenient to maintain the identity of opening or closing of multiple nozzles. On the other hand, when the sealing air bag moves upward, it will scrape off the residual flux on the inner wall, avoid exposure to air, and form crystals under the influence of high temperature to ensure the inner wall of the nozzle cavity. Clean, secondly, when the nozzle is closed, because the cut-off air bag cuts off the flux injection pressure at the upper end, and at the same time forms a negative pressure under the pressure plate, the pressure on the air bag is less and it is easier to seal.

Owner:九天智能科技(宁夏)有限公司

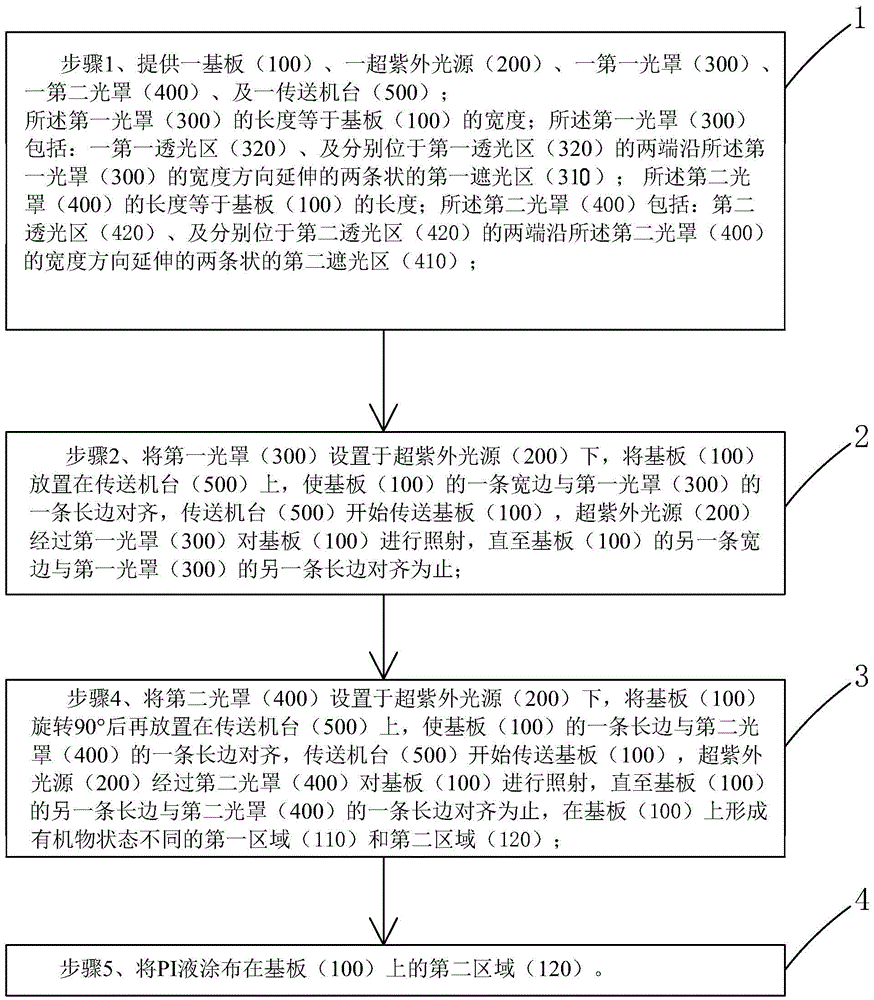

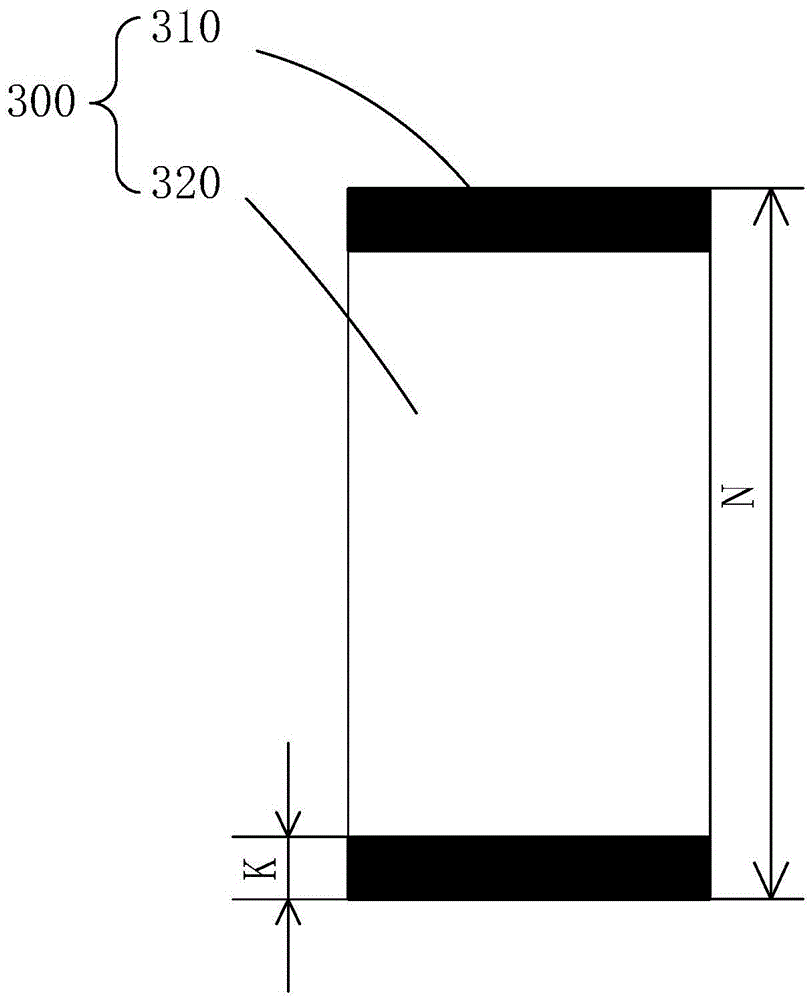

PI liquid coating method

The invention provides a PI liquid coating method. A first light cover and a second light cover are adopted, wherein the length of the first light cover and the length of the second light cover are equal to the width and length of a substrate respectively. A first shading area and a second shading area are arranged on the wide edge of the first light cover and the wide edge of the second light cover, wherein the width of the first shading area and the width of the second shading area are equal to the width of frame adhesives. After irradiating the substrate through the first light cover for the first time, an ultraviolet light source is rotated by 90 degrees and irradiates the substrate through the second light cover for the second time; a second area located on the substrate is irradiated by ultraviolet light twice, and therefore the concentration of organic matter is low. A first area is irradiated less than two times, the concentration of organic matter is high, PI liquid is not dispersed to the first area from the second area easily, the precision of PI liquid coating is controlled, the quality of an alignment film is improved, and defects of products are reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

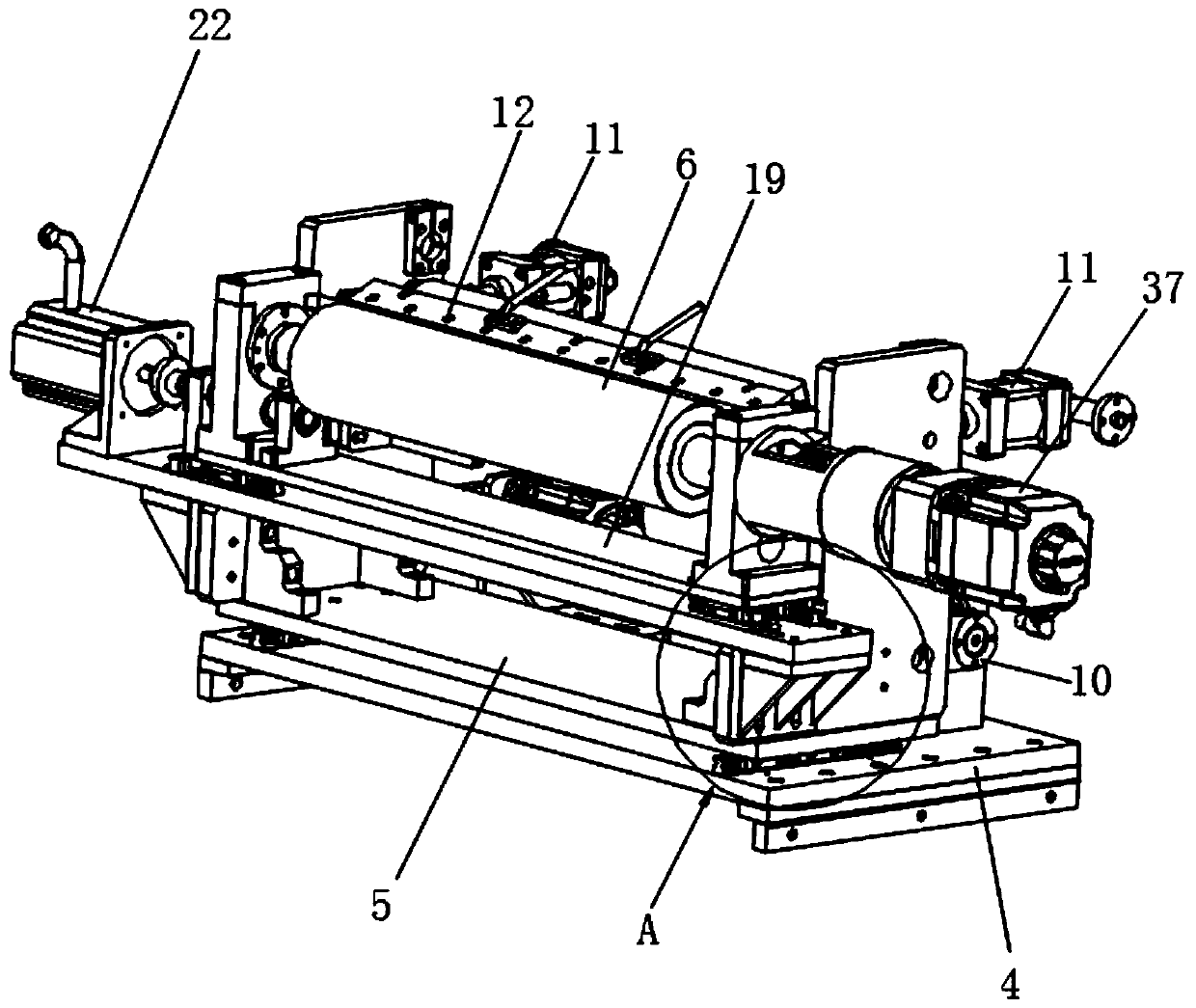

Coating device and coating machine

PendingCN111744721AHigh precisionImprove coating accuracyLiquid surface applicatorsSpraying apparatusMechanical engineeringCoating

The invention relates to the technical field of coating, in particular to a coating device and a coating machine. The coating device comprises a rack, a coating roller component which is arranged on the rack, a rubber roller component which is arranged on the rack and located below the coating roller component, an adjusting component which is arranged on the rack and used for adjusting the liftingof the rubber roller component, a first driving component which is arranged on the rack and in driving connection with the coating roller component, and a second driving component which is arranged on the rack and used for driving the rubber roller component, wherein the transmission speed ratio of the coating roller component is faster than the transmission speed of the rubber roller component,and the transmission directions of the coating roller component and the rubber roller component are opposite; an upper roller structure and a lower roller structure are adopted to coat a product, thereverse speed ratio transmission is adopted, the coating process is stable and reliable, and the coating precision is high. Moreover, the adjusting component is used for adjusting the lower roller structure, and products with different thickness sizes can be adapted.

Owner:HITEK POLYMER MATERIAL

Method for simultaneously coating and measuring parts

InactiveUS7537797B2Improve coating accuracyImprove coating efficiencyElectric discharge heatingSpraying apparatusContinuous measurementSprayer

A method and apparatus for simultaneously coating and measuring a part. The apparatus includes a part support, a sprayer and a part measurer positioned adjacent to the part support and a display device positioned adjacent to the part support. The sprayer applies a coating to a section of the part while the part measurer continuously measures a dimension of the section of the part being coated. In one embodiment, an initial amount of coating and a final amount of coating are applied to the section of the part based on the dimension measurements and desired dimension of the part. In another embodiment, the amount of coating applied to the part is based on the desired coating thickness. As a result, the apparatus and method of the present invention significantly reduces the margin of error related to the application of coatings to parts.

Owner:DIMENSION BOND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com