PI liquid coating method

A coating method and substrate technology, applied in optics, instruments, nonlinear optics, etc., can solve problems affecting product quality, easy to spread unevenly, and PI liquid diffusion exceeds, etc., to reduce product defects and evenly distribute PI liquid , Improve the effect of film forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

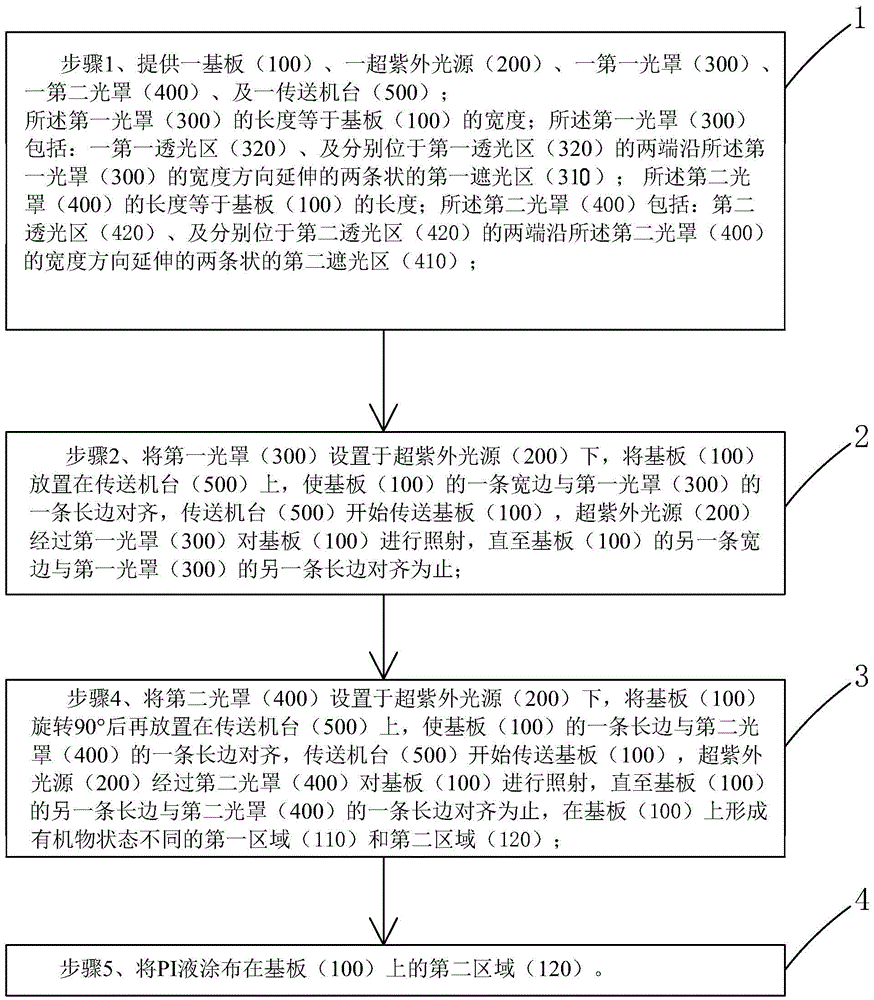

[0037] see figure 1 , the invention provides a kind of PI liquid coating method, comprises the following steps:

[0038] Step 1. Please refer to Figure 4 , and combined with figure 2 and image 3 , providing a substrate 100 , an ultra-ultraviolet light source 200 , a first mask 300 , a second mask 400 , and a transfer machine 500 .

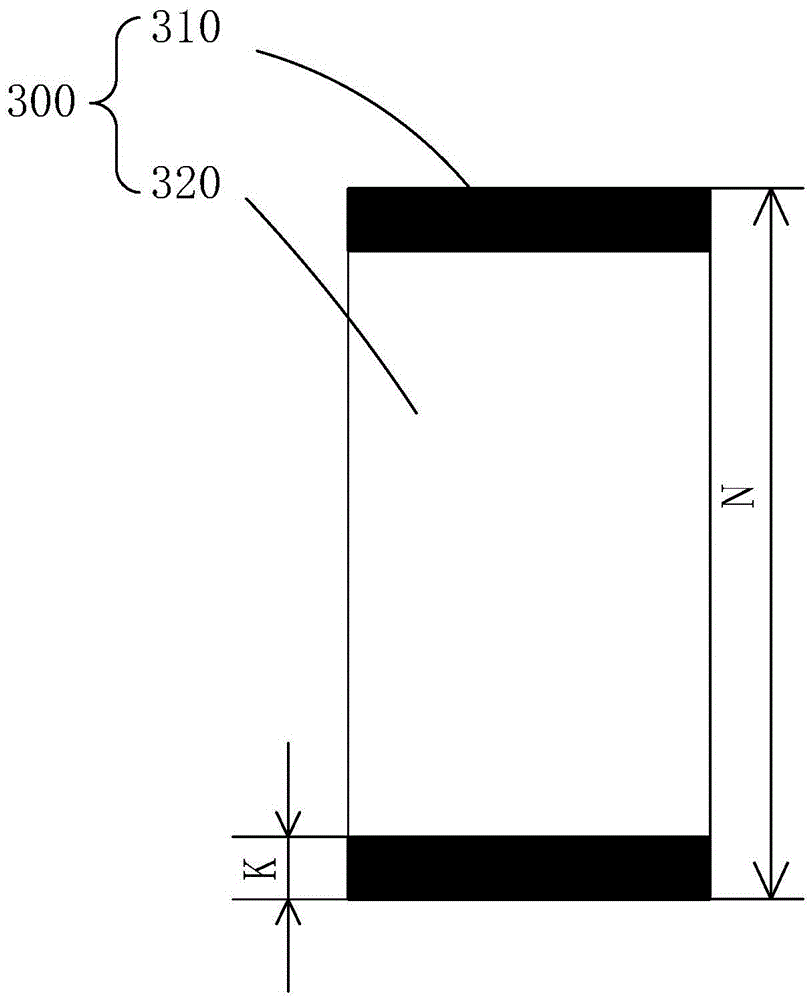

[0039] The length of the first mask 300 is equal to the width of the substrate 100;

[0040] The first photomask 300 includes: a first light-transmitting region 320 , and two first light-shielding regions respectively located at both ends of the first light-transmitting region 320 and extending along the width direction of the first photomask 300 310.

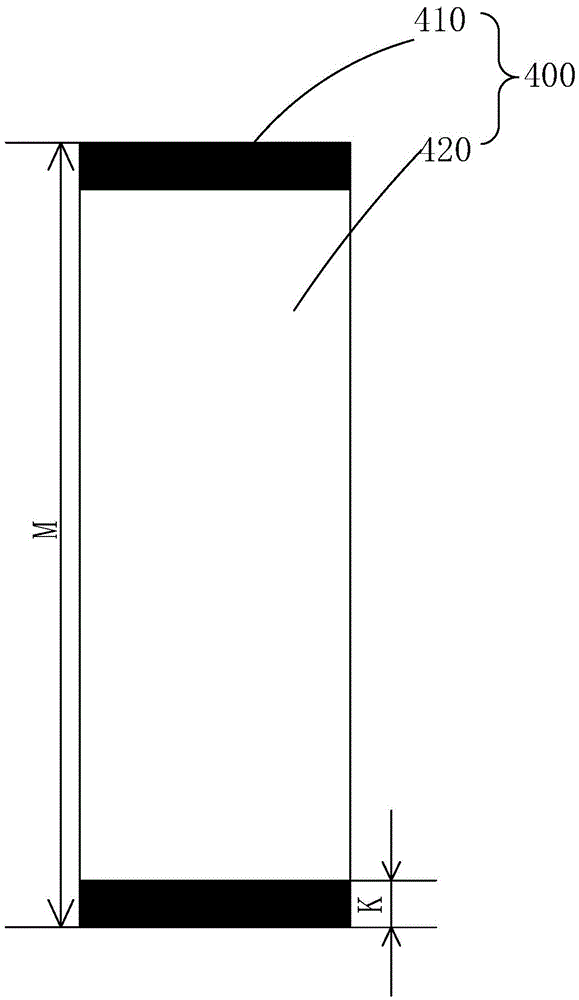

[0041] The length of the second mask 400 is equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com