Method for batch-coating epoxy resin on corner insulation box of LNG (Liquefied Natural Gas) ship liquid cargo tank

A technology of epoxy resin and LNG ship, which is applied to the device and coating of the surface coating liquid, which can solve the problems of instability, time-consuming and labor-intensive coating accuracy, etc., and achieve easy mastery, reduce labor intensity, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

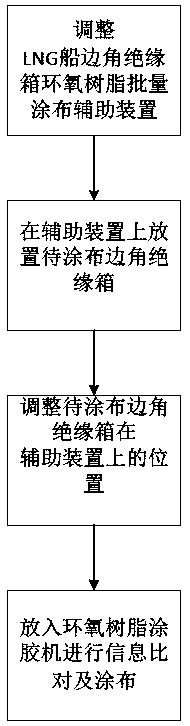

[0047] Embodiment: a kind of method of epoxy resin batch coating of LNG cargo tank corner insulation box, such as figure 1 shown, including the following steps:

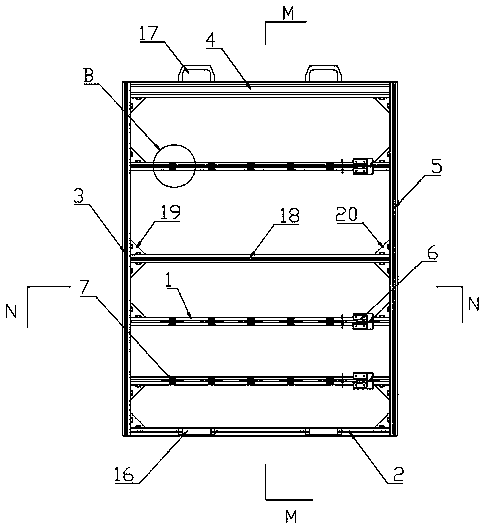

[0048] Step 1. Loosen the first locking bolt and the second locking bolt of the epoxy resin batch coating auxiliary device of the corner insulation box of the LNG ship, and adjust the sliding beam 1 on the left frame rod according to the size of the corner insulation box to be coated 3 and the position on the right frame rod 5, so that the sliding beam 1 is parallel to the front frame rod 2, fasten the first locking bolt and the second locking bolt;

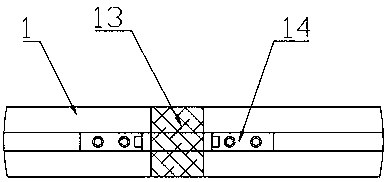

[0049] Step 2, according to the number of barrier mechanisms 7 on each sliding beam 1 in the LNG ship corner insulating box epoxy resin batch coating auxiliary device, determine the number of corner insulating boxes to be coated placed on the sliding beam 1 quantity, and place the corner insulation box to be coated on the auxiliary device. The left side of the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com