Encapsulation method for dye sensitization solar cell

A technology of solar cells and encapsulation methods, which is applied in the fields of capacitor casing/encapsulation, photovoltaic power generation, electrical components, etc., can solve the problems of poor encapsulation effect and strong corrosion of encapsulation materials, and achieve shorten encapsulation time, strong adhesive performance, The effect of high coating accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

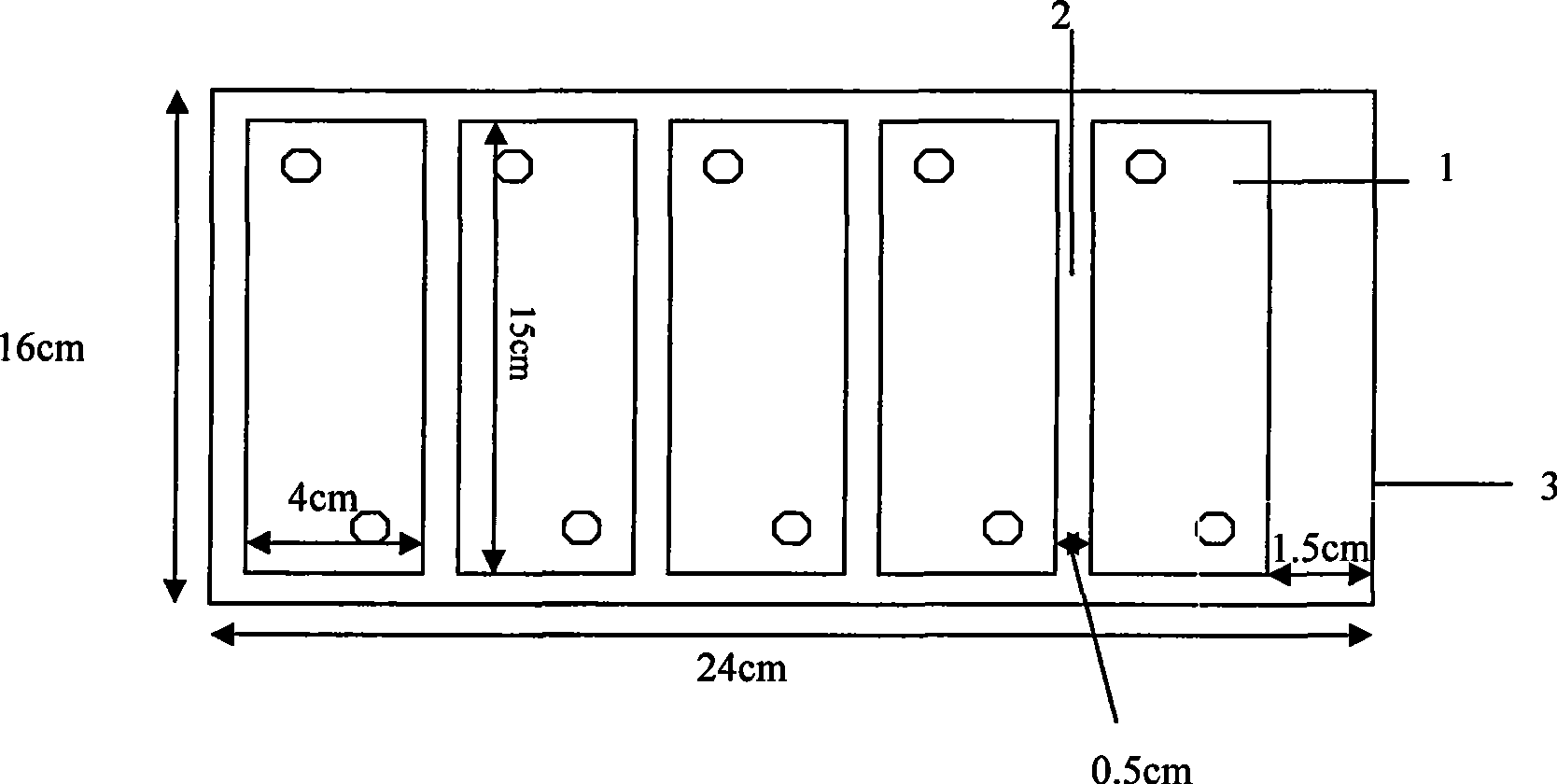

[0022] 1) First, on the FTO conductive glass that will be used as the platinum electrode substrate, a through hole is made perpendicular to the glass surface, and the hole diameter of the through hole is 1mm, so that the electrolyte can be poured after the battery is packaged;

[0023] 2) Use a 300-mesh screen to print titanium dioxide on the FTO conductive glass for making the photoanode to make a rectangular sheet film, the thickness is generally controlled at about 25 microns, and leave a gap of 5 mm between each titanium dioxide sheet film;

[0024] 3) Sinter the printed titanium dioxide flake film from room temperature to 450°C, and control the heating rate at 5°C / min, and keep it at 450°C for 30 minutes, and then let it naturally and slowly cool down to room temperature. Sintering is completed at room temperature;

[0025] After the sintering is completed, the titanium dioxide flake film is taken out and soaked in N3 dye for 18 hours.

[0026] 4) Use screen printing tec...

Embodiment 2

[0030] 1) First, on the FTO conductive glass that will be used as the platinum electrode substrate, a through hole is made perpendicular to the glass surface, and the hole diameter of the through hole is 1.5 mm, so that the electrolyte can be poured after the battery is packaged;

[0031] 2) Use screen printing technology (screen selection 300 mesh) to print titanium dioxide on the FTO conductive glass for making photoanodes. The titanium dioxide is printed into several rectangular sheet films and pasted on the FTO conductive glass. The thickness is controlled at About 25 microns, leave a gap with a width of 4mm between each titanium dioxide film to facilitate wiring and packaging;

[0032] 3) Sinter the printed titanium dioxide film, specifically: gradually heat the temperature of the FTO conductive glass printed with titanium dioxide film from room temperature to 450°C in 2.5 hours, and keep this temperature for 40 minutes, and then naturally and slowly lower it to room tempe...

Embodiment 3

[0037] 1) First, on the FTO conductive glass that will be used as the platinum electrode substrate, a through hole is made perpendicular to the glass surface, and the hole diameter of the through hole is 0.5mm, so that the electrolyte can be poured after the battery is packaged;

[0038] 2) Use screen printing technology to print titanium dioxide on the FTO conductive glass for making photoanodes, wherein the screen selection is 300 mesh, and the titanium dioxide is printed into several rectangular sheet films and pasted on the FTO conductive glass. The thickness of the titanium dioxide film is Control it at about 26 microns, leave a gap with a width of 4mm between each titanium dioxide film to facilitate wiring and packaging;

[0039] 3) Sintering the printed titanium dioxide film, specifically: gradually heating the temperature of the FTO conductive glass printed with the titanium dioxide film from room temperature to 500°C in 2 hours, and maintaining this temperature for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| The peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com