Coating production line for release films

A production line and release film technology, which is applied in the device, coating, pretreatment surface, etc. for coating liquid on the surface, which can solve the problems such as affecting the coating accuracy of the coating head, complex process film routing, affecting product quality, etc. , to achieve the effect of improving the film route, the simple route and shortening the length of the film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

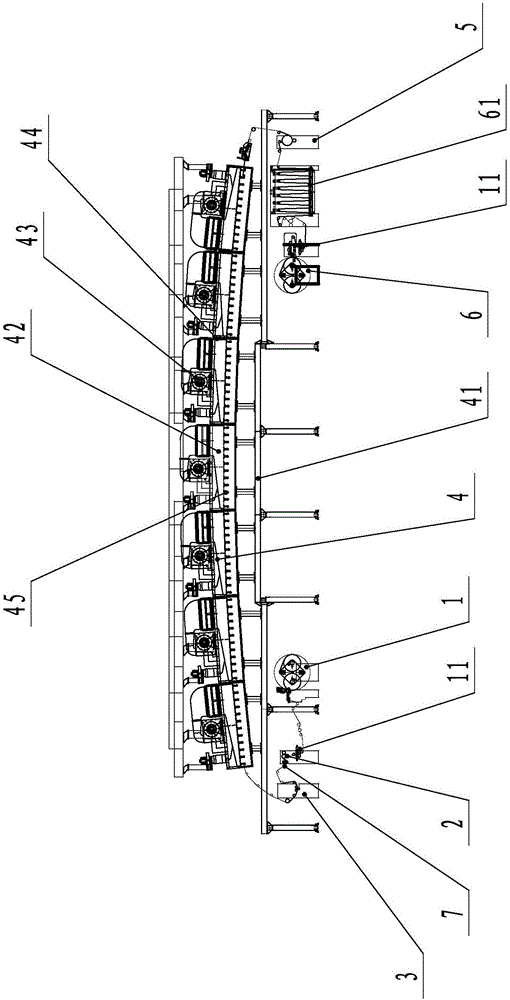

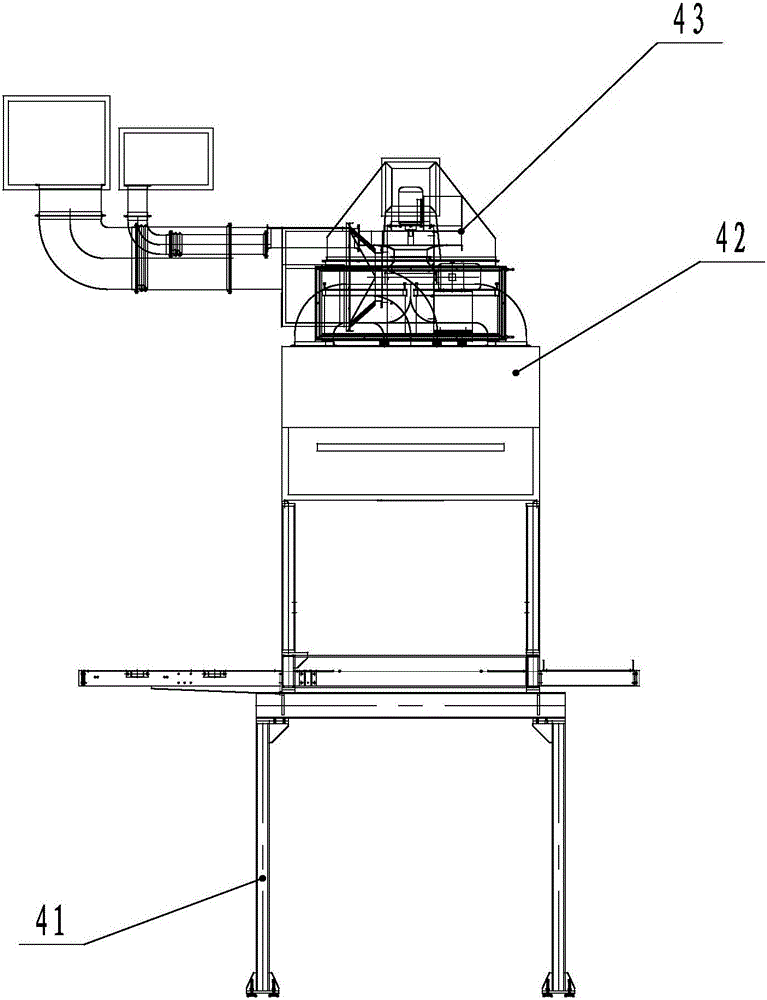

[0015] refer to figure 1 , figure 2 , a release film coating production line, including an unwinding unit 1, a corona unit 2, a feeding traction unit 7, a coating unit 3, a heating system 4, a cooling traction unit 5 and a winding unit 6 connected in sequence, heating The system 4 is provided with a rack 41, and a plurality of ovens 42 are installed above the rack 41, and a fan 43 is installed on the oven 42. By placing the fan 43 directly on the top of the oven 42, the distance to the oven opening is shortened, thereby reducing the air duct. At the same time, the heat source is changed from traditional electric heating and oil heating to natural gas heating, which saves energy and reduces costs; unwinding unit 1, corona unit 2, feeding traction unit 7, coating unit 3, cooling traction unit 5 and The winding units 6 are respectively arranged under the frame 41 , and both the unwinding unit 1 and the winding unit 6 are provided with a dust removal device 11 . A release film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com