Preparation method of curved web surface titanium alloy superplastic forming-diffusion bonding blank

A superplastic forming and diffusion joining technology, applied in welding equipment, metal processing equipment, forming tools, etc., can solve the problems of difficulty in ensuring the accuracy of parts unfolding, scrapping, and difficult to meet the requirements of high-precision coating of solder resist.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

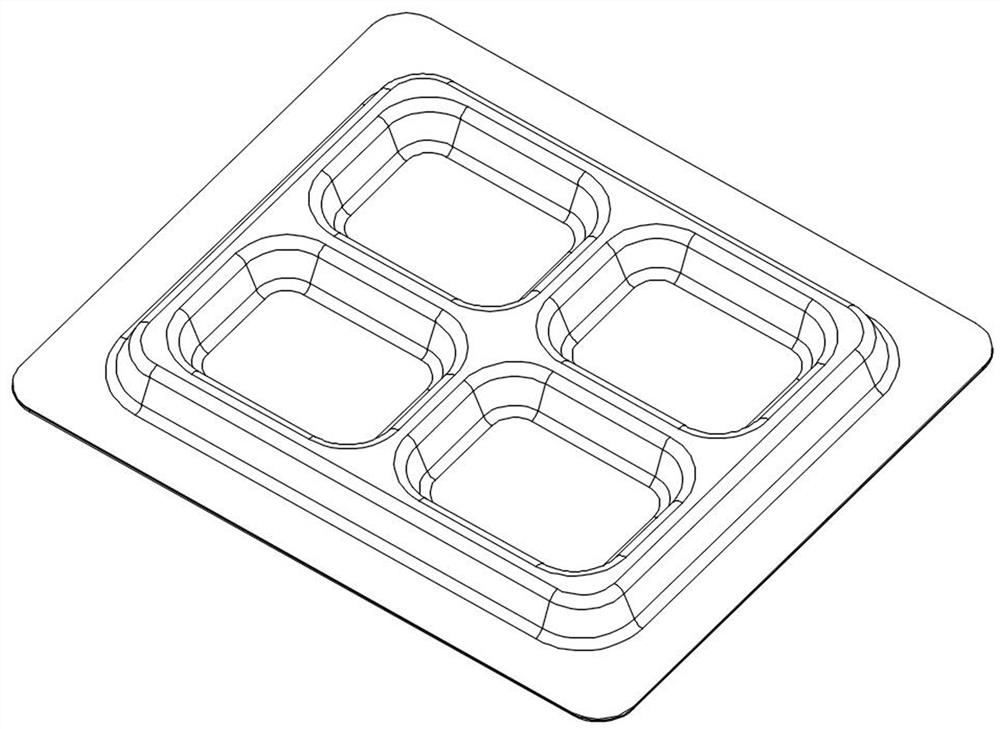

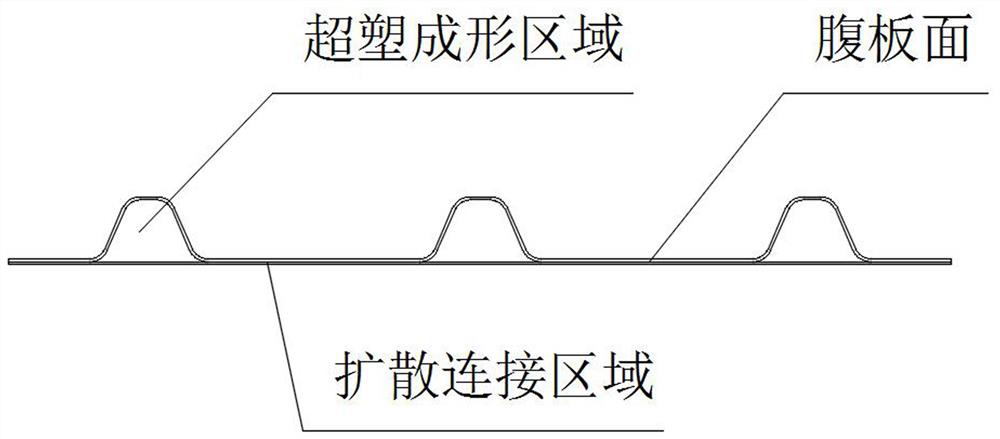

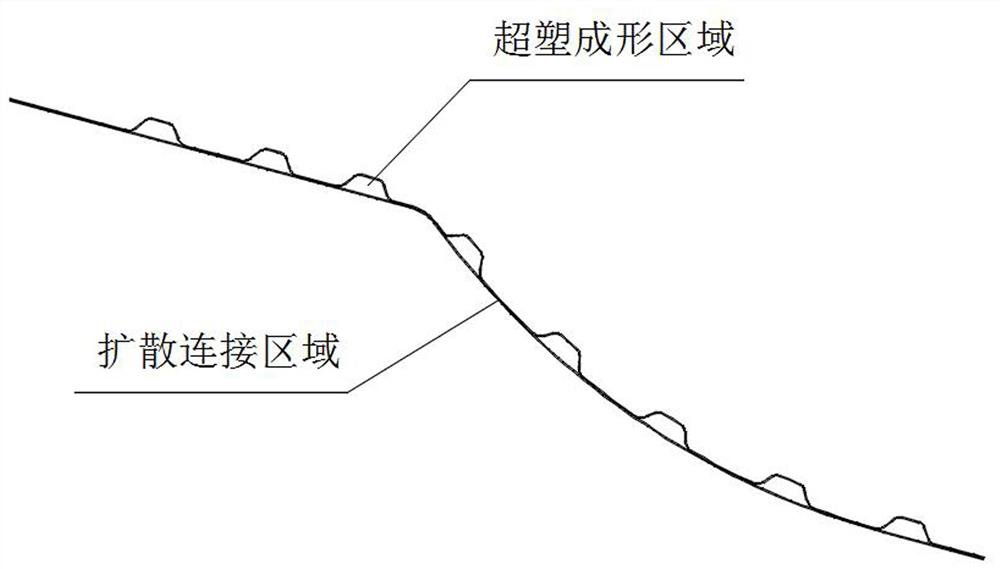

[0052] In this embodiment, the invention solution is described in detail by taking the superplastic forming / diffusion connector of the titanium alloy double-layer plate structure as an example. Titanium alloy parts in this invention scheme, such as image 3 shown, consisting of two layers of curved panels (constructed as Figure 4 , Figure 5 As shown, the curved web surface of sheet Ⅰ is set as a continuous superplastic forming area, and the rest of the area is a diffusion connection area, and the curved web surface of sheet Ⅱ is coordinated with the curved web surface of sheet Ⅰ. During forming, the bonded areas of sheet I and sheet II are bonded together under high temperature and pressure, and the non-laminated surface is attached to the surface of the superplastic forming / diffusion bonding mold under air pressure. The non-fitting area needs to be coated with solder stop flux to prevent the area from being diffused and bonded together during forming.

[0053] 1) Process...

Embodiment 2

[0075] In this embodiment, the titanium alloy multilayer plate structure is taken as an example to prepare the blank. The specific process is as follows: Figure 12 As shown, the preparation method of the multi-layer board blank:

[0076] For superplastic forming / diffusion joints of titanium alloy multilayer plate structure, the solder stop flux coating method is similar to that of superplastic forming / diffusion joints of double layer plate structure. There are (n-1) places on the bonding surface of the n-layer blank, and one set of hot pressing die pre-forming and (n-1) sets of scribing templates are required for solder stop flux coating on the bonding surface. The billet preparation process is as follows:

[0077] S1 The required titanium alloy n-layer flat blanks are hot-pressed separately to form the curved surface shape of the margin surface shown in the process model, and the parts are cleaned after forming.

[0078] S2 Adhesive film is integrally coated on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com