Roller coater

A roll coater and coating technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problem that the coating head cannot be maintained online and change colors, etc., and achieve manpower saving, high automation level, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

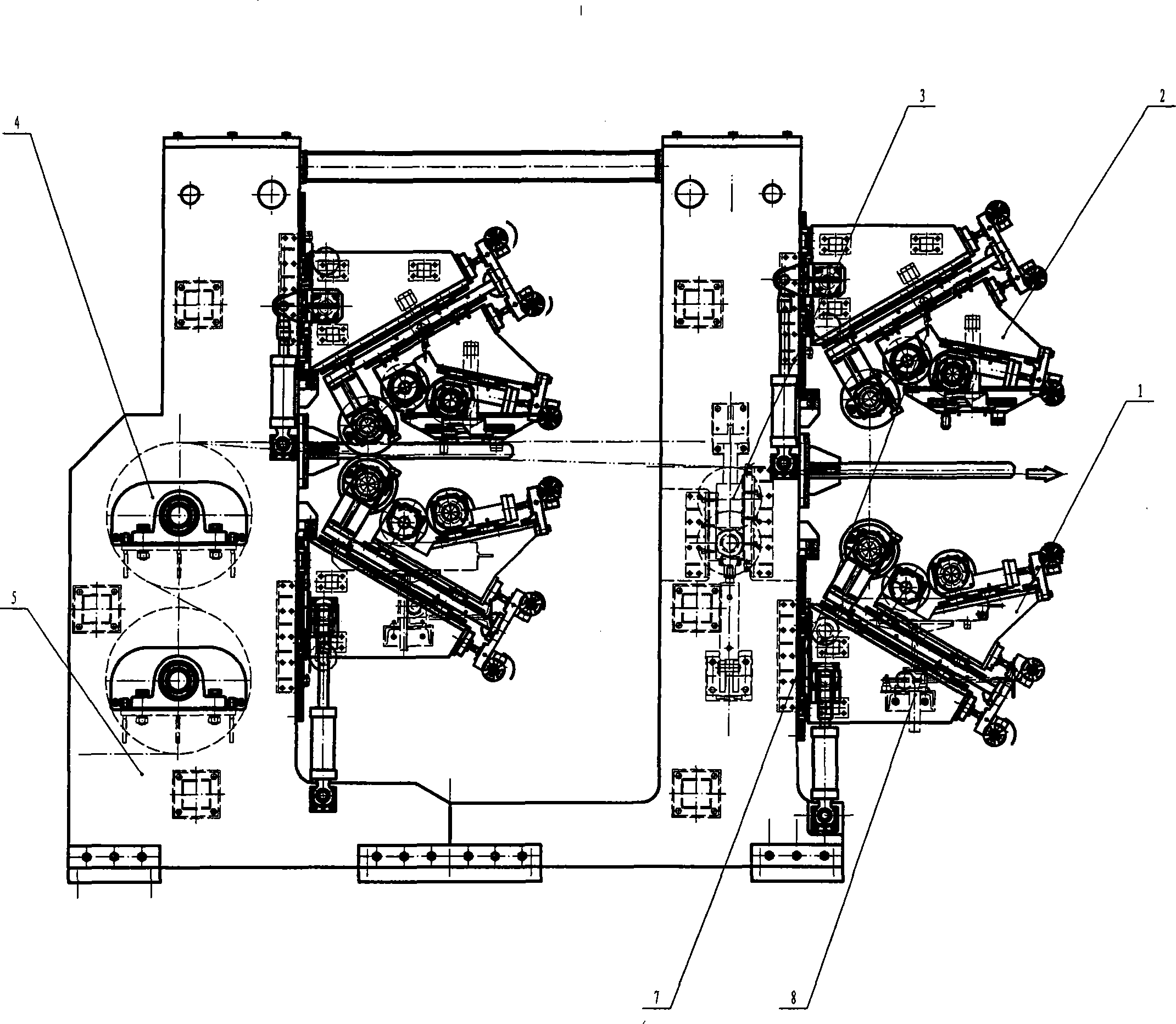

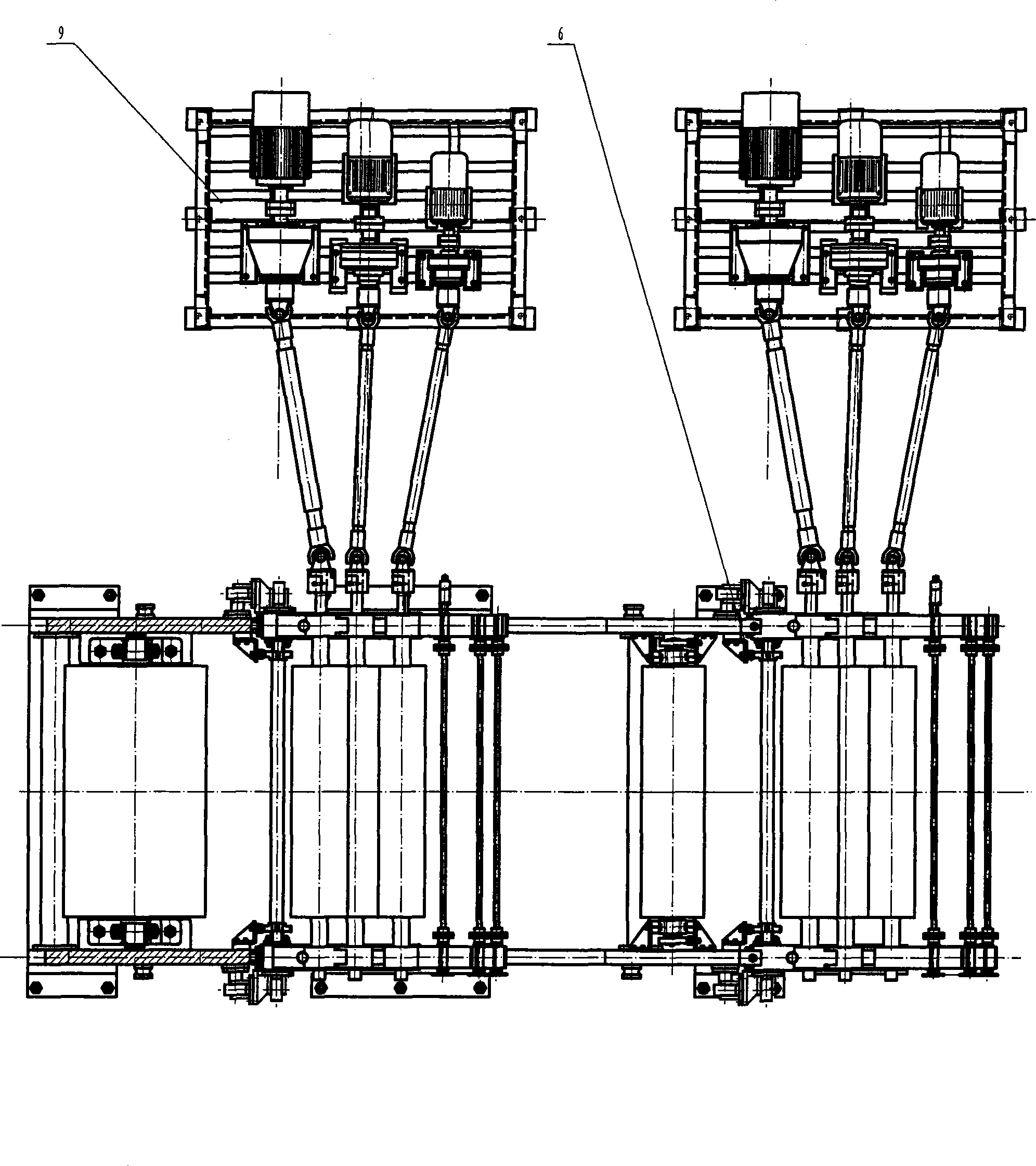

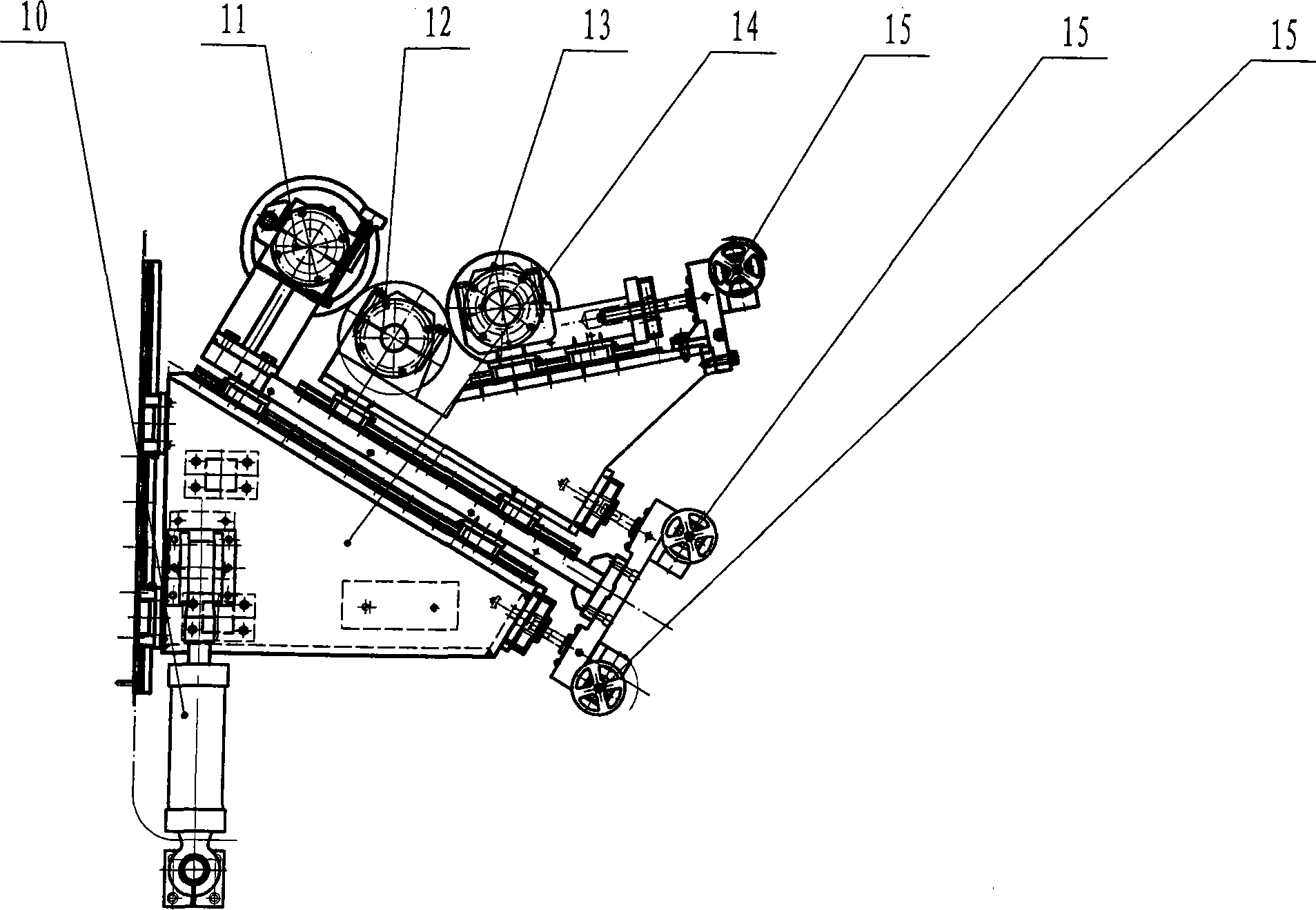

[0018] Including the electrical control system, the equipment consists of two sets of top-to-top arrangement of back coating mechanism 1, front coating mechanism 2, support mechanism 3, steering roller assembly 4, frame 5, synchronization mechanism 6, spray pipeline 7 , Back-coating lifting device 8, transmission mechanism 9, paint supply system 10. The back coating mechanism 1 is composed of a roller coating roller 11, a take-up roller 12, an adjusting roller 13, a paint pan 17, and an adjusting mechanism 15. The front coating mechanism 2 has the same structure as the back coating mechanism 1. Adjust the gap between the adjusting roller 13 of the back coating mechanism 1 and the reclaiming roller 12: shake the hand wheel 26 of the adjusting mechanism 15, and the hand wheel 26 is connected with the dial 27 to drive the worm wheel 28 to rotate. The worm wheel 28 is connected to the wire through the key. The bar 29 is connected to drive the take-up roller 12 to move on the linear gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com