Patents

Literature

33results about How to "Precision control is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

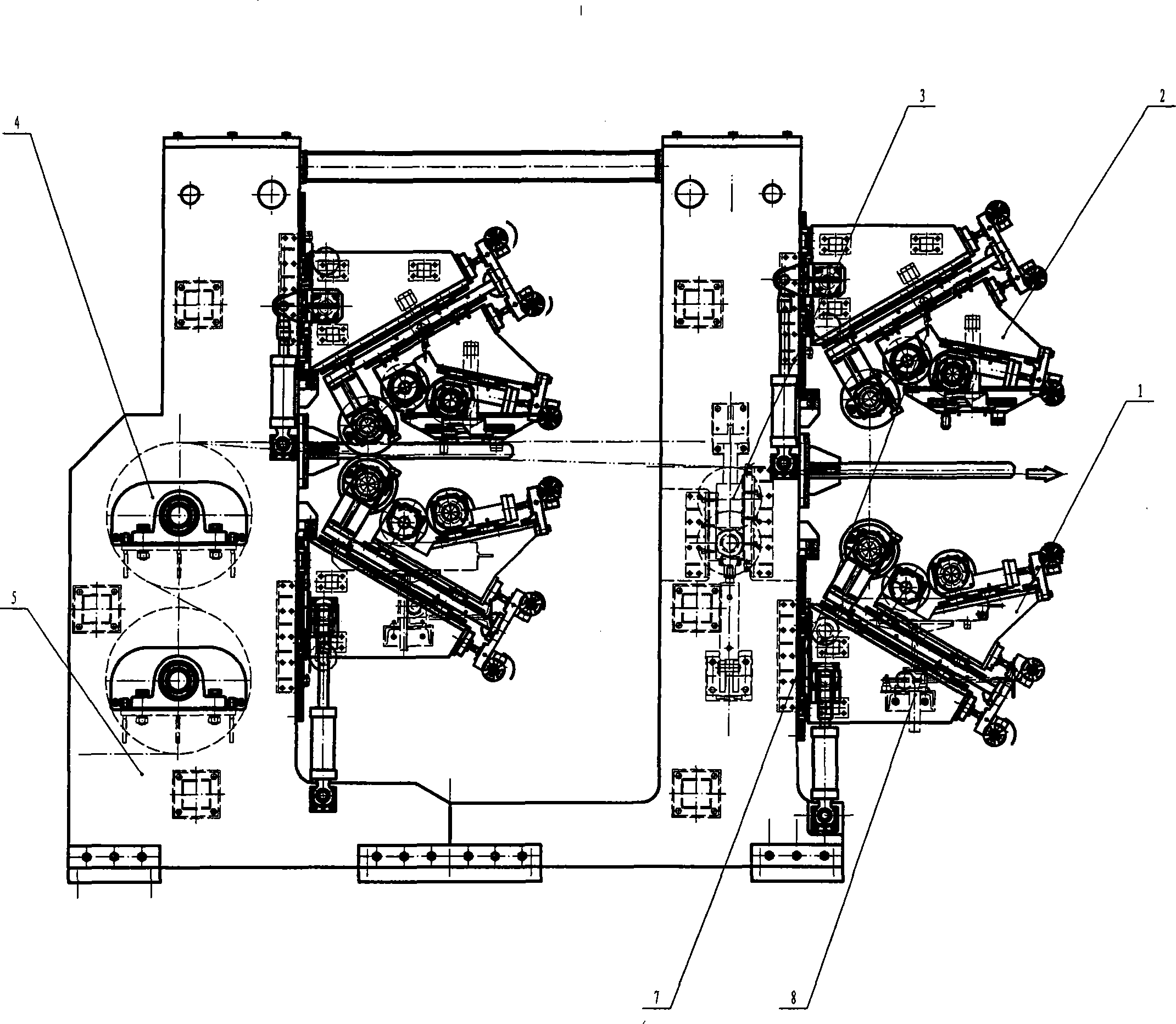

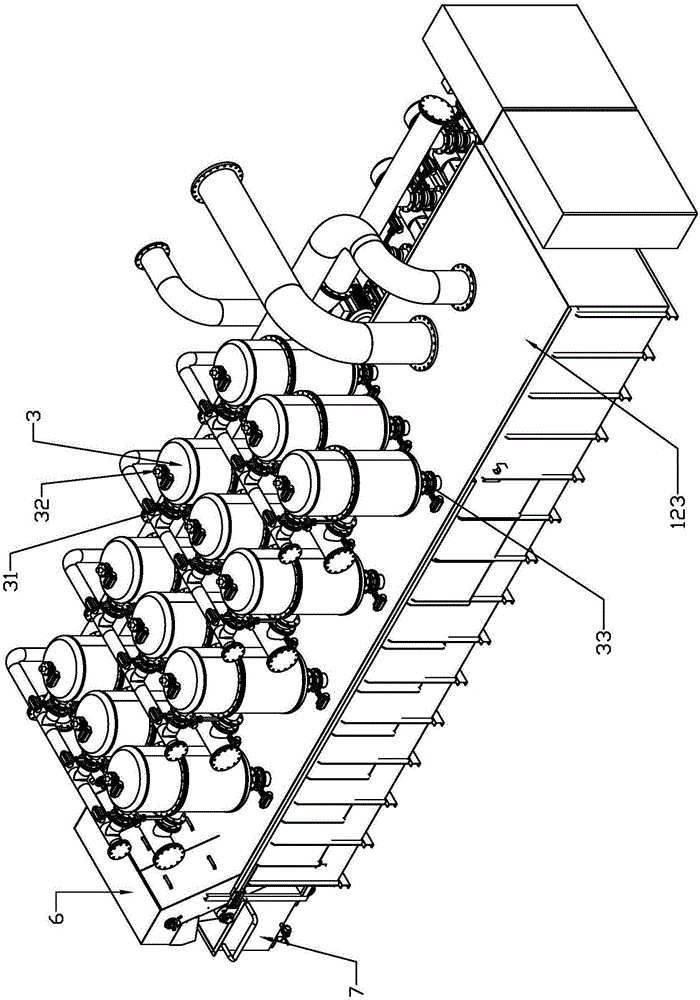

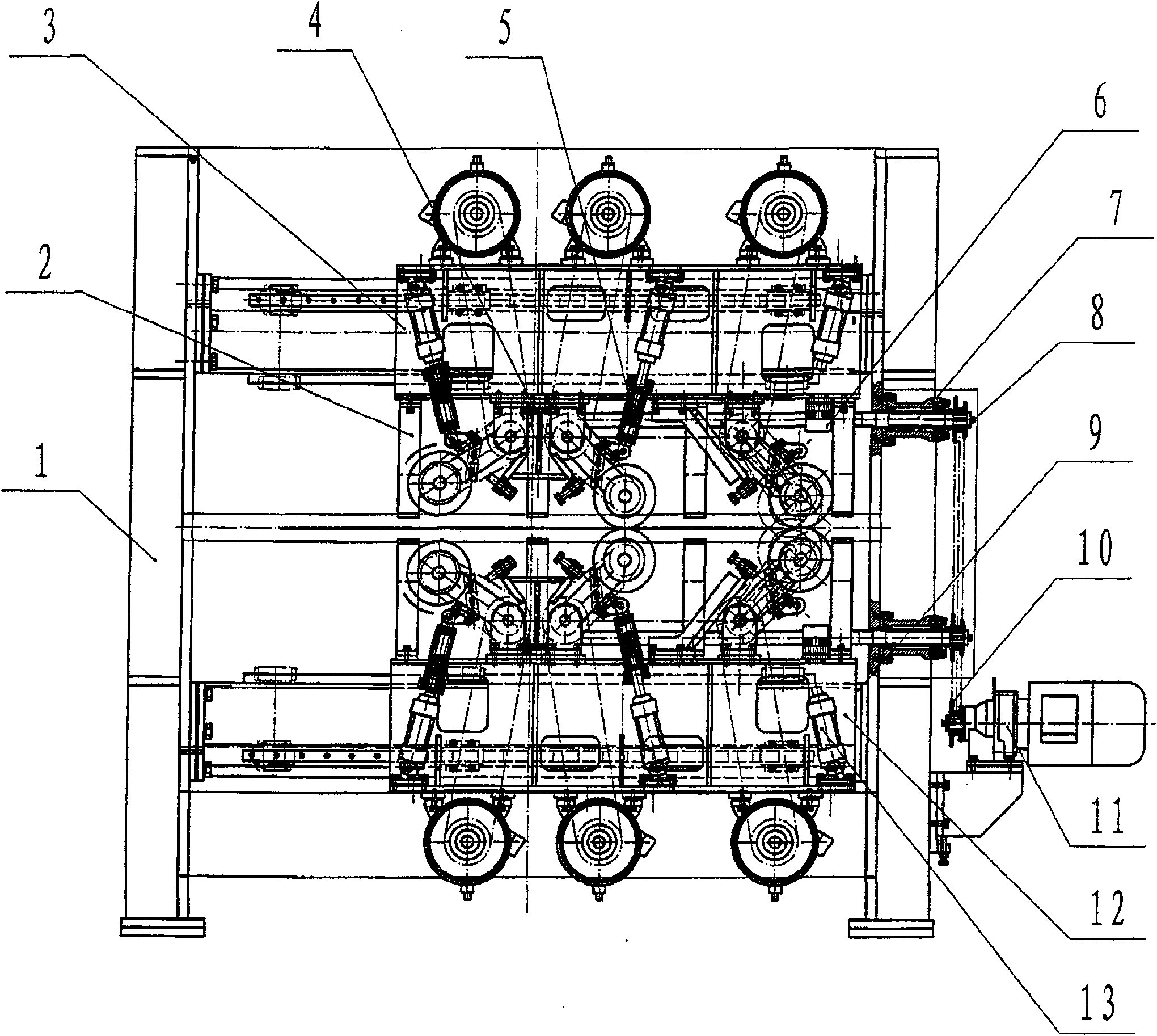

Roller coater

ActiveCN101244413ASolve the problem of coating qualityRealize online maintenance and color changeLiquid surface applicatorsCoatingsLacquerEngineering

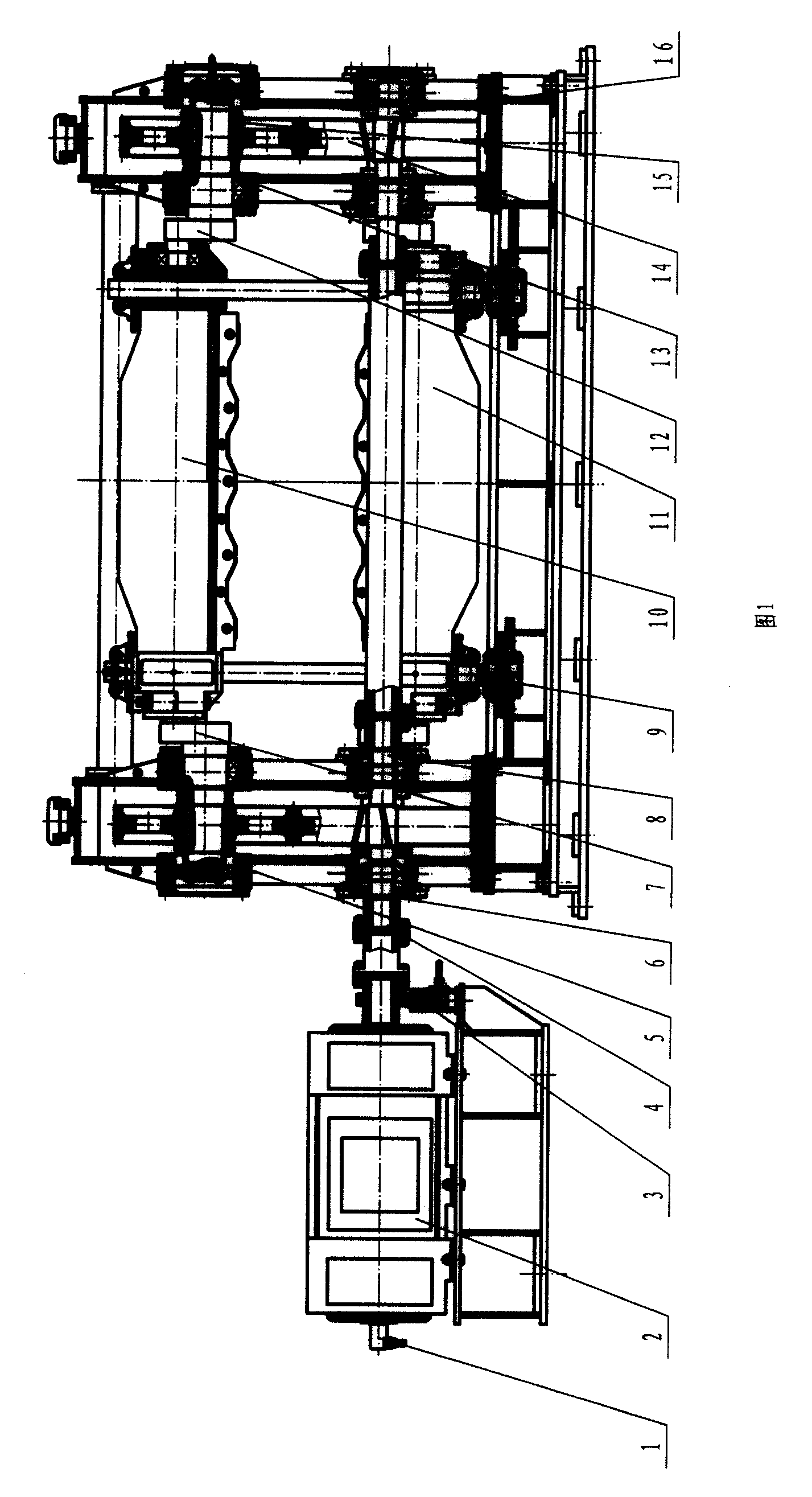

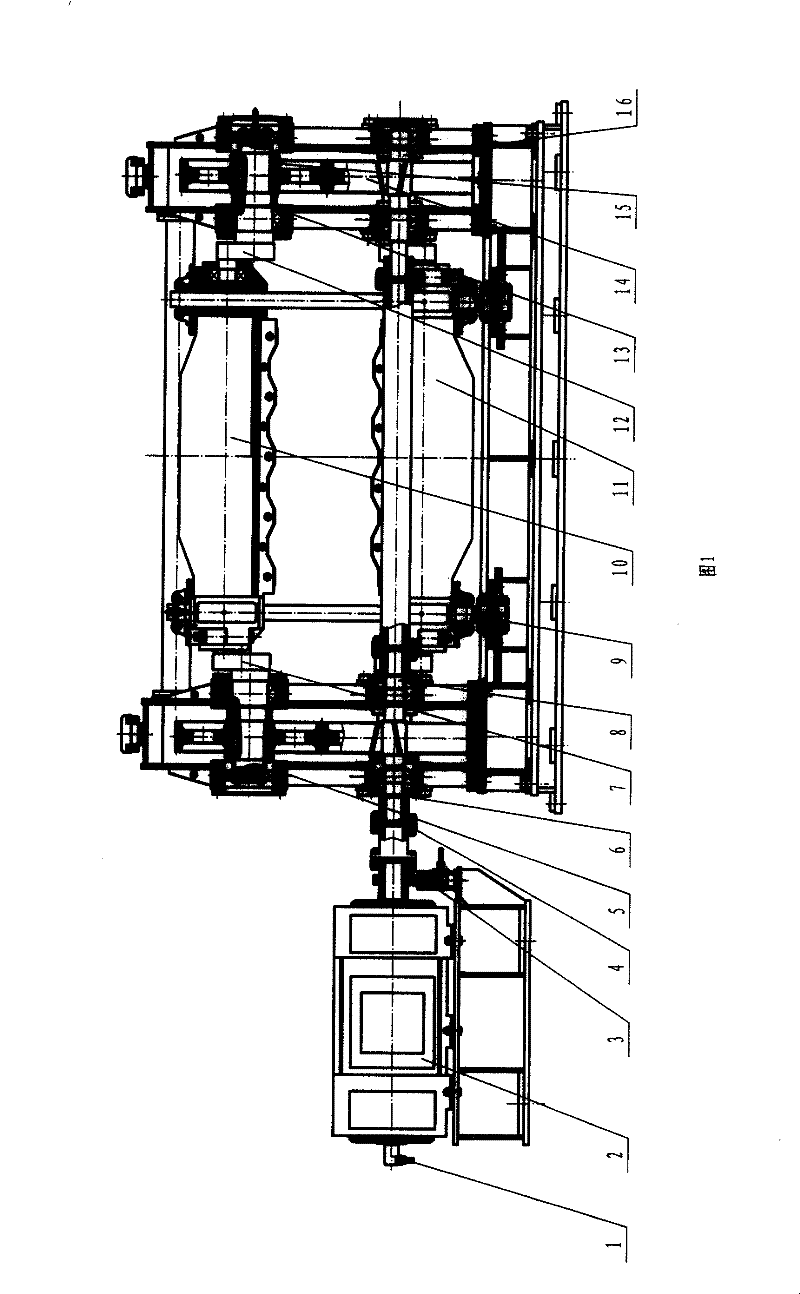

The invention provides a roller machine suitable for coating chemical coating, which is characterized in that the roller machine comprises two sets of coating mechanism arranged top to top, a support roller mechanism, a turning roller component, a frame, a synchronous mechanism, a shower, a back-coated lifting device and a transmission mechanism. Back coating frames of a coating roller device, a reclaiming roller device and a regulating roller device fitted with specially made polyurethane material are driven by an oil cylinder and synchronous lifting at both sides is assured by the synchronous mechanism in the coating mechanism; clearance among the coating roller device, the reclaiming roller device and the regulating roller device is regulated by the regulating mechanism to regulate coating thickness. The shower line is in a lacquer tray of a front coating mechanism and a flat mouth shower with a valve is arranged on the shower line; flow rate of the paint is controlled and coating thickness is adjusted by regulating the valve. Jet tube mode is adopted in the lacquer tray of a bottom roller in the back coating mechanism; paint is agitated to prevent from deposition. The roller machine has the advantages that double-roller coating structure is adopted and one is used and the other is standby, maintenance and exchanging color are carried out online, time is saved and productivity is improved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

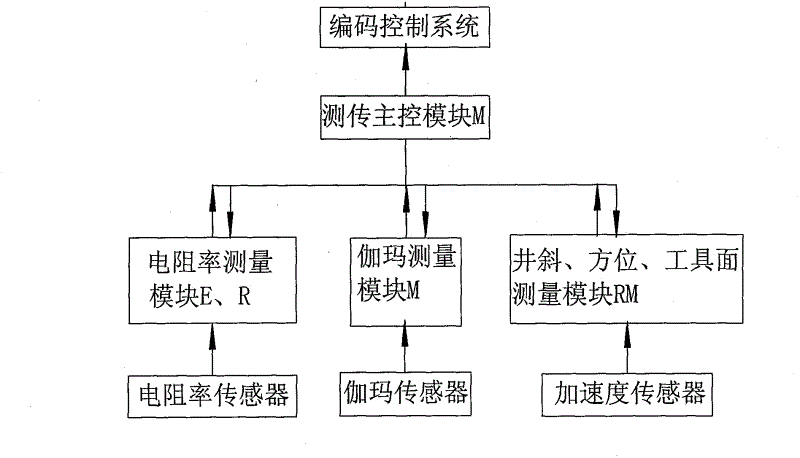

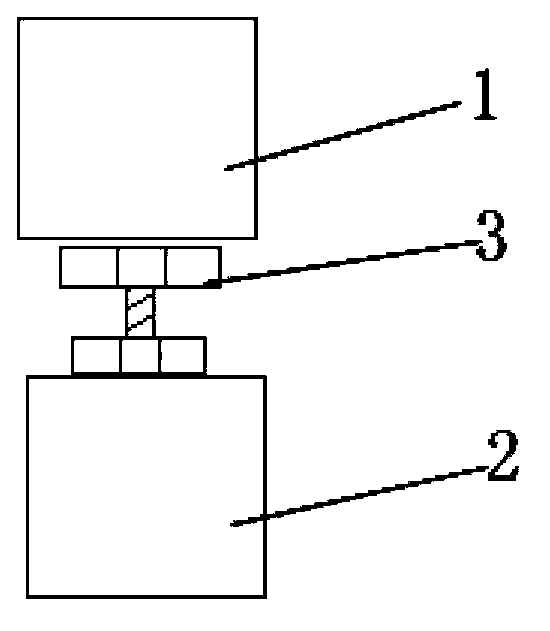

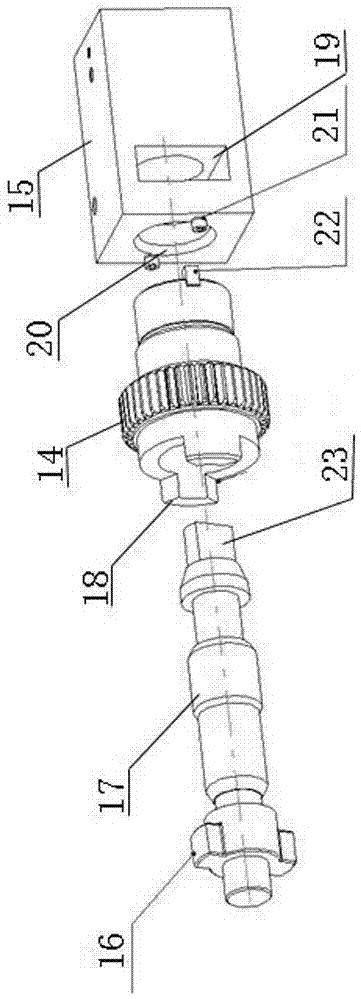

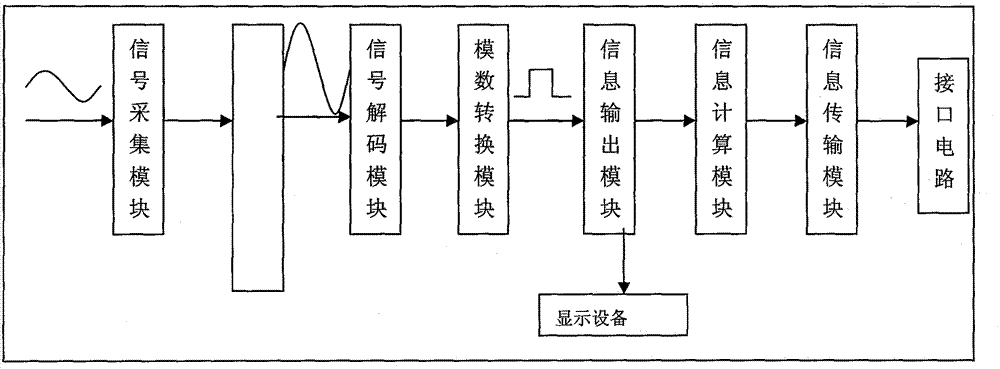

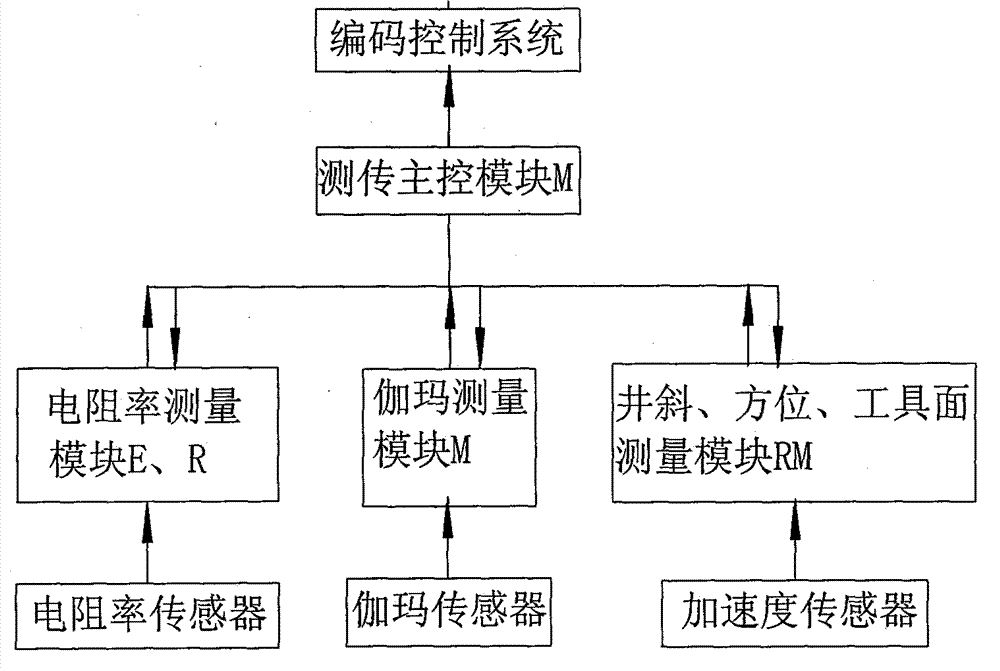

Steering drilling system based on top driving and ground control and drilling operation method

ActiveCN102619498AImprove work efficiencyPrecision control is accurateAutomatic control for drillingTop driveEngineering

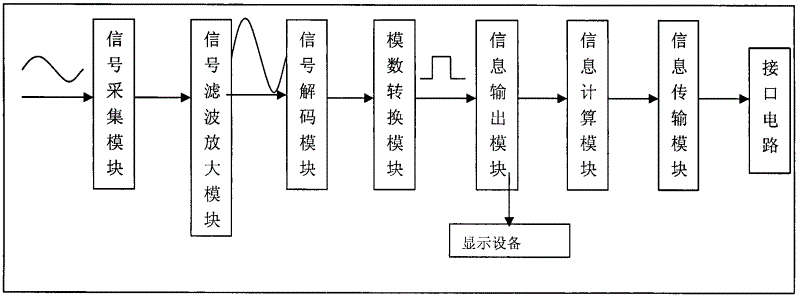

The invention relates to a steering drilling system based on top driving and ground control, and a drilling operation method. The steering drilling system comprises a top driving device; a ground signal processing system comprises a signal acquisition module which is connected with a signal filtering and amplification module; the signal filtering and amplification module is connected with a signal decoding module, and can filter clutter out of electric signals, amplify and enhance effective signals and transmit the effective signals to the signal decoding module; the signal decoding module is connected with an analog-to-digital conversion module; the analog-to-digital conversion module is connected with an information output module; the information output module is connected with an information calculation module and display equipment; the information calculation module is connected with an information transmission module; and the information transmission module is connected with a top driving electric control device by an interface circuit. For the steering drilling system based on the top driving and the ground control and the drilling operation method, the operation efficiency is high, the control is precise, the working performance is stable, and the operation can be carried out under various geologic conditions.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

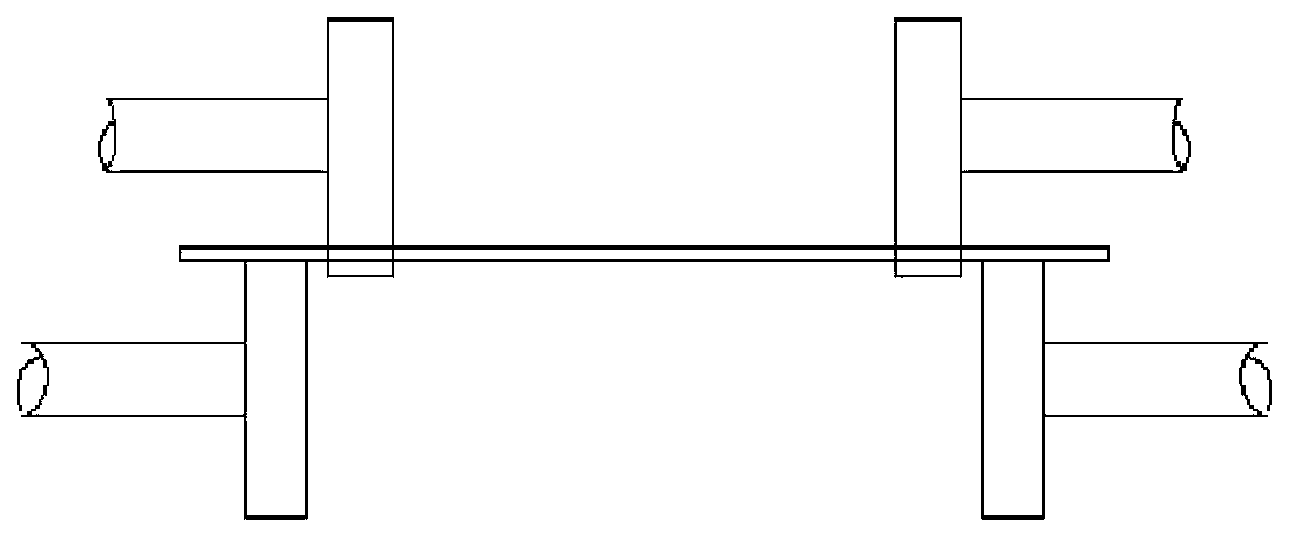

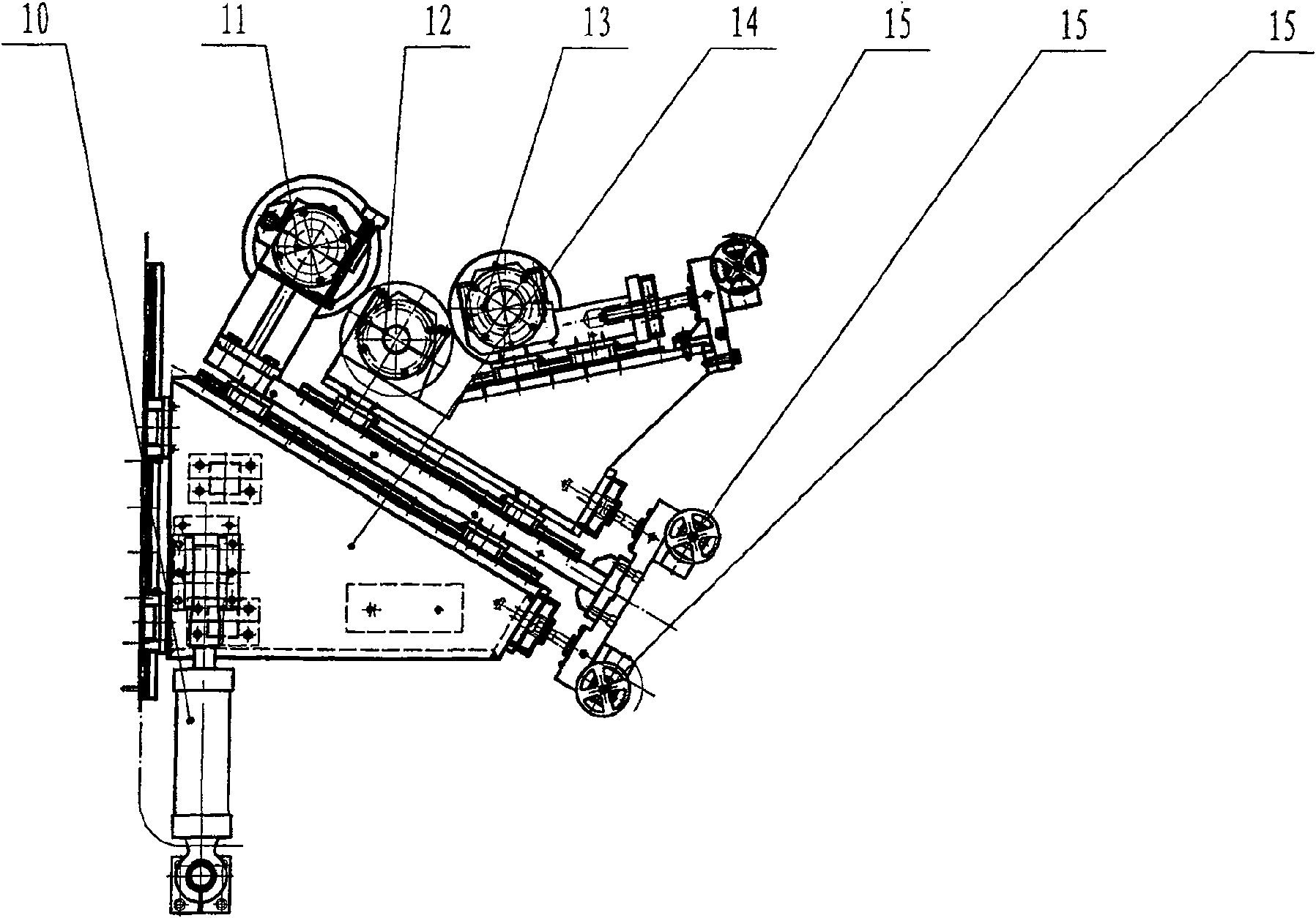

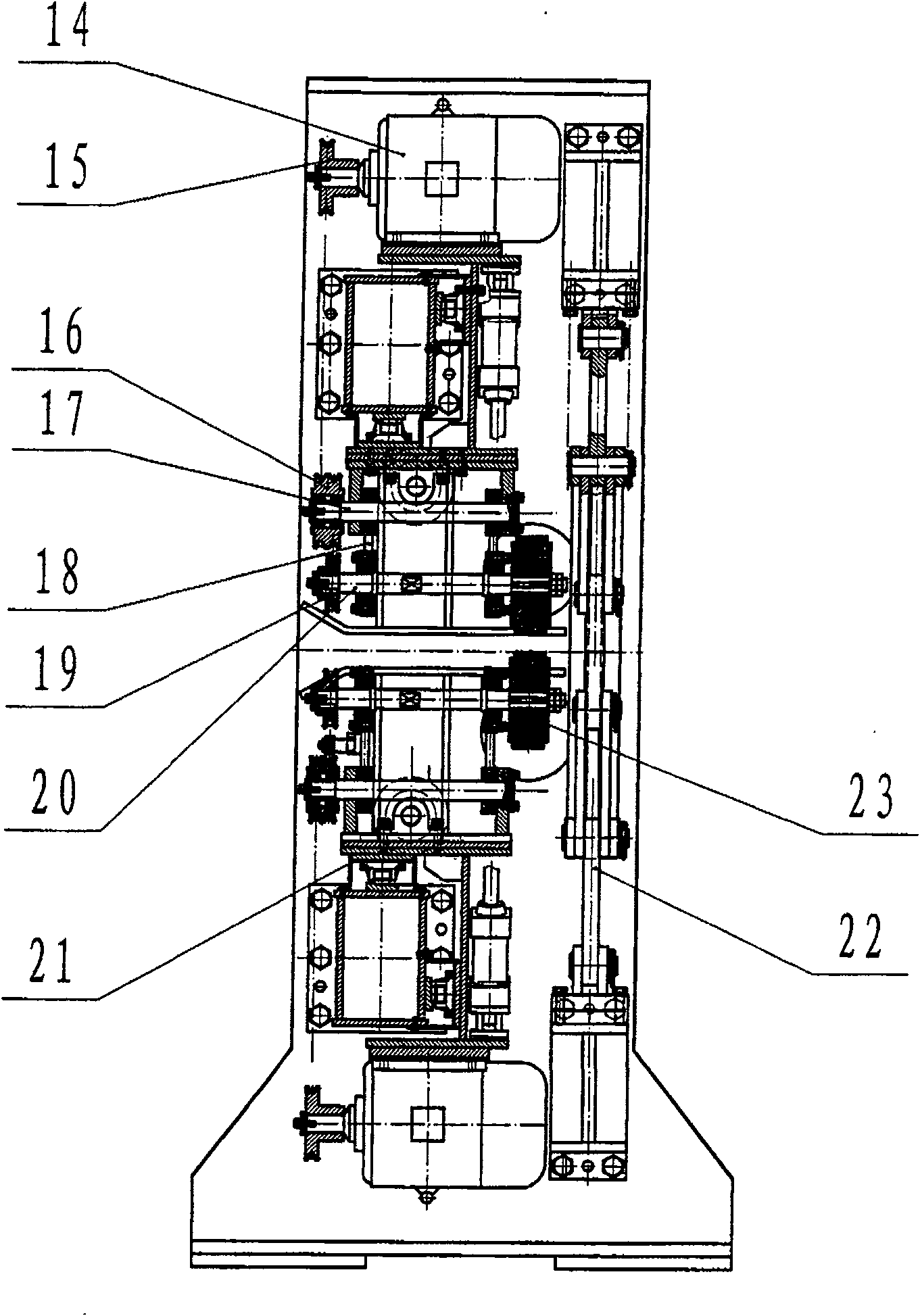

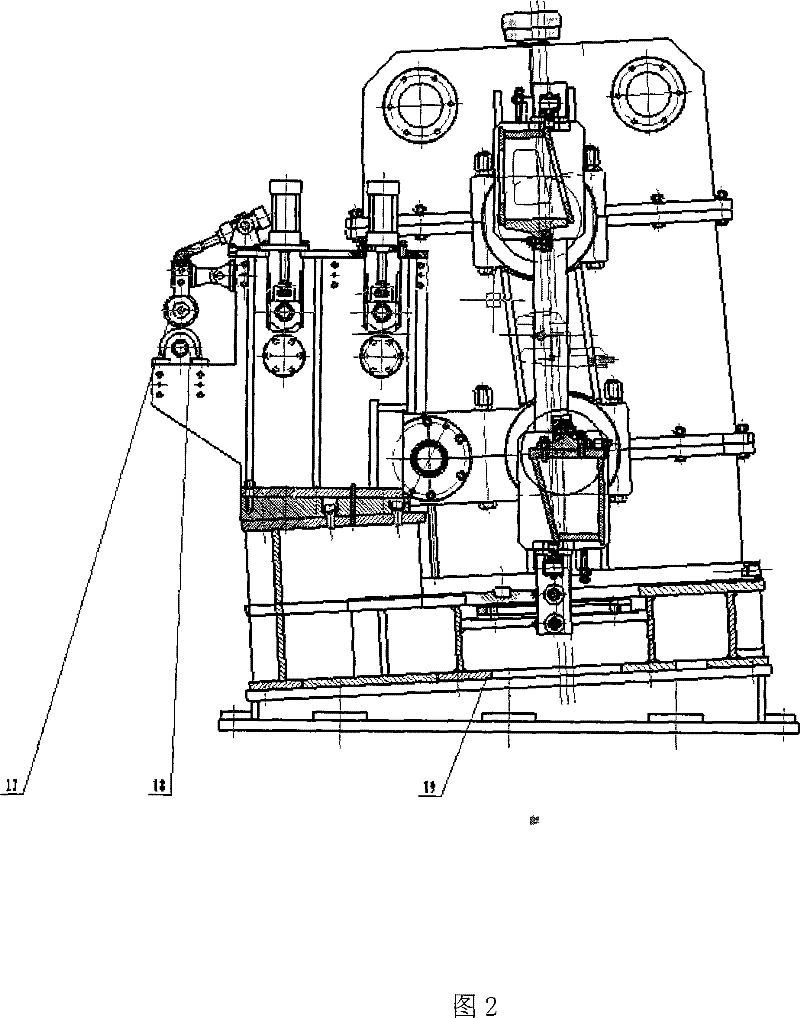

Flying shear for shearing corrugated plate

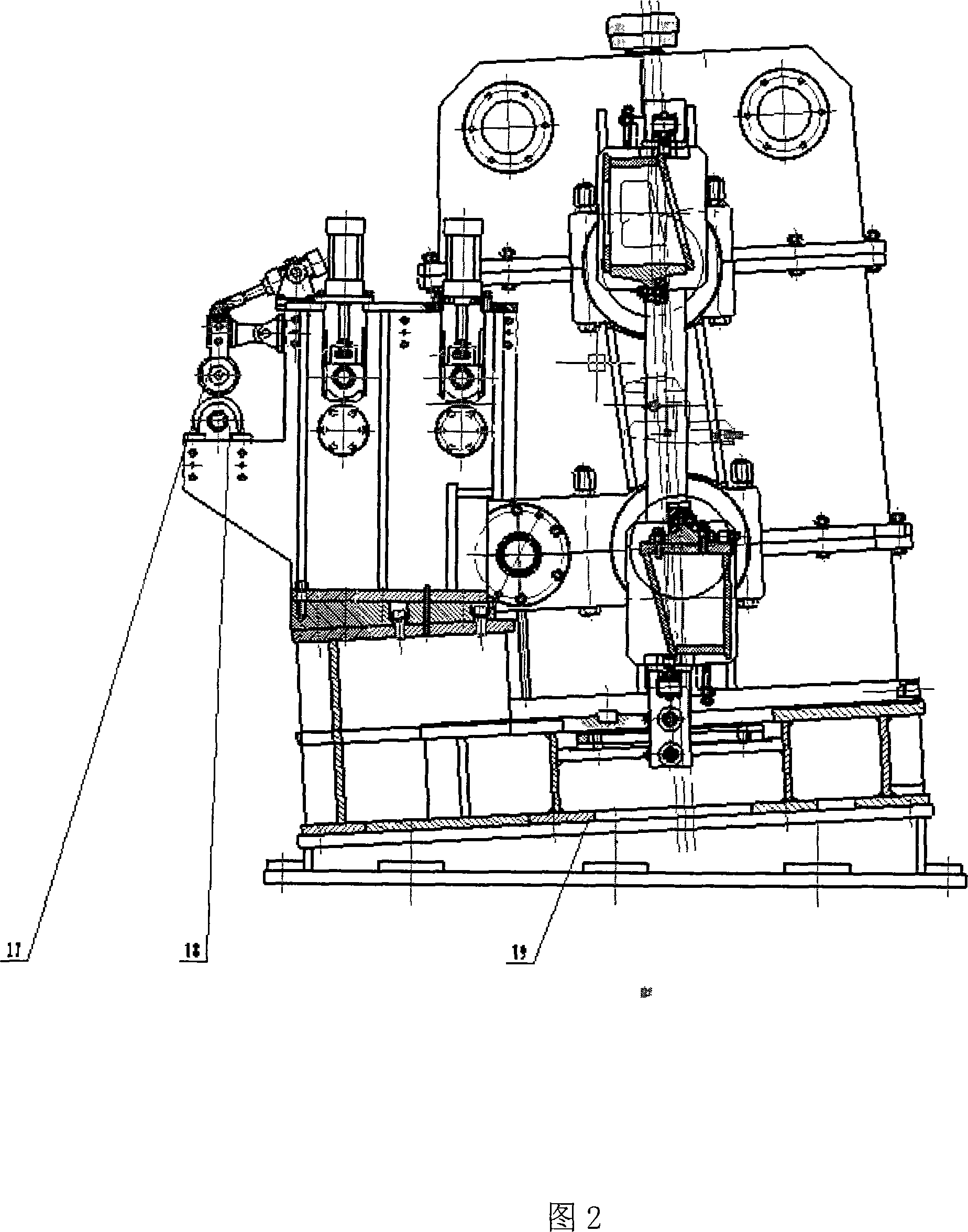

ActiveCN101234439ASolve the problem of uneven cross-sectionSolve uneven problemsStock shearing machinesShearing machine accessoriesSheet steelClosed loop

The invention provides a flying shear applicable to cutting a corrugated plate applied in metallurgy field, and includes an electric control system; the flying shear comprises an actuating motor 2, a locking device 3, a left and a right wheel boxes, an upper and a lower cutting devices, a leader device 9, a pedestal 19, a pinch roll, and a measuring motion, etc. The flying shear is characterized in that a section of the corrugated plated cut by the flying shear is vertical, whereas a section cut by a current flying shear is oblique; shapes of an upper and a lower blades are compatible with the shape of the corrugated plate; when adjusting a blade gap, the locking device is functioned as controlling a position of ''a bottom stop'' of the lower blade and a safe protection; while the pinch roll and the pinch roll of the measuring motion adopt heterotype to be suited for the waveform of the corrugated plate, thus functioned as locating a board and controlling the position of the board, and when cut, the steel plated has a fixed position; the equipment is provided with three encoders wherein the encoders are coordinated with each other according to difference of given signals, thus a controlling function of a closed loop is accomplished; a fixed length can be carried out accurately, thus ensuring that the precision of the fixed length is controlled within plus or minus 1.0mm.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Manufacturing method of microporous membrane sinter filter element

InactiveCN103071400AEasy to acceptSimple molding processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisChemical reactionThree-dimensional space

The invention discloses a manufacturing method of a microporous membrane sinter filter element, is applicable to mounting and assembly occasions of combined type water purifiers and belongs to the technical field of water resource purification. Micropores of the microporous membrane sinter filter element manufactured through the method are formed through pure-physical hot melt binding instead of a chemical reaction; and the method adopts the principle that during the heating and sintering process of a main material, after being bonded with an auxiliary material during the melting process, the main material shrinks in the following cooling process to form three-dimensional space clearances, and the micropores are related to the main material and the auxiliary material in shapes and particle sizes. The manufacturing method has the advantages of simplicity and convenience in process molding, comprehensive formula, accuracy in precision control, reliable performance and low manufacturing cost.

Owner:NINGBO HO WATER PURIFICATION EQUIP TECHCO LTD

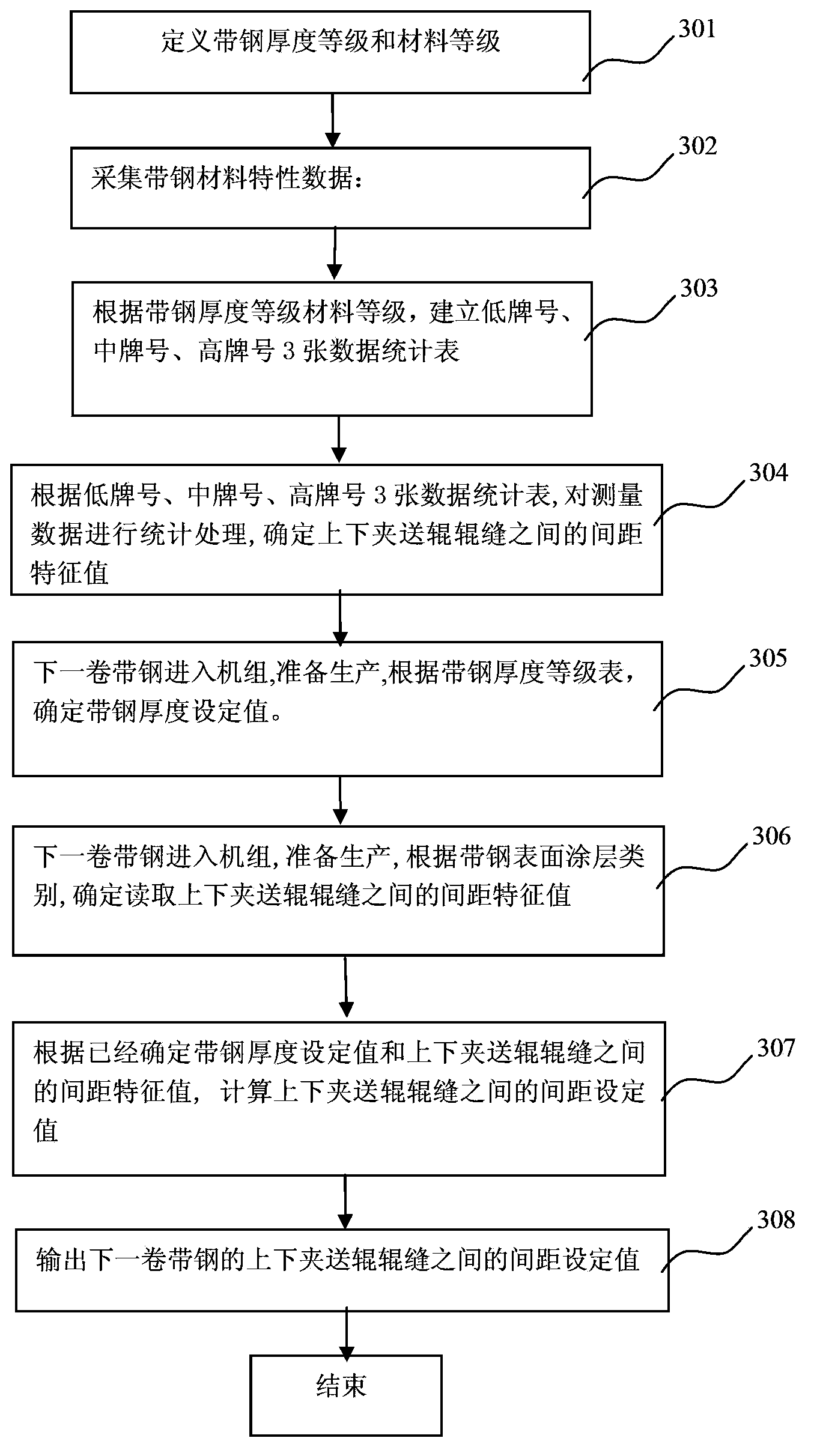

Method for controlling roll gap of pinch roll

ActiveCN104117599AQuality assuranceImprove stabilityMetal-working feeding devicesPositioning devicesLower gradeLow graded

The invention discloses a method for controlling a roll gap of a pinch roll. The method includes the steps of (1) grading strip steel thicknesses and material silicon content; (2) collecting strip steel material characteristic data; (3) respectively building low-grade, medium-grade and high-grade material silicon content data statistical tables, and obtaining historical actual performance values and historical set values, corresponding to the strip steel thickness grades and the material silicon content grades, of the roll gap between an upper clamping roll body and a lower clamping roll body; (4) enabling strip steel to enter a unit, and determining the strip steel thickness set value T according to the strip steel thickness grades; (5) determining a gap control coefficient K of the strip steel according to the material silicon content grade data statistical tables; (6) calculating the finial set value G of the roll gap between the upper clamping roll body and the lower clamping roll body, wherein the G is the product of the T and the K and is the finial set value of the roll gap of the clamping roll, and the T is the strip steel thickness set value. The method is accurate in accuracy control and high in expansibility and adaptability, a steel strip head can be normally clamped and conveyed and can normally penetrate through the clamping roll, defects are avoided, and the strip steel yield is high.

Owner:BAOSHAN IRON & STEEL CO LTD

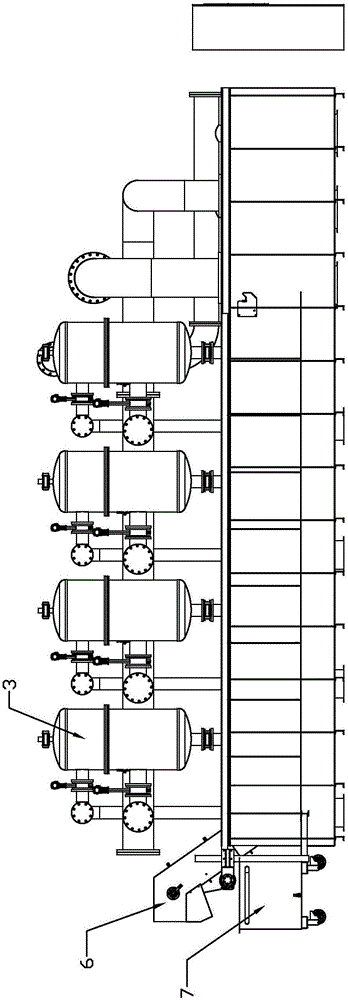

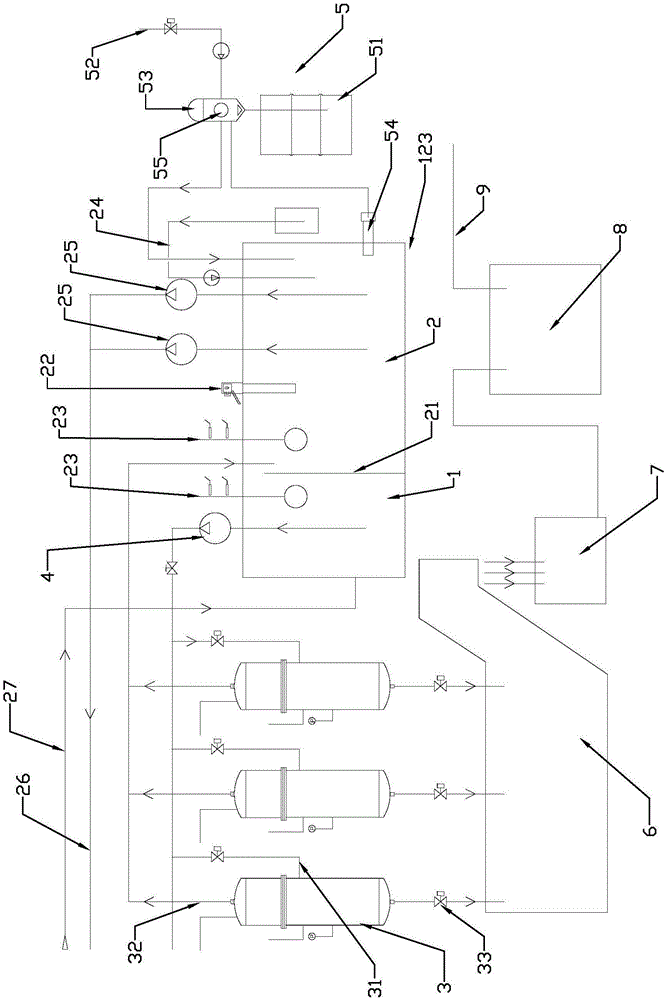

Back-flushing filtration system and filtration method for cutting fluid

PendingCN106492537AReduce volumeMeet the needs of different precisionSeparation devicesGravity filtersFiltrationEngineering

The invention provides a back-flushing filtration system and filtration method for a cutting fluid, belonging to the technical field of machining equipment. The back-flushing filtration system and filtration method overcome the technical problems of no self-cleaning capability and the like of conventional filter cores. The back-flushing filtration system comprises a fluid storage case provided with a dirty fluid chamber and a clean fluid chamber; the dirty fluid inlet of the dirty fluid chamber is communicated with a dirty fluid returning pipeline of a machine tool; the clean fluid outlet of the clean fluid chamber is connected with a clean fluid supply pipeline via fluid supply pumps; one side of the fluid storage case is provided with back-flushing self-cleaning filters equipped with filter core bodies; each back-flushing self-cleaning filter is provided with a filter inlet, a filter outlet and a blow-off valve and further provided with an evacuation and back-flushing structure capable of filling the filter inlet and / or the filter outlet with air; the dirty fluid outlet of the dirty fluid chamber is communicated with the filter inlets of the back-flushing self-cleaning filters via a filtering pump; and the filter outlets of the back-flushing self-cleaning filters are communicated with the clean fluid outlet of the clean fluid chamber. The back-flushing filtration system and filtration method have the advantages of high filtration accuracy and high filtering efficiency, and the filter cores have a self-cleaning function.

Owner:江苏威泽智能科技股份有限公司

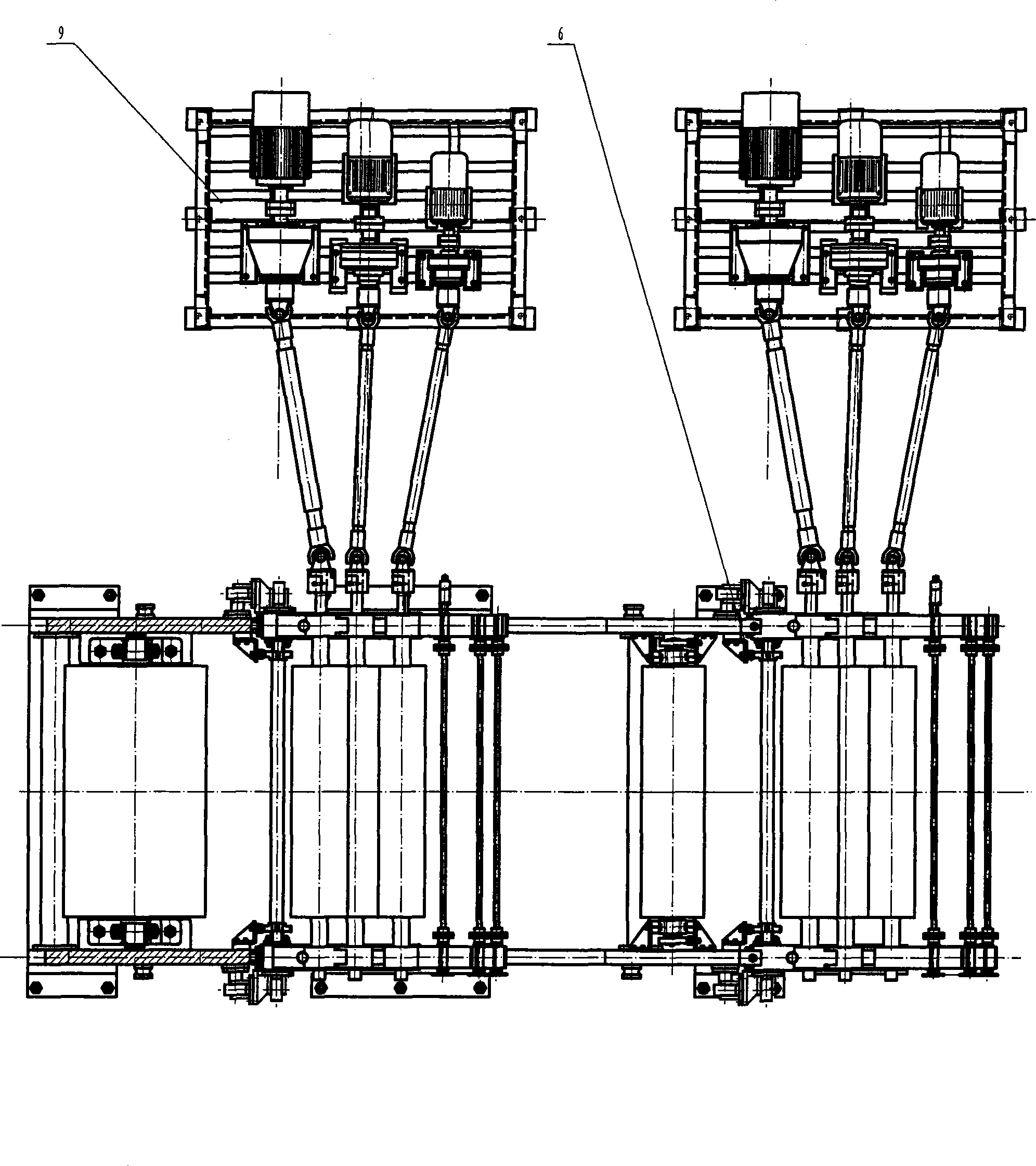

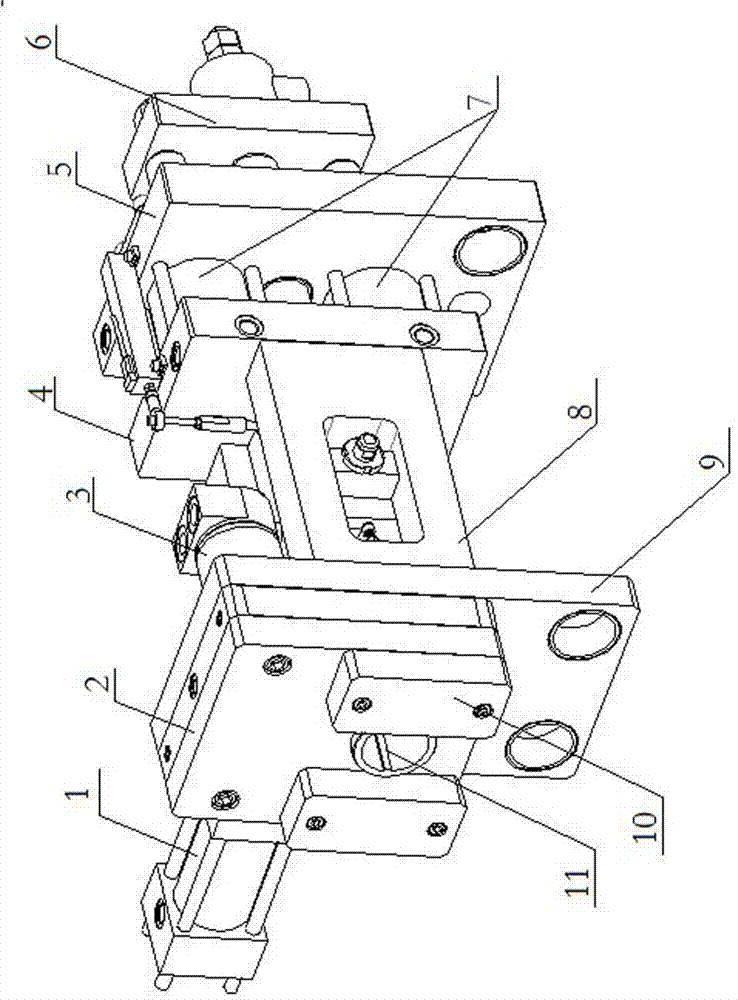

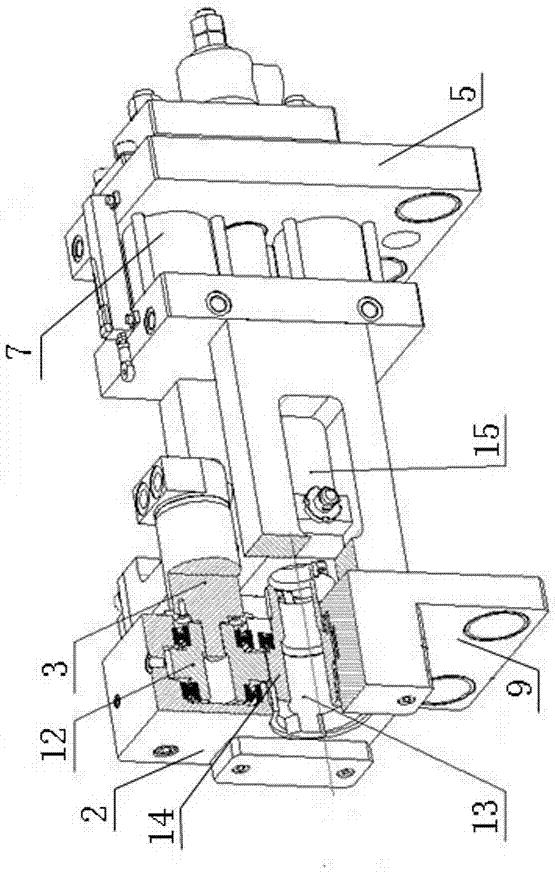

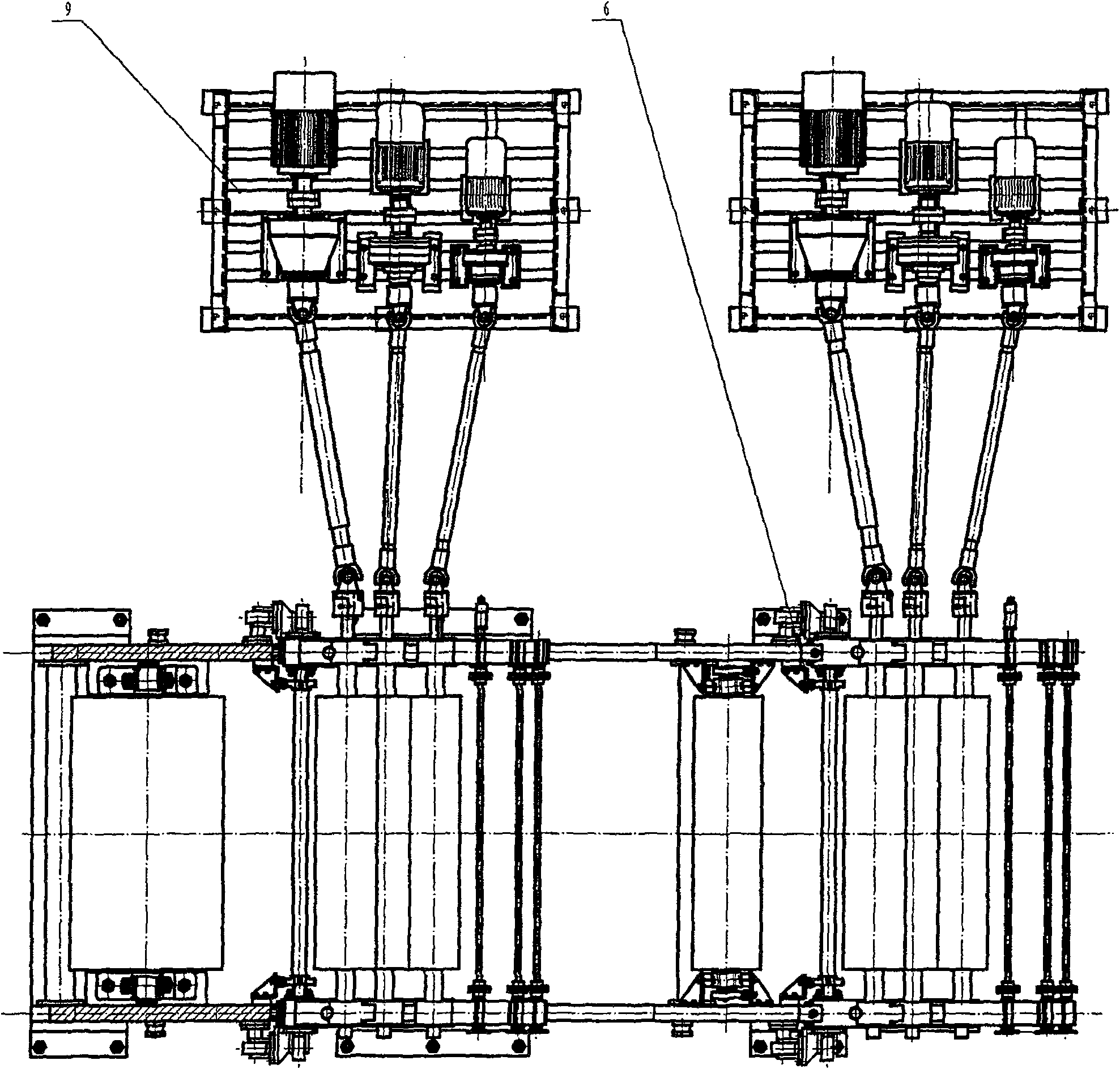

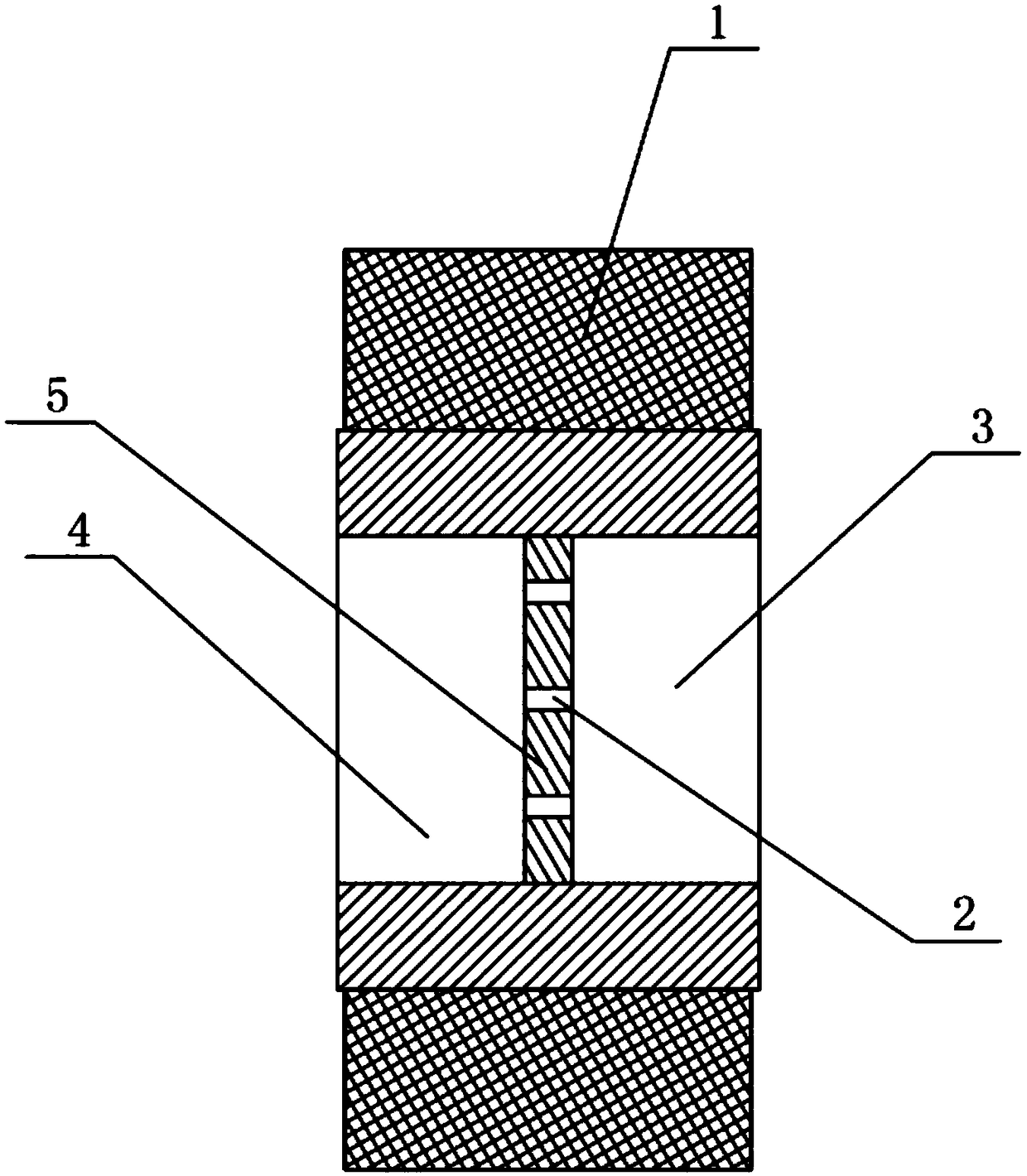

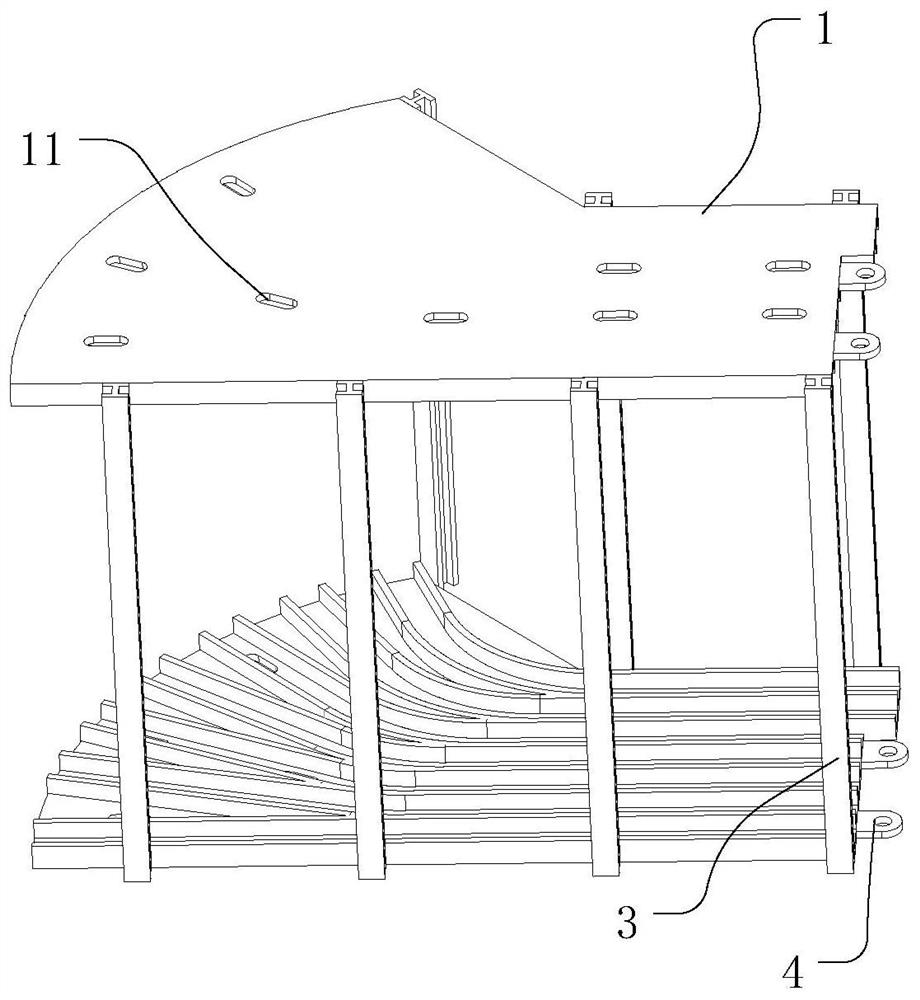

Reinforcing steel bar tensioning device of high-speed railway ballastless track plate with pre-tensioning method

PendingCN106945170APrecision control is accurateGuaranteed to work independentlyCeramic shaping apparatusLocking mechanismRebar

A reinforcing steel bar tensioning device of a high-speed railway ballastless track plate with a pre-tensioning method comprises a tensioning power mechanism fixed to a tensioning bed box through a guide post and a guide rod. The tensioning power mechanism is composed of two tensioning oil cylinders fixed side by side as a whole and is provided with a tensioning rod link head connected with a tensioning rod. The tensioning rod link head is connected with the end of a tensioning oil cylinder rod. The upper hole of the tensioning rod link head is a tensioning rod hole. According to the reinforcing steel bar tensioning device of the high-speed railway ballastless track plate with the pre-tensioning method, the tensioning device is fixed on the tensioning bed box through the guide post and the guide rod, installation, overhaul and replacement are convenient, the two tensioning oil cylinders corresponds to one tensioning rod and operates synchronously, the device volume is reduced and the tensioning power is ensured. a location locking mechanism is arranged to cooperate with the tensioning oil cylinders, precisely locating and locking in time during the tensioning process are realized, the synchronous tensioning and locking of all reinforcing steel bars are ensured, the situation of difference stress does not happen. The plug plate mechanism enables all tensioning mechanisms to be locked synchronously. In addition, plug plates are cooperated with each other in a contacting mode, the synchronous placing of the plug plates is ensured, the independent work between the tension mechanism and the corresponding tensioning rod is ensured, and the tensioning accuracy control is more accurate.

Owner:SHANXI GAOHANG HYDRAULIC

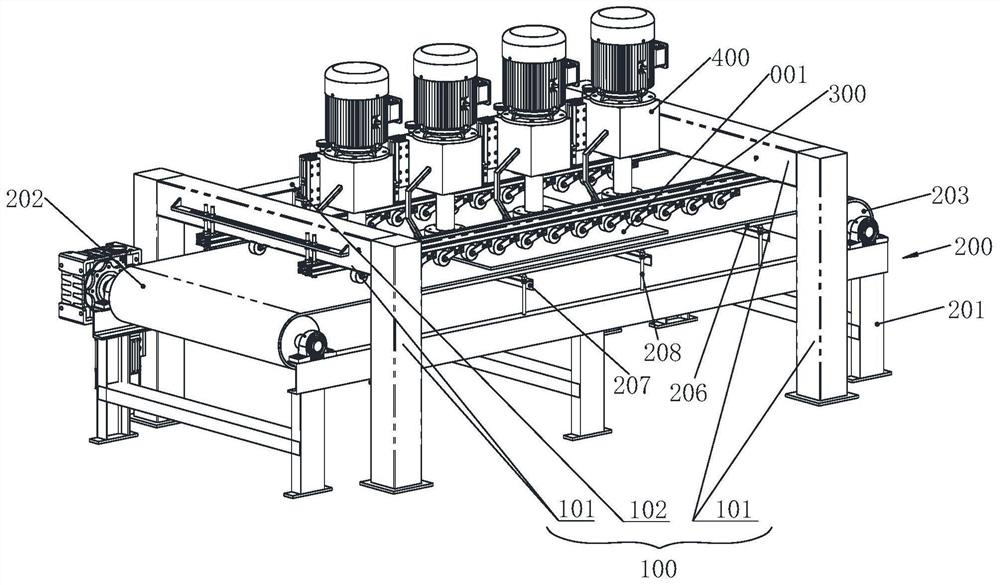

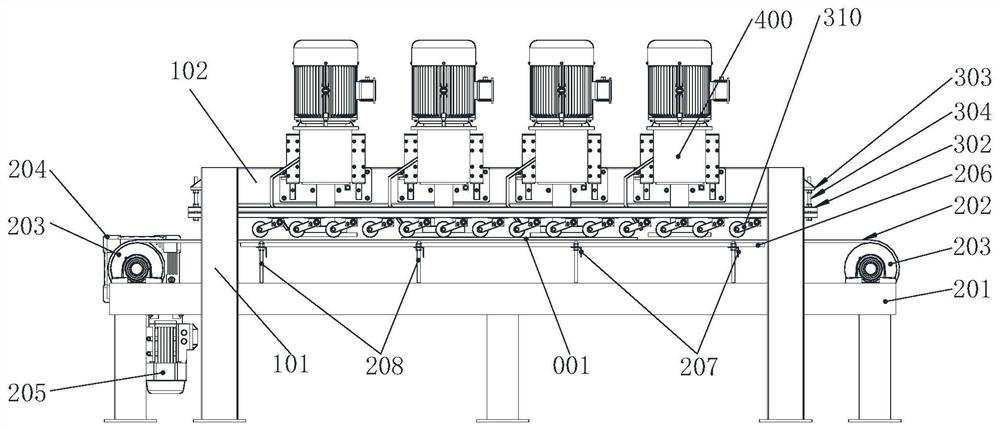

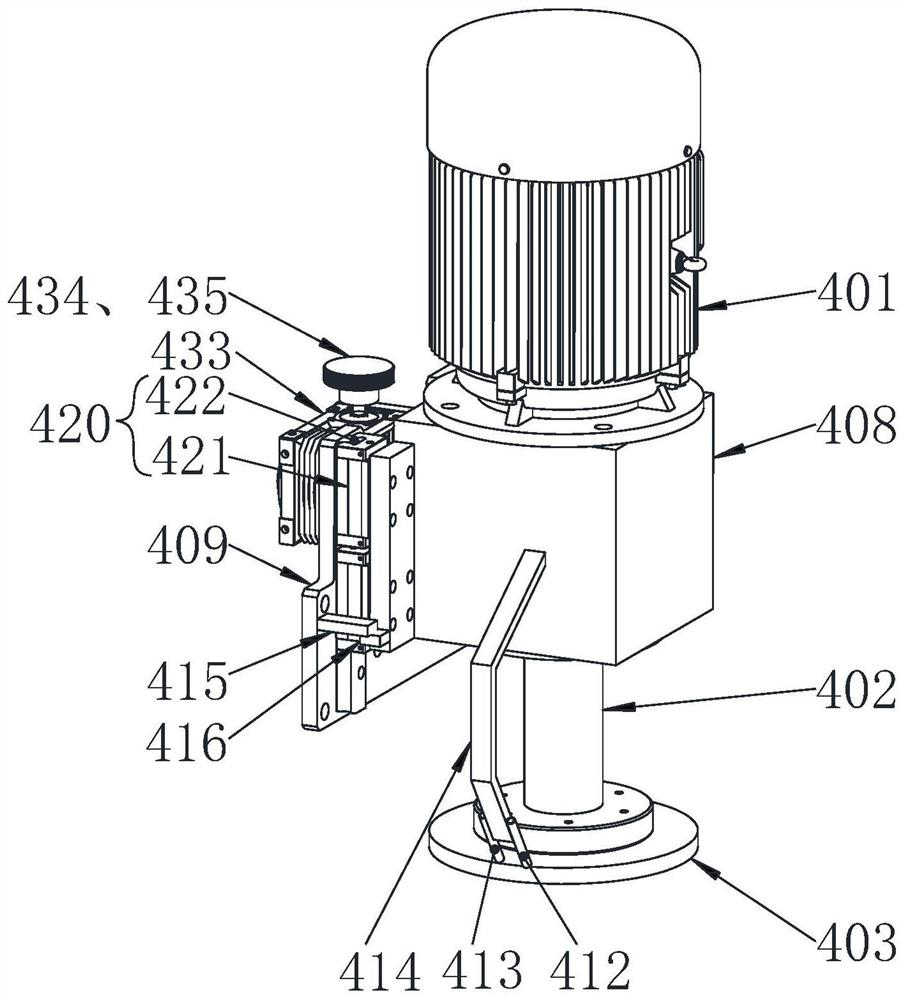

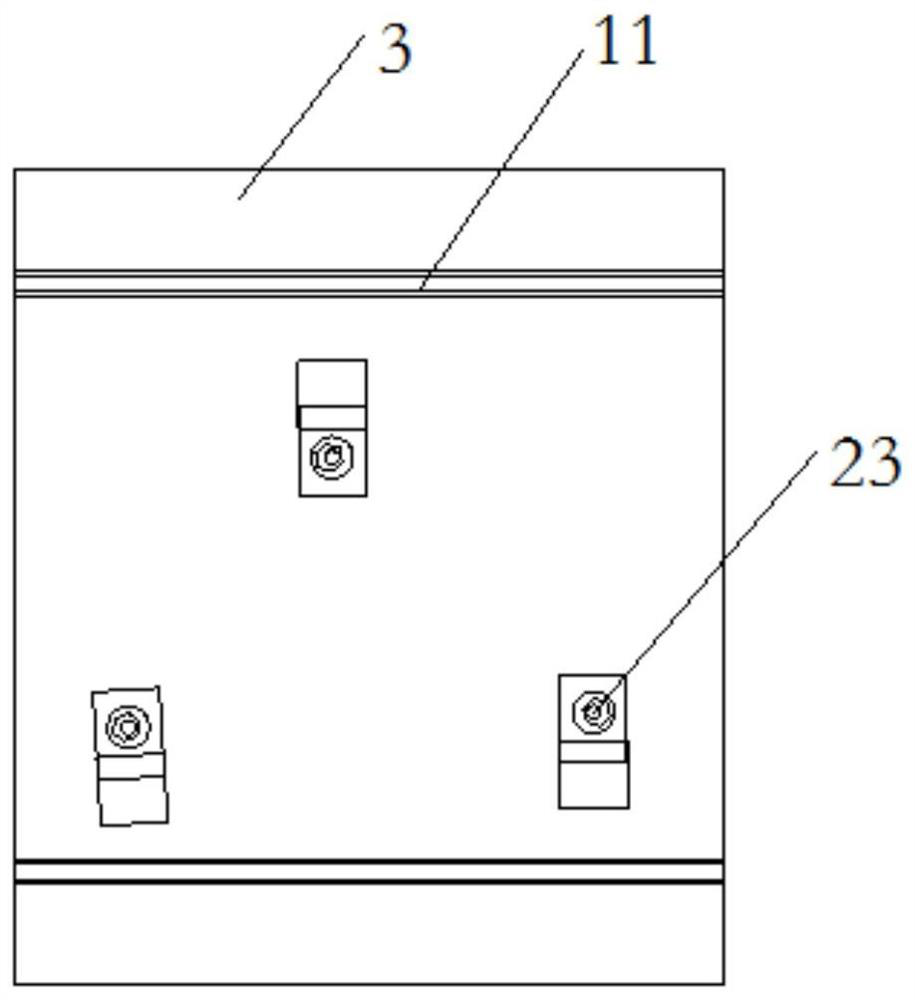

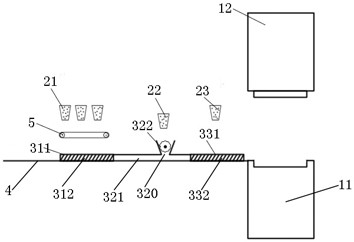

Pretreatment device for water absorption detection sample of ceramic tile and control method of pretreatment device

ActiveCN113275962AImprove accuracyImprove objectivityGrinding drivesPreparing sample for investigationControl systemStringer

The invention relates to a pretreatment device for a water absorption detection sample of a ceramic tile and a control method of the pretreatment device. The pretreatment device comprises a rack, a conveying mechanism, a positioning mechanism, a plurality of groups of milling mechanisms and a control system; the rack is composed of a pair of longitudinal beams and a cross beam fixedly arranged at the tops of the longitudinal beams, the positioning mechanism is arranged at the bottom of the cross beam of the rack and used for fastening ceramic tiles on the conveying mechanism to prevent the ceramic tiles from unnecessarily moving in the milling process, the groups of milling mechanisms are arranged at the top of the positioning mechanism, the milling mechanisms are used for milling the surfaces of the ceramic tiles, the conveying mechanism is arranged at the bottom of the positioning mechanism, the conveying mechanism is used for conveying the to-be-treated ceramic tiles in place and providing continuous translation driving force in the milling process, and the control system is used for controlling the pretreatment device.

Owner:JIANGXI HEMEI CERAMICS +1

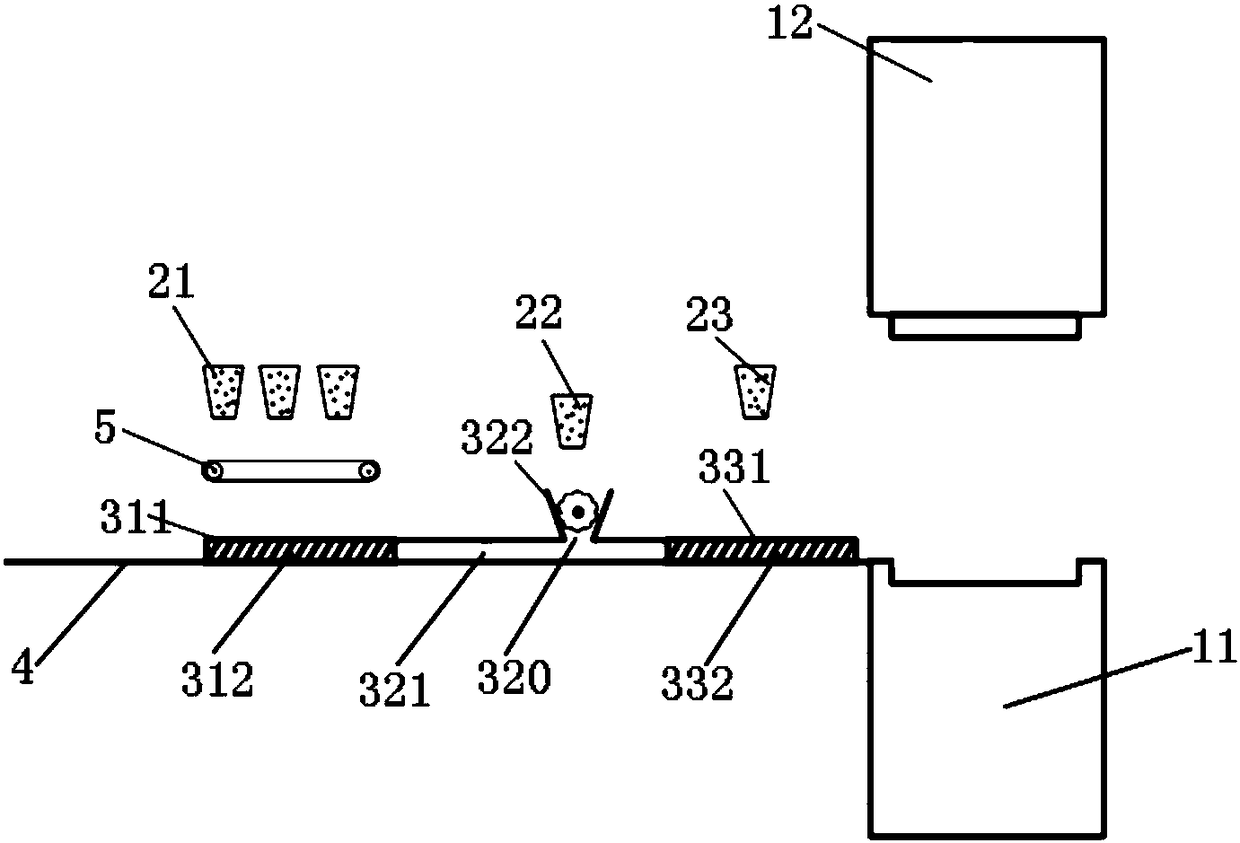

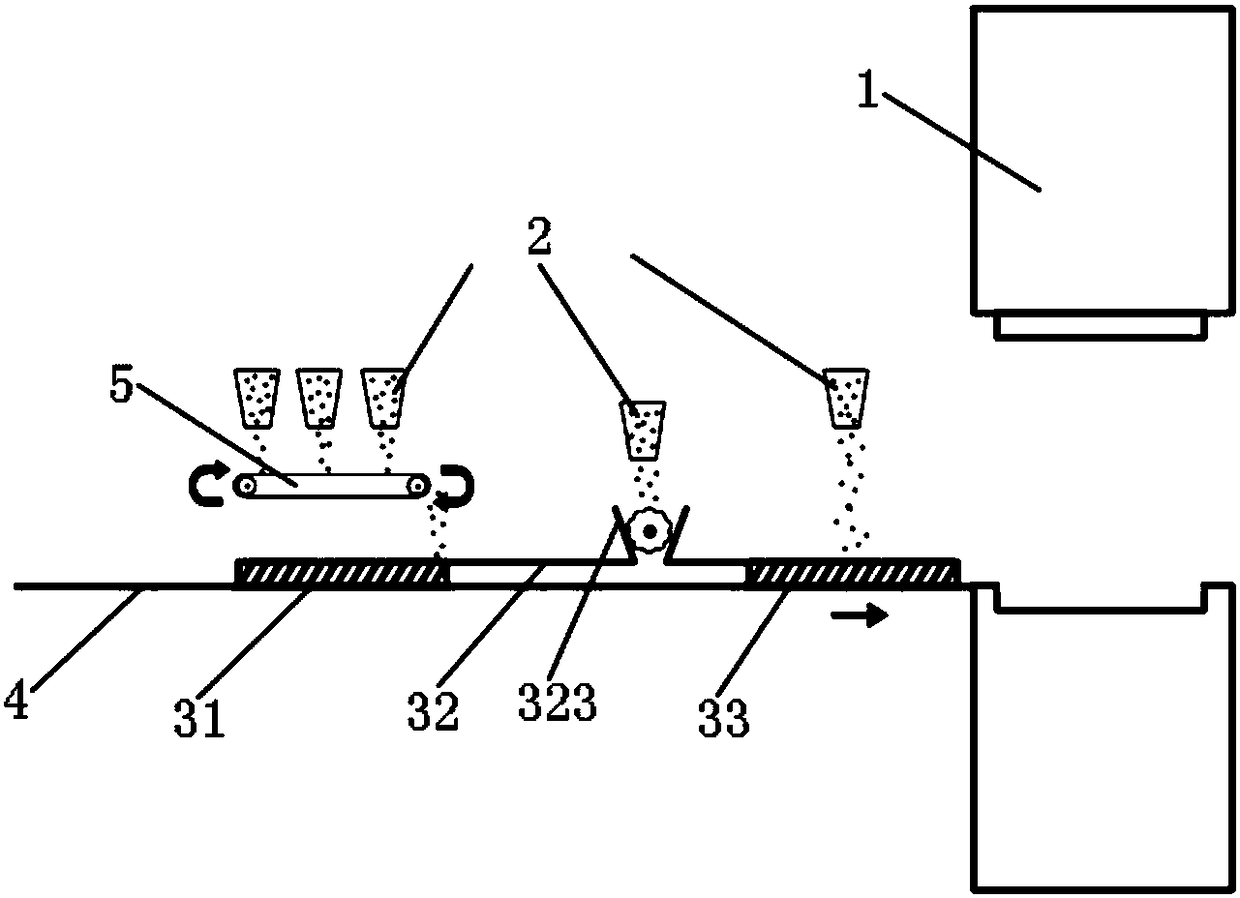

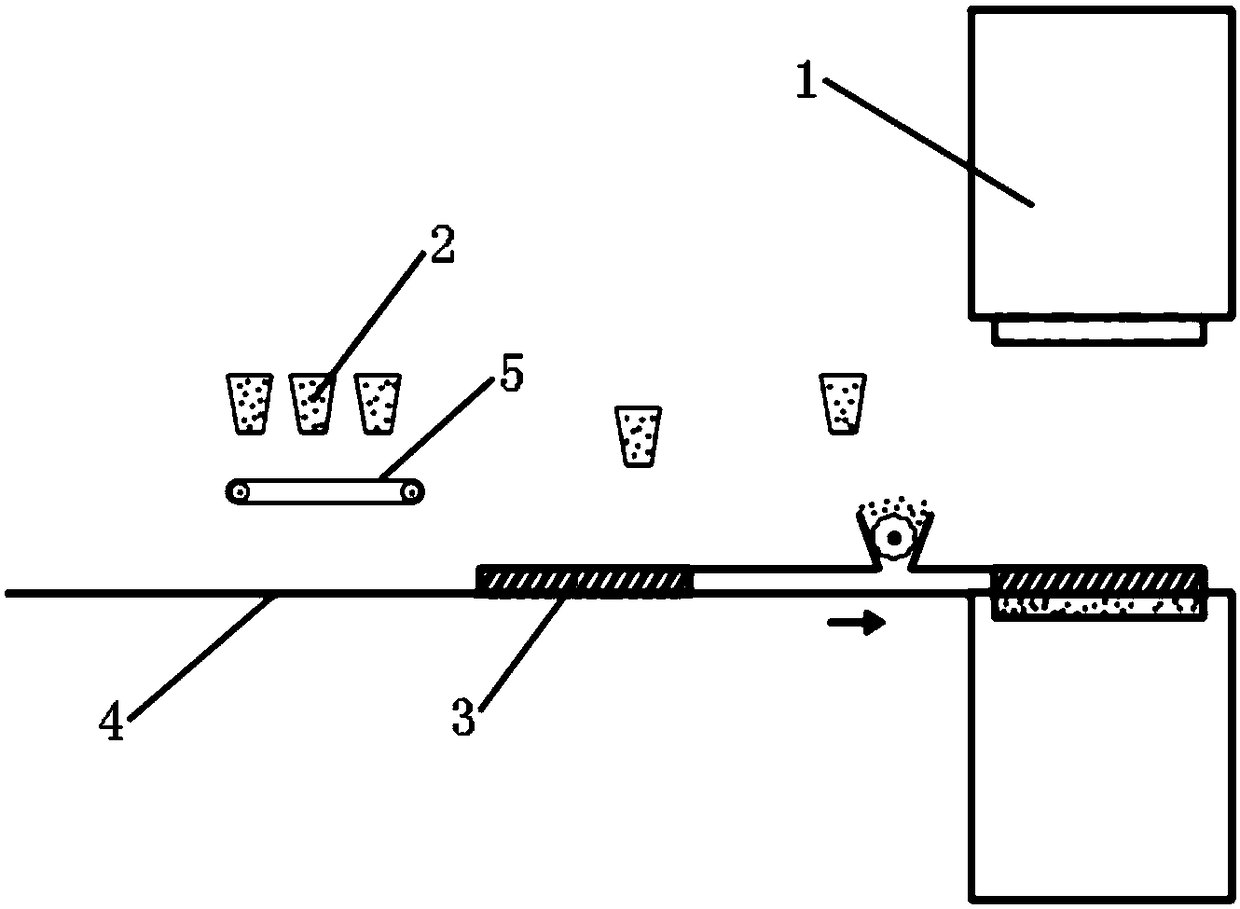

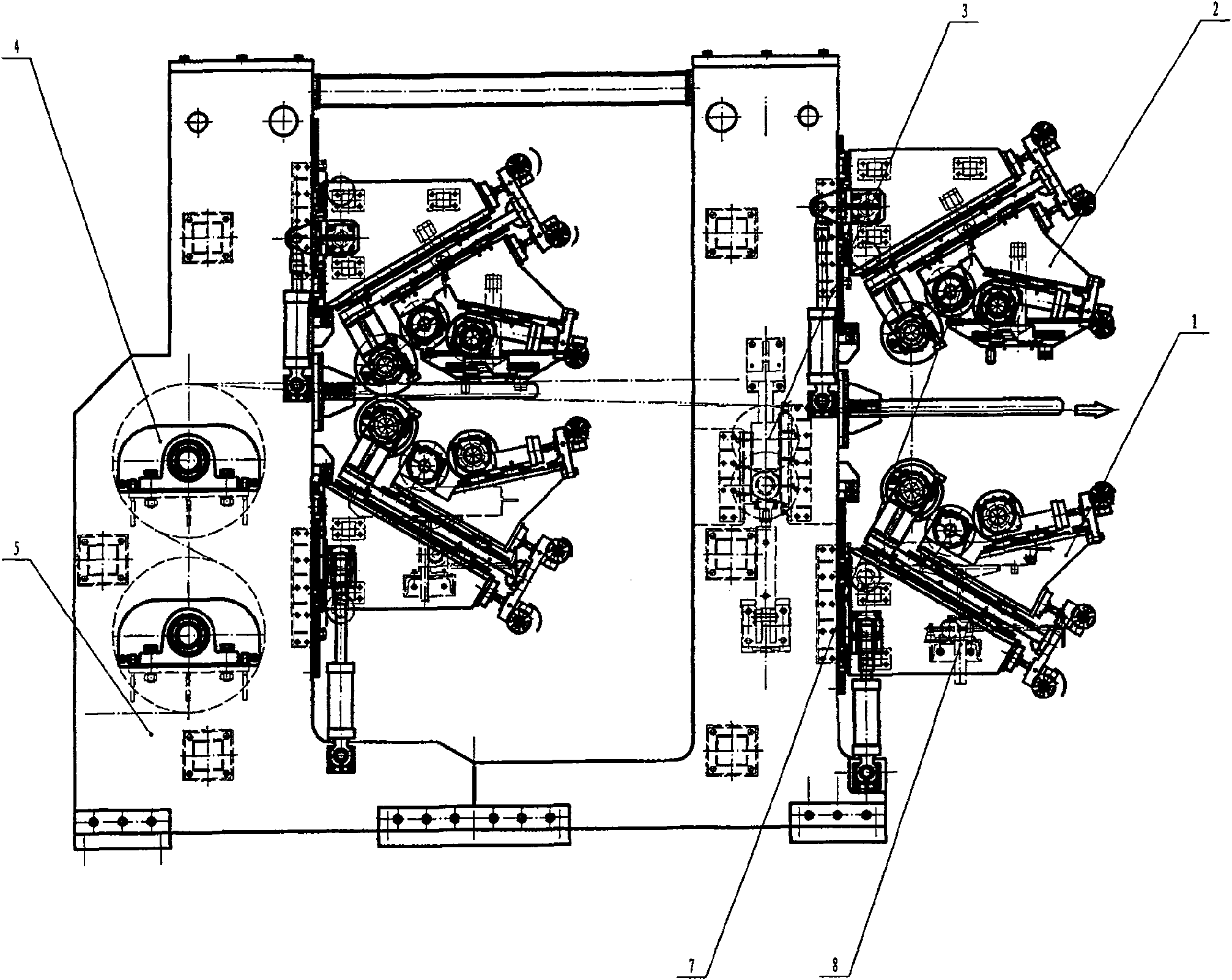

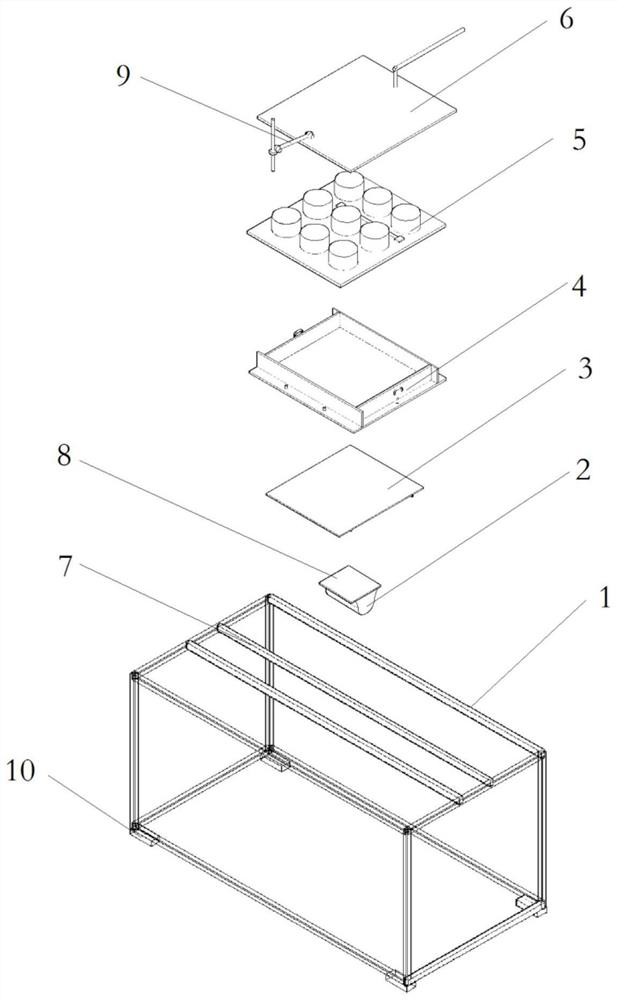

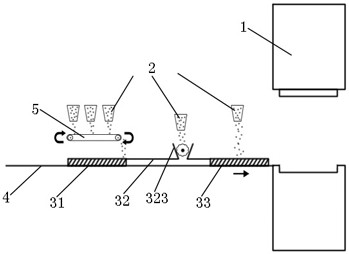

Distribution equipment and preparation method of marble-like hole bricks

ActiveCN108407066AImprove efficiencyPrecision control is accurateFeeding arrangmentsShaping press ramBrickEngineering

The invention discloses distribution equipment and a preparation method of marble-like hole bricks. The distribution equipment comprises a press, a holding device, a distribution device and a conveying device; the holding device is arranged on one side of the press; the distribution device is mounted on the conveying device, and is positioned below the holding device; the distribution device comprises a surface basket, a hole basket and a bottom basket; the surface basket, the hole basket and the bottom basket are horizontally mounted on the conveying device, and form an integral-molded structure; the bottom of the distribution device is leveled with the top of a lower mold of the press; and the conveying device conveys the distribution device into the lower mold of the press in the horizontal direction for distribution. The distribution equipment for preparation of the marble-like hole bricks realizes synchronous conveying and single ordered distribution of three ceramic blank raw materials with different functions of backing materials, surface materials and hole materials, and is simple in structure and high in distribution efficiency.

Owner:FOSHAN DONGHUA SHENGCHANG NEW MATERIAL CO LTD +3

Roller coater

ActiveCN100591426CSolve the problem of coating qualityRealize online maintenance and color changeLiquid surface applicatorsCoatingsLacquerMechanical engineering

The invention provides a roller machine suitable for coating chemical coating, which is characterized in that the roller machine comprises two sets of coating mechanism arranged top to top, a supportroller mechanism, a turning roller component, a frame, a synchronous mechanism, a shower, a back-coated lifting device and a transmission mechanism. Back coating frames of a coating roller device, a reclaiming roller device and a regulating roller device fitted with specially made polyurethane material are driven by an oil cylinder and synchronous lifting at both sides is assured by the synchronous mechanism in the coating mechanism; clearance among the coating roller device, the reclaiming roller device and the regulating roller device is regulated by the regulating mechanism to regulate coating thickness. The shower line is in a lacquer tray of a front coating mechanism and a flat mouth shower with a valve is arranged on the shower line; flow rate of the paint is controlled and coating thickness is adjusted by regulating the valve. Jet tube mode is adopted in the lacquer tray of a bottom roller in the back coating mechanism; paint is agitated to prevent from deposition. The roller machine has the advantages that double-roller coating structure is adopted and one is used and the other is standby, maintenance and exchanging color are carried out online, time is saved and productivity is improved.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

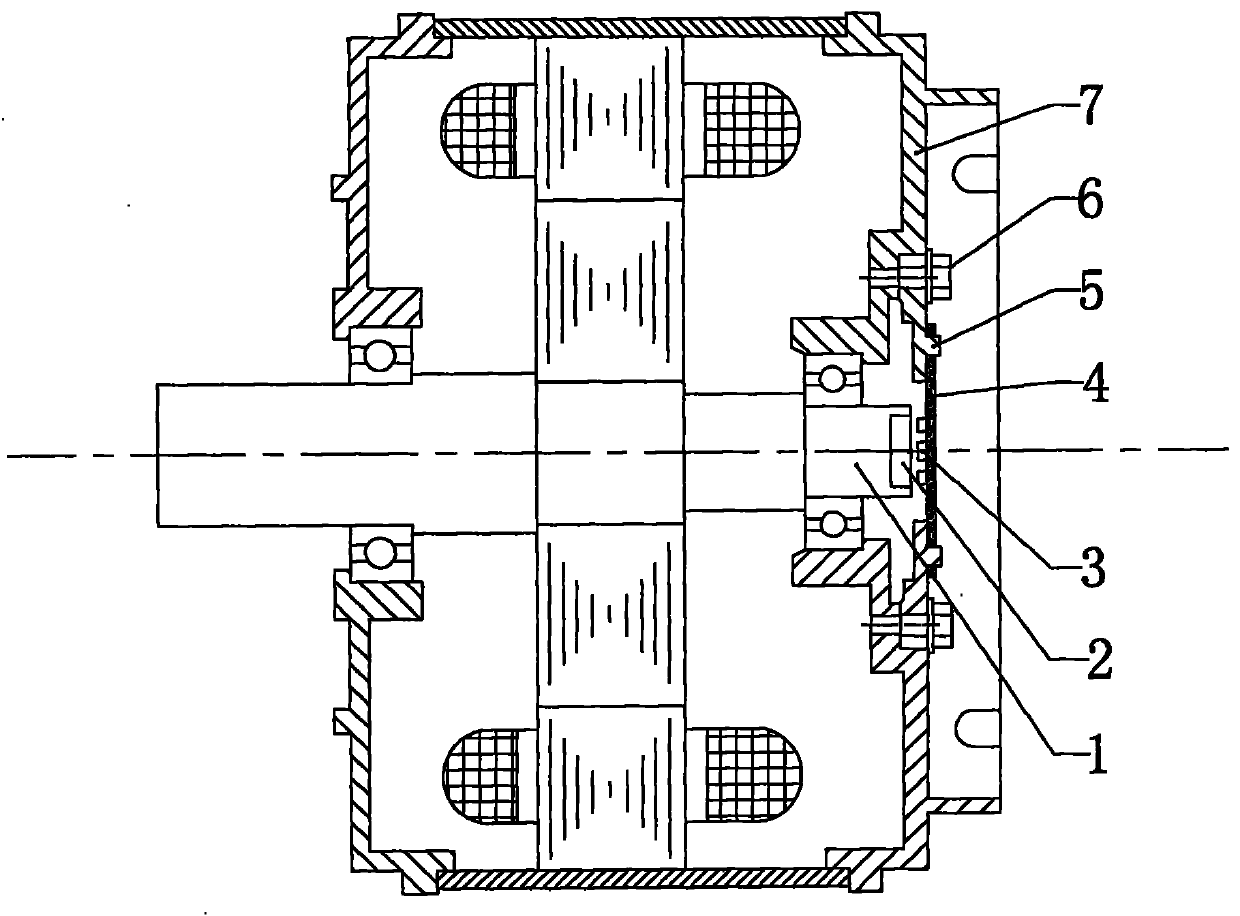

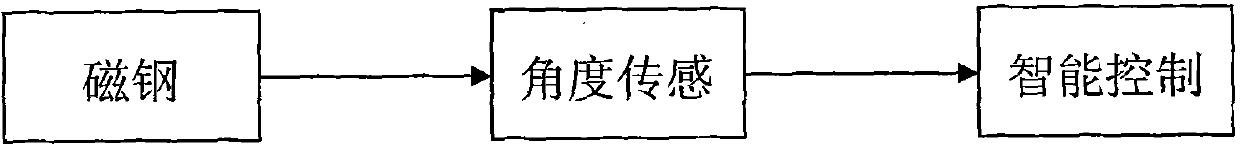

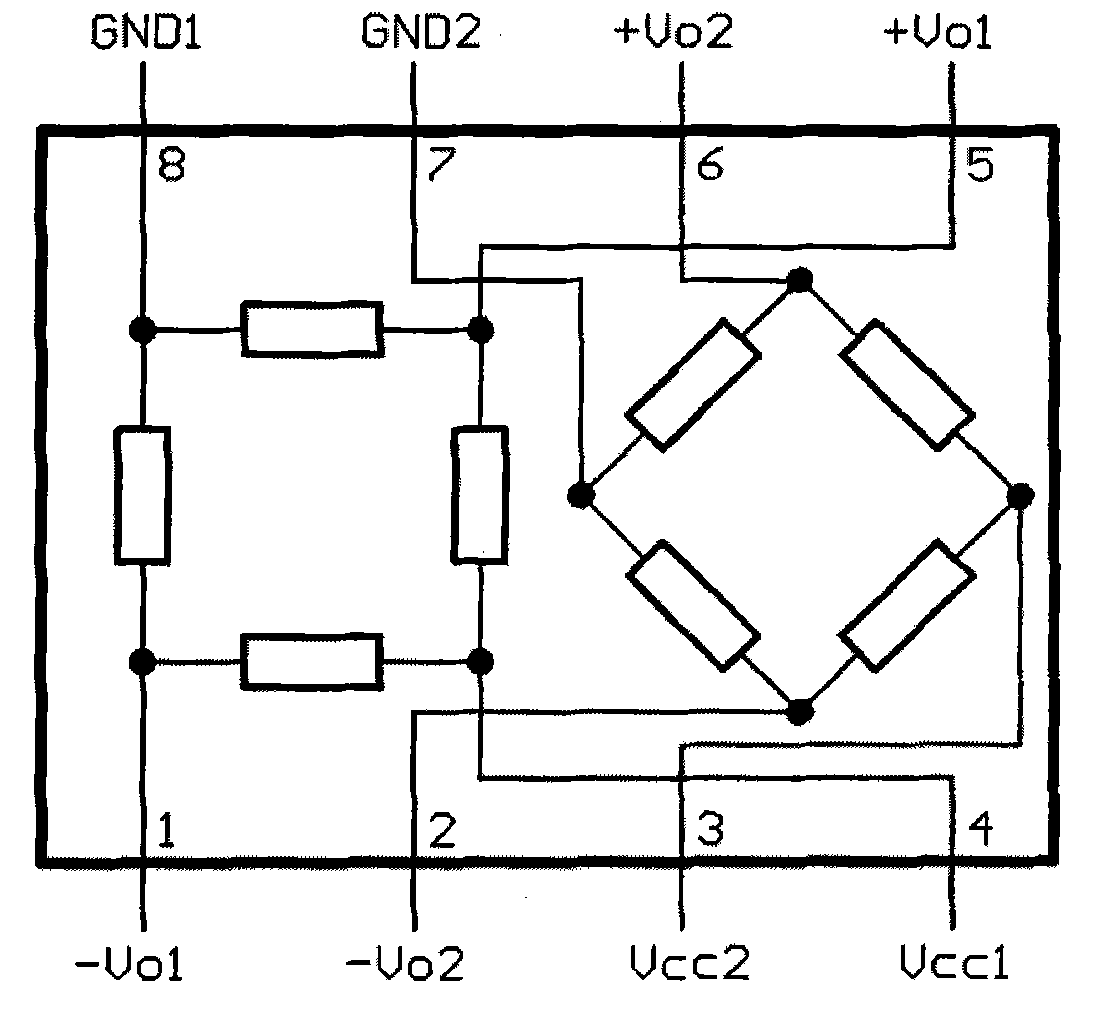

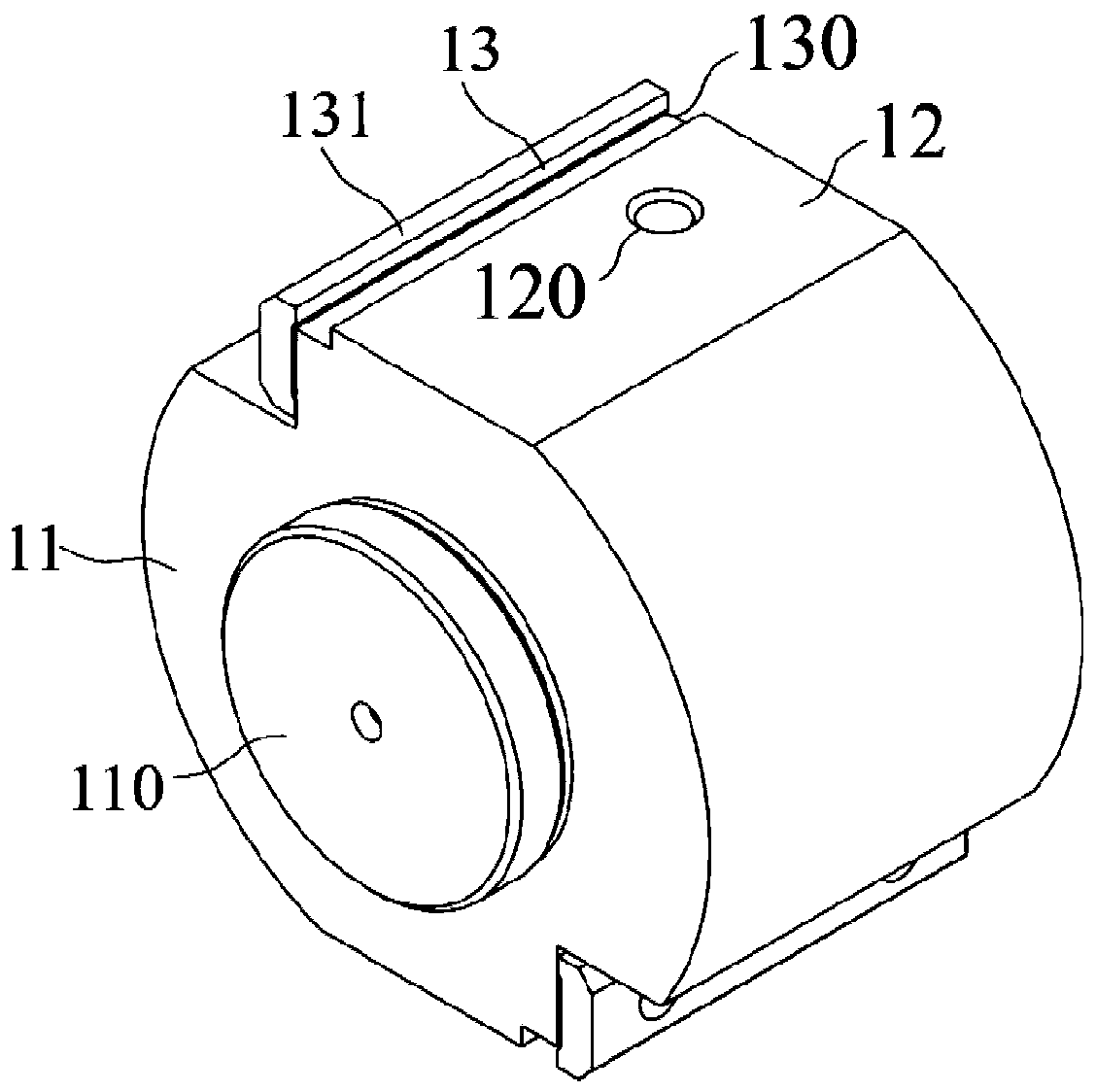

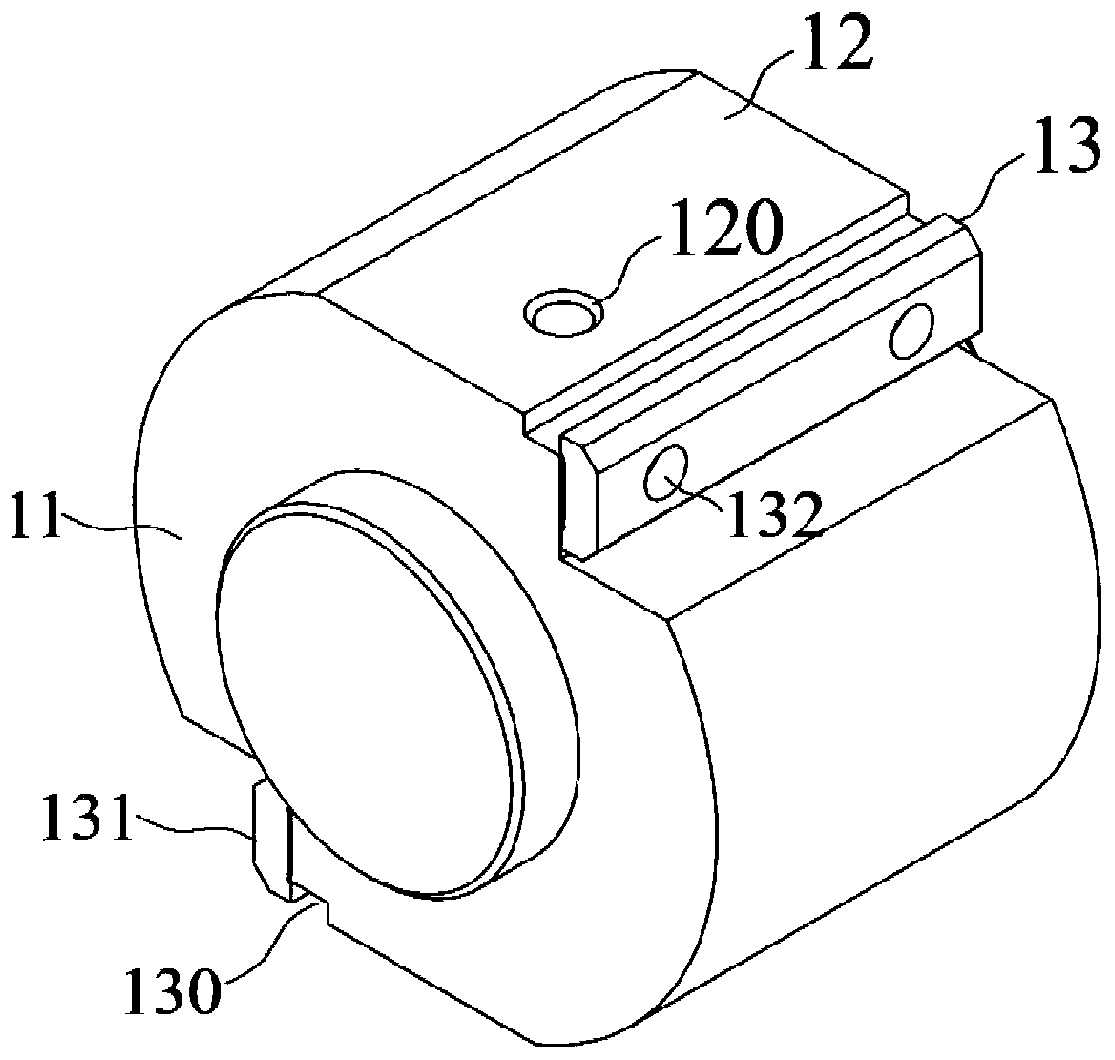

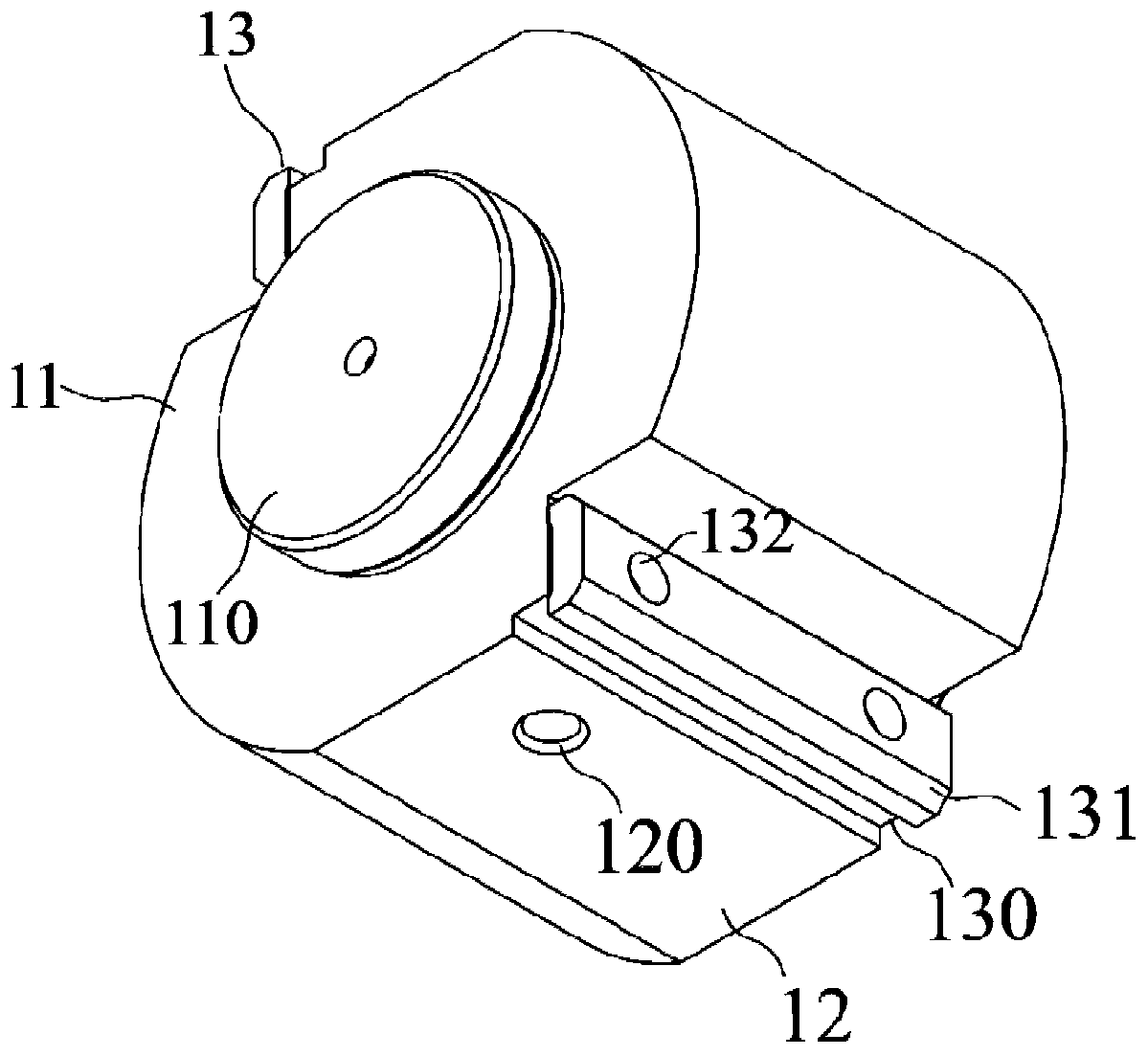

Intelligent control device of motor for electric automobile

InactiveCN103762784AImprove operational efficiencyImprove driving comfort performanceSingle motor speed/torque controlElectric machinesControl systemPhase difference

The invention relates to an intelligent control device of a motor for an electric automobile. The intelligent control device can control operation of the motor precisely and improve operating efficiency of the motor. The intelligent control device comprises an angle induction device and a magnetic field emission device, wherein the angle induction device is composed of an angle transducer, a circuit board and a mounting plate, the mounting plate is fixed to an end cover of the motor, the circuit board is fixed to the mounting plate and provided with the angle transducer, the magnetic field emission device comprises magnetic steel, the magnetic steel is fixed to the end portion of a motor shaft and has an N pole and an S pole, when the motor shaft is started to operate, a sine wave waveform with a phase difference of 45 degrees is generated between the magnetic steel and the angle transducer, a control system controls the sine wave waveform so as to control the motor to stably operate, more accurate precision control is achieved, operating efficiency of the motor is improved, driving comfort of the finished automobile is improved and the continuous operational mileage of the finished automobile is lengthened.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

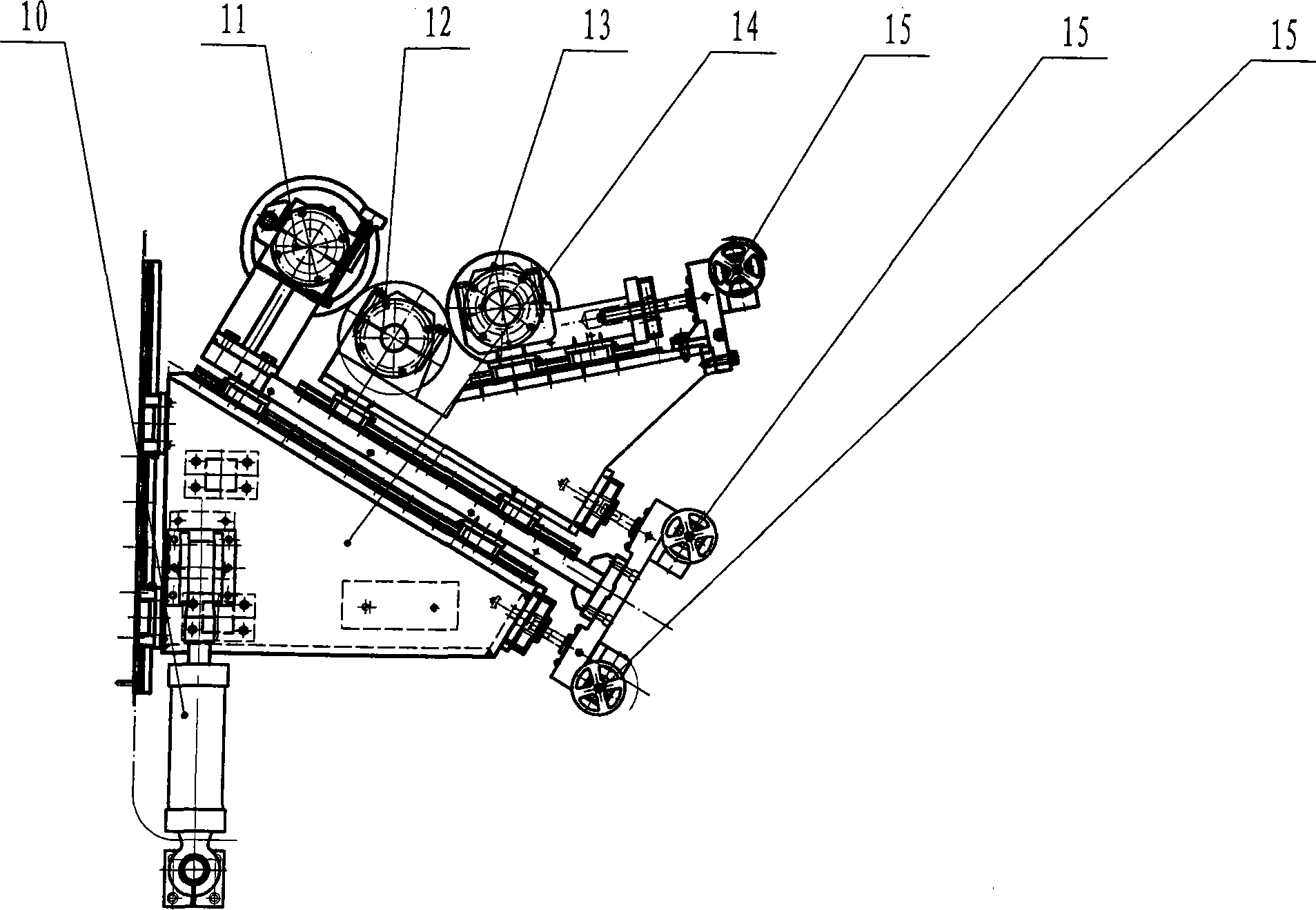

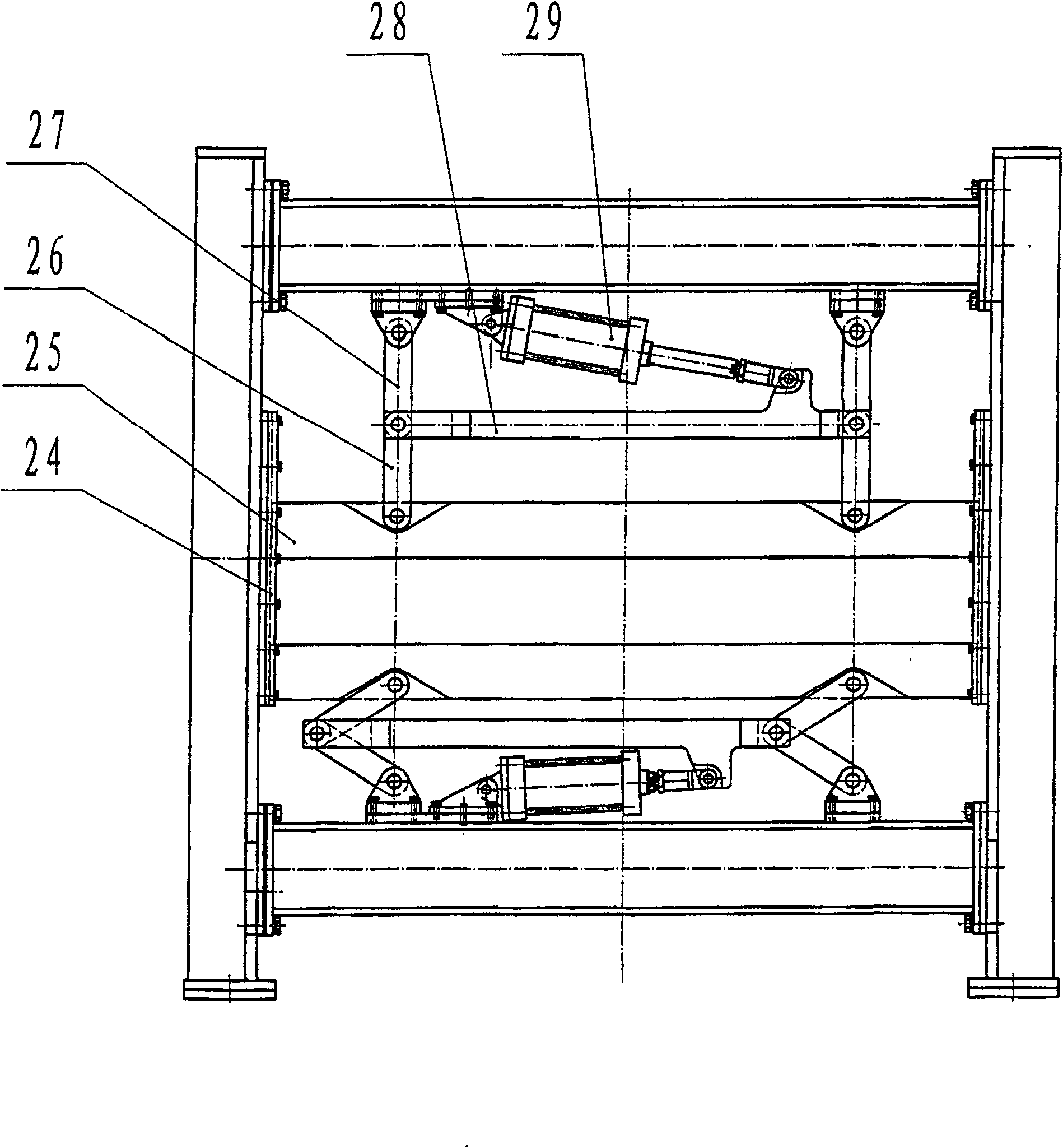

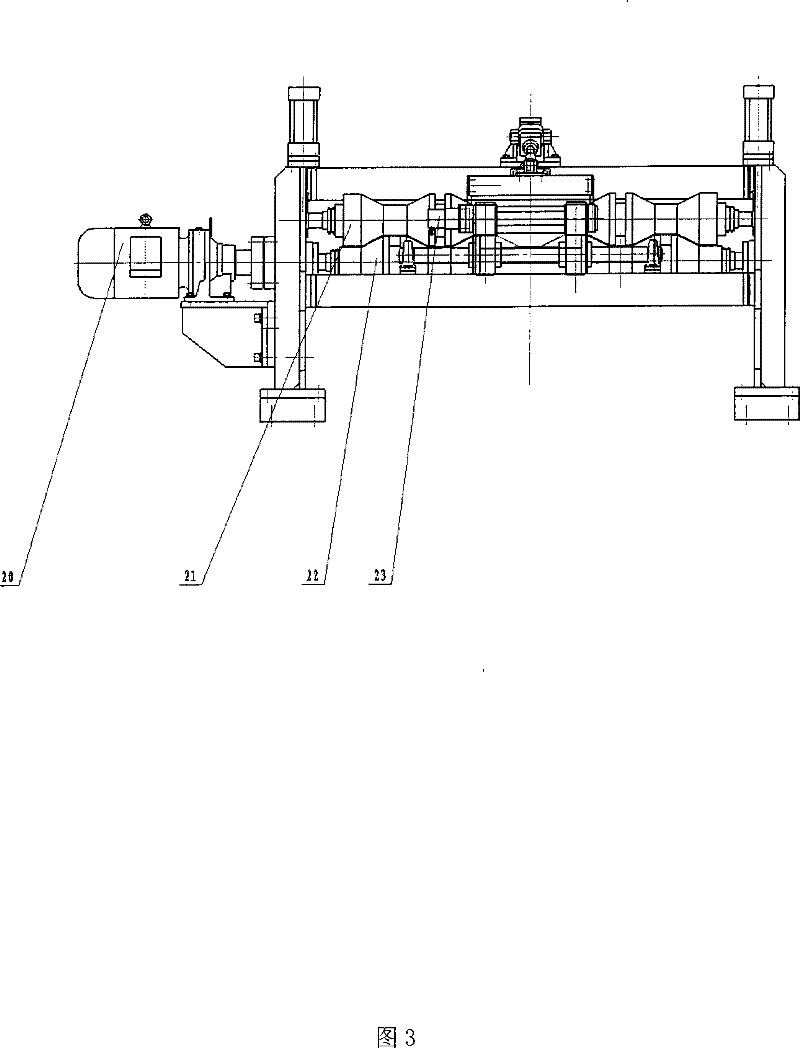

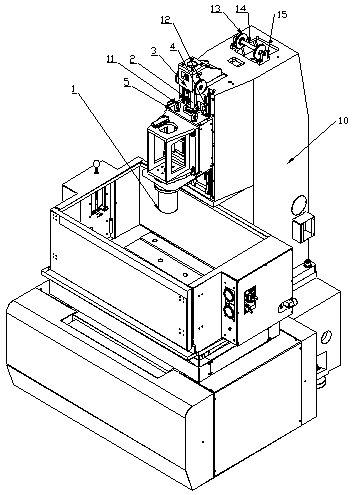

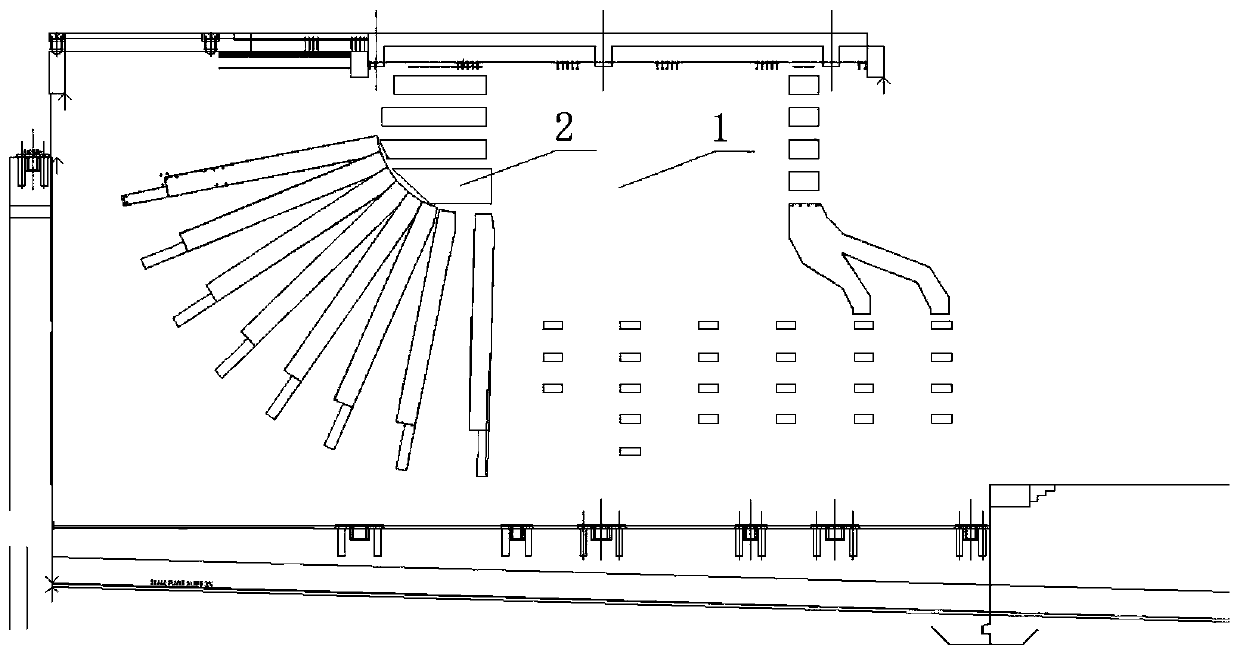

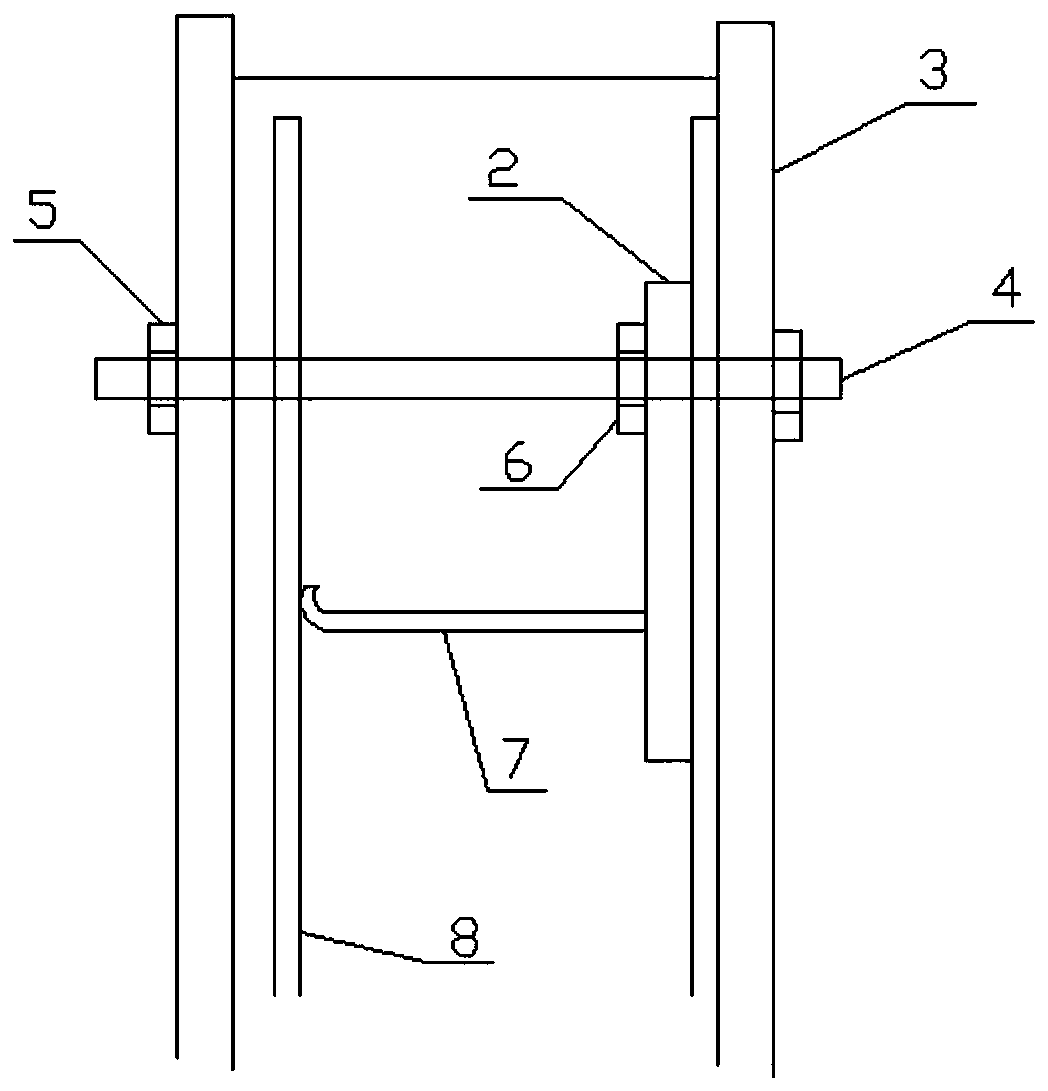

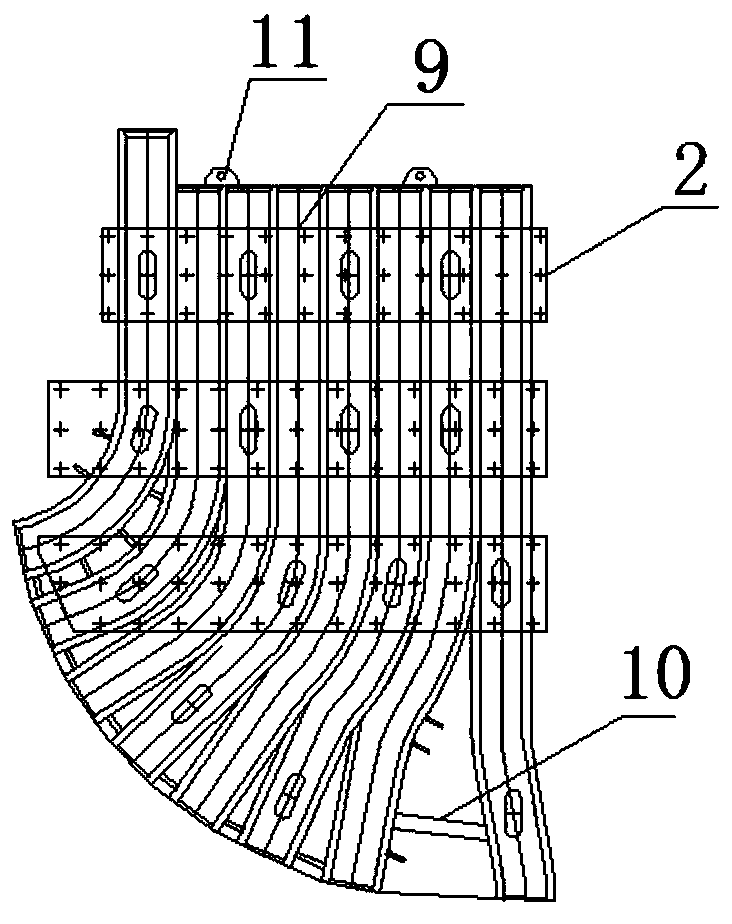

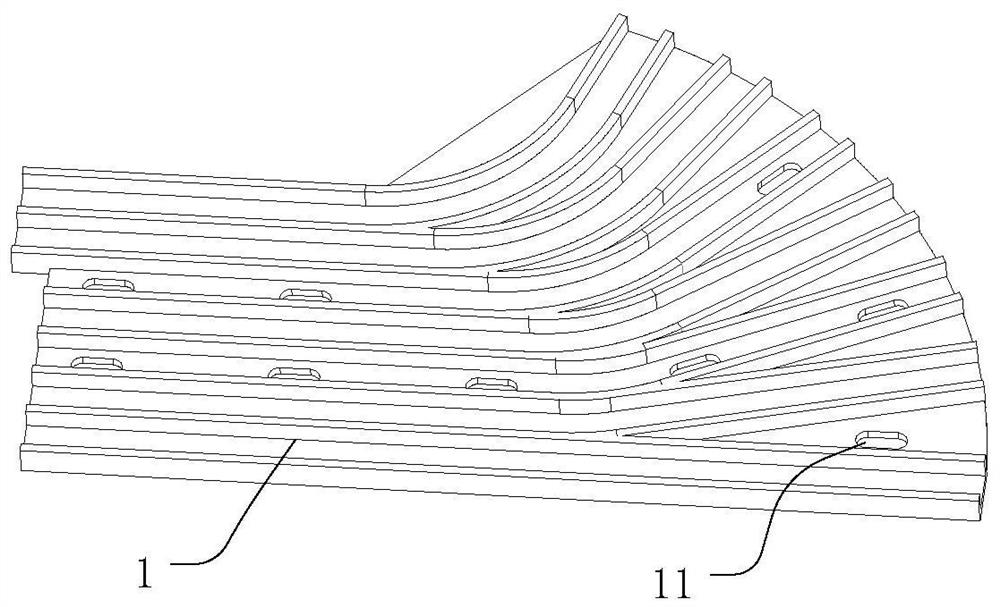

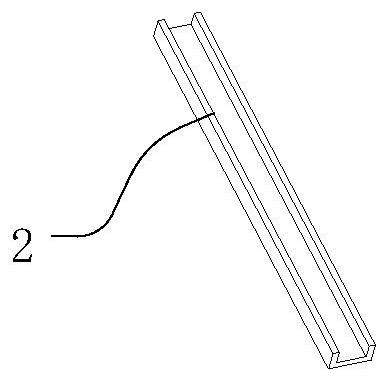

Novel rust cleaning machine

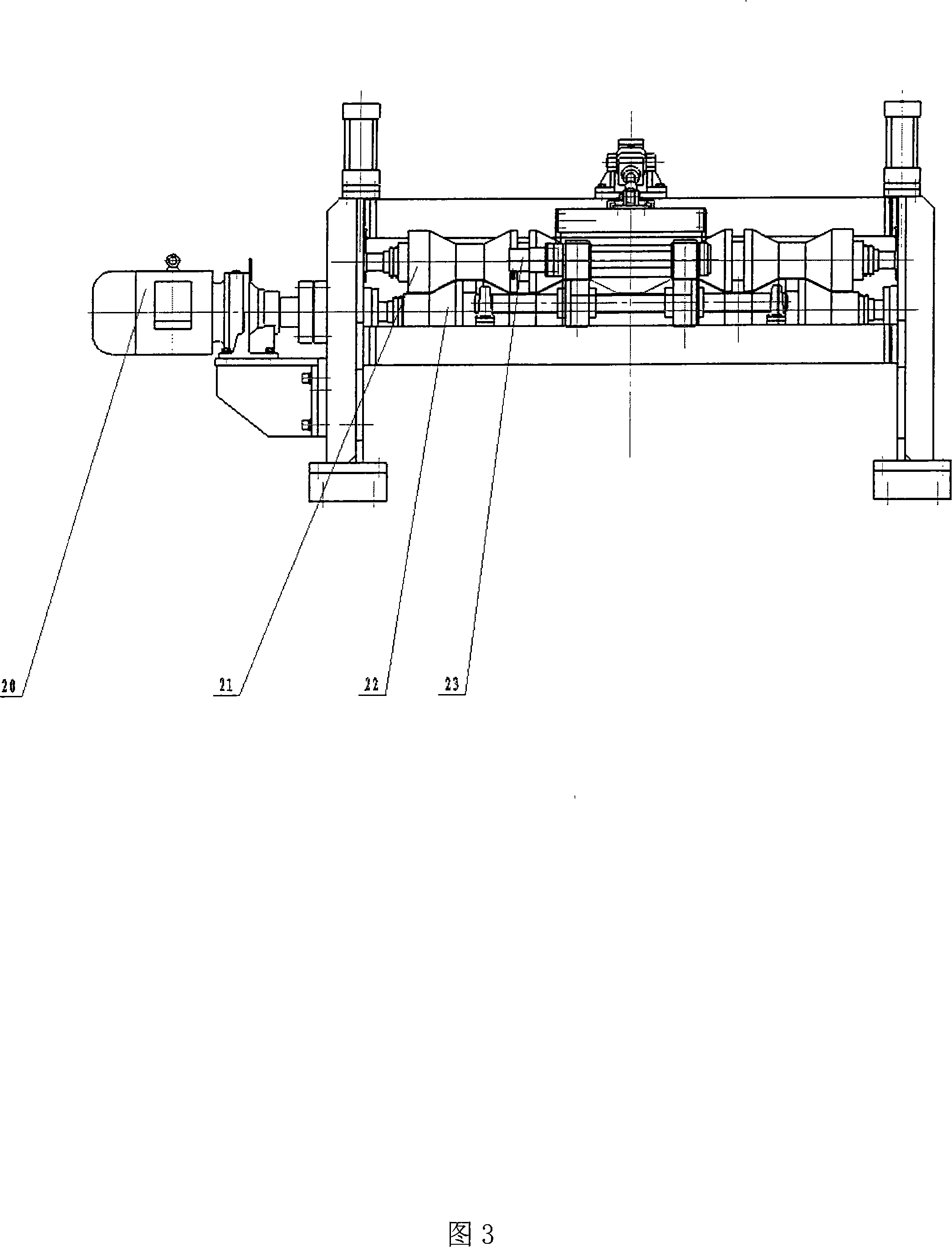

The invention provides a novel derusting machine for strip local double-sided derusting in the metallurgy field. The derusting machine consists of a memorial archway 1, an inlet feeding plate 2, a pressure plate device 22, and a beam 9. A synchronous motor 11 fixed on the memorial archway 1 drives a silk pole 7 to rotate, so that the a silk pole nut 6, and an upper door frame 3 and a lower door frame 12 fixed on the silk rod nut is only required to synchronously horizontally move a very short distance along the beam 9 through a linear guide rail to complete the derusting work of the whole width of the steel band. A swing frame cylinder 13 fixed on a swing frame 18 is thread-connected with a connecting guide sleeve 5 which is provided internally with a buffer spring. The stretching of the swing frame cylinder 13 provides impetus pairs of multi-strand steel wire twisted brushes 23 to swing up and down. The pulley motor 14 provides impetus for a driving pulley 15 to drive a driven pulley19 through a middle pulley 16 to rotate a main shaft 20 and the multi-strand steel wire twisted brush 23. The derusting machine is safe and friendly to environment, and has high level of automation.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Flying shear for shearing corrugated plate

ActiveCN101234439BSolve the problem of uneven cross-sectionSolve uneven problemsStock shearing machinesShearing machine accessoriesSheet steelClosed loop

The invention provides a flying shear applicable to cutting a corrugated plate applied in metallurgy field, and includes an electric control system; the flying shear comprises an actuating motor 2, a locking device 3, a left and a right wheel boxes, an upper and a lower cutting devices, a leader device 9, a pedestal 19, a pinch roll, and a measuring motion, etc. The flying shear is characterized in that a section of the corrugated plated cut by the flying shear is vertical, whereas a section cut by a current flying shear is oblique; shapes of an upper and a lower blades are compatible with the shape of the corrugated plate; when adjusting a blade gap, the locking device is functioned as controlling a position of ''a bottom stop'' of the lower blade and a safe protection; while the pinch roll and the pinch roll of the measuring motion adopt heterotype to be suited for the waveform of the corrugated plate, thus functioned as locating a board and controlling the position of the board, and when cut, the steel plated has a fixed position; the equipment is provided with three encoders wherein the encoders are coordinated with each other according to difference of given signals, thus a controlling function of a closed loop is accomplished; a fixed length can be carried out accurately, thus ensuring that the precision of the fixed length is controlled within plus or minus 1.0mm.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

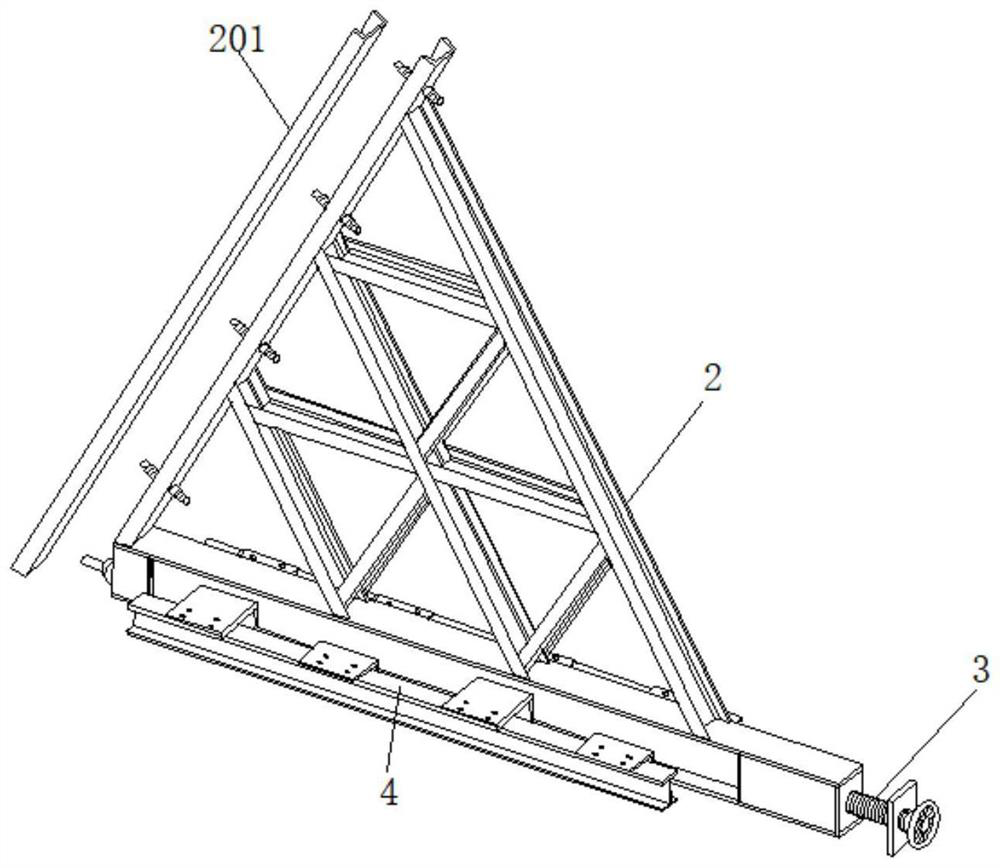

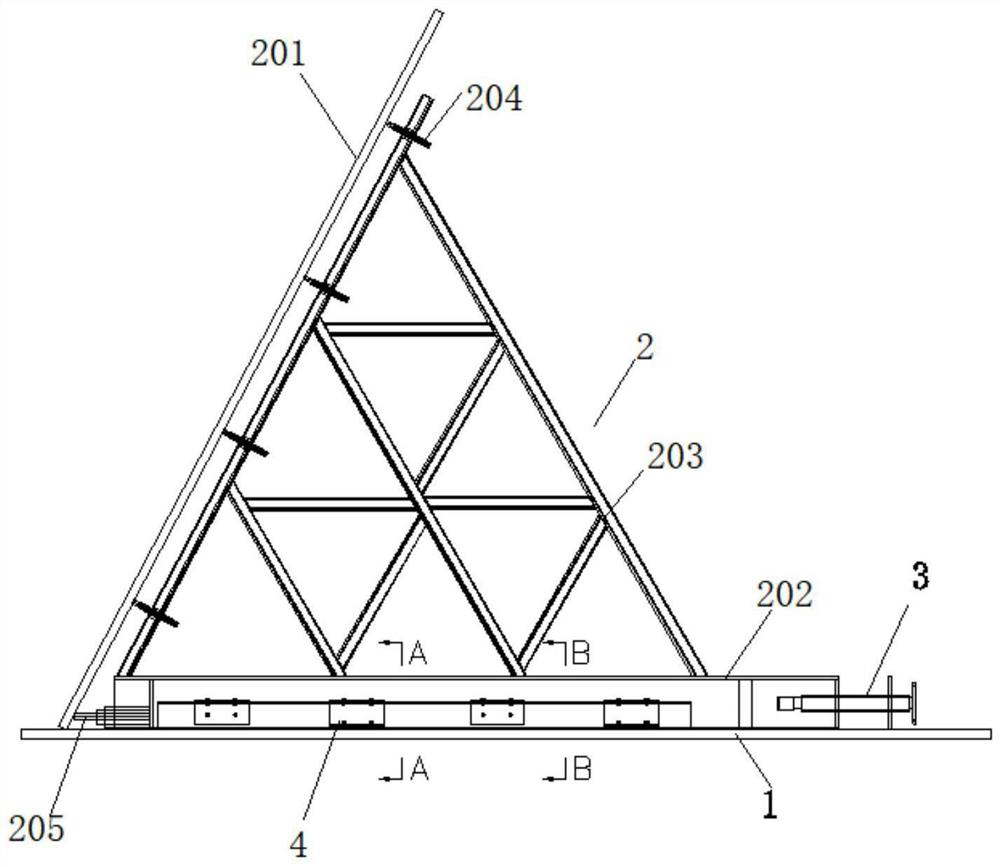

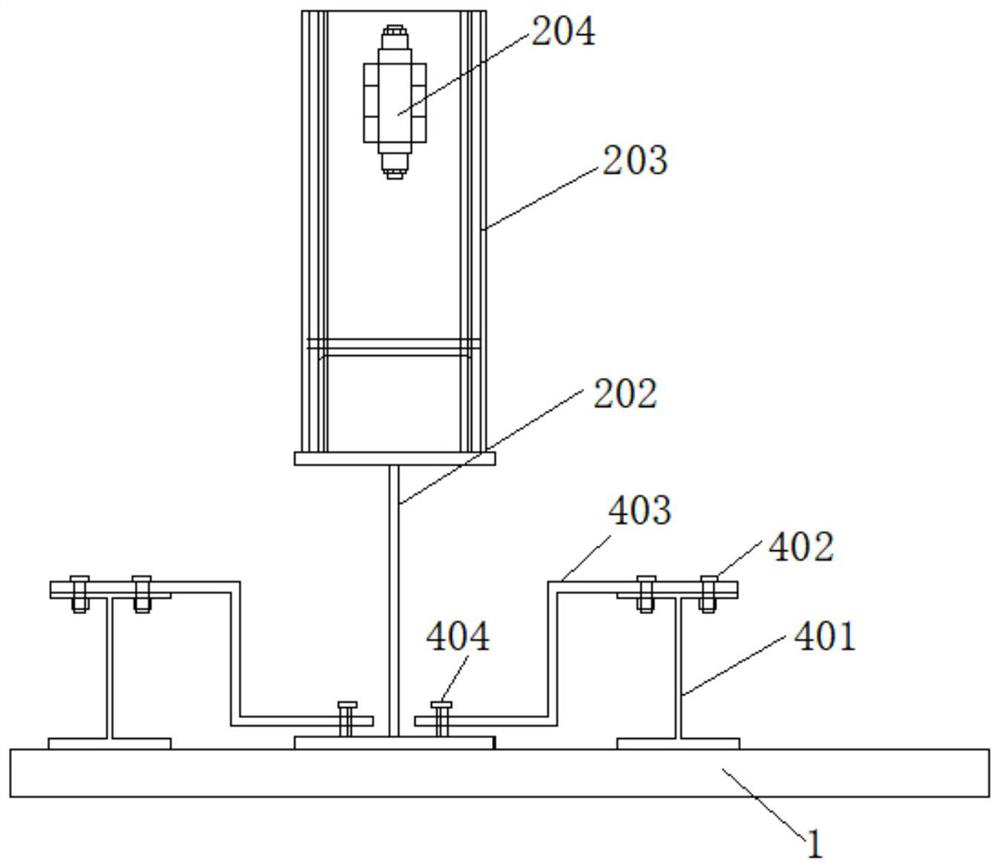

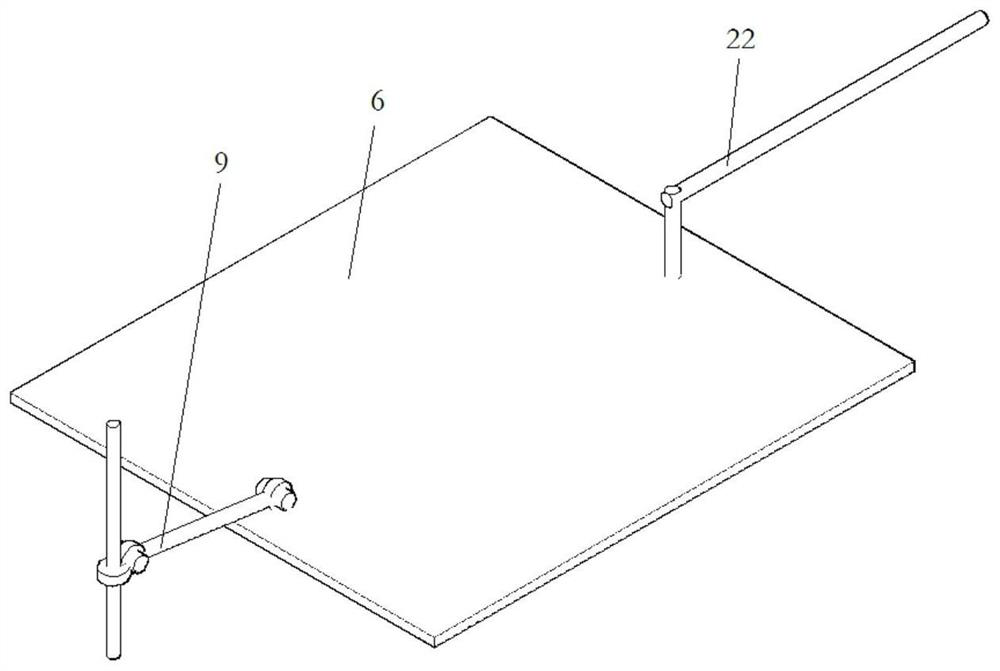

Method and system for controlling assembly precision of variable cross-section space angle steel member

PendingCN114776050AEasy to controlFine-tuning controlBridge erection/assemblyBuilding material handlingMaterial consumptionMan machine

The invention provides a variable cross-section space angle steel component assembling precision control method and system. The method comprises the following steps of detecting a jig frame platform, marking out the jig frame platform, installing the system on the jig frame platform, finely adjusting the system, performing secondary fine adjustment on the system after a steel tower component is in place, assembling segments, disassembling the system and reusing the system. The problems that an existing segment manufacturing method and tool are low in efficiency, large in material consumption, large in damage, low in universality, large in man-machine consumption for disassembly and assembly and potential safety hazards exist are solved. The system is accurate in precision control, wide in application range, high in repeated utilization rate, convenient to operate and good in safety; the method can be used for assembling and precision control of various variable cross-section space angle steel members, the manufacturing precision is guaranteed, meanwhile, the production efficiency is improved by two times, the tool cost is reduced by 50%, and cost reduction and efficiency improvement are remarkable; positioning, assembling and adjusting are convenient and fast; labor and machinery can be saved in each link, and construction tasks can be efficiently completed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

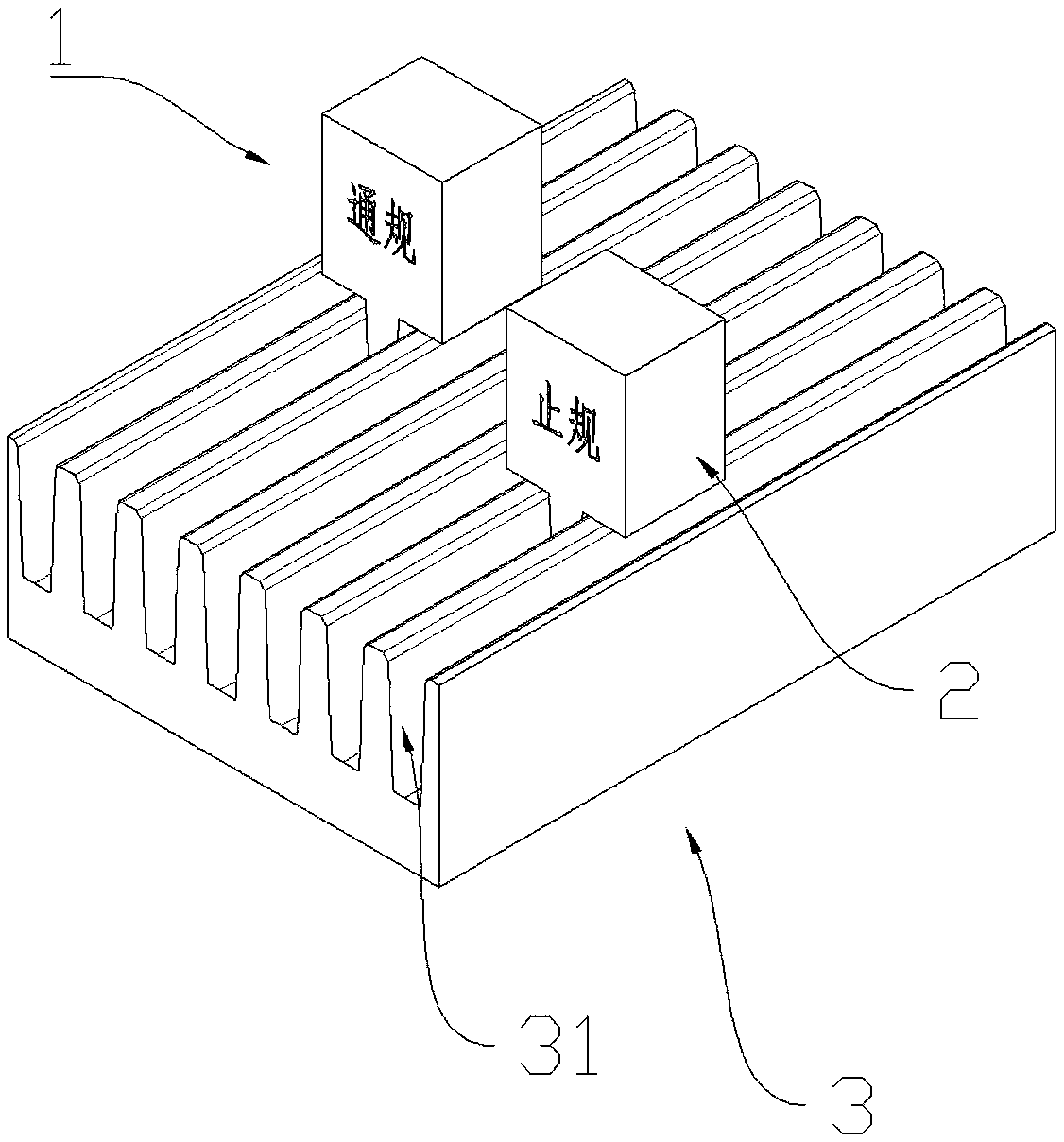

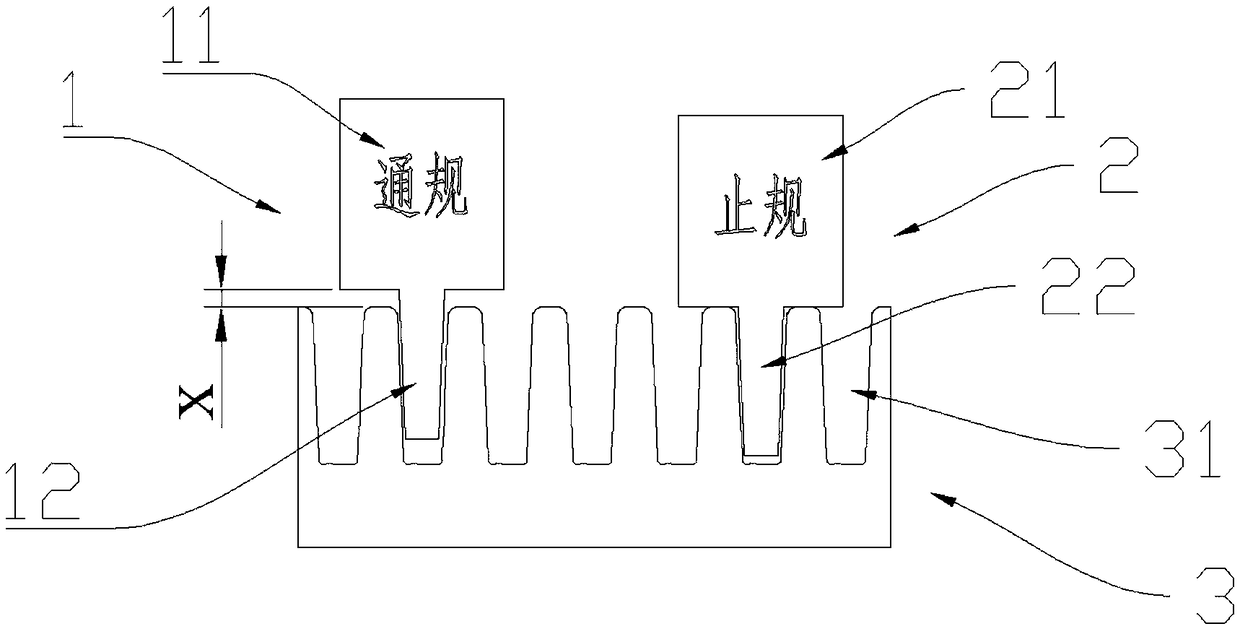

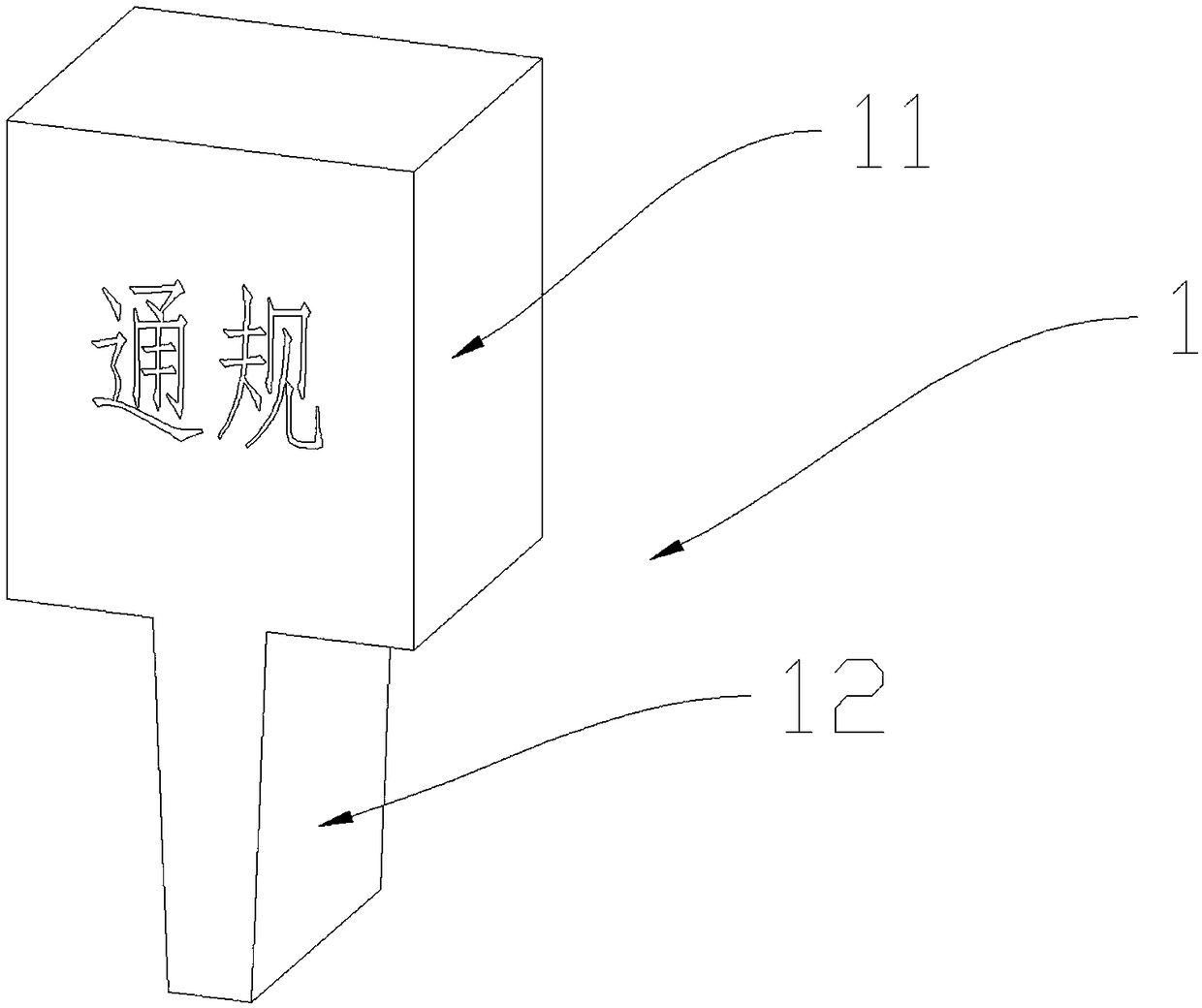

Cascade mold inspection tool

The invention discloses a cascade mold inspection tool. The inspection tool comprises a go gauge and a no-go gauge used cooperatively with the go gauge, wherein the go gauge comprises a holding part Aand a detection part A fixedly connected with a bottom end of the holding part A; the holding part A and the detection part A are integrally formed; the no-go gauge comprises a holding part B and a detection part B fixedly connected with a bottom end of the holding part B; and the holding part B and the detection part B are integrally formed. The cascade mold inspection tool disclosed by the invention has the beneficial effects of simple structure, easy manufacturing, low cost, high detection efficiency, accurate precision control, short detection time and simple determination standard.

Owner:SUZHOU GUANGXING MOLD

Sawtooth driving mechanism for electric saw

InactiveCN107717115ALimit travel rangeEasy to adjustMetal sawing tool makingElectrical-based auxillary apparatusElectrical and Electronics engineeringEngineering

The invention relates to a sawtooth driving mechanism for an electric saw, which includes a driving slider, a driving guide rail and a proximity switch; the driving guide rail has a pair, which are symmetrically installed on the side wall of the gantry frame, and the two ends of the driving slider are respectively installed on two on a driving guide rail, and can be driven by the driving device to move up and down; the proximity switch is installed on the side end of the driving slider, and at the same time, a contact plate used with the proximity switch is also provided on the gantry frame. There is also a scale plate, and the contact plate can be adjusted up and down according to the scale of the scale plate. The advantage of the invention is that the device can provide a basis for precise control of the working stroke of the main shaft.

Owner:如皋千骏工具有限公司

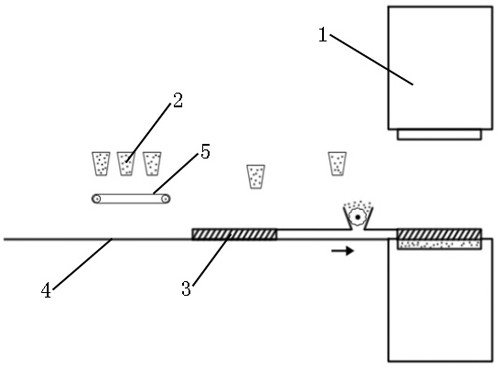

A kind of pavement panel manufacturing equipment and method for manufacturing composite block pavement panel by the device

ActiveCN108705653BAdjustable thicknessEasy to operateSingle unit pavingsCeramic shaping apparatusPavement engineeringConstruction engineering

The present invention relates to a road slab manufacturing equipment and a method for making a composite block road slab with the equipment, comprising a support stand, a block forming device and a vibrating motor, a guide rail is arranged on the support stand, and a block forming device is placed on the guide rail. The block material forming device includes a base plate, a mold, a pellet positioning plate, and a pressure plate. The lower surface of the base plate is provided with a guide rail groove and is slidingly connected with the guide rail of the supporting platform. The mold and the base plate are disassembled and connected. The plate is placed above the inner material surface of the mold, and the vibration motor is fixedly connected under the bottom plate through the motor base. The production equipment of composite block material path panels can produce composite block material path panels of different specifications, the precision control is accurate, and the detachable device is convenient for mold removal and maintenance. Composite block material road panel is convenient and quick to assemble and construct during road paving. The size of the block material can be adjusted flexibly according to the location and plane shape of the road surface project, and the paved road surface is resistant to shifting and salt corrosion.

Owner:UNIV OF SCI & TECH LIAONING

A kind of distributing equipment and its preparation method of imitation marble hole brick

ActiveCN108407066BImprove efficiencyPrecision control is accurateFeeding arrangmentsShaping press ramBrickEngineering

A kind of material distributing equipment and its preparation method of imitation marble hole brick, this material distributing equipment comprises press machine, material holding device, material distributing device and conveying device; Said material holding device is arranged on one side of said press machine, said material distributing device The device is installed on the conveying device and is located below the material holding device. The cloth distributing device includes a fabric frame, a hole material frame and a base material frame, and the fabric frame, the hole material frame and the base material frame are horizontally installed on the conveying device and the three are integrally formed; the bottom of the distributing device is flush with the top of the lower mold of the press, and the distributing device is conveyed horizontally to the top of the press by the conveying device The material is distributed in the lower mold; a material distribution equipment for preparing imitation marble hole bricks, which realizes the synchronous transmission of ceramic body raw materials with three different functions of base material, surface material and hole material, and separate and orderly material distribution. The structure is simple and High cloth efficiency.

Owner:FOSHAN DONGHUA SHENGCHANG NEW MATERIAL CO LTD +3

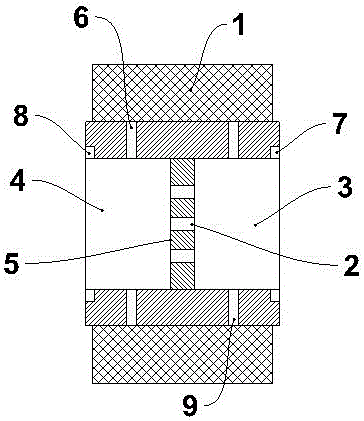

Planetary gear device

InactiveCN106763693AEasy to processPrecision control is accuratePortable liftingGear lubrication/coolingEngineeringFlange

The invention discloses a planetary gear device. The planetary gear device comprises a gear body. The gear body is provided with a flange. Gears are arranged on the periphery of the flange of the gear body. A left end inner hole and a right end inner hole are formed in the center of the flange of the gear body. A left end annular groove is formed in the position, on the flange of the gear body, of the left end of the left end inner hole. A right end annular groove is formed in the position, on the flange of the gear body, of the right end of the right end inner hole. A baffle ring is arranged between the left end inner hole and the right end inner hole and provided with evenly distributed baffle ring holes. A plurality of left end oil holes formed in the radial direction of the left end inner hole are formed in the wall, on the left side of the baffle ring, of the left end inner hole. A plurality of right end oil holes formed in the radial direction of the right end inner hole are formed in the wall, on the right side of the baffle ring, of the right end inner hole. All the left end oil holes and the right end oil holes communicate with the roots of teeth outside the gear body. The planetary gear device is good in lubricating and radiating performance, convenient to machine and mount and has quite high application and popularization value.

Owner:新昌县东韩机械有限公司

A kind of production method of microporous membrane sintered filter element

InactiveCN103071400BSimple molding processPerfect formulaSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisChemical reactionThree-dimensional space

The invention discloses a manufacturing method of a microporous membrane sinter filter element, is applicable to mounting and assembly occasions of combined type water purifiers and belongs to the technical field of water resource purification. Micropores of the microporous membrane sinter filter element manufactured through the method are formed through pure-physical hot melt binding instead of a chemical reaction; and the method adopts the principle that during the heating and sintering process of a main material, after being bonded with an auxiliary material during the melting process, the main material shrinks in the following cooling process to form three-dimensional space clearances, and the micropores are related to the main material and the auxiliary material in shapes and particle sizes. The manufacturing method has the advantages of simplicity and convenience in process molding, comprehensive formula, accuracy in precision control, reliable performance and low manufacturing cost.

Owner:NINGBO HO WATER PURIFICATION EQUIP TECHCO LTD

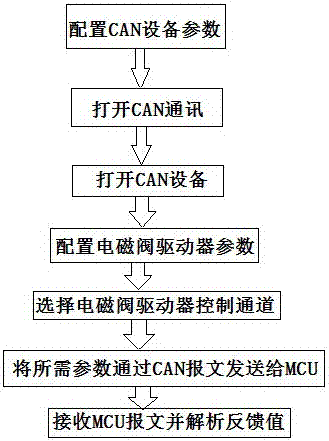

Host control method

InactiveCN107966929AMeet control needsReasonable designProgramme controlComputer controlMicrocontrollerControl communications

The invention relates to a host control method and belongs to the communication control field. The method comprises steps that CAN device parameters are configured; CAN communication is opened, and interconnection among a CAN device, a PC and an MCU microcontroller is established; the CAN device is opened, and parameters of a solenoid valve driver are configured; a to-be-controlled control channelis selected; required parameters are sent to the MCU microcontroller through the CAN message; an MCU microcontroller message is received, and a feedback value is analyzed. The method is advantaged inthat design is reasonable, the method is stable and reliable, is simple and convenient and is easy for operation, precision control is accurate, and use demands of people can be satisfied.

Owner:HANGZHOU GAOPIN AUTOMATION EQUIP

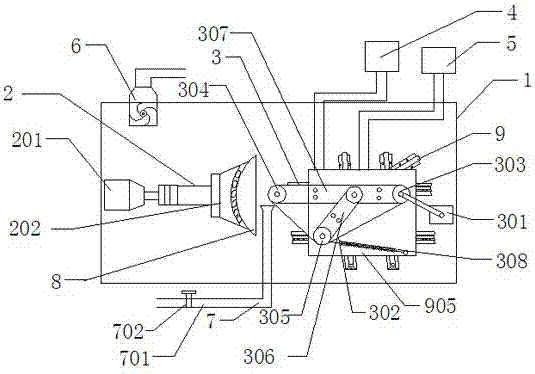

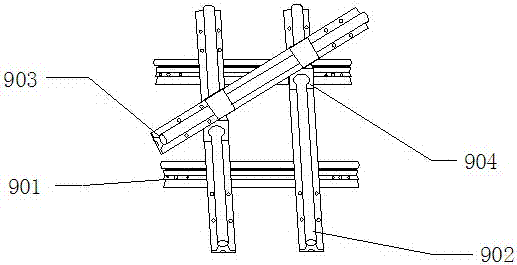

a pan grinder

InactiveCN105014508BReduce the temperatureZhang progress is convenientBelt grinding machinesGrinding/polishing safety devicesDust controlEngineering

The invention relates to a pot polishing machine. The pot polishing machine comprises a closed machine frame shell. A clamping device and a polishing device are arranged in the machine frame shell, wherein the clamping device is used for clamping a pot body to be polished and driving the pot body to be polished to rotate, and the polishing device is used for polishing the pot body to be polished. Besides, the clamping device and the polishing device are controlled through a digital control device and a hydraulic device. The polishing device is arranged on a shifting mechanism and moved on the shifting mechanism so as to polish the pot body to be polished. The shifting mechanism is composed of two transverse guide rails, two longitudinal guide rails and an oblique guide rail. The transverse guide rails are arranged horizontally. The longitudinal guide rails slide on the transverse guide rails through sliding blocks to constitute a guide rail set shaped like a Chinese character 'jing'. The oblique guide rail is arranged on the longitudinal guide rails in a sliding mode through sliding blocks and fixedly connected with the polishing device through a fixed plate I fixed to the oblique guide rail. The pot polishing machine is provided with the polishing device with the guide rails, a dust removal device, a cooling device and the like, thereby being accurate in precision control, simple in structure, integrally formed, high in working efficiency, capable of improving the environment, safe and durable.

Owner:程远魁

Planet gear

InactiveCN109139866AEasy to processPrecision control is accuratePortable liftingGearing elementsEngineeringMachining

The invention relates to a planet gear. The planet gear comprises a gear body and is characterized in that the gear body is provided with a gear rim, the outer circle surface of the gear rim of the gear body is provided with a gear, and the pressure angle of the gear is 25-27 degrees; the center of the gear rim of the gear body is provided with a left end inner hole and a right end inner hole; andbaffle rings are arranged between the left end inner hole and the right end inner hole. According to the planet gear, the baffle rings are arranged between left end inner hole and the right end innerhole of the planet gear, the left end inner hole and the right end inner hole are the same in diameter, machining and manufacturing are convenient, and precision control is accurate; and in addition,the pressure angle of the gear is 26.5 degrees, so that the pressure angle of the planet gear is more reasonable, the mechanical strength is good, and the service life is prolonged.

Owner:扬州市轩煌铸造有限公司

Scrap cutter edge surface machining method

The invention discloses a scrap cutter edge surface machining method, and belongs to the field of scrap cutter edge machining. The scrap cutter edge surface machining method comprises the following steps: (1) turning: scrap cutter edges to be machined are assembled in a lathe after installation on a turning and grinding fixture; and scrap cutter edge surfaces to be machined are roughly turned by the lathe; (2) milling: the scrap cutter edges roughly turned in the step (1) are assembled in a milling machine after installation on a milling fixture; and the scrap cutter edge surfaces are milled by the milling machine; and (3) grinding: the scrap cutter edges milled in the step (2) are assembled into a grinding machine after installation on the turning and grinding fixture; and the scrap cutter edge surfaces are finely grinded by the grinding machine. The edge surfaces of the scrap cutter edges to be machined are machined through the turning, milling and grinding steps, and all the steps can be performed at the same time, so that the machining method achieves higher overall efficiency; and through each step machining, the precision of the scrap cutter edge surfaces is continuously improved, and the scrap cutting effect and the service life of the scrap cutter edges are improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

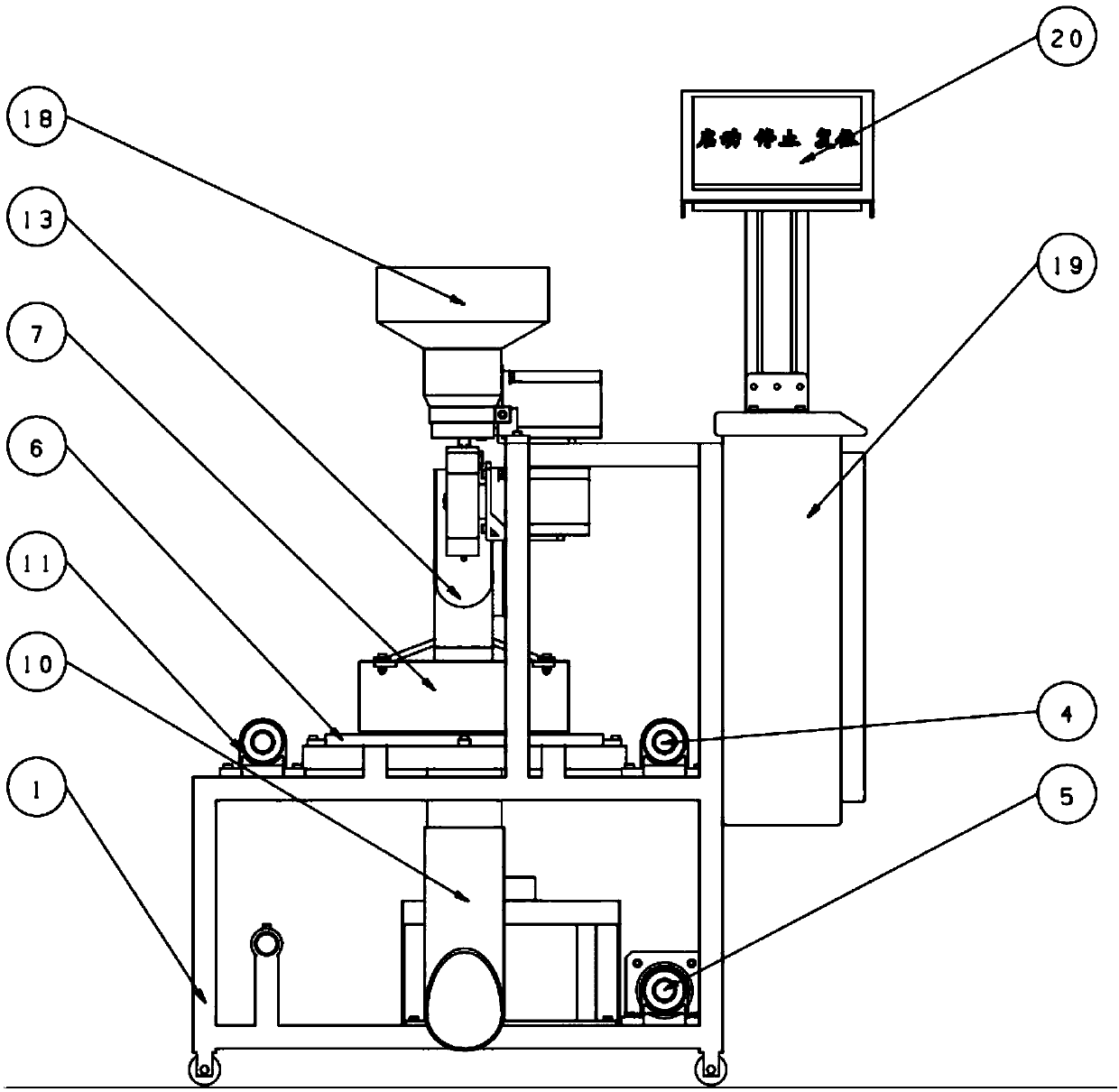

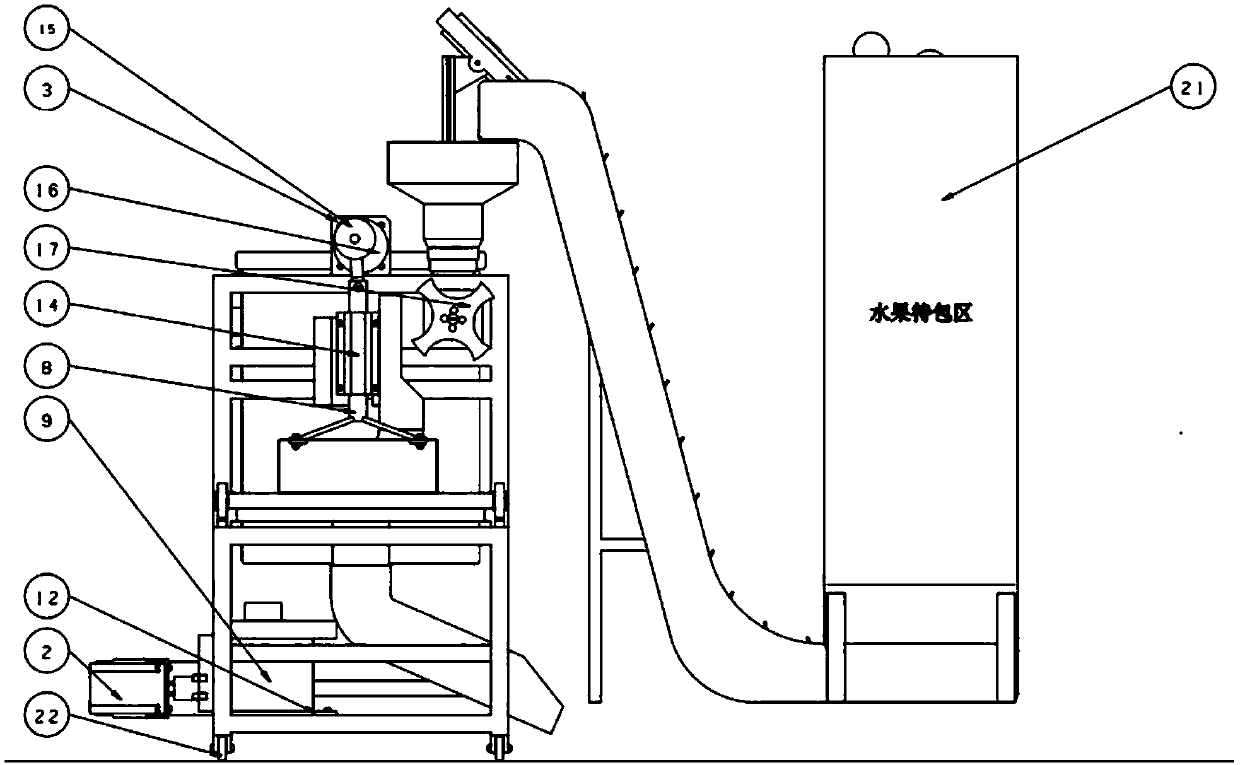

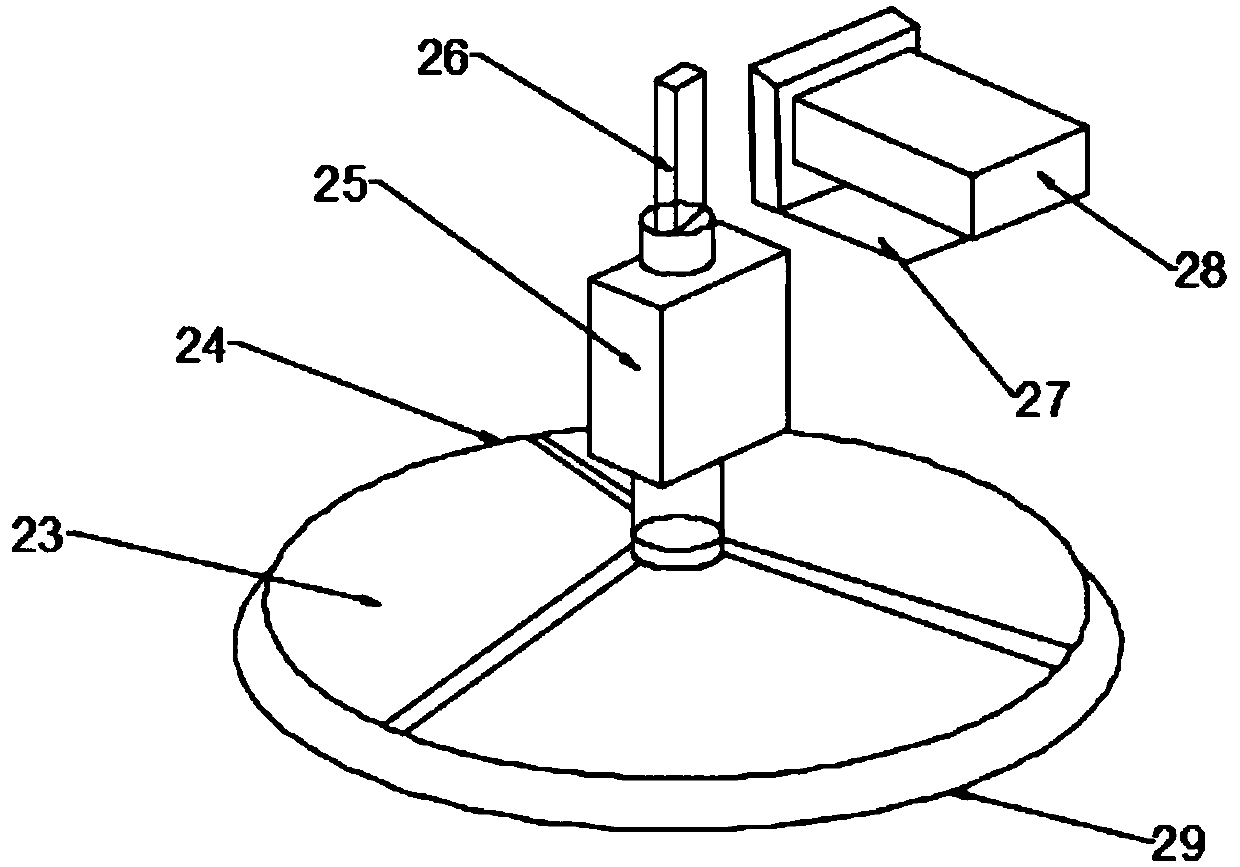

Citrus packaging machine

InactiveCN110789763APacking speed is fastImprove packaging efficiencyPackaging fruits/vegetablesControl systemCrank

The invention discloses a citrus packaging machine. The citrus packaging machine comprises a rack, a transmission device, a heat-assisted cutting device, a to-be-packaged sorting and positioning device, a film shrinkage and finished product conveying damping device and an intelligent high-definition control system, wherein the cutting device is composed of a supporting cutter, an upper cutter, a sliding block, a motor base, a connecting rod, a crank, a coupler and a heat-assisted cutter; the supporting cutter is of a funnel-shaped structure and is fixed to the rack through bolts, and plastic with the thickness being 3mm is arranged on the surface of the supporting cutter; the upper cutter is formed by welding a round support and an optical shaft with the shaft diameter being 30mm; a cutterfor cutting a preservative film is fixed to the bottom end of the round support; and the optical shaft is matched with the fixed sliding block with the inner diameter being 30 mm. The citrus packaging machine is easy and convenient to operate, low in manpower requirement and beneficial to improving the labor productivity. The citrus packaging quality is stable, the packaging rejection rate is low, and the production cost is obviously reduced. The citrus packaging machine can conduct operation conveniently and rapidly, the labor intensity of workers can be relieved, and the single citrus packaging and processing time is shortened.

Owner:QUZHOU COLLEGE OF TECH

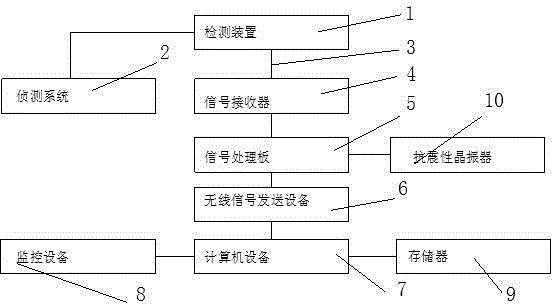

Position detection system

InactiveCN105537283ADetection location preparationPrecision control is accurateMeasuring devicesMetal rolling arrangementsLocation detectionSignal processing

The invention discloses a position detection system. The position detection system comprises a detection device. The detection device is connected with a sensing system and connected with a signal receiver through a light wave wire. The signal receiver is connected with a signal processing panel through a light wave wire. The signal processing panel is connected with computer equipment through wireless signal sending equipment, and the computer equipment is provided with monitoring equipment. The position detection system has the advantages that position detection is accurate, the precision is well controlled, and the accuracy coefficient of the system is improved.

Owner:SHAANXI JOIN CREATE SCI & TECH

Power fiber optic communication line fault monitoring device

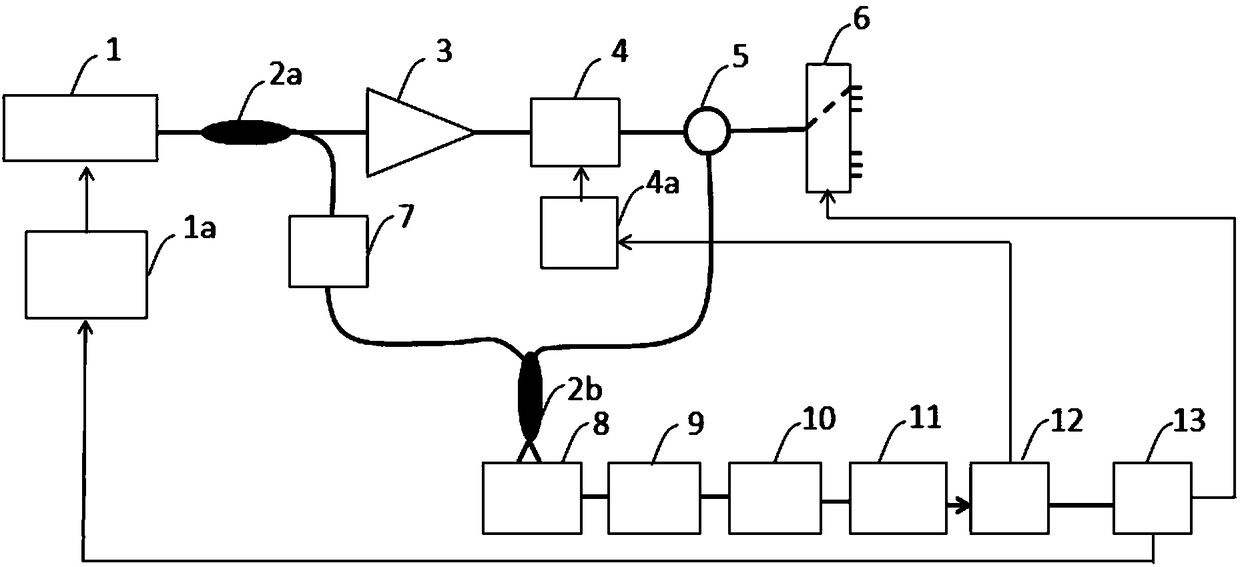

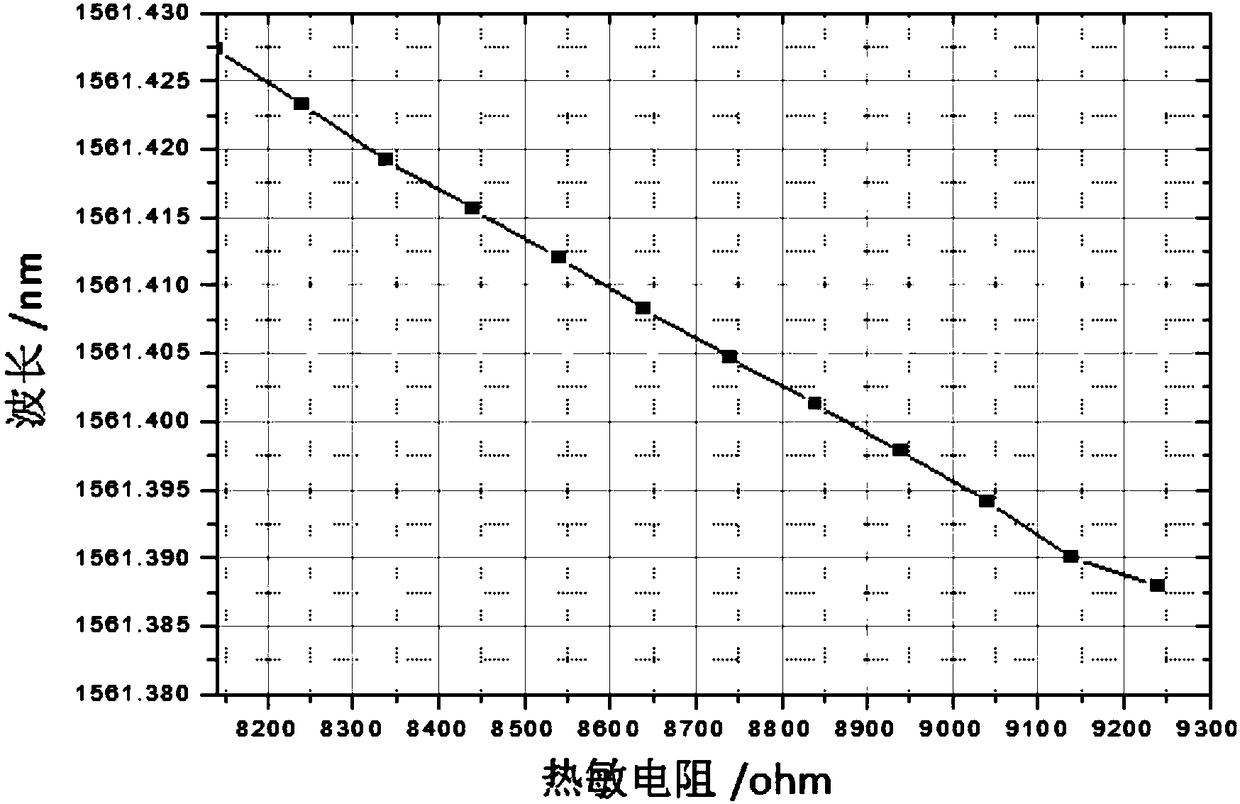

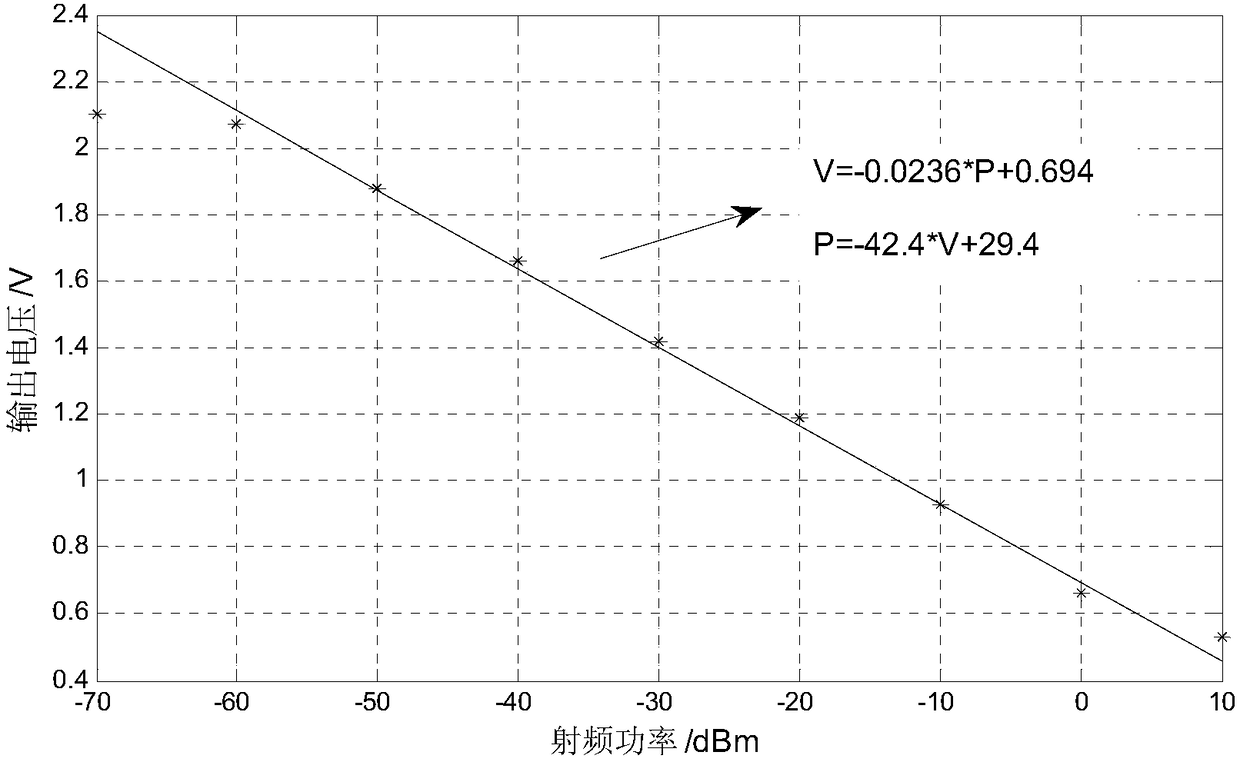

ActiveCN106533547BAdd line patrol monitoring functionCompact structureFibre transmissionElectromagnetic transmittersRayleigh scatteringFiber

The present invention discloses an electric power optical fiber communication line fault monitoring device. The electric power optical fiber communication line fault monitoring device employs an optical time domain reflection technology to extract distributed Rayleigh scattering optical signals of the electric power optical fiber communication line, employs a coherent detection mode to improve the sensitivity, employs the logarithmic amplifier and average mode to improve the extraction efficiency of the detection signals and employs the laser frequency hopping scheme based on the pulse counting to reduce the fading noise on the time domain reflection curve. The system program of the device controls a laser driving unit, a signal transmit / receive unit and an optical switch communication control unit to realize the control of the laser output frequency, the sending of the detection optical pulse, the collection and processing of the time domain electric signals and the switching of a detected optical fiber line. The electric power optical fiber communication line fault monitoring device is compact in device structure, high in sensitivity and short in measurement time consumption, can support online monitoring, can rapidly poll all the optical fiber communication lines in a transformer substation communication machine room, and is wide in monitoring range and high in timeliness.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

A Modularized Principle-based Replacement Guide Rail Installation Method for Sector Sections

ActiveCN109653042BEasy to implementProcess setting is convenient and quickRailway track constructionWhole bodyMachining

The invention discloses a sector section changing guide track mounting method based on a modularization principle, and relates to the technical field of building materials. The method comprises the following steps: 1, before concrete of a wallboard is poured, ensuring that positioning of embedded parts is accurate, and the embedded parts and the concrete on the outer side of the wallboard are located on the same plane; 2, when the upper portion of a sector section changing guide track is mounted, reasonably dividing a combination unit, combining the upper portions of the sections 1-8 of the sector section changing guide track and the upper portions of the sections 13-14 of the sector section changing guide track into two integral bodies, assembling the integral bodies on the ground to forma whole body and then hoisting the whole body, wherein the problems about safety, precision and efficiency caused by split mounting are avoided; and 3, adjustment of the changing guide track: carrying out data adjustment, secondary machining adjustment and mounting of a guiding plate and final simulated running of a sector section changing guide track verifying device to ensure precision. The method has the advantages that the process principle is convenient and fast to set, the method is convenient to implement, the construction progress and the quality are guaranteed, the design requirements are met, and the method has strong practicability.

Owner:CHINA MCC17 GRP

Installation method for replacing the guide rail of the sector section of the continuous casting machine

The invention relates to a method for installing a replacement guide rail of a continuous casting machine segment, which includes the following steps: Step 1. The upper assembly of the left and right symmetrical two replacement guide rails and the lower section of the multi-piece replacement guide rail are symmetrically placed respectively, and the two symmetrical pieces Replace the upper assembly of the guide rail or replace the lower section of the guide rail as a group, adjust the distance between the two replacement guide rails of each group to meet the design requirements; step 2, use rigid connection between the adjusted two replacement guide rails in each group The rods are connected and fixed; step 3, hoist each group of replacement guide rails connected as a whole to the installation position, adjust the installation position to meet the design requirements, and weld the replacement guide rails on the installation pads of the walls on both sides; step 4, wait for all welding After the seams are connected, the rigid connecting rods are removed. This installation method only needs to measure the data of the replacement guide rail on one side when the fan-shaped segment is replaced with the guide rail, which takes a short time, and at the same time, the welding deformation of the replacement guide rail is small, which improves the installation efficiency and installation quality.

Owner:CHINA FIRST METALLURGICAL GROUP

Drilling operation method of steering drilling system based on top driving and ground control

ActiveCN102619498BImprove work efficiencyPrecision control is accurateAutomatic control for drillingHandling systemElectric control

The invention relates to a steering drilling system based on top driving and ground control, and a drilling operation method. The steering drilling system comprises a top driving device; a ground signal processing system comprises a signal acquisition module which is connected with a signal filtering and amplification module; the signal filtering and amplification module is connected with a signal decoding module, and can filter clutter out of electric signals, amplify and enhance effective signals and transmit the effective signals to the signal decoding module; the signal decoding module is connected with an analog-to-digital conversion module; the analog-to-digital conversion module is connected with an information output module; the information output module is connected with an information calculation module and display equipment; the information calculation module is connected with an information transmission module; and the information transmission module is connected with a top driving electric control device by an interface circuit. For the steering drilling system based on the top driving and the ground control and the drilling operation method, the operation efficiency is high, the control is precise, the working performance is stable, and the operation can be carried out under various geologic conditions.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com