Distribution equipment and preparation method of marble-like hole bricks

A technology of imitating marble and holes, applied in the field of building ceramics, can solve the problems of large quality gap of bricks, influence of decorative effect, difficult to control the distribution of pore-forming agent, etc., and achieve the effect of accurate precision control, stable distribution efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

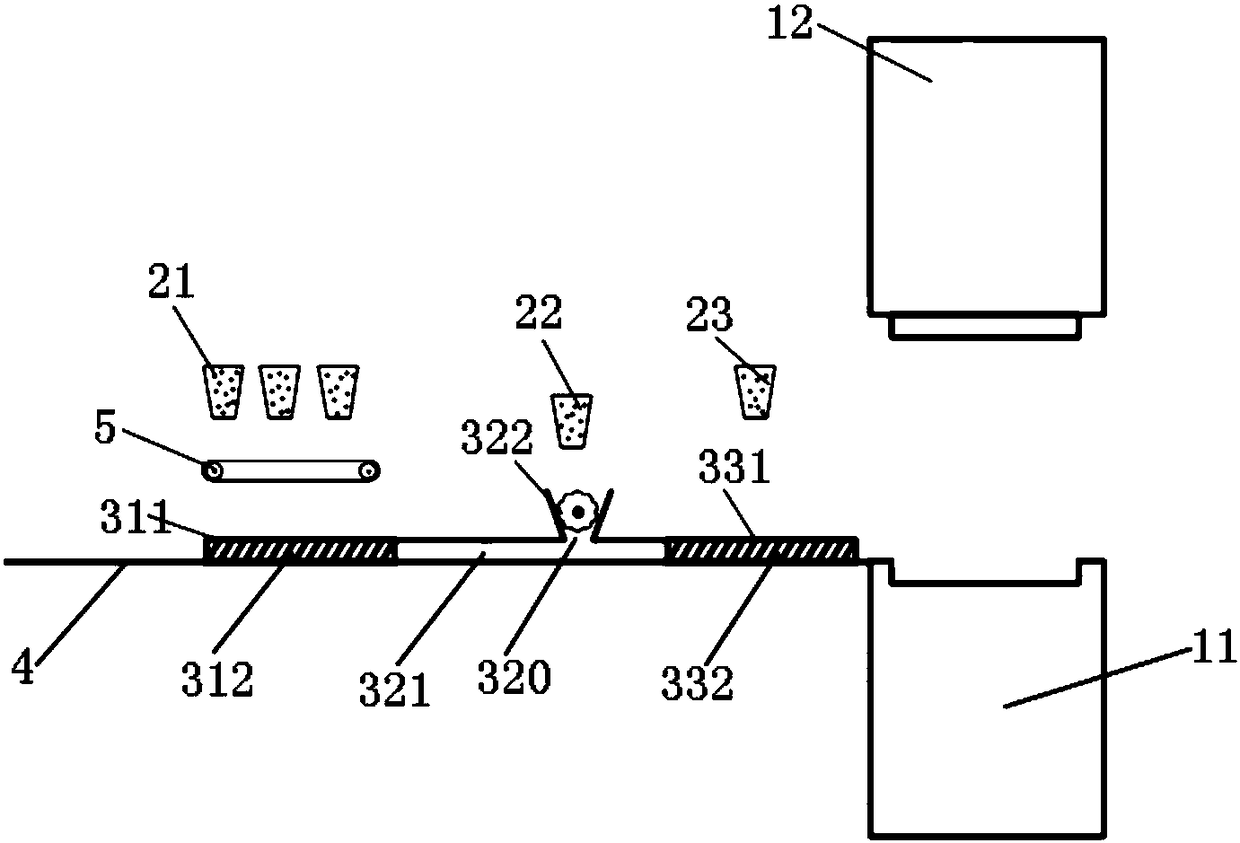

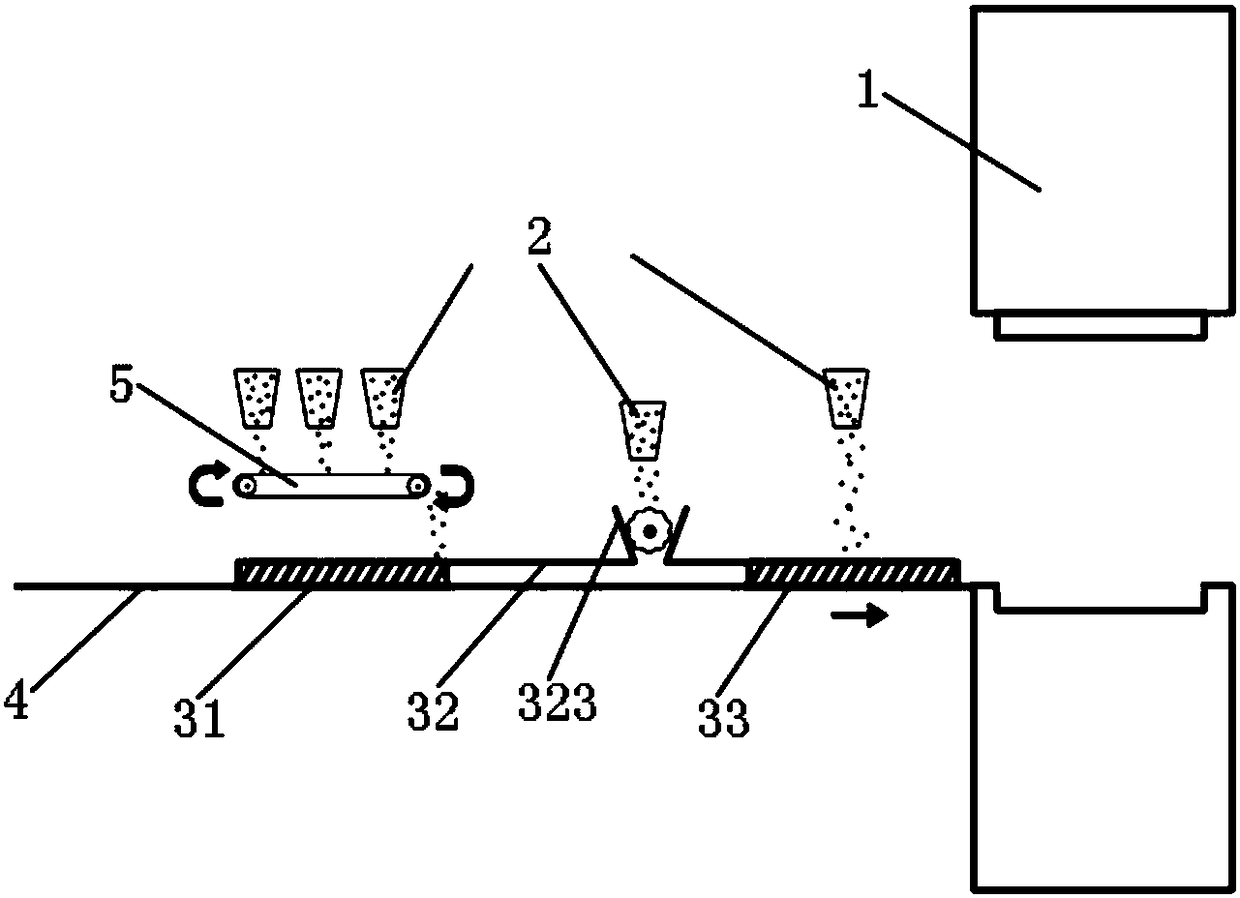

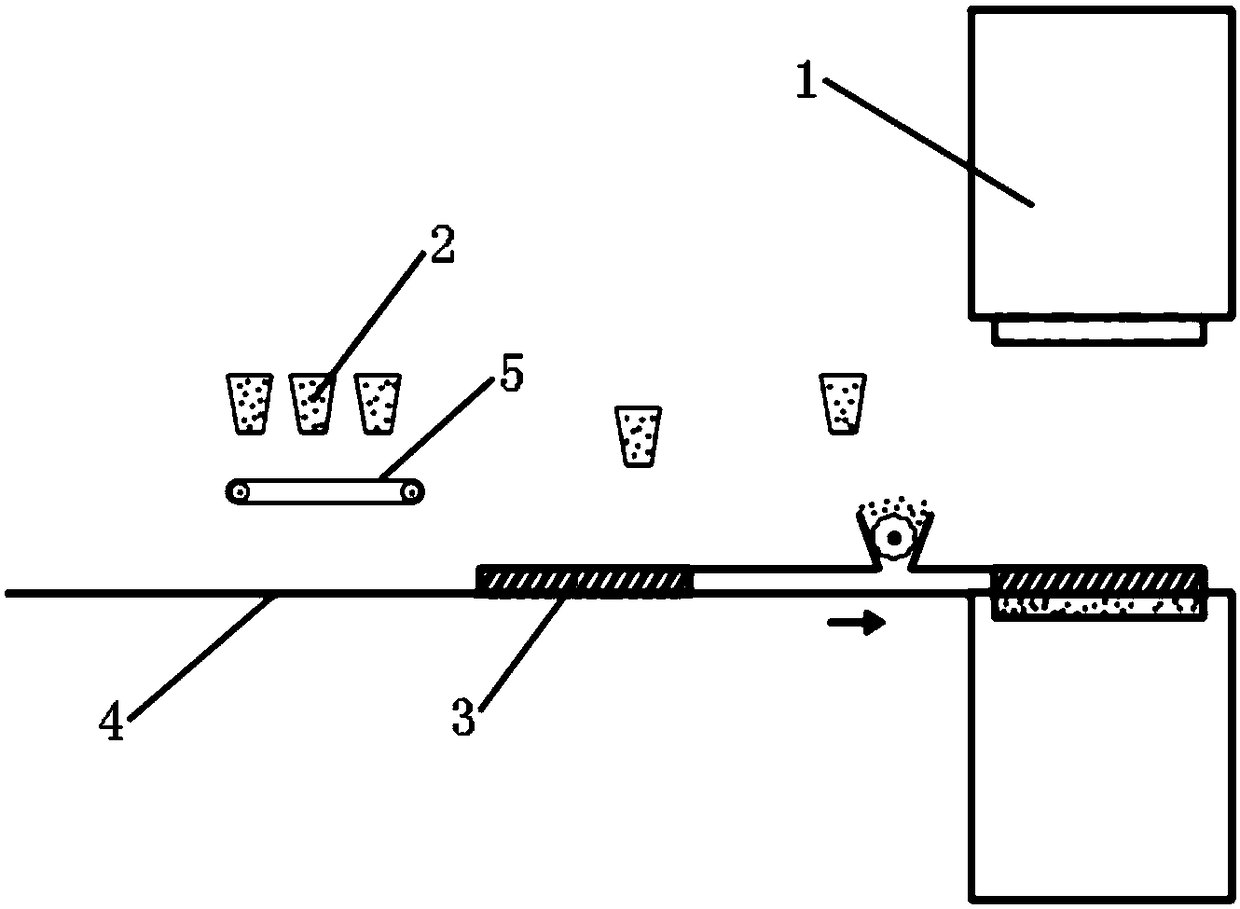

[0026] A cloth equipment for preparing imitation marble hole bricks, comprising a press 1, a material holding device 2, a cloth device 3 and a conveying device 4; the material holding device 2 is arranged on one side of the press 1. The cloth device 3 is installed on the conveying device 4 and located below the material holding device 2. The cloth device 3 includes a fabric frame 31, a hole material frame 32, and a bottom material frame 33. The fabric frame 31, the hole material frame 32 and the bottom material frame 33 are horizontally installed on the conveying device 4, and the three are an integral structure;

[0027] The bottom of the cloth device 3 is flush with the top of the lower mold 11 of the press 1, and the conveying device 4 transports the cloth device 3 in the horizontal direction to the top of the lower mold 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com