A kind of pavement panel manufacturing equipment and method for manufacturing composite block pavement panel by the device

A technology for road slabs and equipment, which is applied in the field of road slab production equipment, can solve problems such as difficulty in ensuring the paving effect, and achieve the effects of easy form removal and maintenance, easy operation, and accurate precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

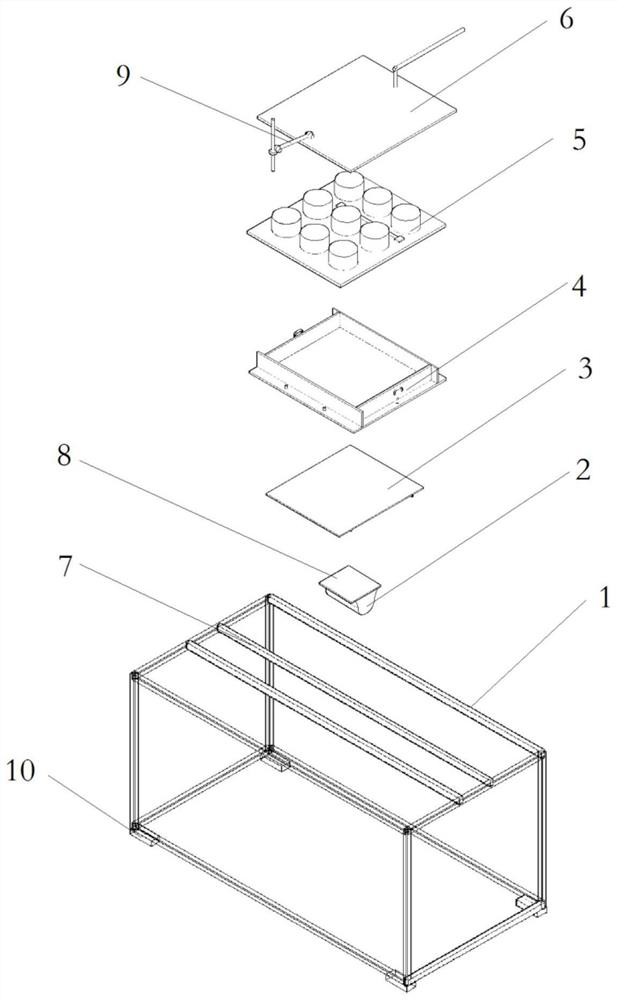

[0038] The method for making a composite block material road panel with a specification of 30cm×30cm×6cm by using road panel manufacturing equipment comprises the following steps:

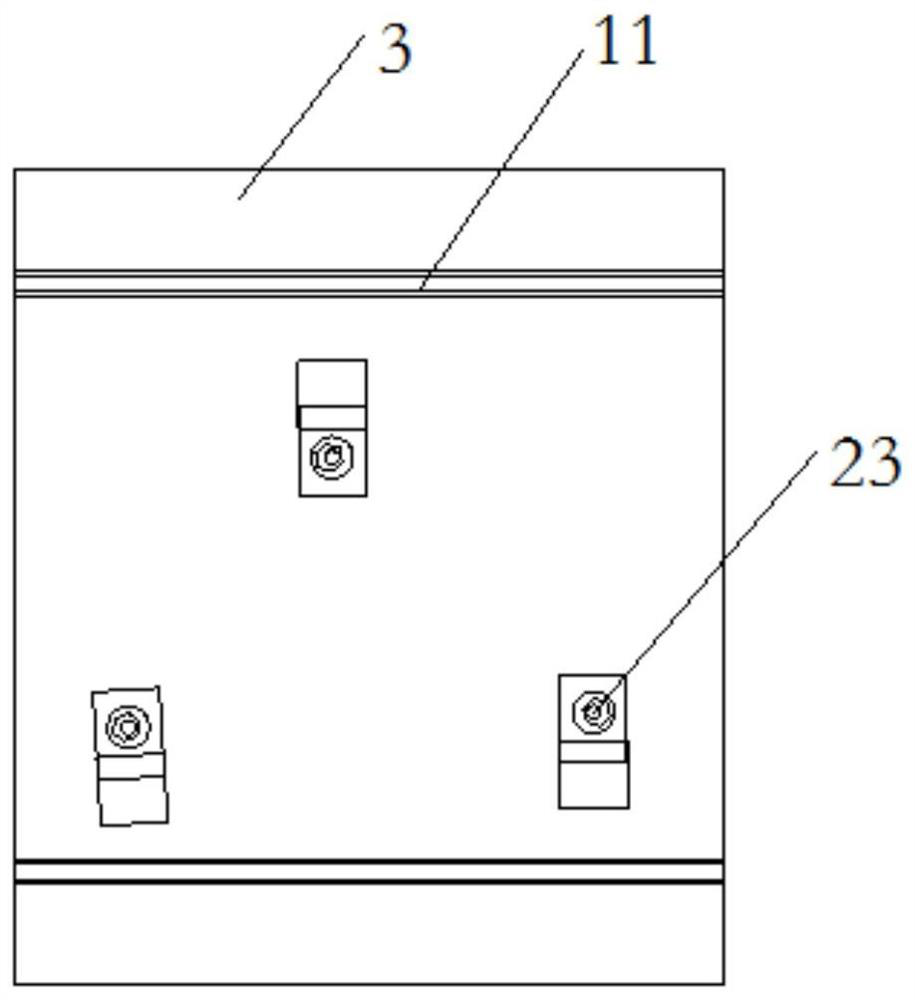

[0039] 1) Install the road slab production equipment, select a 30cm×30cm mold, 9 positioning holes are evenly distributed on the mold, and the diameter of the positioning holes is 40mm+2mm, pour cement concrete into the mold of the composite block road slab production equipment, and start the vibration motor , vibration dense;

[0040] 2) Place the pellet positioning plate on the concrete, the side of the pellet positioning plate with the retaining ring faces up, and put the pellets with a particle size of 40mm in the positioning hole of the pellet positioning plate, one pellet per hole;

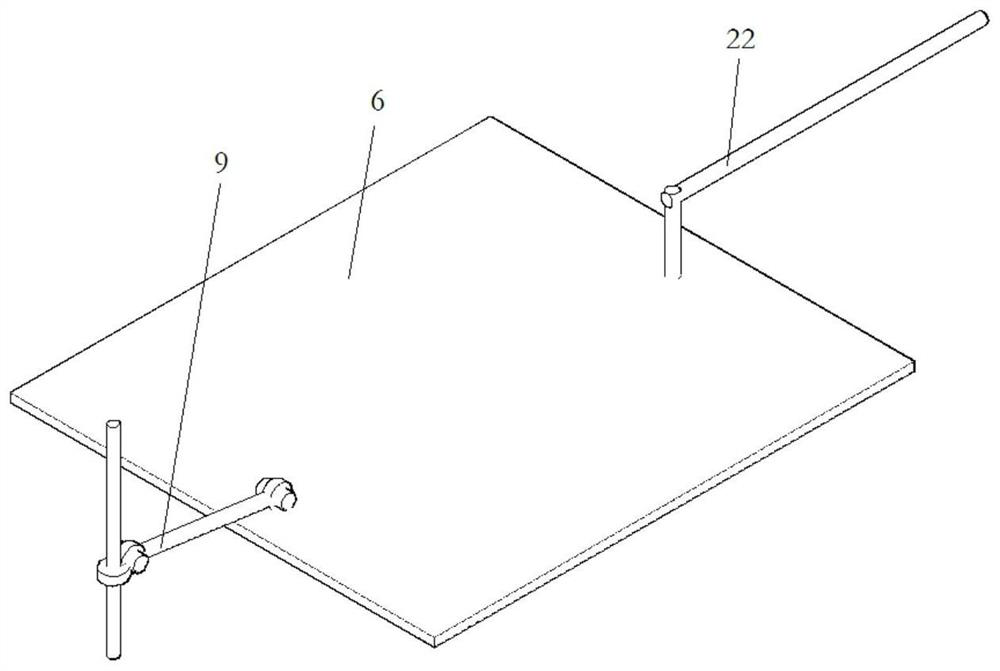

[0041] 3) Press down the pressure plate to press the pellets into the concrete until the pressure plate is in close contact with the retaining ring of the pellet positioning plate;

[0042] 4) Lift the pressing ...

Embodiment 2

[0046] The method for making a composite block road panel with a specification of 50cm x 50cm x 6cm by using road panel production equipment comprises the following steps:

[0047] 1) Install the road slab production equipment, choose a 50cm×50cm mold, 25 positioning holes are evenly distributed on the mold, and the diameter of the positioning holes is 40mm+2mm, pour cement concrete into the mold of the composite block road slab production equipment, and start the vibration motor , vibration dense;

[0048] 2) Place the pellet positioning plate on the concrete, the side of the pellet positioning plate with the retaining ring faces up, and put the pellets with a particle size of 40mm in the positioning hole of the pellet positioning plate, one pellet per hole;

[0049] 3) Press down the pressure plate to press the pellets into the concrete until the pressure plate is in close contact with the retaining ring of the pellet positioning plate;

[0050] 4) Lift the pressing plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com