Scrap cutter edge surface machining method

A processing method and cutting edge cutting technology, which are applied in the field of cutting edge cutting edge surface processing, can solve the problems of low production efficiency and poor processing precision of cutting edge cutting edge surface, so as to improve the precision, improve the cutting edge effect, and improve the overall Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A method for processing the edge surface of a chipped cutting edge, the steps are as follows:

[0093] 1. Turning: install the cutting edge to be processed on the turning and grinding fixture and then assemble it into the lathe, and the lathe performs rough turning on the cutting edge surface 103 to be processed;

[0094] 2. Milling: install the chipped edge cutting edge after rough turning in step 1 on the milling fixture and then assemble it into the milling machine, and the milling machine performs milling processing on the chipped edge cutting edge surface 103;

[0095] 3. Grinding: install the chipped edge after milling in step 2 on the turning and grinding fixture, and then assemble it into the grinding machine, and the grinder performs fine grinding on the chipped edge surface 103 .

[0096] like Figure 20 As shown, in the method for processing the surface of the chipping and cutting edge in this embodiment, the surface of the chipping and cutting edge is rough...

Embodiment 2

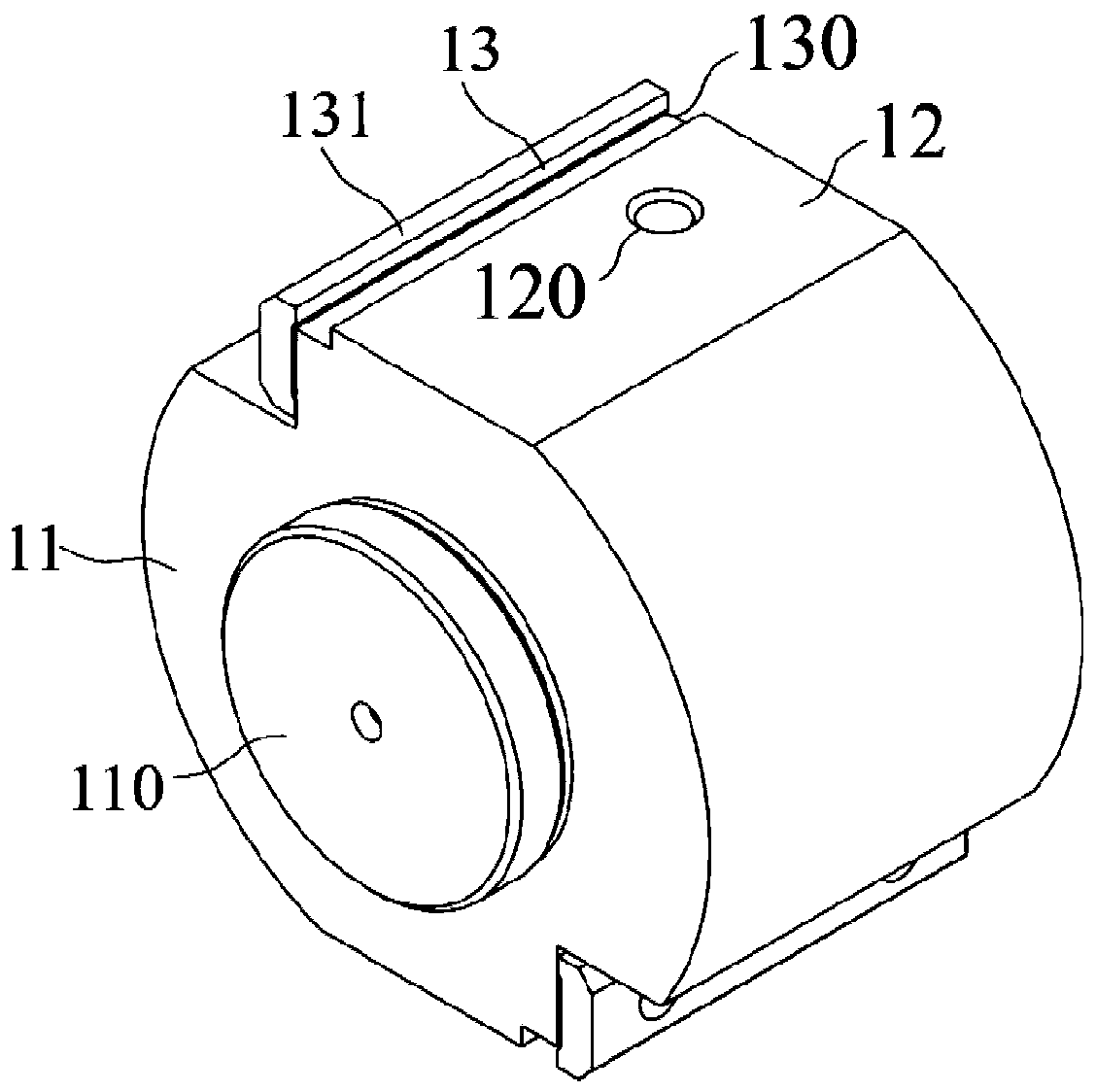

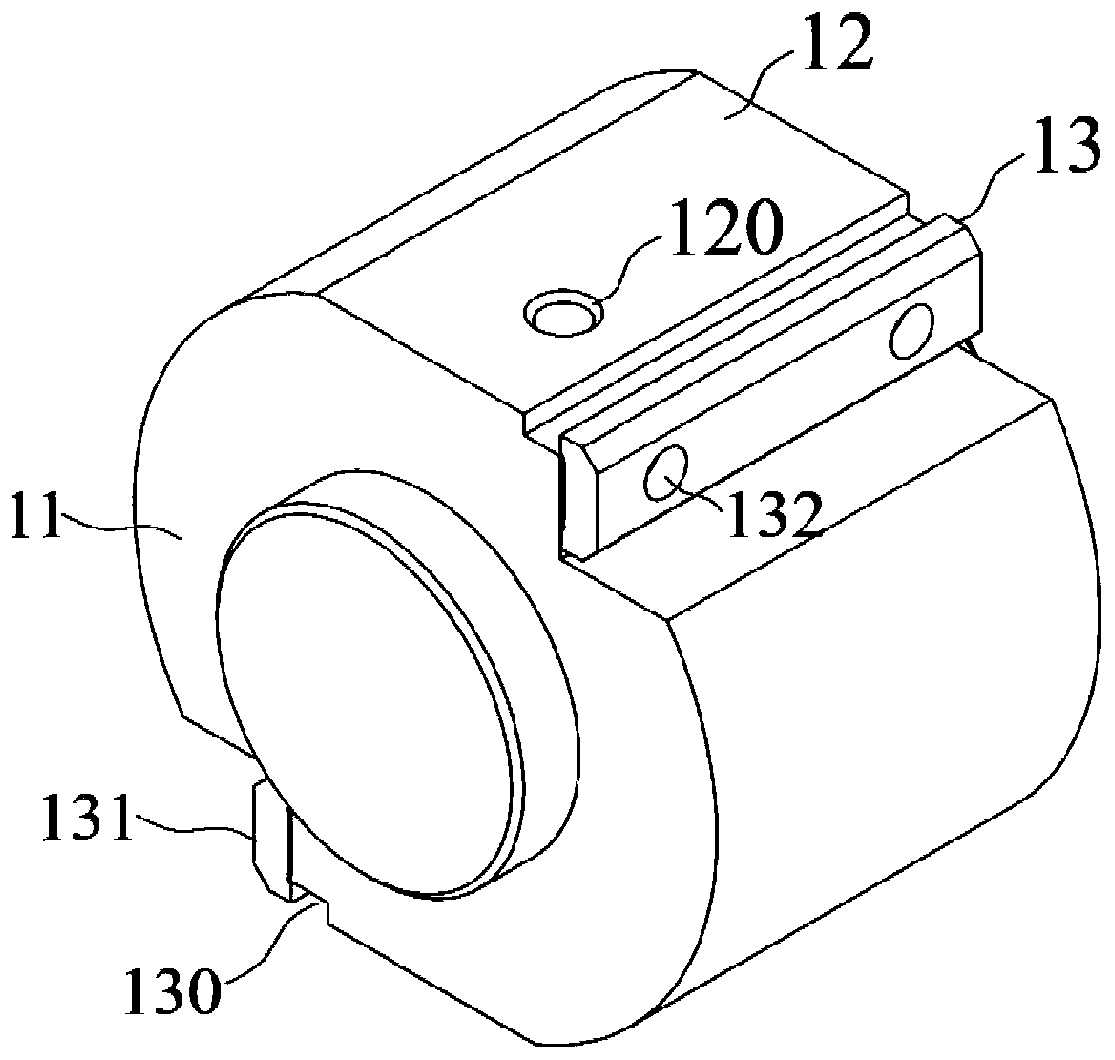

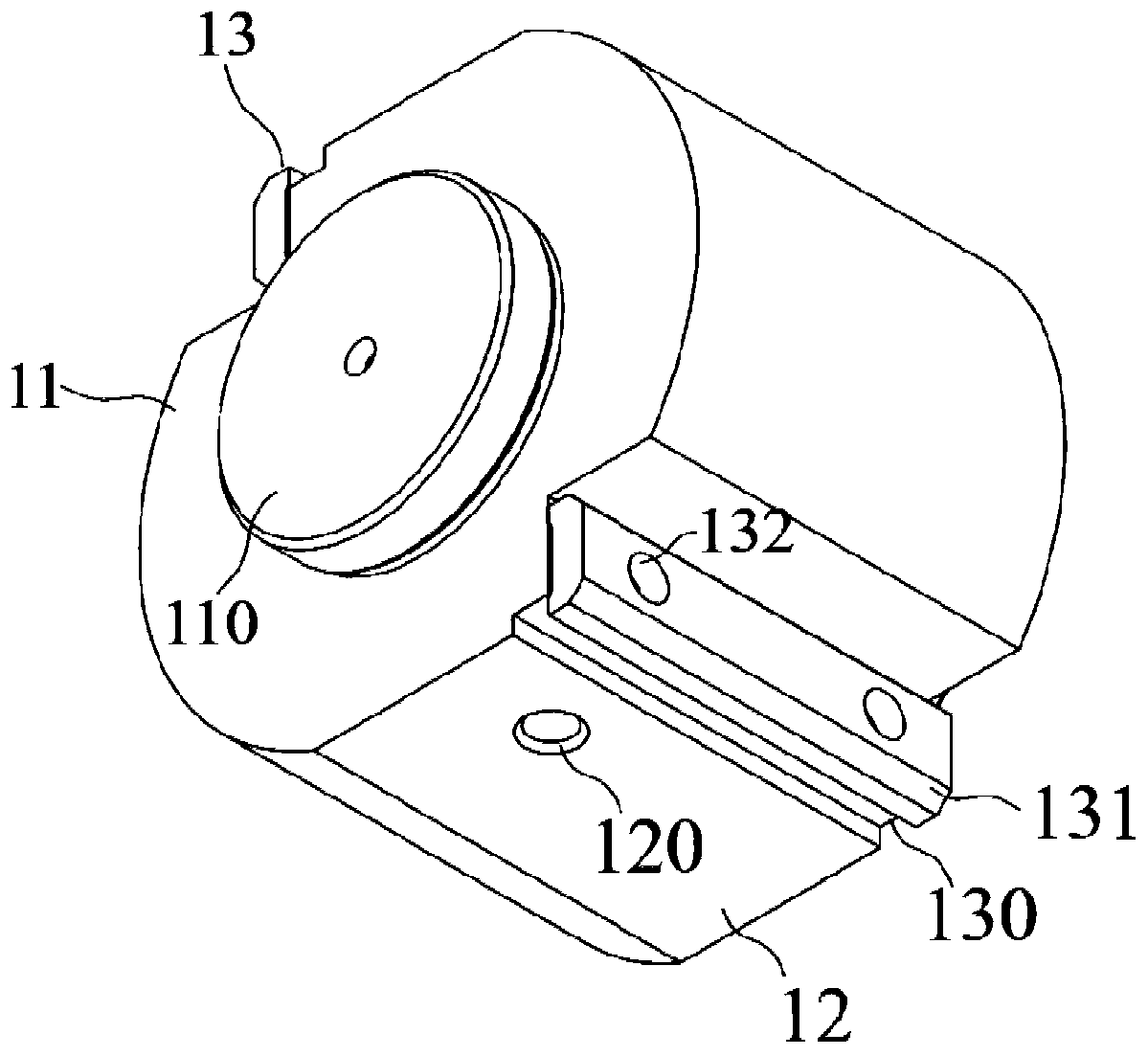

[0099] like figure 1 and Image 6 As shown, a method for processing the cutting edge and cutting edge surface of the present embodiment is further improved on the basis of embodiment 1, and the described turning and grinding fixture includes:

[0100] matrix 11, which is a columnar body;

[0101] An assembly platform 110, which is arranged at the center of an end surface of the base body 11, is used for assembling the fixture on the machine tool;

[0102] The installation surface 12 is a plane arranged on the side of the base body 11, and the installation surface 12 is horizontal to the central axis of the base body 11;

[0103] Mounting hole 120, which is formed on the mounting surface 12, is shaped to match the mounting hole 102 of the trimmer;

[0104] A concave structure 13 is formed on one side of the installation surface 12 along the central axis of the base body 11, and is used for placing the lower convex eaves 101 of the cutting edge.

[0105] During the processin...

Embodiment 3

[0112] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 11 As shown, a method for processing the cutting edge and cutting edge surface of this embodiment is further improved on the basis of Embodiment 2. The concave structure 113 of the turning and grinding fixture includes:

[0113] A concave step 130, which is arranged axially along the center of the base body 11, is in the shape of a two-step concave step, and is set on the side of the installation surface 12;

[0114] Fastening plate 131, which is detachably connected to the secondary vertical surface 1302 of the concave step 130;

[0115] The fastening plate 131 and the first horizontal surface 1300 and the first vertical surface 1301 of the concave step 130 form a groove structure.

[0116] The concave structure 13 can be a variety of structures, such as the groove directly opened on one side of the mounting surface 12, but there are certain defects in the directly opened groove structure. The amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com