Reinforcing steel bar tensioning device of high-speed railway ballastless track plate with pre-tensioning method

A technology for high-speed railways and ballastless tracks. It is applied to ceramic molding machines and manufacturing tools. It can solve the problems of high control difficulty, poor positioning, poor tensioning accuracy, and large equipment volume, so as to achieve precise control of tensioning accuracy and ensure tension. The effect of pulling power and reducing the volume of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

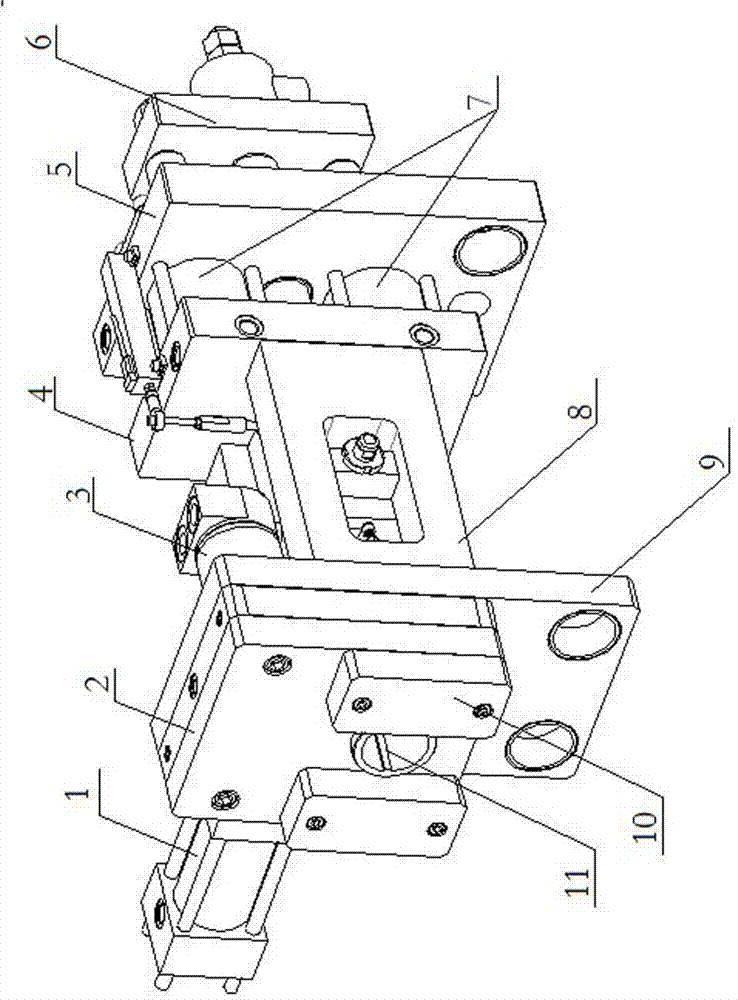

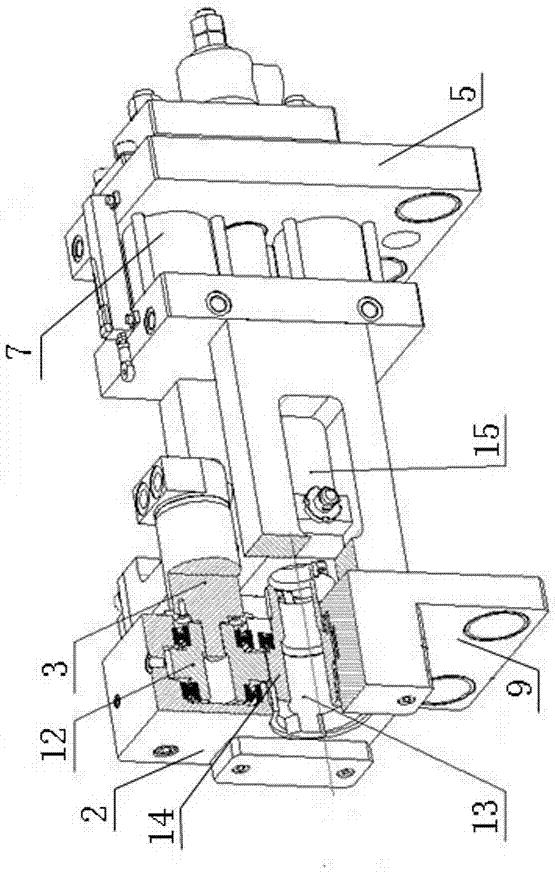

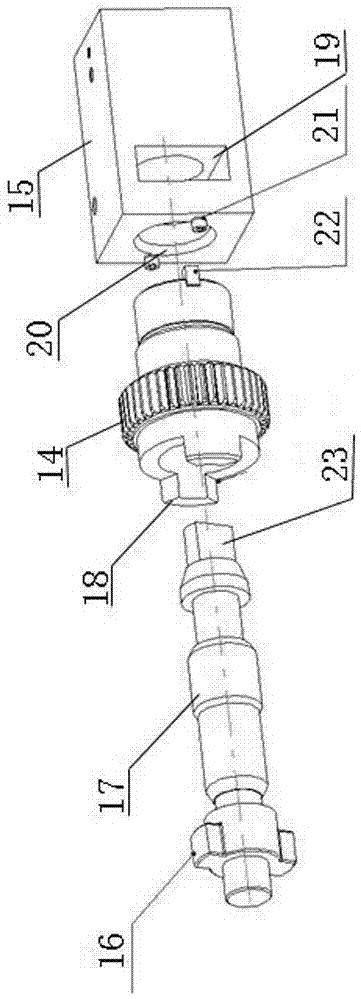

[0018] figure 1 As shown, the pretensioning method of the present invention produces a steel bar tensioning device for ballastless track slabs of high-speed railways, including a tensioning and positioning locking mechanism, wherein the tensioning mechanism consists of at least two tensioning cylinders 7 to form a tensioning cylinder group or The tensioning power mechanism is in one-to-one correspondence with the reinforcing bars / tensioning rods on the corresponding side of the track slab mould. The above-mentioned tensioning oil cylinder is installed on the tensioning platform through the horizontally arranged guide columns fixed on the tensioning platform and the guide plates matched with the guiding columns. In this embodiment, two tensioning cylinders 7 are longitudinally arranged and installed between the fixed plate 4 and the rear guide plate 5. A tensioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com