Pretreatment device for water absorption detection sample of ceramic tile and control method of pretreatment device

A pretreatment device and sample detection technology, applied in the field of ceramics, can solve the problems that cannot directly reflect the fluctuation of process parameters and the quality change of finished products, the detection results are easily affected by the enamel part, and the difference in water absorption of the green layer, so as to avoid grinding Stuck head, smooth milling process, smooth rotation and compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with accompanying drawing:

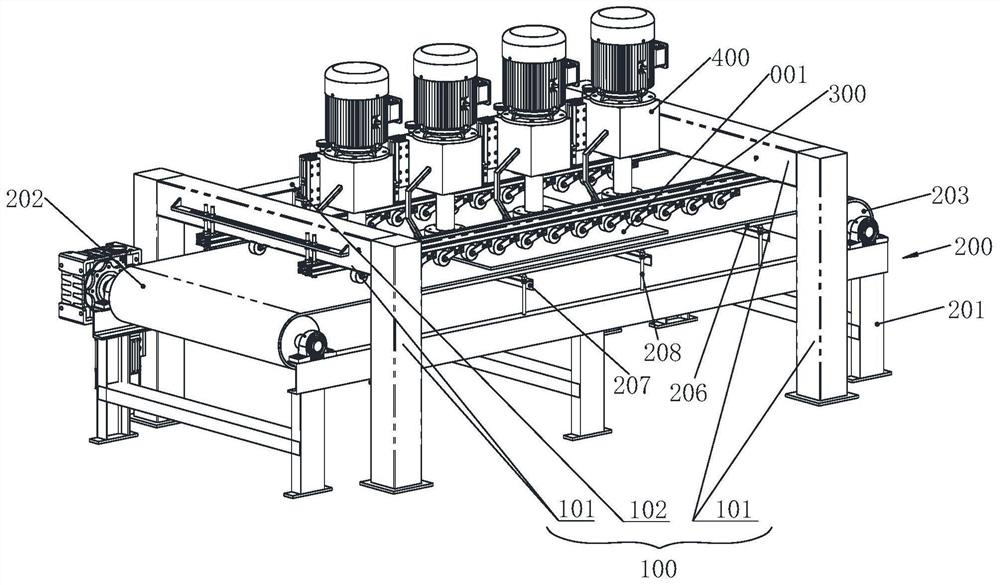

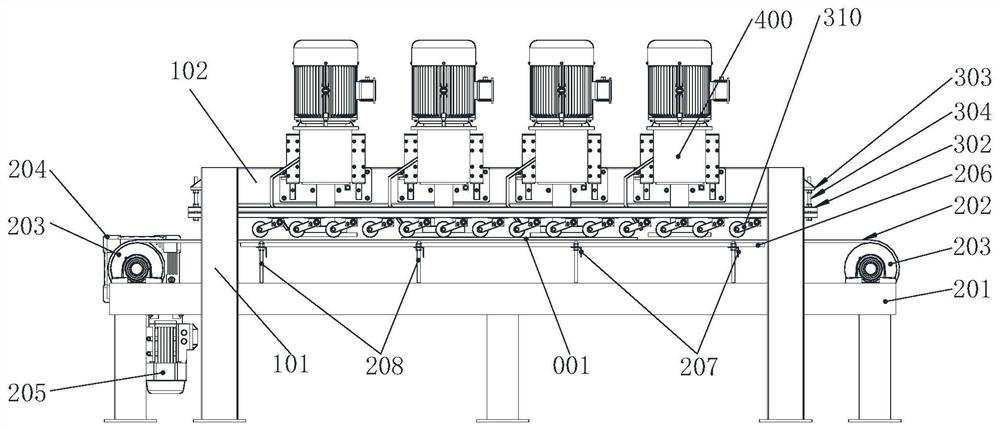

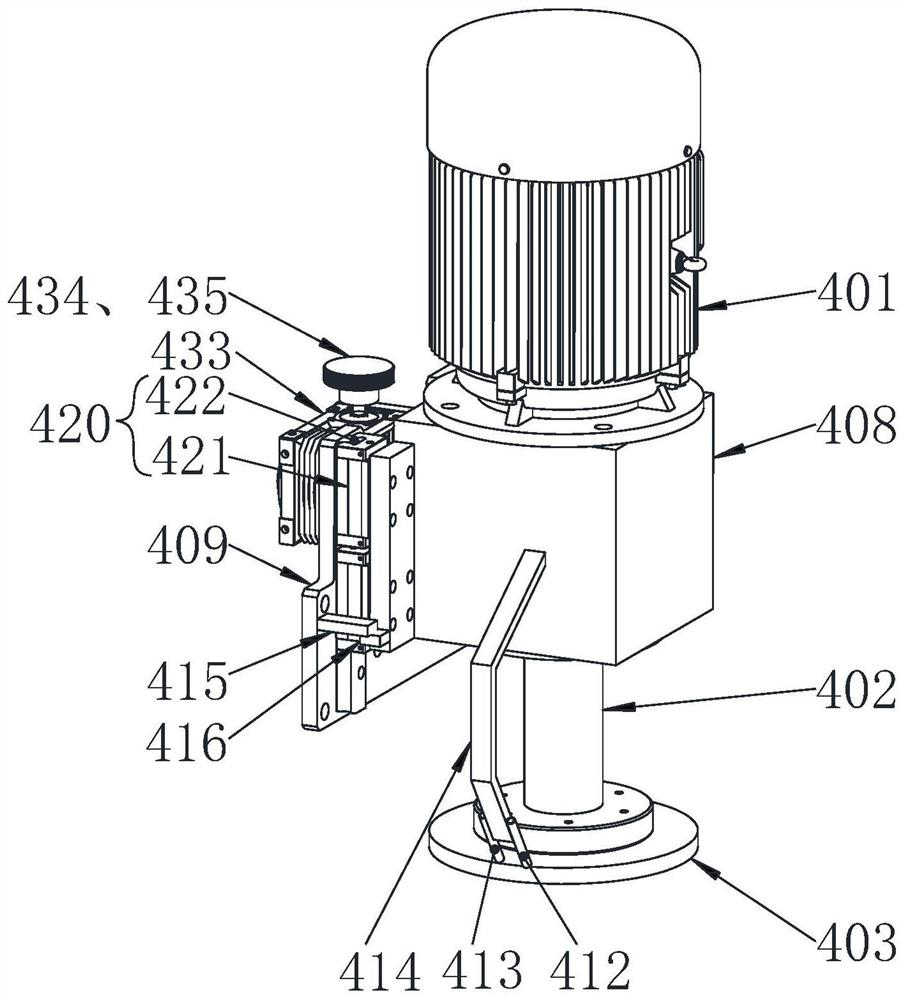

[0055] see figure 1 As shown, the pretreatment device for testing samples of ceramic tile water absorption includes a frame 100 , a conveying mechanism 200 , a positioning mechanism 300 , a milling mechanism 400 and a control system 500 . The conveying mechanism 200 is used to convey the ceramic tile 001 to be processed in place, and provides a continuous translation driving force during the milling process; the frame 100 is used to install the positioning mechanism 300 and the milling mechanism 400; the positioning mechanism 300 is used for the conveying mechanism 200 Fasten the ceramic tiles on it. Prevent unnecessary displacement of the ceramic tile 001 during the milling process; the milling mechanism 400 is used to mill the surface of the ceramic tile; the control system 500 is used to control the above mechanism.

[0056] The conveying mechanism 200 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com