Measurement and display method for film thickness reflectivity of optical coated film

A technology of optical coating and display method, which is applied in the measurement of scattering characteristics, optics, optical components, etc., can solve the analysis, evaluation, improvement and adjustment, cannot visually see the change of the real-time value of the reflectance of the coating, and cannot perform coating. Monitor system performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

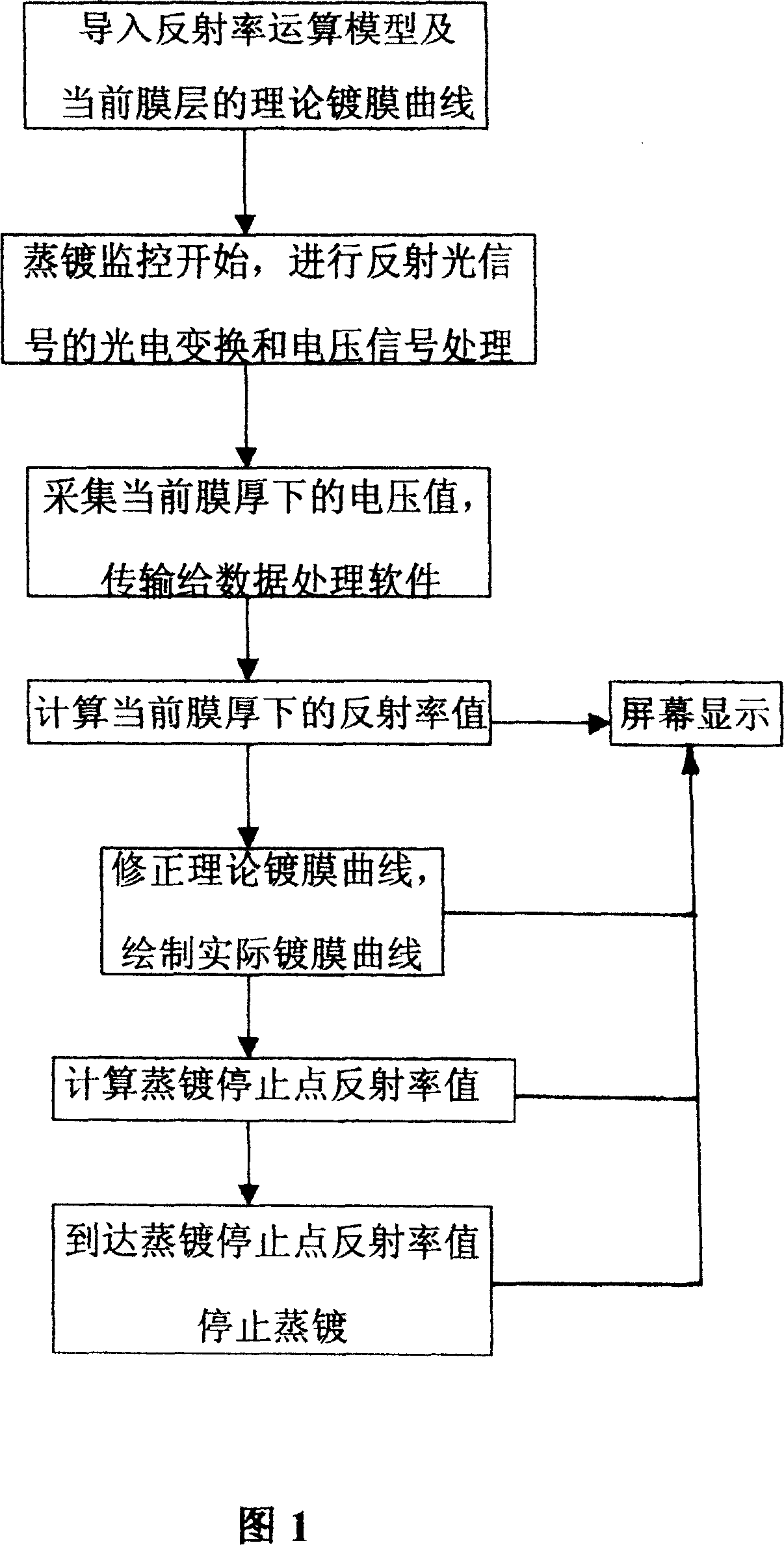

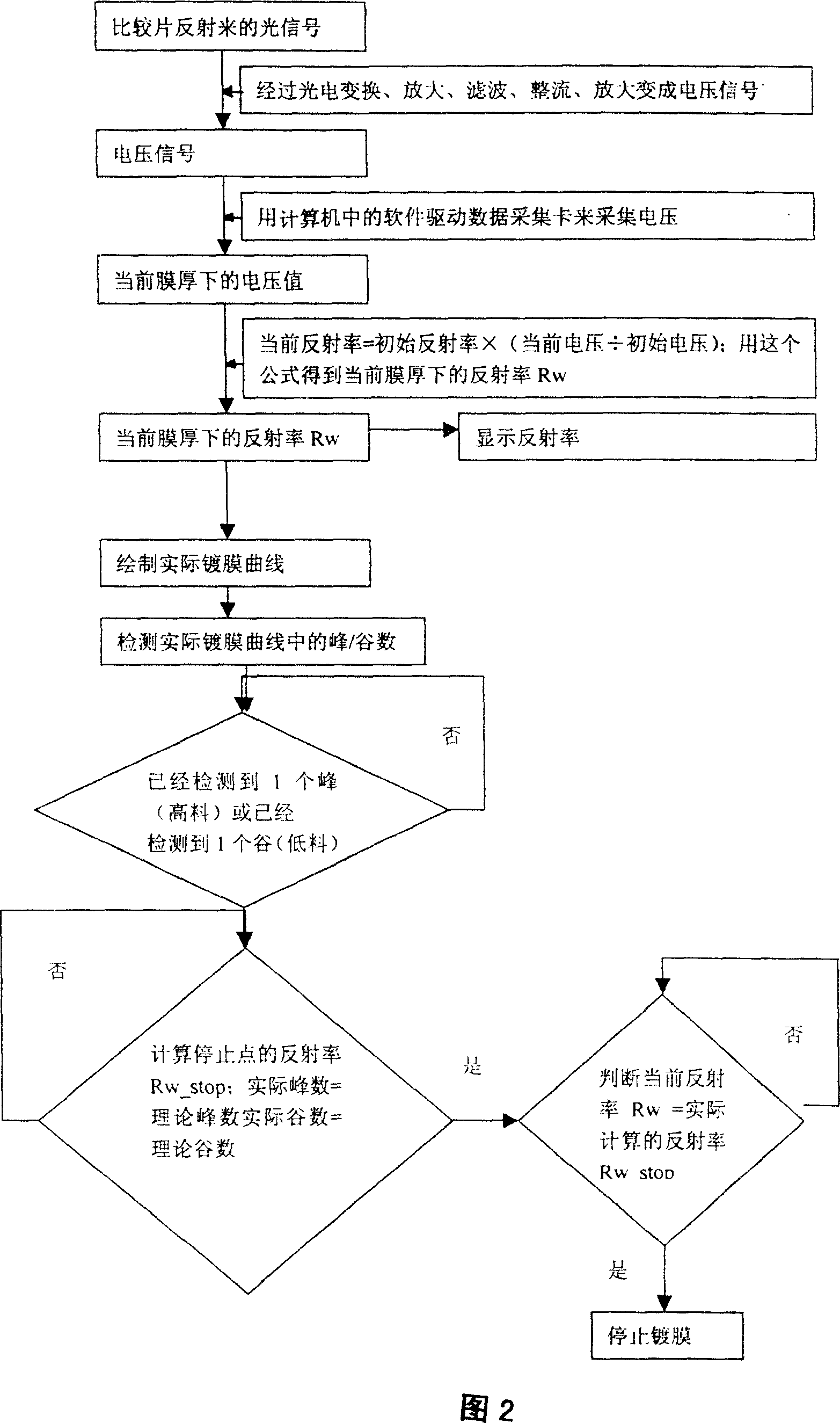

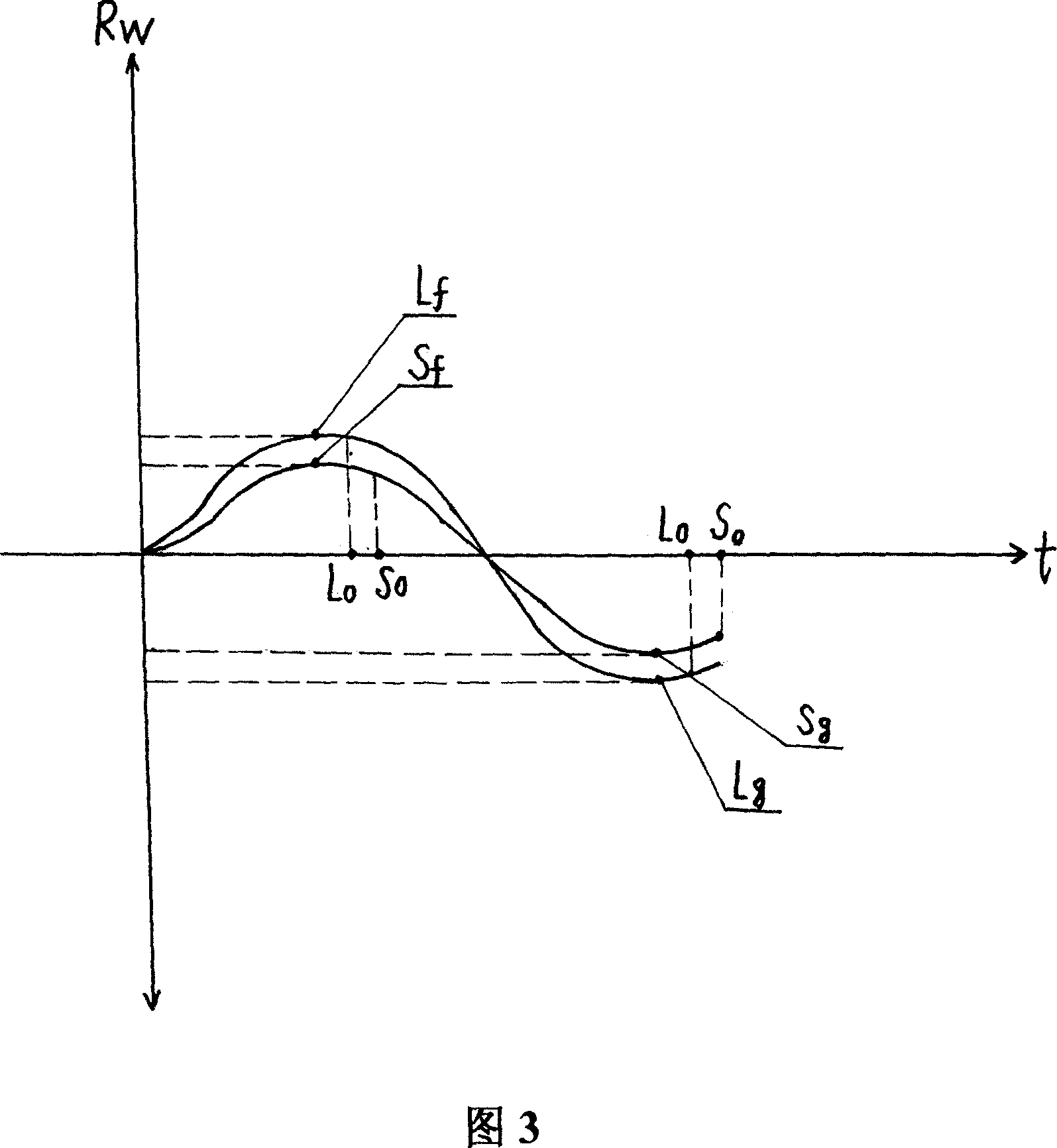

[0016] Referring to Figure 1 and Figure 2, in the process of optical coating, as the thickness of the film layer changes continuously, the reflectivity, refractive index and the corresponding reflected light energy are all changing, and the reflectivity or transmittance, the refractive index is the optical Main spectral characteristics of coated parts. Therefore, the monitoring of the thickness of the optical film is to measure and control the reflectivity or transmittance of the film. When monitoring, once the measured value reaches the value corresponding to the required film thickness, the evaporation baffle is immediately closed and the film layer is stopped. Evaporation. Therefore, the present invention utilizes the fast and accurate data processing function of the computer to conduct online measurement and real-time display of the change of reflectivity during the thin film evaporation process, so as to achieve the purpose of precisely controlling the thickness of the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com