Slurry composition for porous film in battery, method for manufacturing porous film for secondary battery, porous film for secondary battery, electrode for secondary battery, separator for secondary battery, and secondary battery

A secondary battery and porous membrane technology, which is applied to secondary batteries, battery electrodes, non-aqueous electrolyte storage battery electrodes, etc., can solve the problems of reaction heat generation, expansion of short circuit parts, battery short circuit, etc., and achieve improved safety and smoothness Improve and reduce the effect of thickness unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

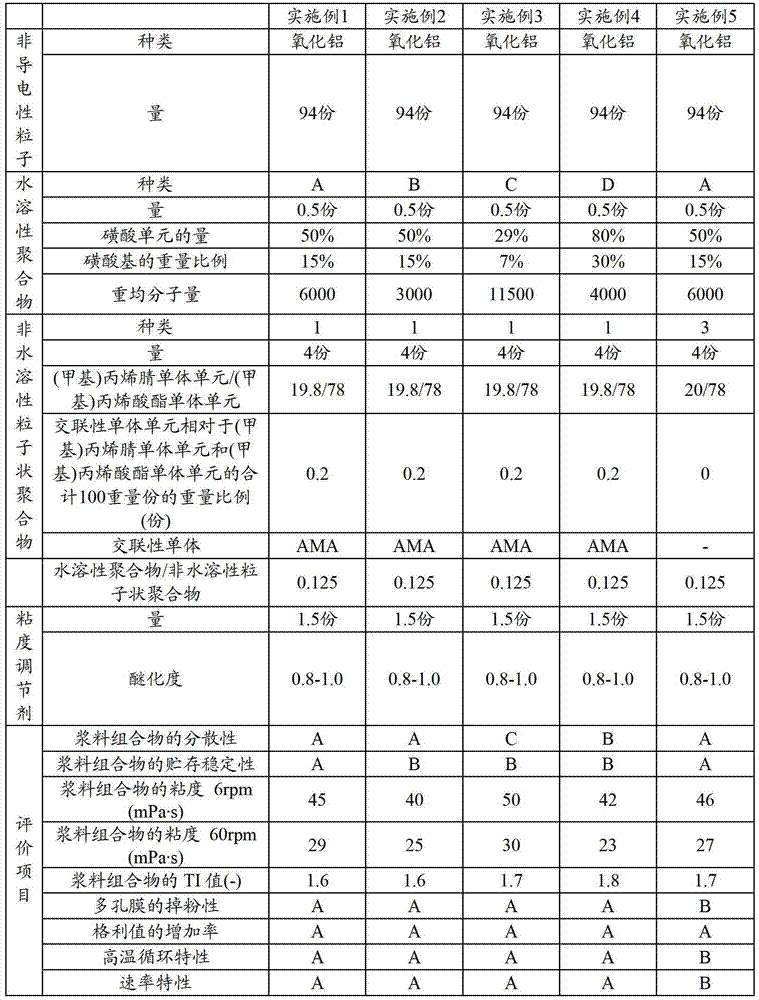

[0222] Hereinafter, the present invention will be specifically described by showing examples, but the present invention is not limited to the following examples, and can be implemented with arbitrary changes within the scope not departing from the claims of the present invention and their equivalents. In addition, in the following description, unless otherwise specified, "%" and "part" which show an amount are based on weight.

[0223] [Evaluation method]

[0224] [Viscosity of slurry composition]

[0225] The viscosity of the slurry composition for porous membranes was measured with a cone-plate rotational viscometer (25° C., rotational speed: 6 rpm, 60 rpm, plate No.: 42) in accordance with JIS Z8803: 1991, and the viscosity was obtained 60 seconds after the start of the measurement. value.

[0226] The TI value (thixotropic index value) was calculated using the following formula from the viscosity η6 after 60 seconds at a rotational speed of 6 rpm and the viscosity η60 af...

manufacture example 1

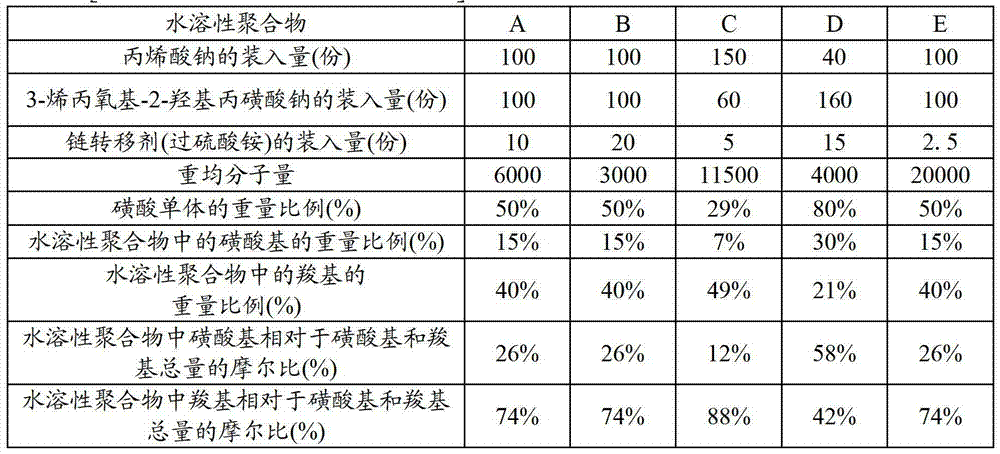

[0274] [Production example 1. Production of water-soluble polymer A]

[0275] 249.0 g of desalted water was placed in a separable SUS flask with a capacity of 1 L equipped with a stirrer, a reflux condenser, and a thermometer, and 286 g of a 35% sodium acrylate aqueous solution was added dropwise over 3.5 hours while stirring at 90°C ( 100 g of solid content), 250 g of 40% concentration of 3-allyloxy-2-hydroxyl-1-propanesulfonic acid sodium aqueous solution (100 g of solid content), and 200 g of 5% concentration of ammonium persulfate aqueous solution. After the completion of all the dropping, the state of reflux at the boiling point was maintained for 30 minutes to complete the polymerization to obtain an aqueous solution of the water-soluble polymer A as a copolymer. As a result of analyzing the obtained aqueous solution of the water-soluble polymer A, the weight average molecular weight of the water-soluble polymer A was 6,000. The quantity of the sulfonic acid unit contai...

manufacture example 2

[0276] [Production example 2. Production of water-soluble polymer B]

[0277] Except having changed the quantity of ammonium persulfate aqueous solution into 400g, it carried out similarly to manufacture example 1, and obtained the aqueous solution of the water-soluble polymer B which is a copolymer. Analysis of the obtained aqueous solution of the water-soluble polymer B revealed that the weight-average molecular weight of the water-soluble polymer B was 3,000. The quantity of the sulfonic acid unit contained in this water-soluble polymer B was 50 weight%, and the weight ratio of the sulfonic acid group in the water-soluble polymer B was 15 weight%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com