Method for on-line measuring refractive index of blooming

A technology of optical film thickness and refractive index, which is used in measurement devices, optical devices, phase influence characteristic measurement, etc. Guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

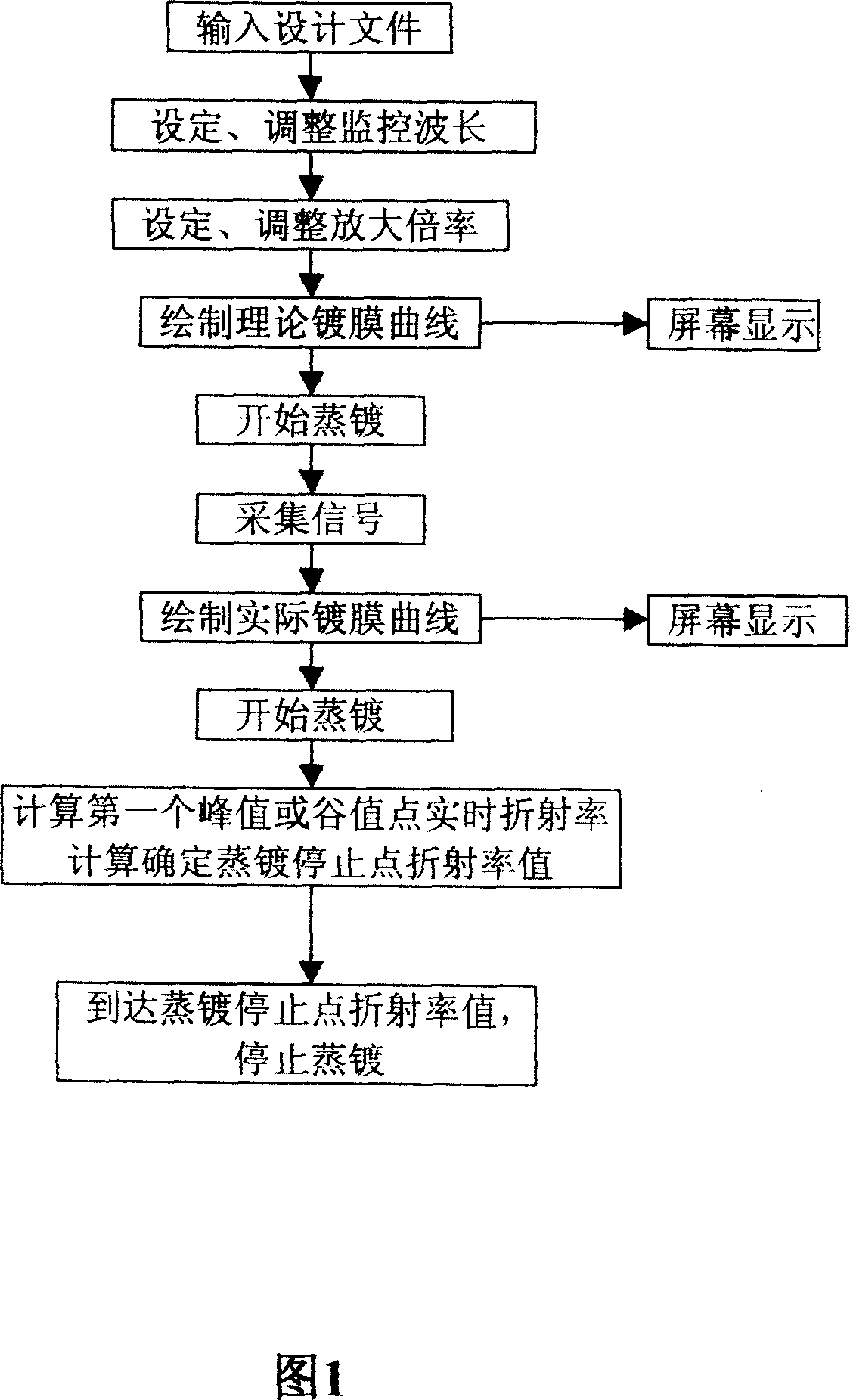

[0020] The method of the present invention is further described in conjunction with Fig. 1:

[0021] (1) According to the TFCalc and Essential Macleod software program, input the design file into the computer. The process design file includes the experimental parameters of the monitoring optical signal wavelength, the refractive index of the film layer, and the absorption rate; the designed film thickness, predetermined packing density, evaporation Theoretical parameters of plating rate, scheduled film forming time, monitoring optical signal wavelength, refractive index of evaporation substrate, vacuum refractive index, and atmospheric refractive index; real-time refractive index (refractive index under current film thickness = initial refractive index × current signal voltage value÷initial signal voltage value), real-time reflectivity (reflectivity under current film thickness=initial reflectivity×current signal voltage value÷initial signal voltage value), film thickness-time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com