Coating die head for single or multiple lithium battery pole pieces

A lithium battery and die technology, which is used in battery electrodes, electrode manufacturing, and devices for coating liquid on surfaces, etc., can solve the problems of low precision, large equipment wear, waste of production materials, etc., to improve product quality, The effect of improving coating accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

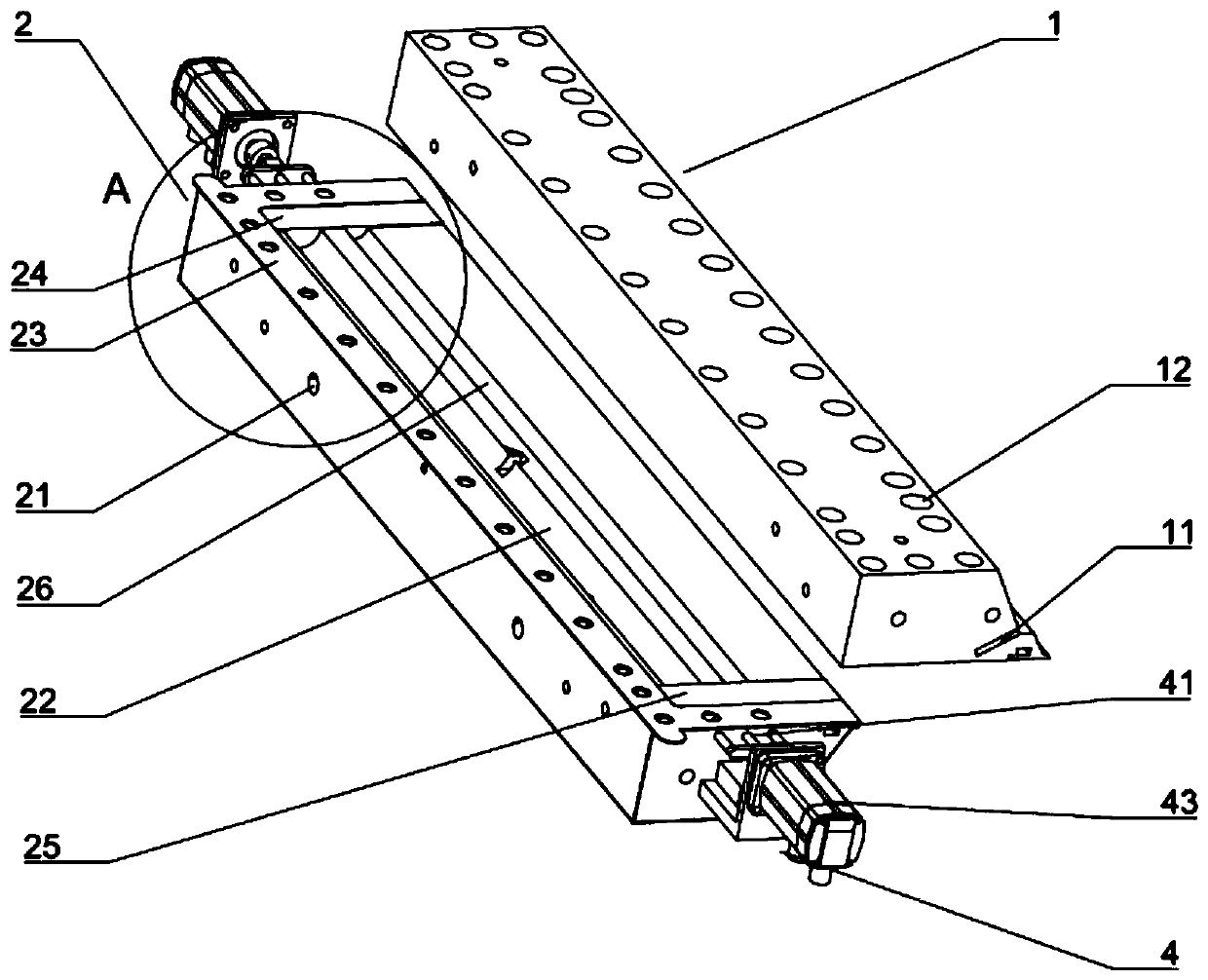

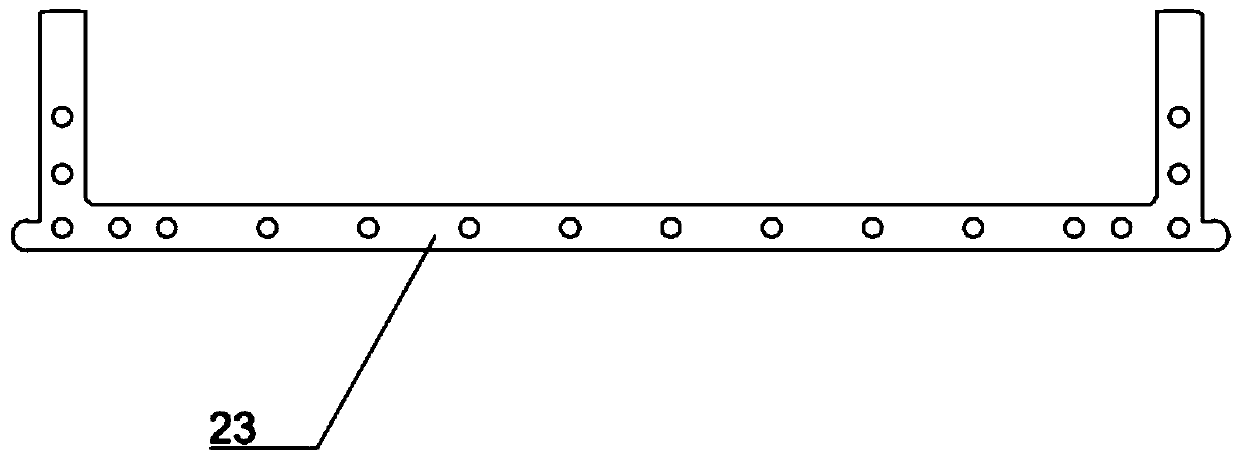

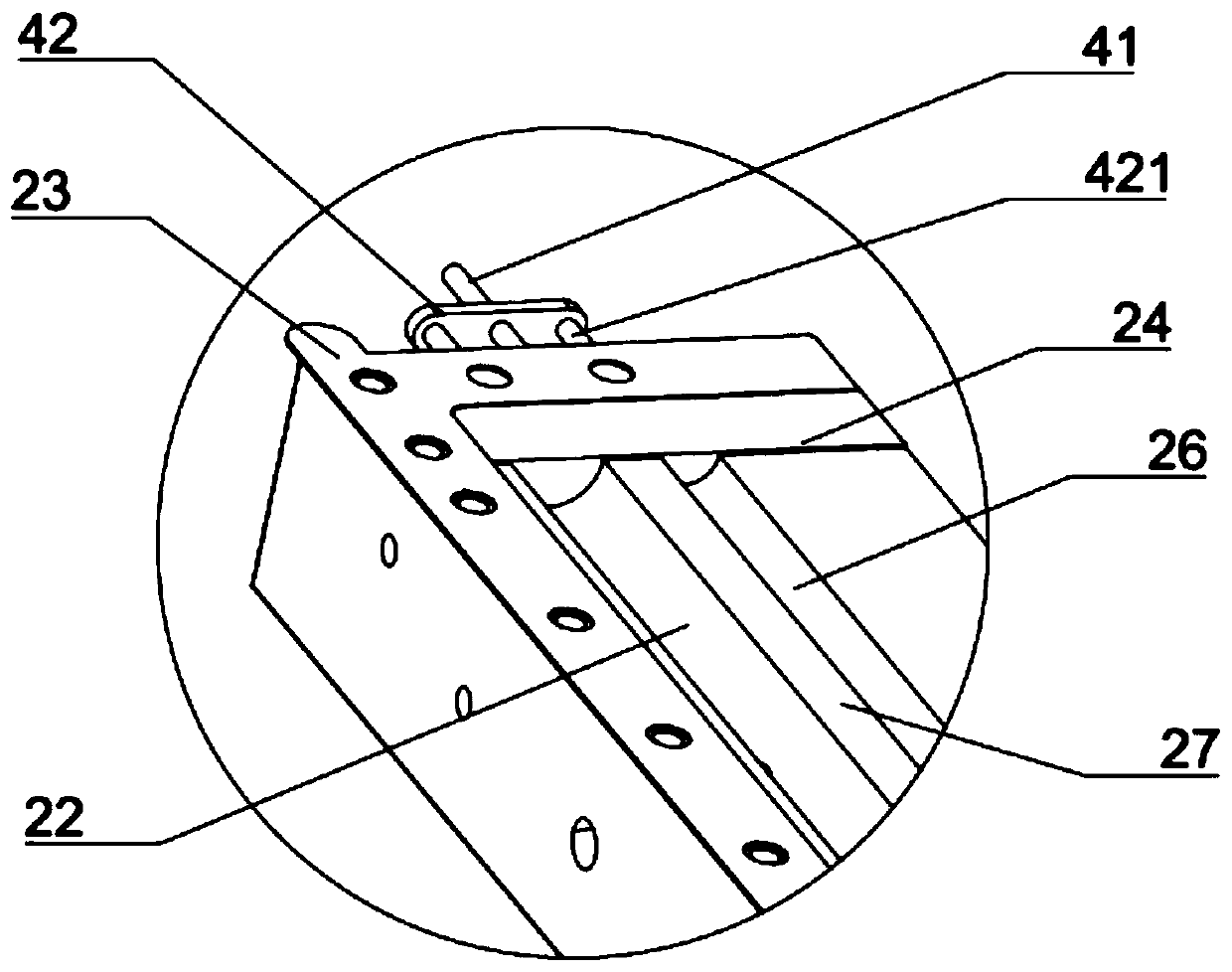

[0036] Such as figure 1 Shown is the coating die for a single set of lithium battery pole pieces in this embodiment, including an upper die 1 and a lower die 2, the lower die 2 is provided with a feed port 21 and is provided with a coating for containing the coating slurry The trough 22 of the material, the feed port 21 communicates with the trough 22, the upper die head 1 and the lower die head 2 surround the mold cavity for coating the slurry, and the front sides of the upper die head 1 and the lower die head 2 are matched. Die mouth 3 is formed. Specifically, the rear side and both sides of the upper die head 1 and the lower die head 2 are connected by studs, and a gasket 23 is arranged at the connection. As shown in Figure 2, the gasket 23 has a certain thickness and is placed on the lower die head. 2 forms the steps on the rear side and both sides, therefore, the rear side and both sides of the upper die head 1 and the lower die head 2 are sealed and connected through th...

Embodiment 2

[0042] This embodiment provides a kind of coating die head that is used for single group lithium battery pole piece, and its structure is similar to embodiment 1, comprises upper die head 1 and lower die head 2, and lower die head 2 is provided with feeding port 21 And be provided with the trough 22 that is used to accommodate coating slurry, feed inlet 21 communicates with trough 22, upper die head 1 and lower die head 2 surround the mold cavity of coating slurry, upper die head 1 and lower die head The front side of the head 2 cooperatively forms a die mouth 3 . The difference is that the connection between the upper die head 1 and the lower die head 2 is not provided with gaskets, such as Figure 4 As shown, the upper die head 1 or the lower die head 2 forms a connection platform 28 at the joint surface, the connection platform 28 is integrally formed with the upper / lower die head, and is arranged at the junction of the rear side and both sides, and is provided with screw ...

Embodiment 3

[0044] Such as Figure 5 and Figure 6 Shown is a preferred embodiment of the coating die for single or multiple sets of lithium battery pole pieces, including an upper die 1 and a lower die 2, and the lower die 2 is provided with a feed port 21 and is used to accommodate The trough 22 for coating the slurry, the feed port 21 is externally connected to the feed pipe and communicated with the trough 22, the upper die head 1 and the lower die head 2 form a mold cavity for coating the slurry, the upper die head 1 and the lower die head The front side of the head 2 cooperatively forms a die mouth 3 . Specifically, the rear side and both sides of the upper die head 1 and the lower die head 2 are connected by studs, and a gasket 23 or an integrally formed connecting platform 28 is arranged on the rear side and both sides of the joint surface. A slit is formed on the front side. Therefore, the rear side and both sides of the upper die head 1 and the lower die head 2 are sealed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com