Process for coating strip with fully-closed outer edge by utilizing magnetron sputtering coating machine

A magnetron sputtering, coating machine technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve problems such as inability to perform coating, achieve clear edges without shadows, high coating accuracy , The effect of accurate film formation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

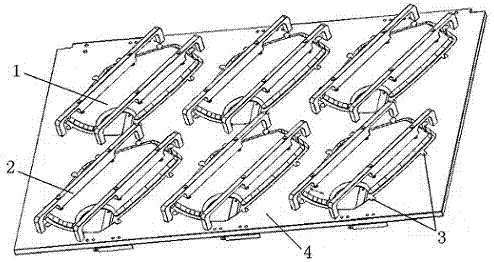

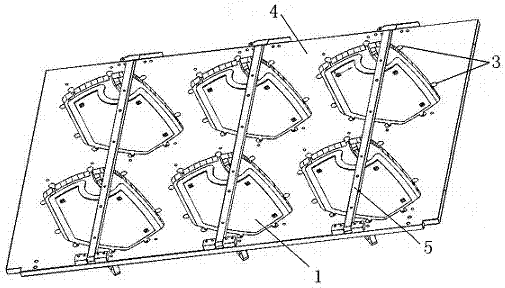

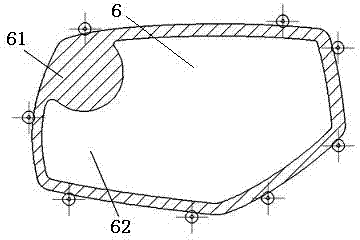

[0029] see Figure 1 to Figure 3 , this embodiment includes the following steps: Carry out CNC machining on the film to be coated, the contour is controlled at 0.1, through SPC control means, Cpk>1.33, and the stop gauge inspection meets +0.1 / -0.15, so as to ensure that the material to be plated during mass production Meet the requirements of coating accuracy; clean the coated sheet; check the state of the tooling before coating, and regularly sandblast it for long-term use; put the coated sheet into the coating tooling, and open the support and fixing frame of the coated sheet with a traceless The suction cup sucks the non-coated surface of the coated sheet, place the coated sheet close to the shielding sheet, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com