Patents

Literature

46results about How to "Eliminate settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

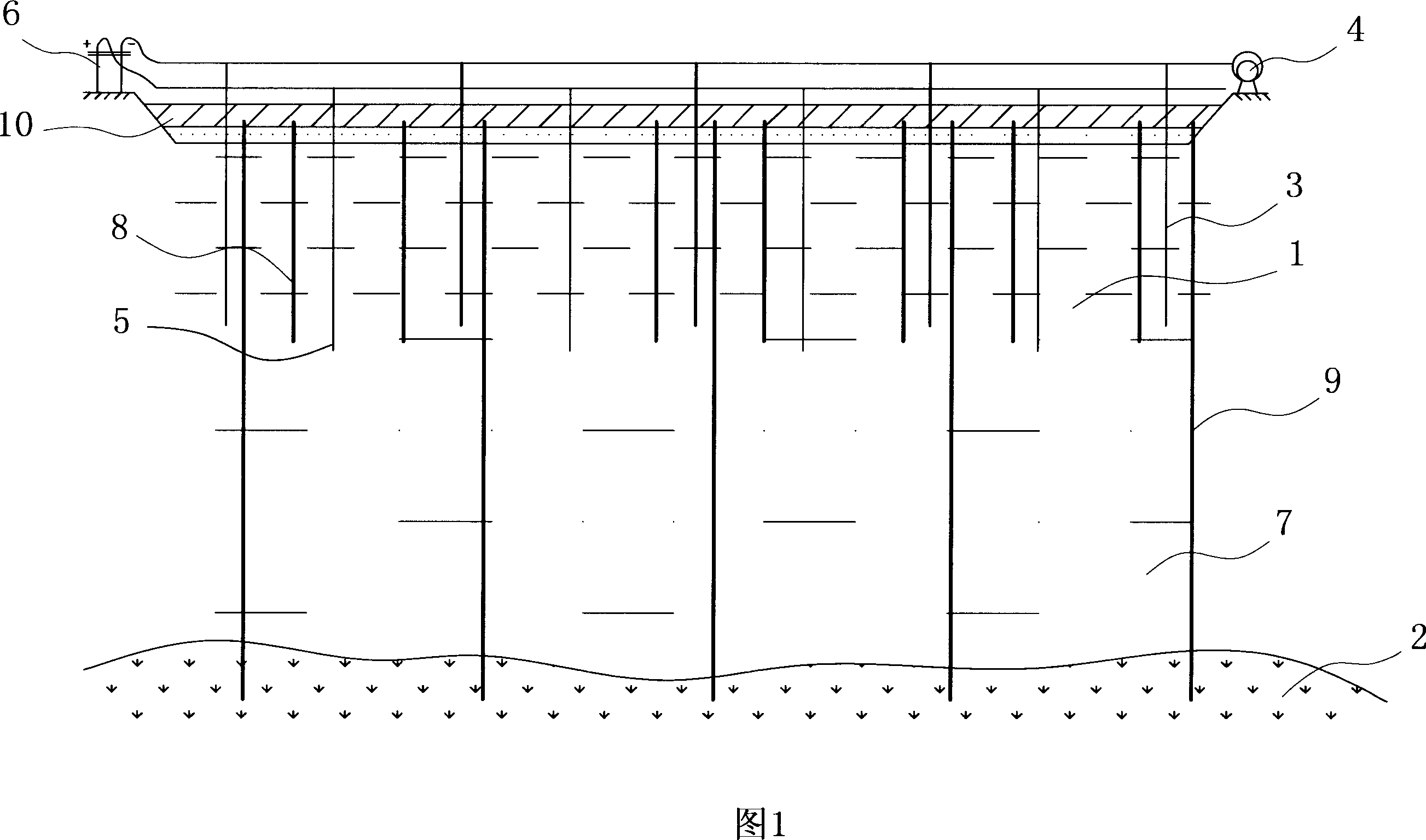

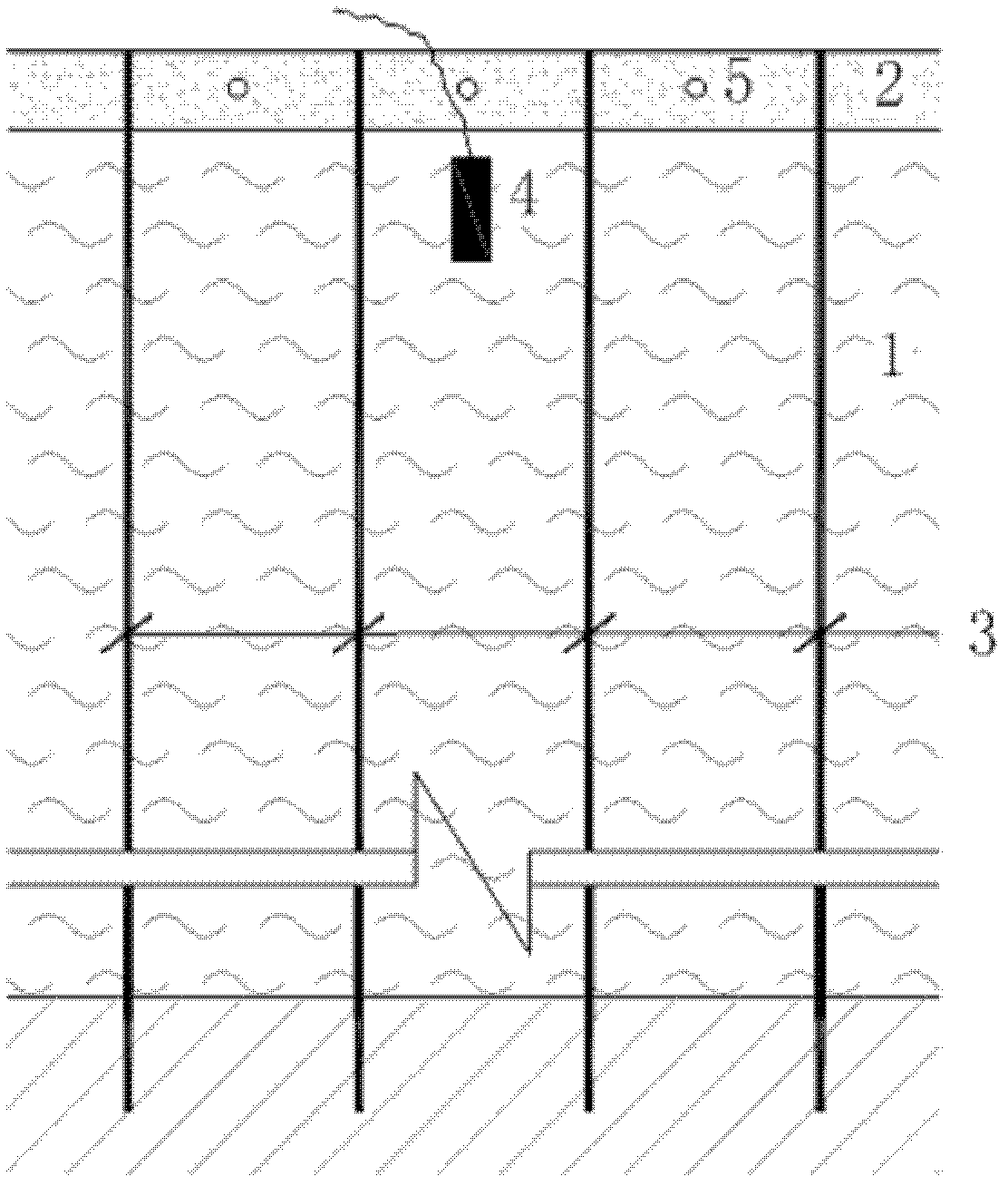

Reinforcement method of deep layer soft soil foundation

InactiveCN1948632AEliminate settlementIncrease the bearing capacity of the foundation soilBulkheads/pilesSoil preservationEngineeringElectron system

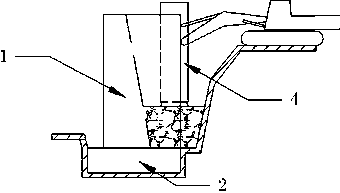

This invention discloses a deep soft soil reinforce method. Its construction steps includes:(1)the vacuum well point declines water (2) vacuum electricity declines a water : vertically plugs electricity tube in a vacuum tube wells inside, installs electric system for vacuum tube wells and electron system the cathode connecting, electron and electron pipe system connecting to form the anode DC circuit; (3) low-energy strong ramming; (4) vibrating roll, flat ground; (5) adding concrete-pile : machine drills hole, adapting tube pump concrete for the construction technology-concrete composite construction of the foundations; (6) lays cushion : concrete pile in the top layer structure and the site uses static compaction cushion construction. This invention by vacuum precipitation and-concrete pile combination of approaches to achieve the reinforcement of the deep soft ground, breakthroughs in the tradition of deep soft soil to use reinforced concrete piles in the traditional concept and reduces the construction cost.

Owner:杨静明 +2

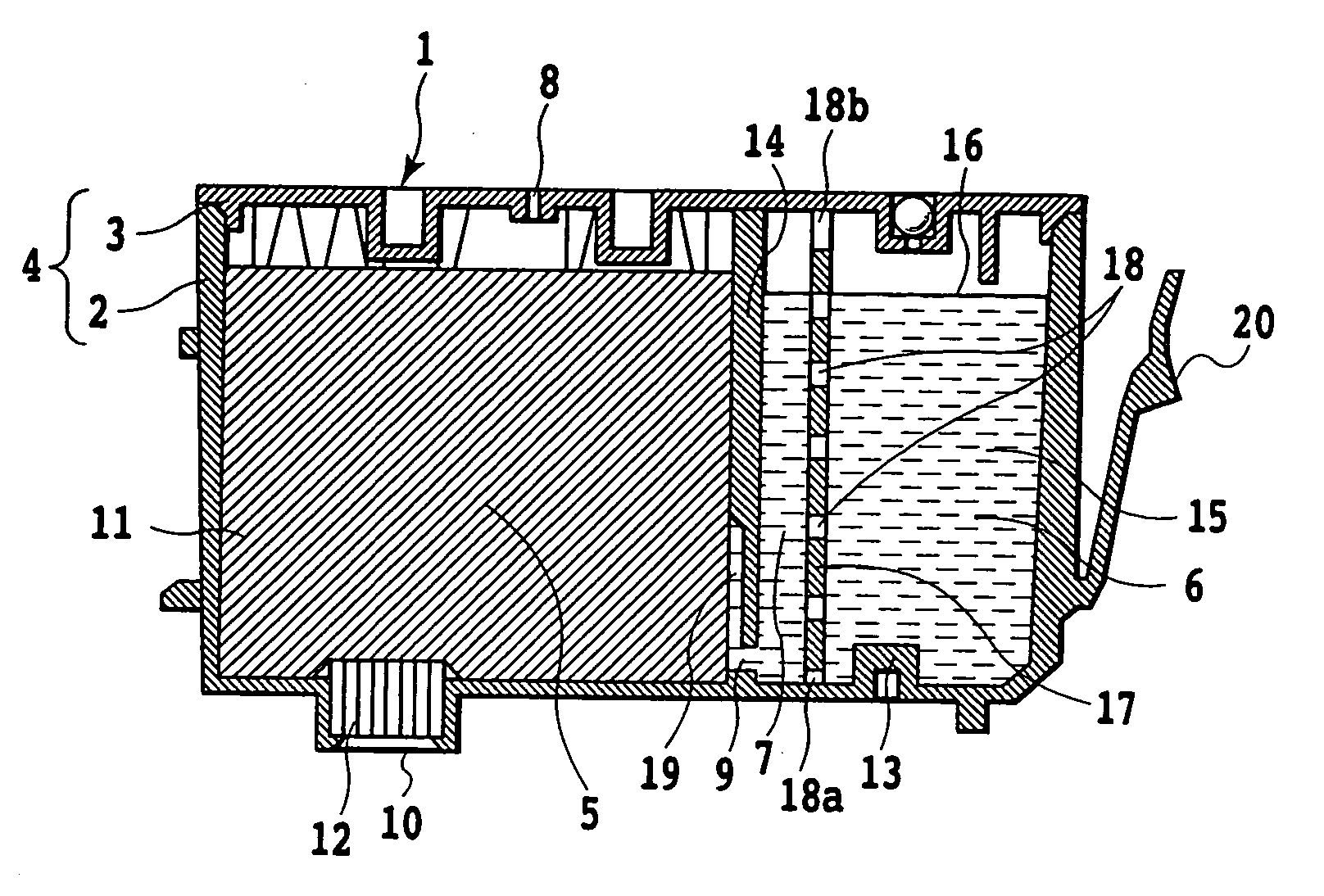

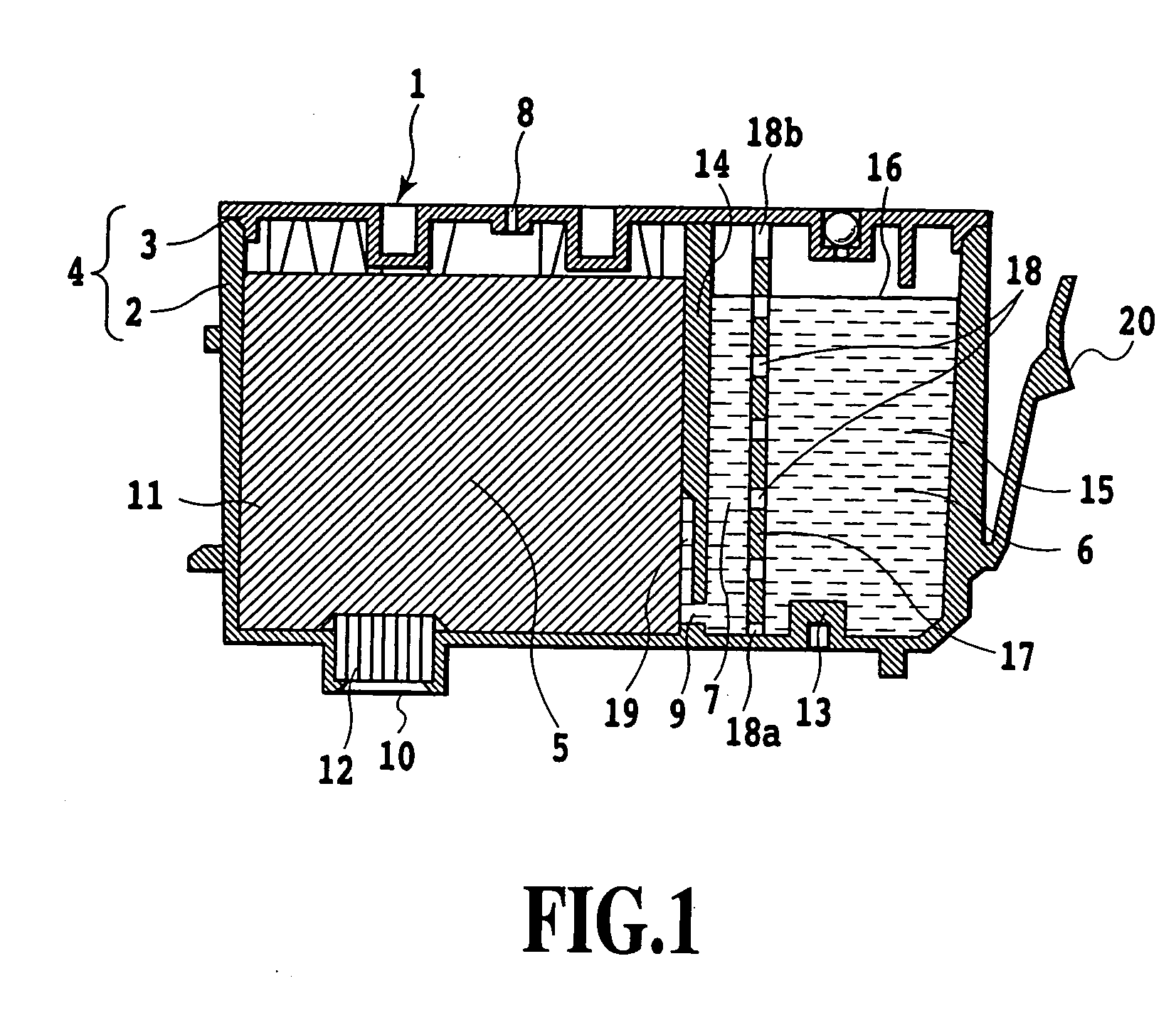

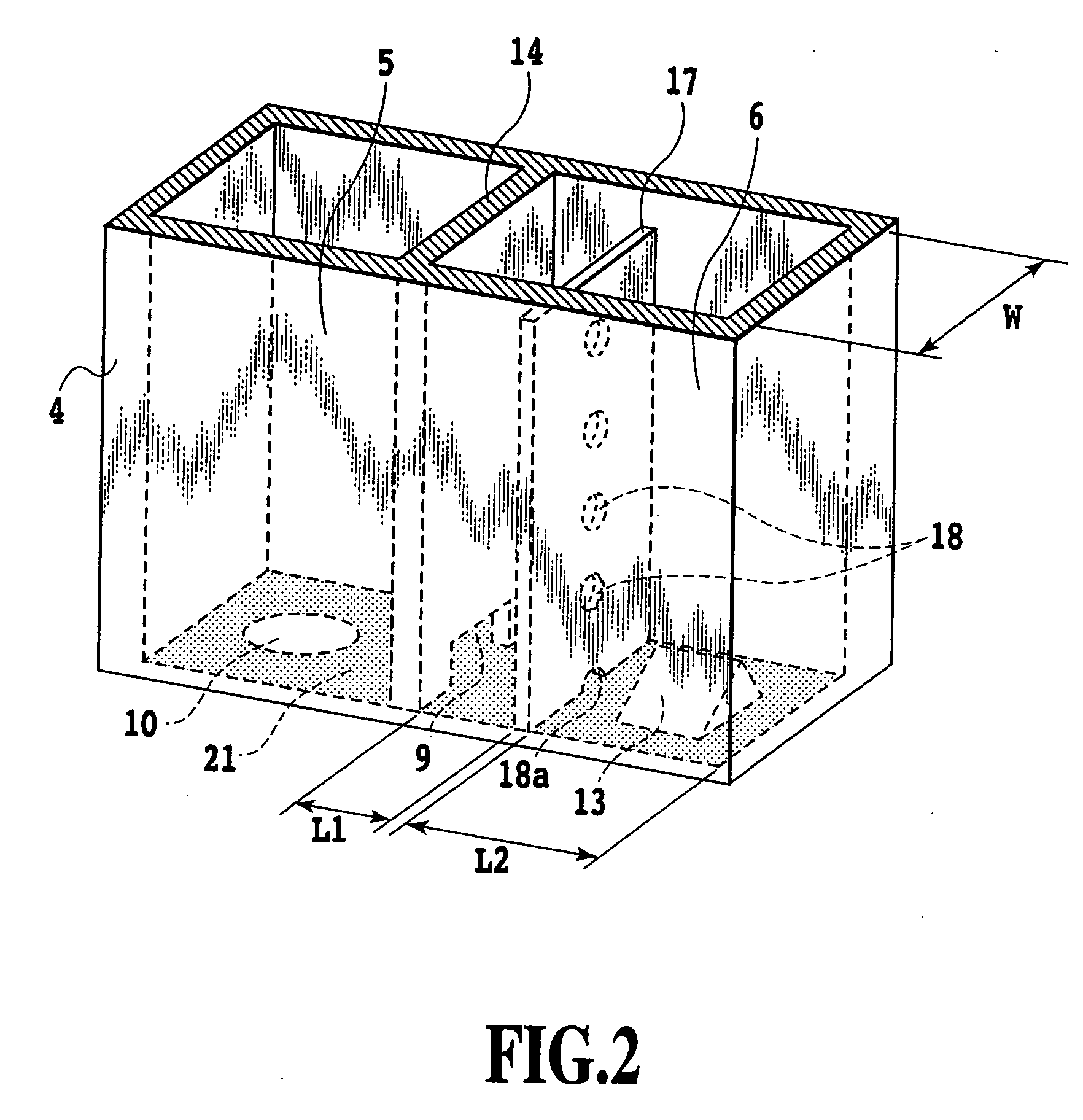

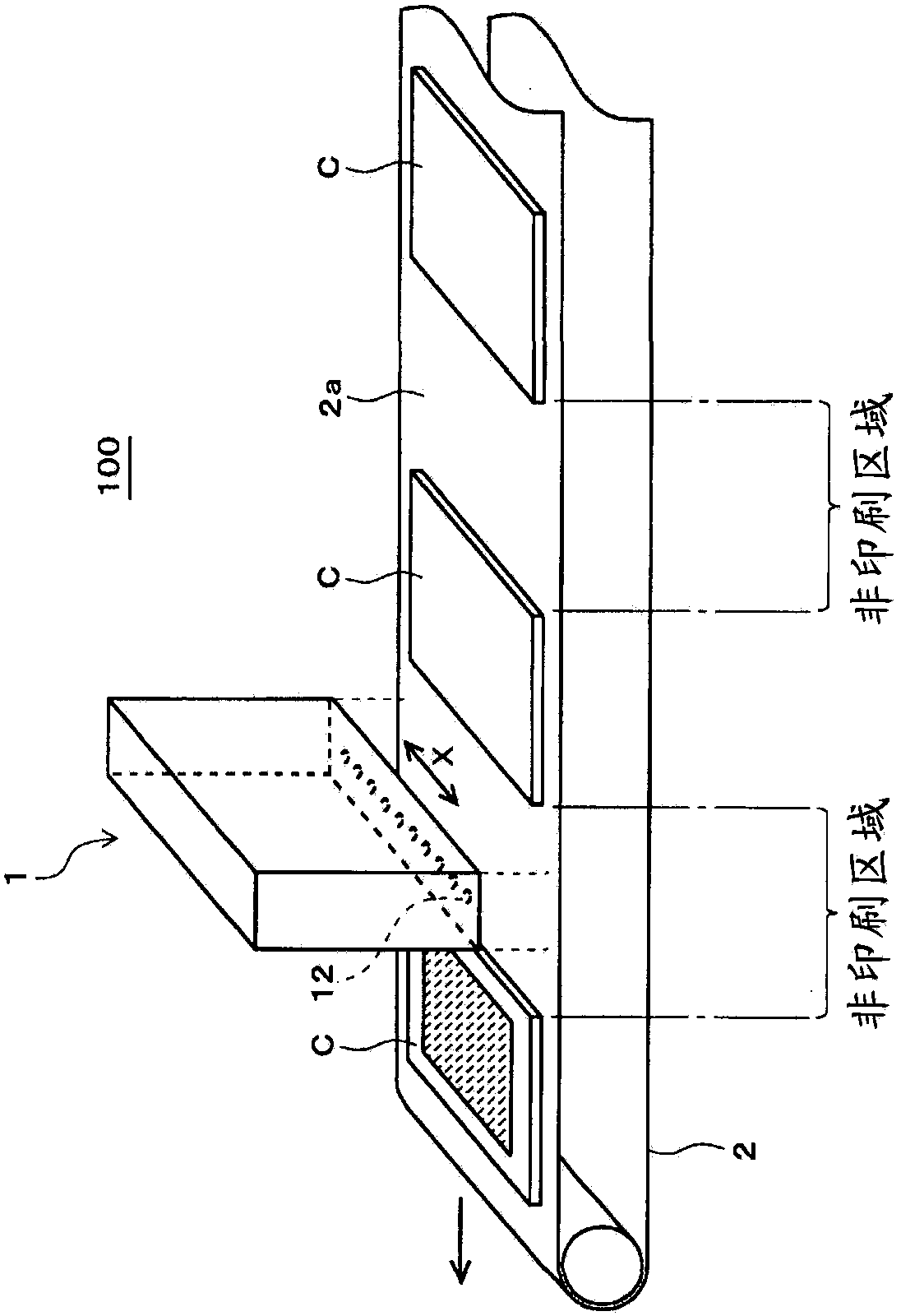

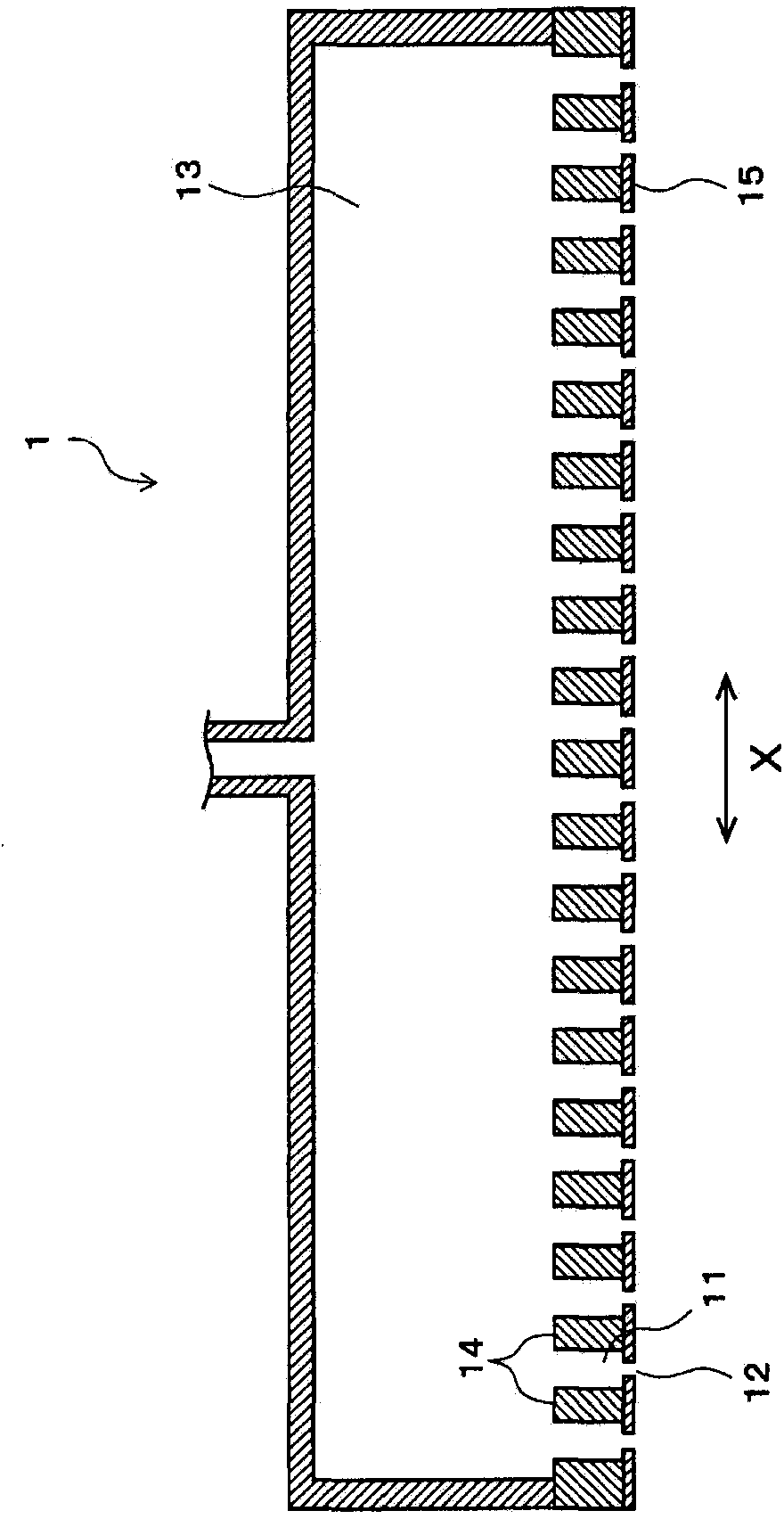

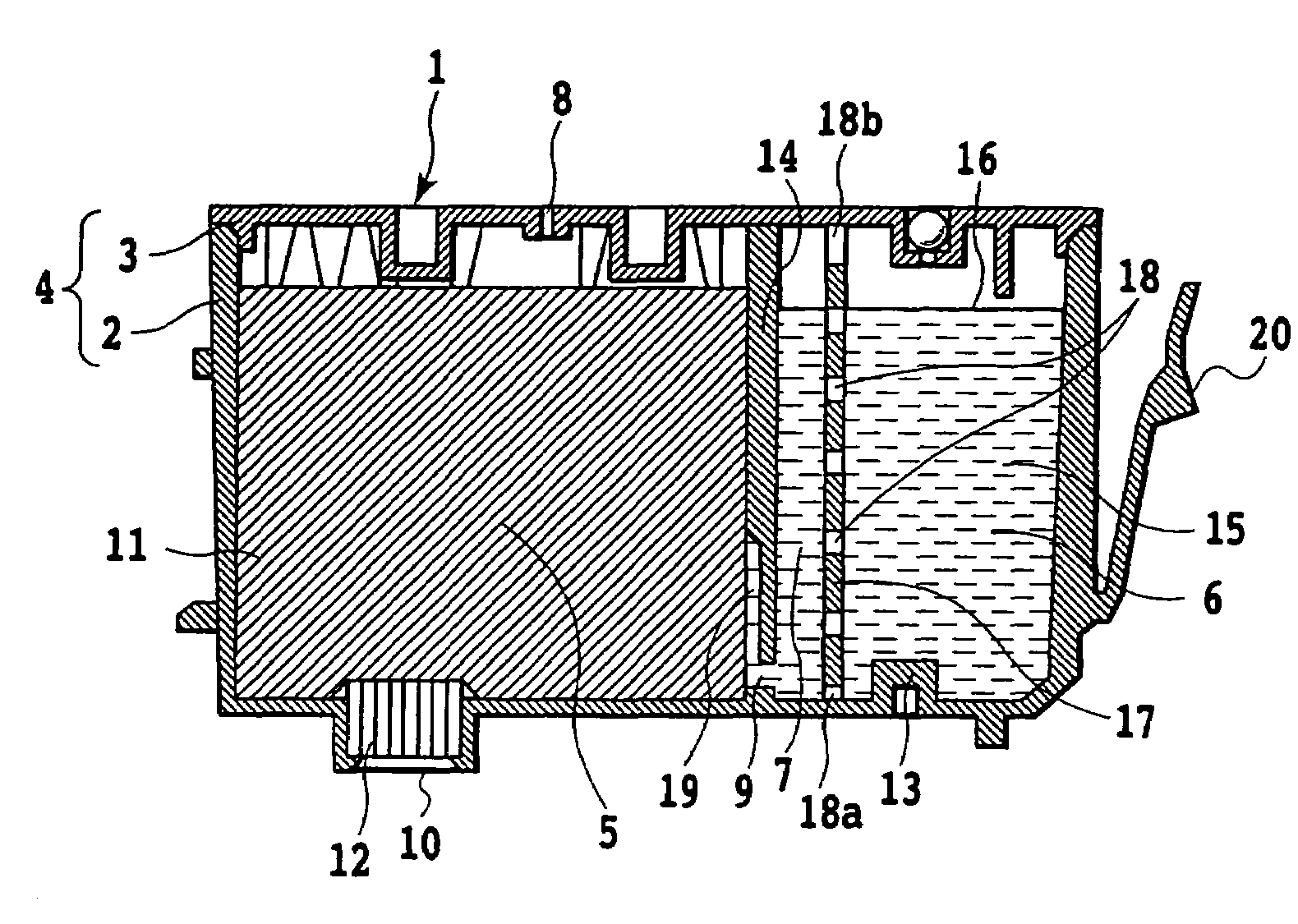

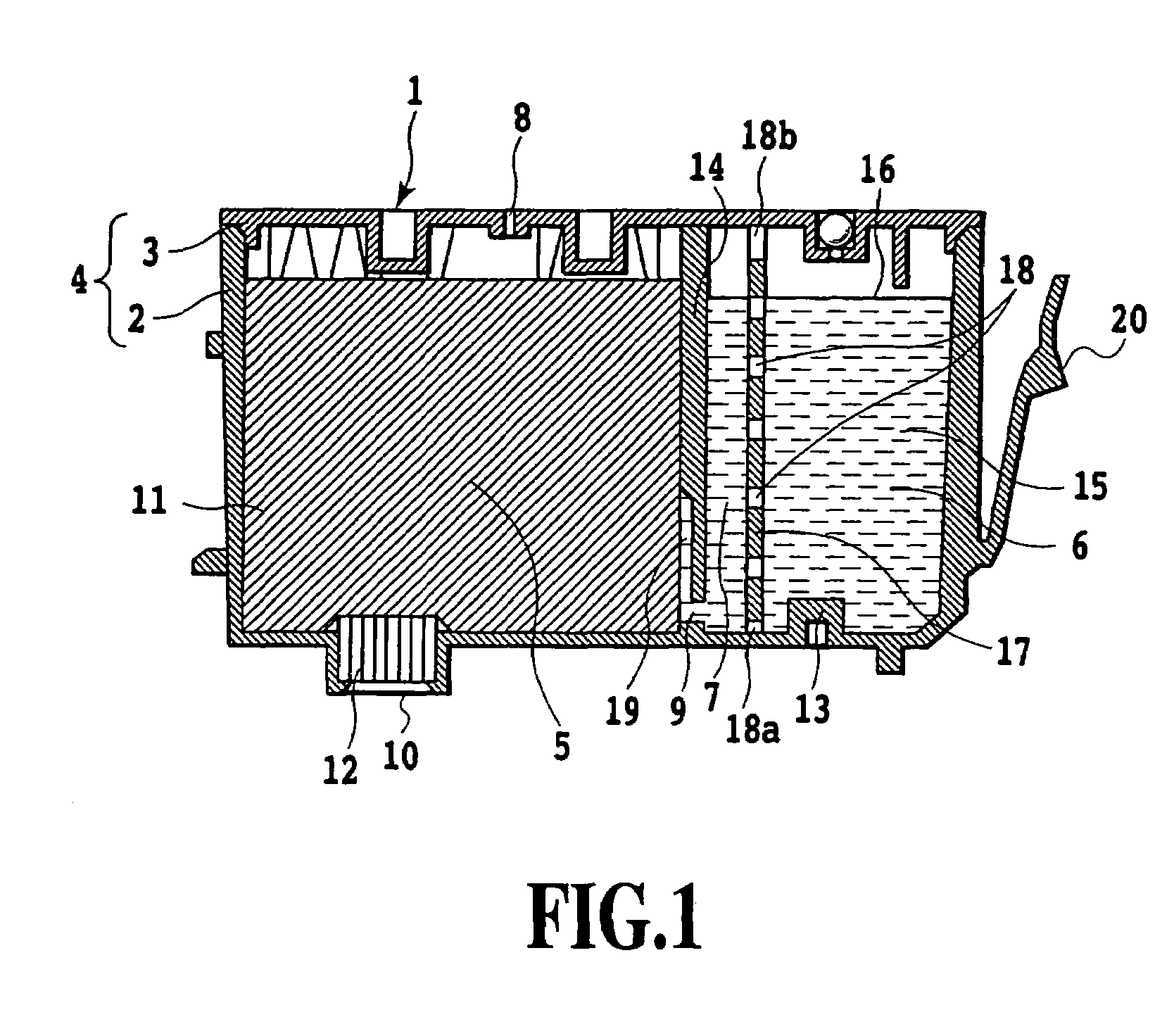

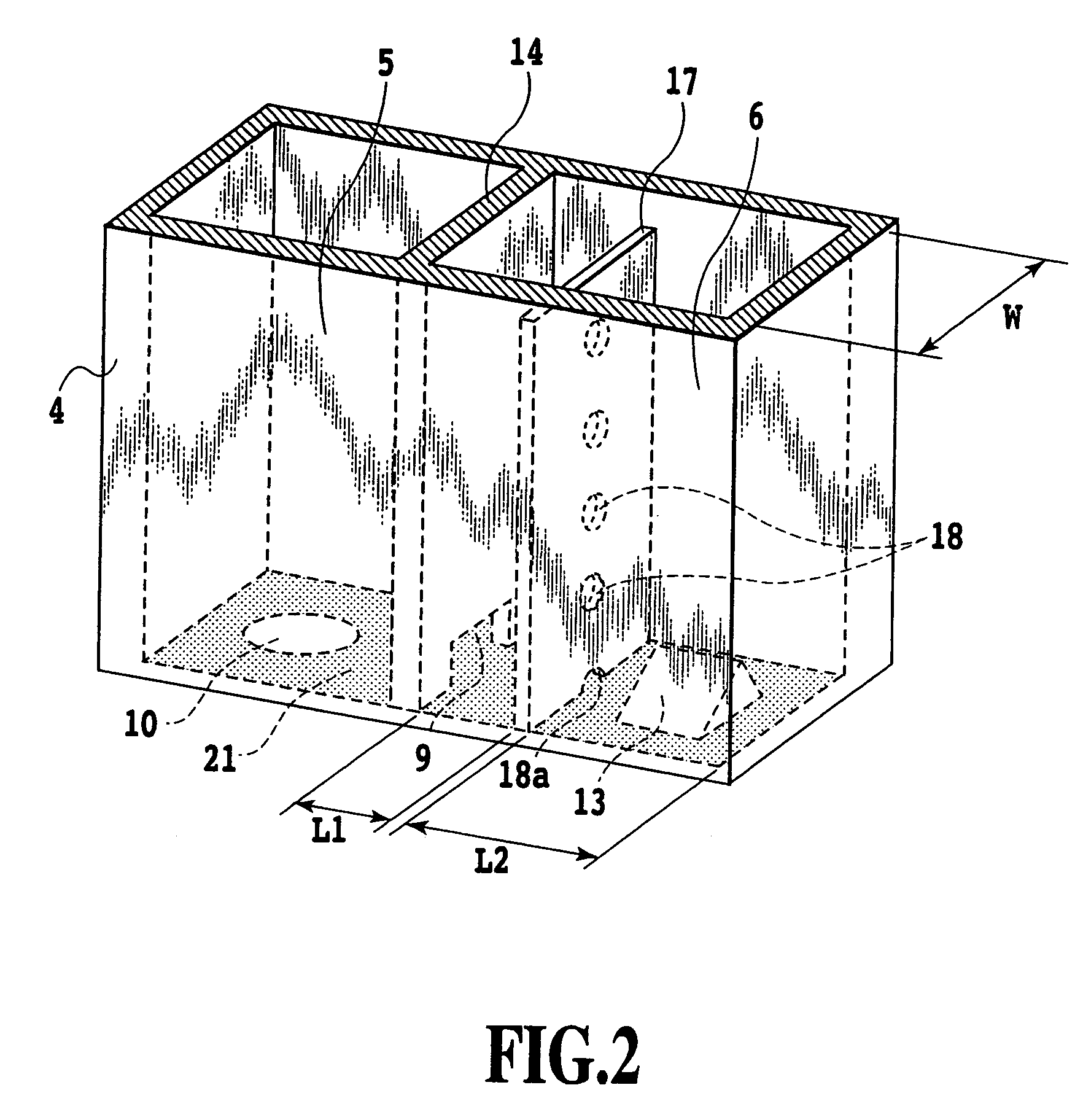

Liquid container and printing apparatus using the same

An intermediate chamber 7 is provided in a liquid storage chamber 6 of a liquid container 1, for separating the liquid storage chamber 6 from a chamber 5 for accommodating a negative pressure generating member. The intermediate chamber 7 communicates with both of the liquid storage chamber 6 and the chamber 5 for accommodating the negative pressure generating member, and further communicates with the liquid storage chamber 6 via a plurality of small openings 18 provided upward from the bottom thereof.

Owner:CANON KK

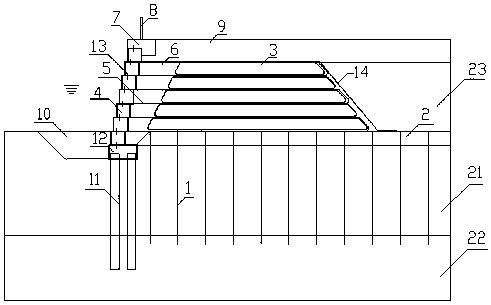

Method for reinforcing soft soil foundation by using calescence type vacuum preloading way

InactiveCN103255761AImprove bearing capacityDrain fastSoil preservationVacuum extractionVacuum pressure

The invention relates to a method for reinforcing a soft soil foundation by using a calescence type vacuum preloading way. The method comprises the steps of: introducing a foundation heating system on the basis of a regular vacuum preloading way; and keeping an under-film vacuum pressure and a temperature of shallow-layer soft soil in a reinforcing region respectively above 80 kPa and 62 DEG C within a period of time of a reinforcing period so as to rapidly vaporize pore water of foundation soil and pump the vaporized pore water by vacuum extraction equipment to cause sedimentation of the foundation. Compared with the prior art, the method for reinforcing the soft soil foundation by using the calescence type vacuum preloading way has the advantages of shorting the construction period, improving reinforcing effects, reducing settlement after the construction, increasing the bearing capacity of foundation soil and the like.

Owner:TONGJI UNIV

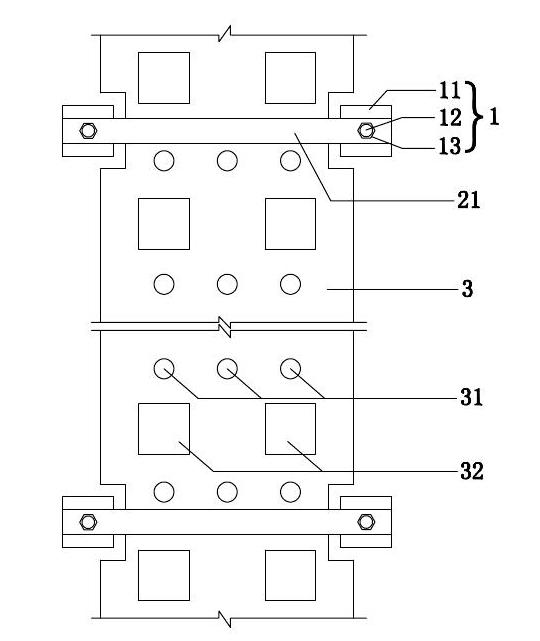

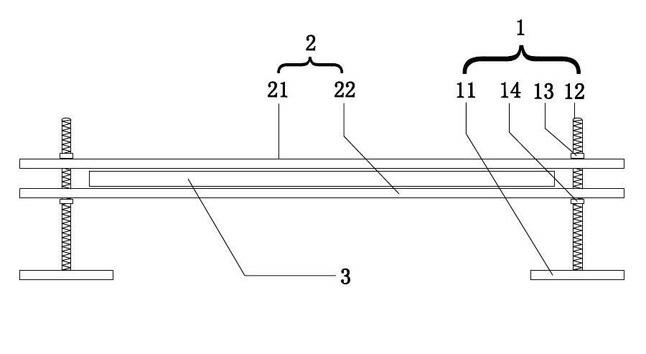

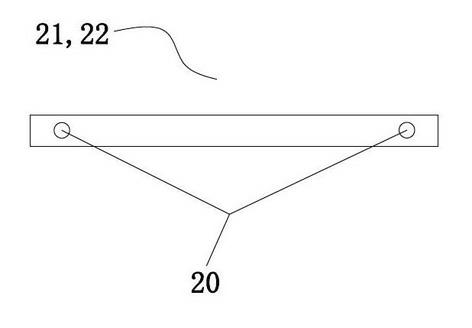

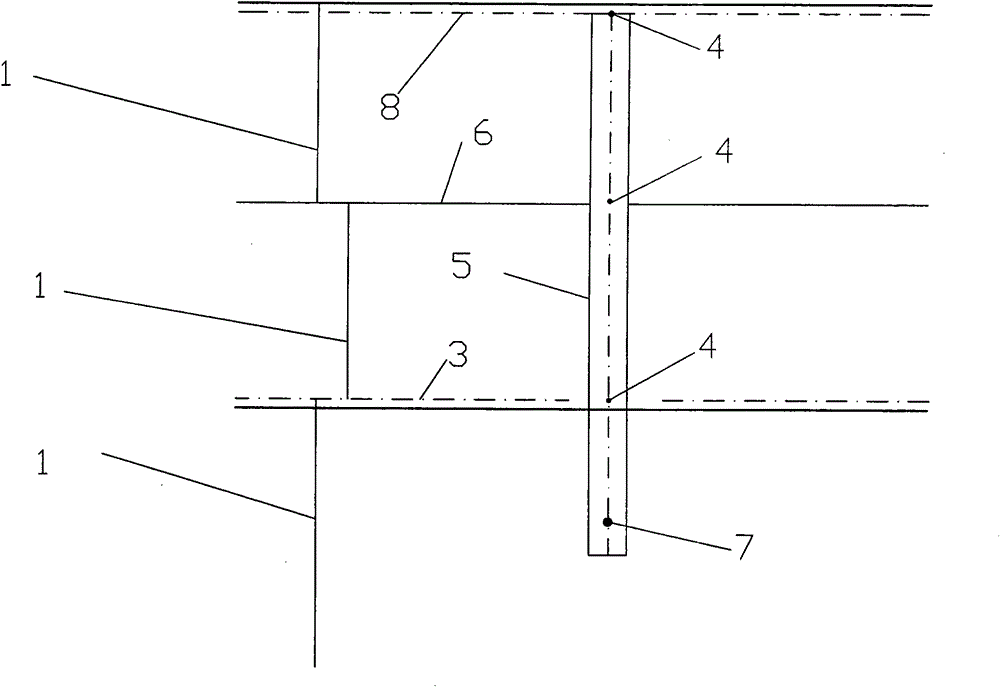

Concrete foundation embedded bolt bracket and embedding method for concrete foundation embedded bolts

InactiveCN102619235ARealize up and down adjustmentEliminate displacementFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses a concrete foundation embedded bolt bracket and an embedding method for concrete foundation embedded bolts. The embedded bolt bracket of a concrete foundation comprises at least four groups of support assemblies, at least two groups of clamping piece steel plates, steel templates, wherein every two groups of support assemblies correspond to a group of clamping piece steel plates; the support assemblies are arranged at the side parts of the steel templates; two ends of the clamping piece steel plates are movably connected with the support assemblies; the clamping piece steel plates comprise upper clamping piece steel plates and lower clamping piece steel plates; the steel templates are respectively clamped between every two clamping piece steel plates; and a plurality of bolt holes for allowing the embedded bolts to pass through are formed in the steel templates. According to the concrete foundation embedded bolt bracket and the embedding method for the concrete foundation embedded bolts, which are disclosed by the invention, the embedded bolts can be adjusted from six directions, the displacement and settlement of the embedded bolts caused by concrete construction are eliminated and high-precision embedding is realized, so that the embedding of the bolts is finished at one time and further the work efficiency is increased.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

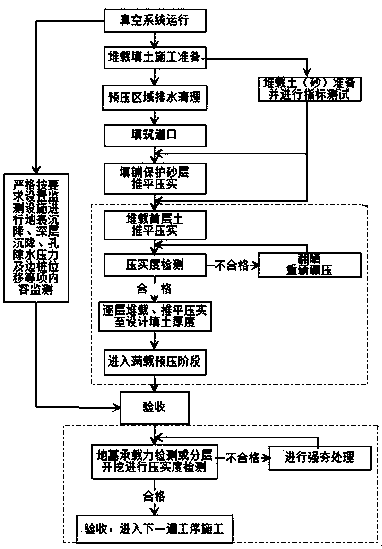

Vacuum combined surcharge preloading construction method applied to soft soil foundation treatment

ActiveCN103866754AImprove loading speedAccelerated settlementIn situ soil foundationSoil preservationElectricitySurface layer

The invention relates to a vacuum combined surcharge preloading construction method applied to soft soil foundation treatment. The vacuum combined surcharge preloading construction method applied to the soft soil foundation treatment comprises a loading method, a monitoring method and an after-engineering disposing method. The loading method comprises steps of a, enabling the vacuum degree to achieve more than 80 KPa, performing voltage stabilization for 10 to 15 days, draining water in a preloading area and covering sealing films to be protected at the early operation stage of the preloading area vacuum system; b, filling a level crossing; c, filling a first layer; d, filling other layers in a supercharge mode; the monitoring method comprises steps of a, settlement monitoring of a surface layer of the preloading area; b, settlement monitoring of a deep layer of the underlying stratum; side inclining and side pile observation; d, monitoring of the vacuum degree under the films; the after-engineering disposing method is applied after the vacuum combined surcharge preloading treatment and adopts detection of the bearing capacity of foundation soil or adopts layered excavation to perform detection of degree of compaction. The vacuum combined surcharge preloading construction method can reduce consumption of electricity for construction and save construction costs and project management costs.

Owner:CHINA MCC20 GRP CORP

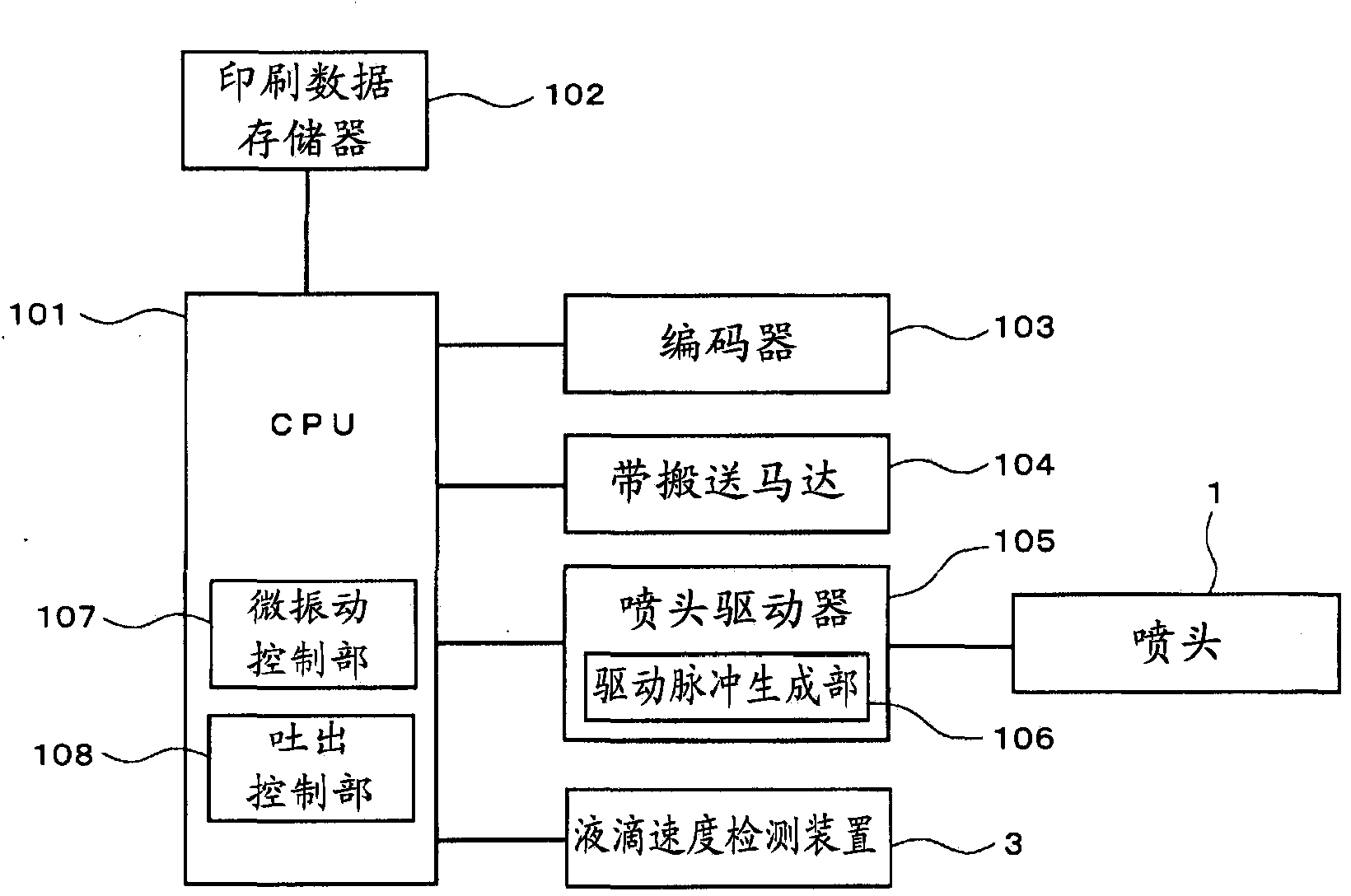

Droplet injection device and nozzle recovery method for droplet injection device

The present invention aims to efficiently eliminate settling of solid particles in the ink, and enable long-term stable droplet injection. Specifically, a droplet injection device comprises an ink chamber, a nozzle corresponding to the ink chamber, an energy imparting unit, and a drive pulse generation unit. The energy imparting unit is impacted and driven by a drive pulse to impart energy to the ink in the ink chamber. The nozzle allows droplets to be sent out from the nozzle, so that a printing area for recording material is printed. The drive pulse generation unit generates a shoot-out pulse allowing a droplet to be sent out from the nozzle, and provides a micro vibration pulse as a drive pulse for the ink in the ink chamber based on a degree that the droplet is not sent out from the nozzle. The ink comprises dispersant, and solid particles with a proportion greater than the dispersant. An updating unit is also provided. The updating unit applies micro vibration motion of a plurality of micro vibration pulses and then a plurality of shoot-out pulses, so as to enable split motion with the same.

Owner:KONICA MINOLTA INC

Liquid container and printing apparatus using the same

An intermediate chamber 7 is provided in a liquid storage chamber 6 of a liquid container 1, for separating the liquid storage chamber 6 from a chamber 5 for accommodating a negative pressure generating member. The intermediate chamber 7 communicates with both of the liquid storage chamber 6 and the chamber 5 for accommodating the negative pressure generating member, and further communicates with the liquid storage chamber 6 via a plurality of small openings 18 provided upward from the bottom thereof.

Owner:CANON KK

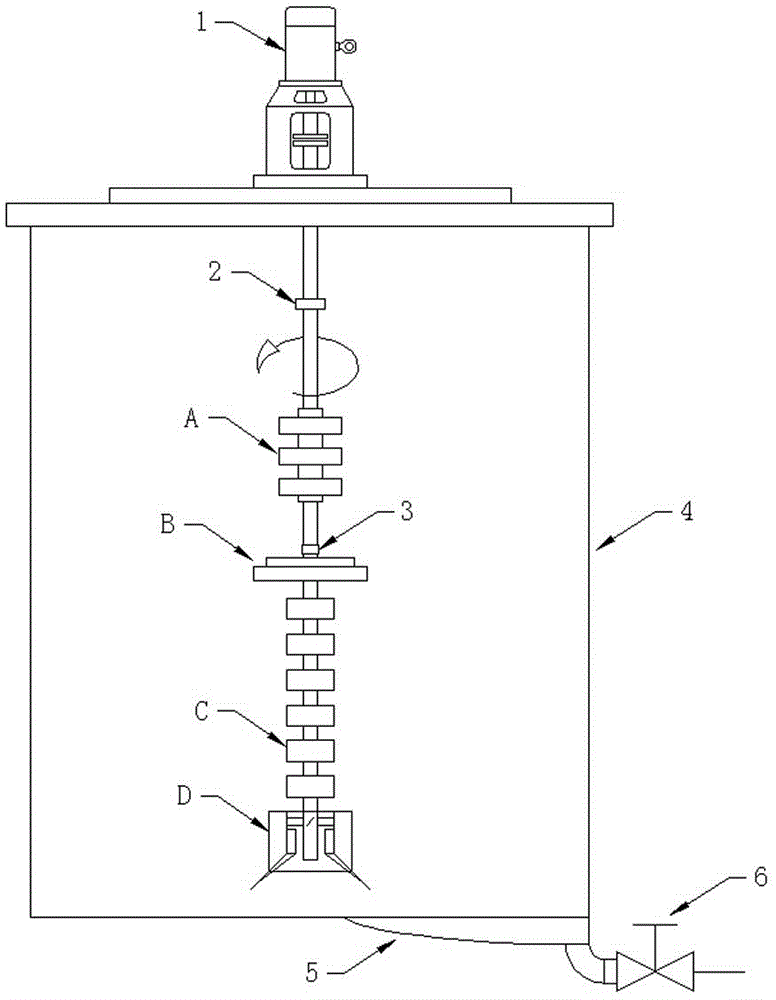

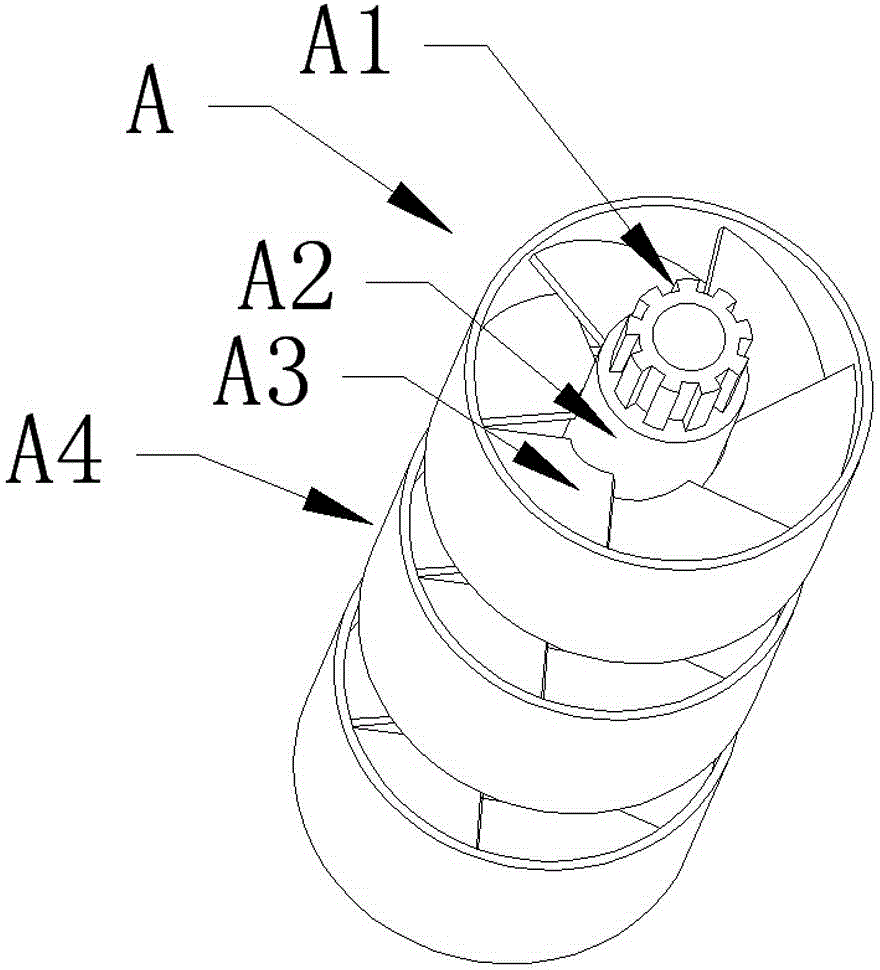

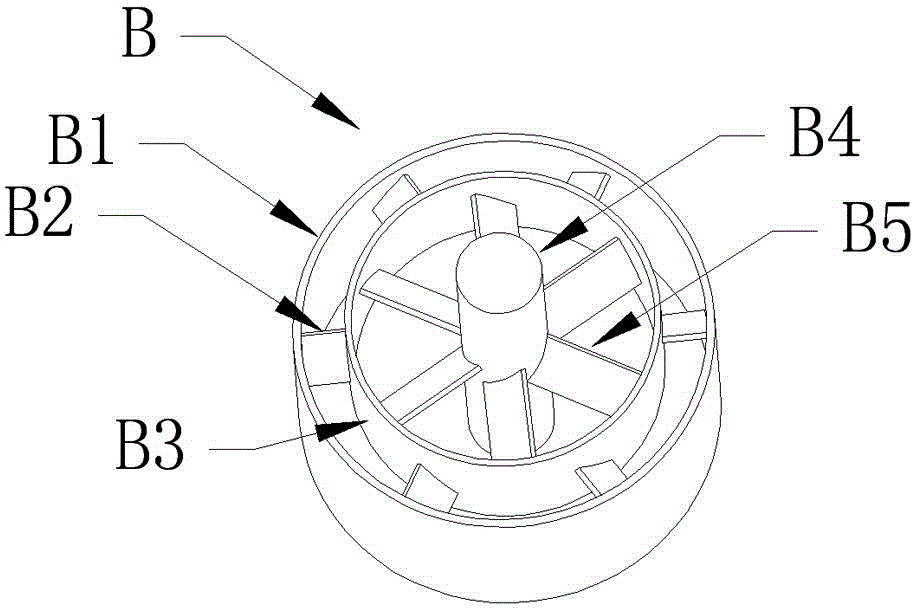

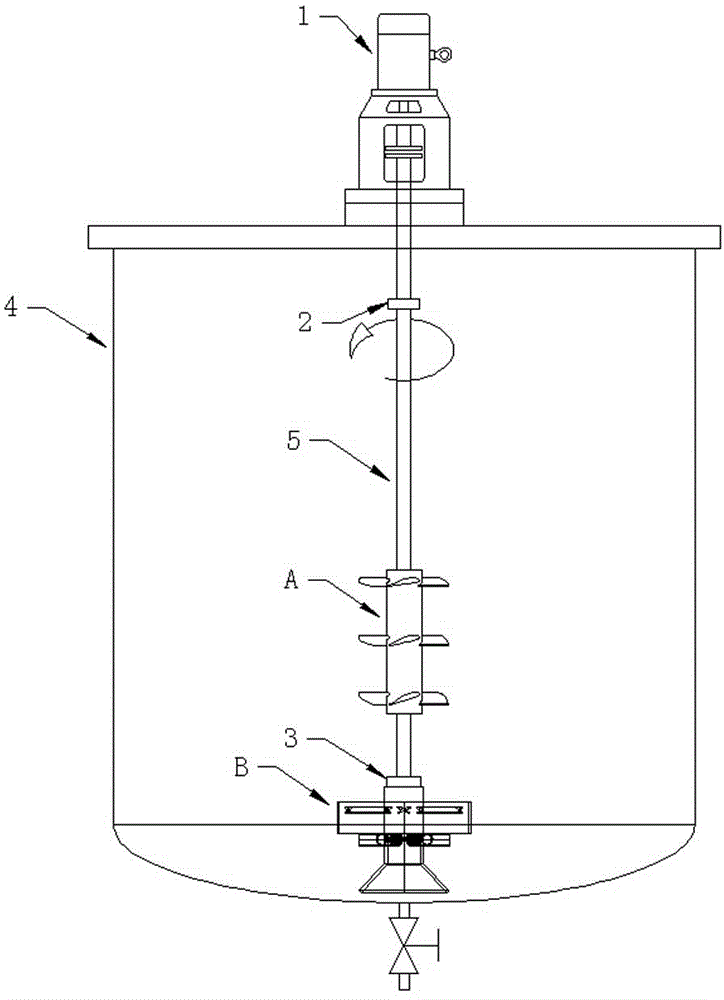

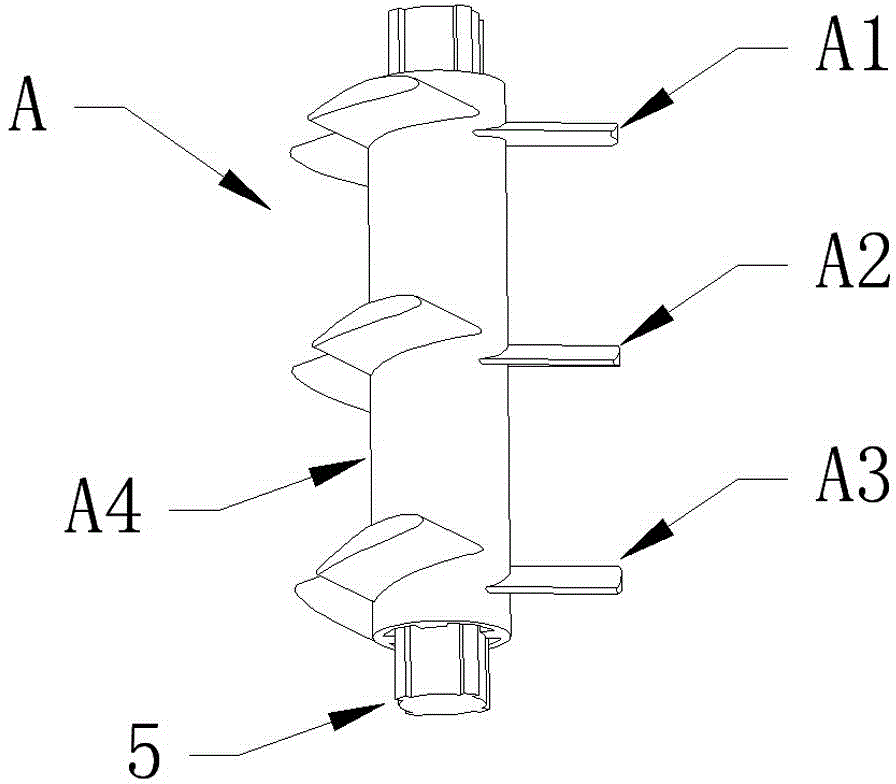

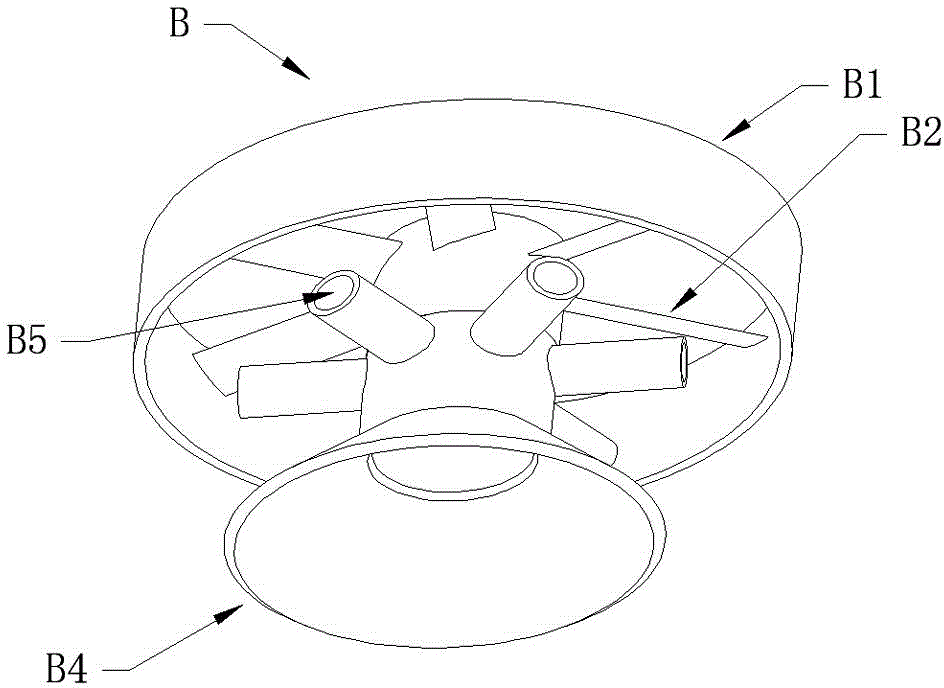

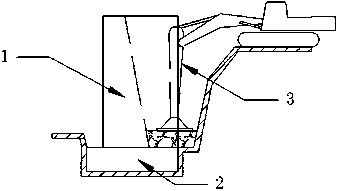

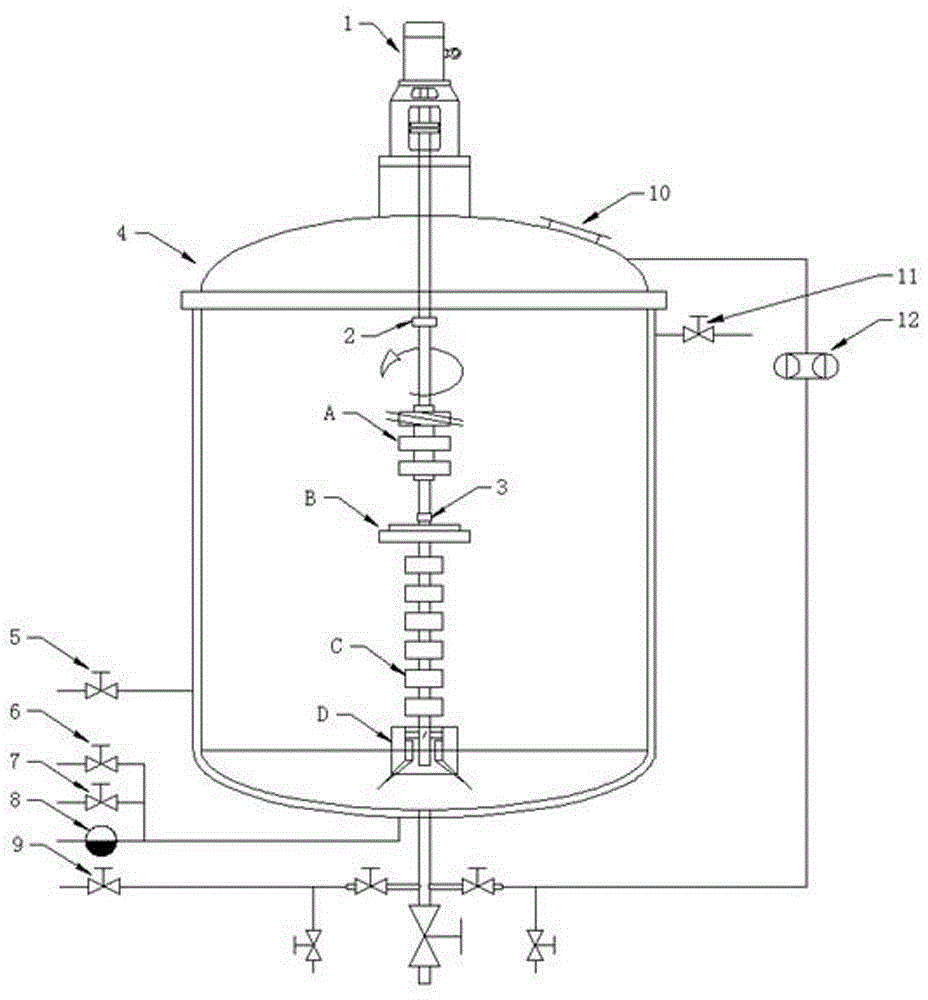

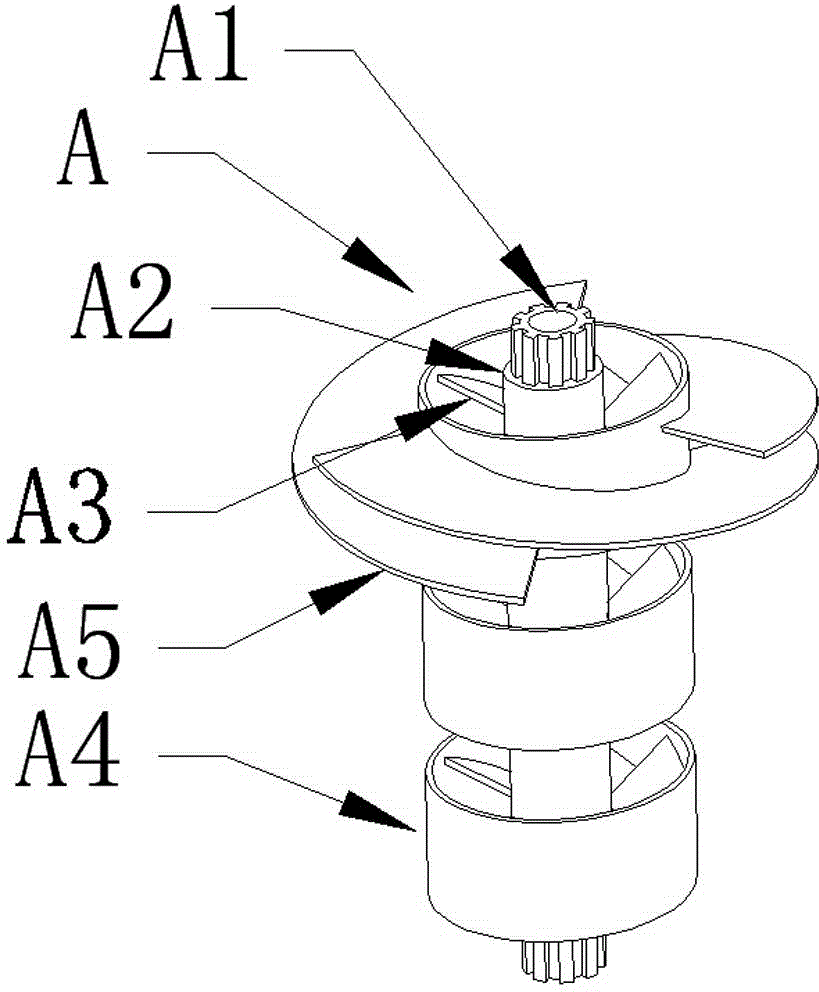

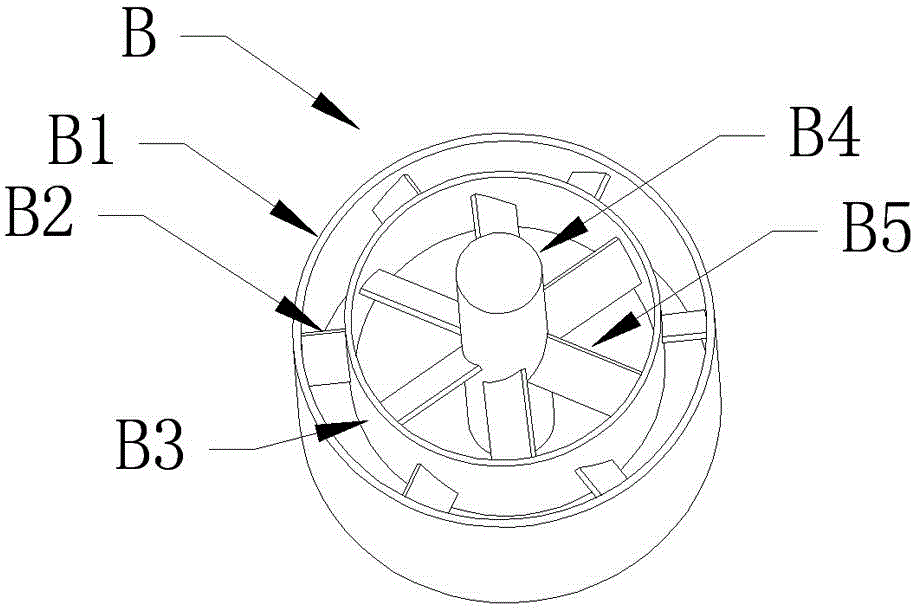

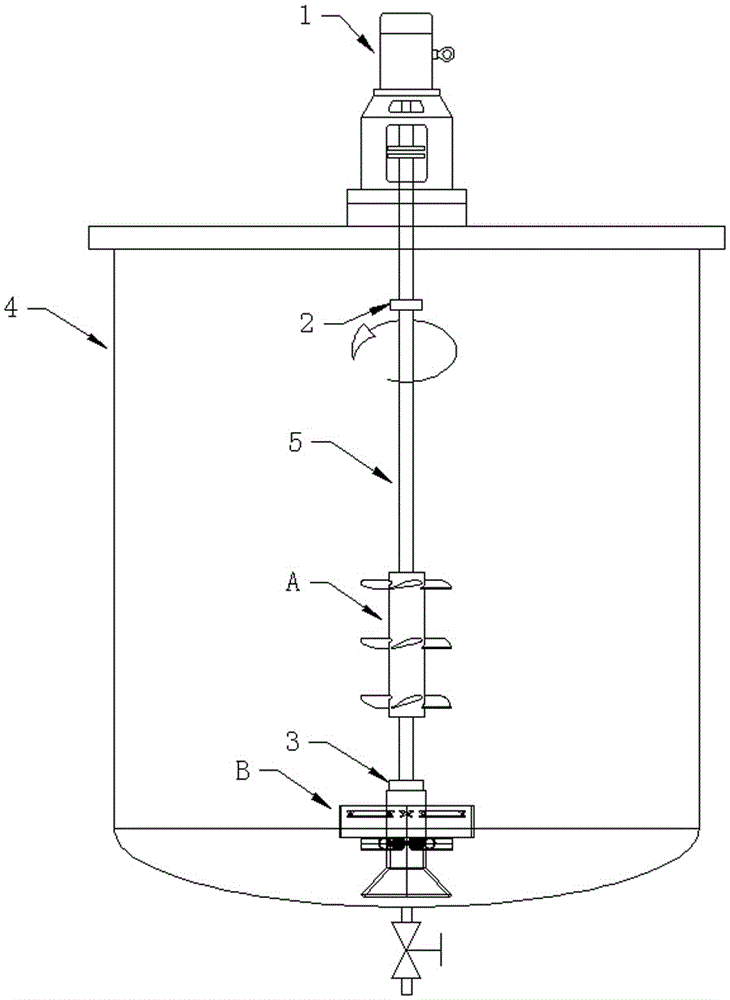

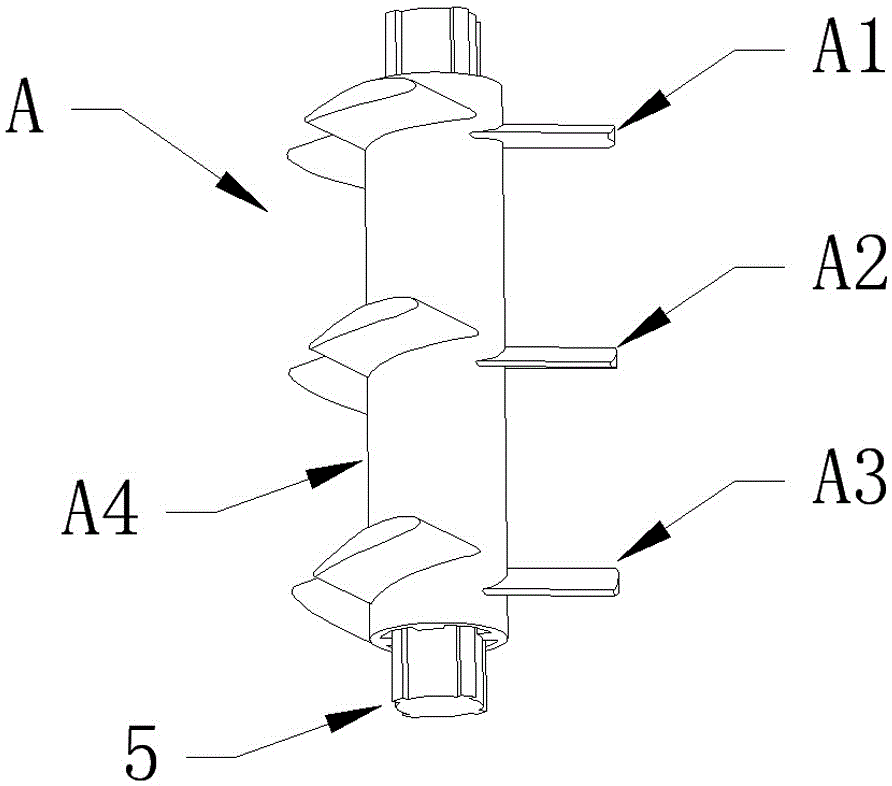

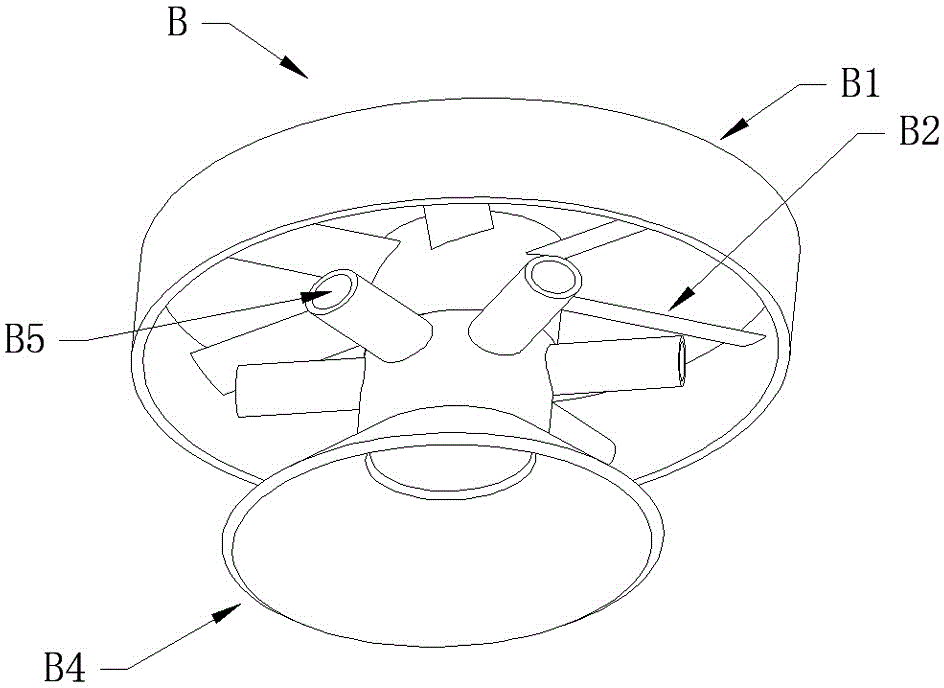

Thick slurry stirring chemical combination bucket

ActiveCN104607076AGood suspensionWon't settleRotary stirring mixersChemical/physical/physico-chemical stationary reactorsSlurryChemical combination

The invention discloses a thick slurry stirring chemical combination bucket. The thick slurry stirring chemical combination bucket comprises a bucket body, a motor, a speed reducer and a stirring shaft, wherein the stirring shaft is inserted in the bucket body; the motor and the speed reducer drive the stirring shaft to rotate; the stirring shaft is sequentially provided with a bottom sweeping stirrer, a multi-stage series lower jet stirrer, a bidirectional jet stirrer and a suspension lower jet stirrer from bottom to top; the suspension lower jet stirrer is limited by upper and lower location steps, and capable of floating up and down. The thick slurry stirring chemical combination bucket disclosed by the invention has the characteristics of being low in energy consumption, great in material circulation, not liable to sink to the bottom, and capable of being started by a light load even if material sedimentation is caused by long-time power failure, as well as has a wide application prospect.

Owner:JISHOU UNIVERSITY

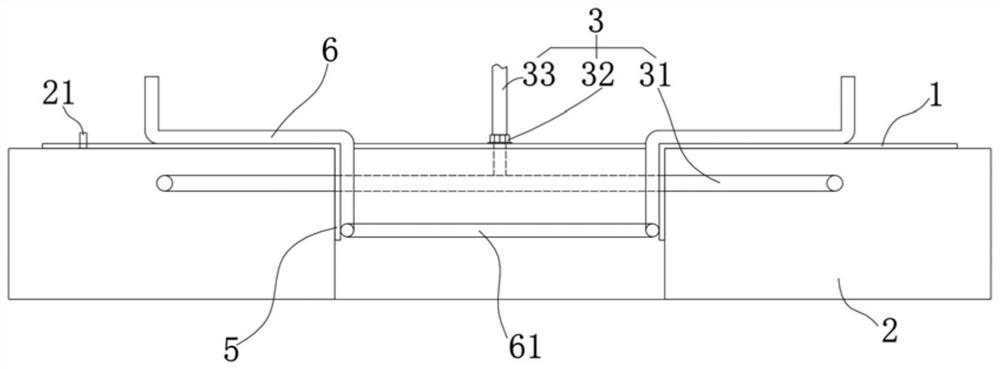

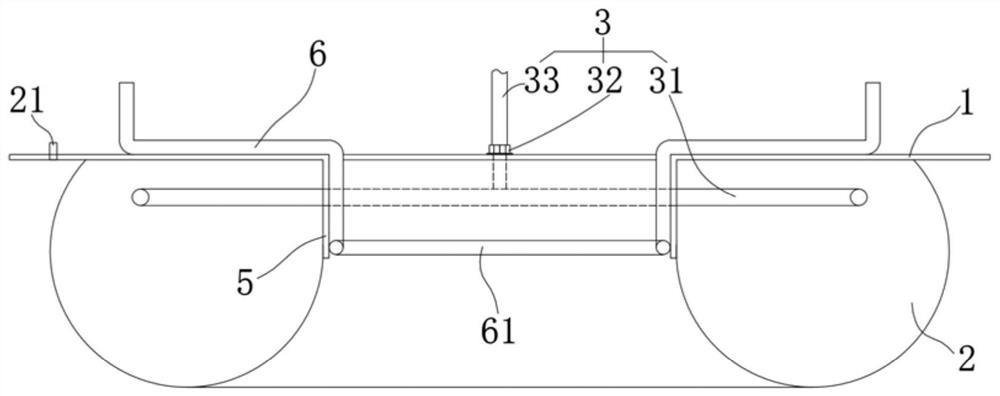

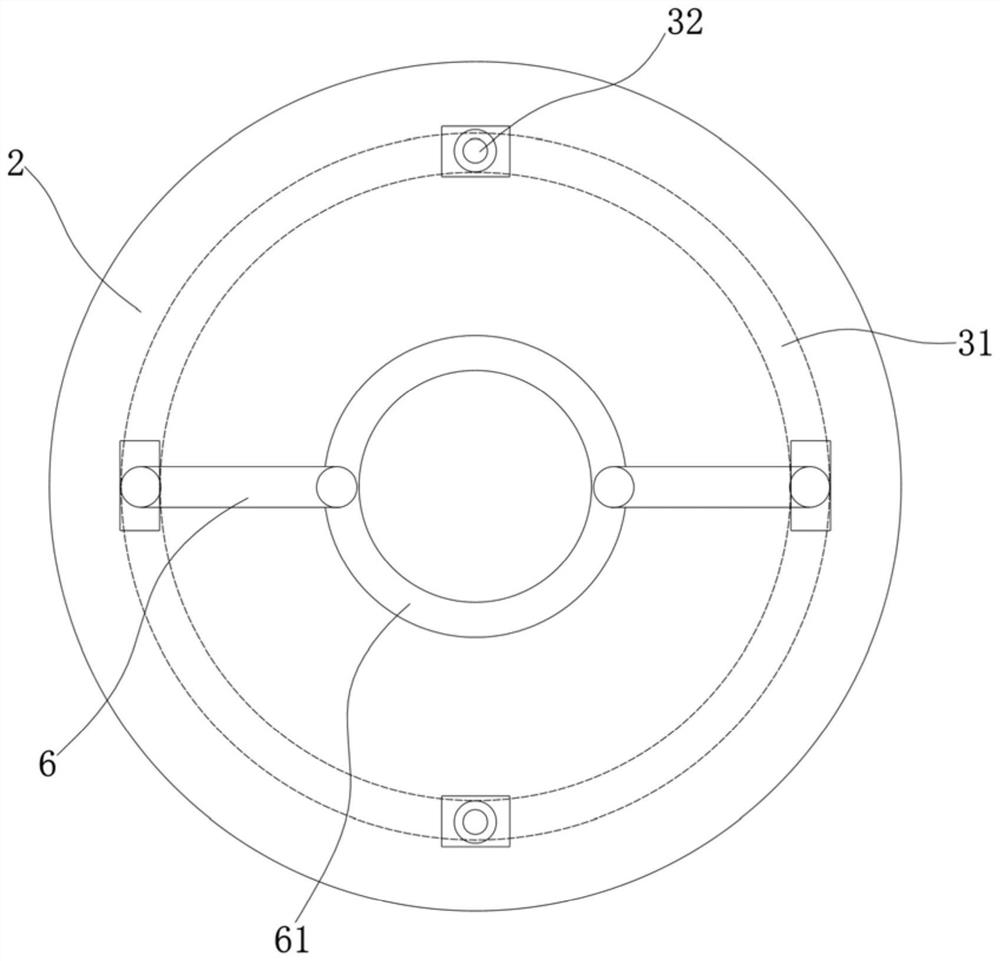

Grouting technology used after hollow (hole) ring-shaped steel plate rubber bag (cavity) is installed on pile bottom of cast-in-place pile

InactiveCN109469050AReduce resistanceGrouting technology is simple and easyBulkheads/pilesPressure groutingSteel plates

The grouting technology used after a hollow (hole) ring-shaped steel plate rubber bag (cavity) is installed on the pile bottom of a cast-in-place pile is applicable to the technical field of foundation and underground space engineering. According to the background technology, for a drill hole using mud to protect the wall, if a steel plate rubber bag is installed on the bottom of a reinforcement cage, collapsing of the wall of the drill hole is caused easily, thus sediment on the bottom of the hole exceeds the standard, silt collapsing from the hole wall accumulates on a steel plate easily, and the quality of the cast-in-place pile with the drill hole. According to the technology, a grouting pipe is tied to the reinforcement cage, a hollow ring-shaped steel plate is installed on the bottom, a hollow rubber bag shaped like a car inner tire is installed on the bottom face of the steel plate, a steel plate ring can also be welded to the portion, perpendicular to the bottom face of the steel plate, of the inner side of the hollow rubber bag, the grouting pipe penetrates through the steel plate and communicates with the rubber bag, after the hole is formed, the reinforcement cage is lowered to the hole bottom, if the sediment on the hole bottom exceeds the standard, a guide pipe is utilized for penetrating through a middle hole of the ring-shaped steel plate rubber bag so that secondary clearing can be carried out on the sediment on the hole bottom below, after the standard is reached, concrete is filled, the cast-in-place pile is formed, and after the strength reaches the standard, pressure grouting begins to be carried out on the pile bottom rubber bag through the grouting pipe.

Owner:高永光 +1

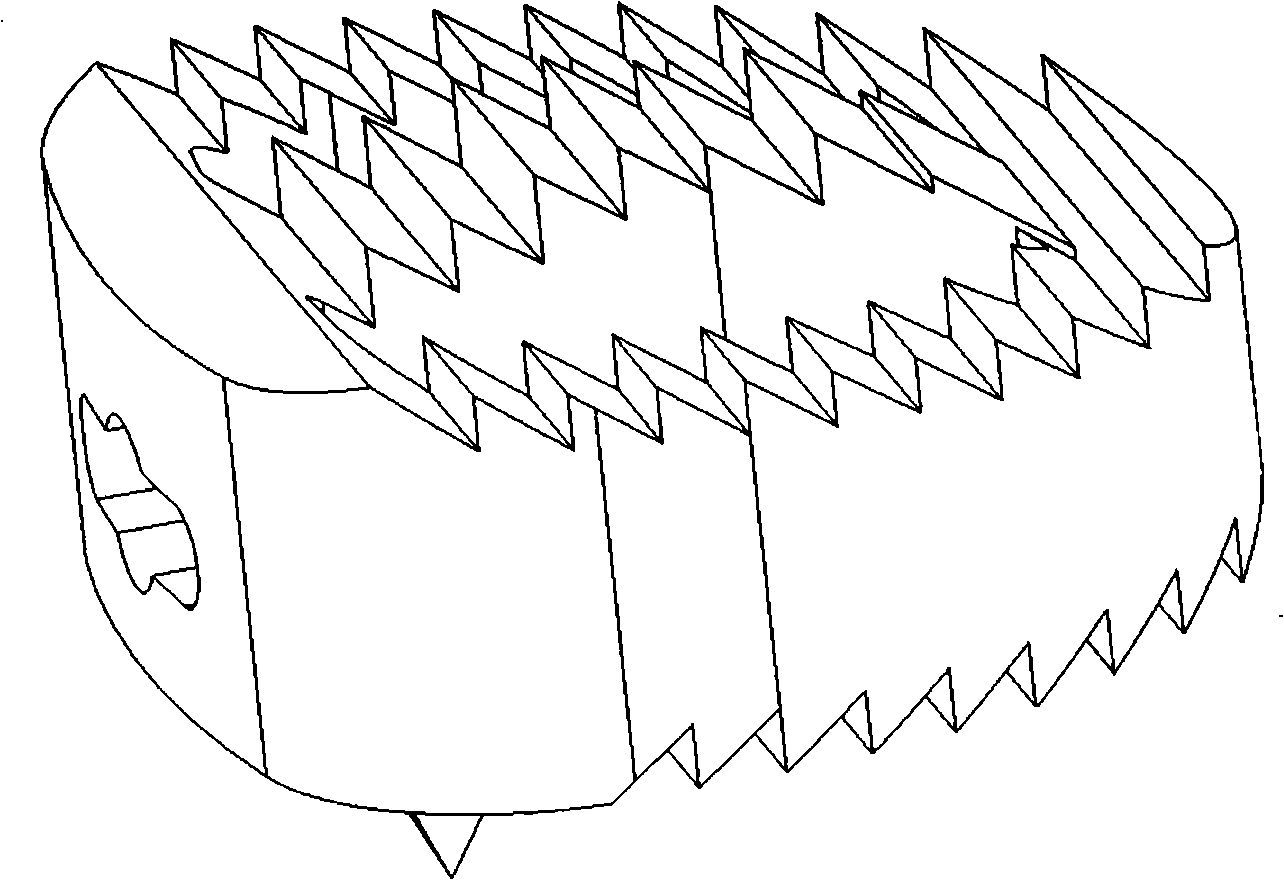

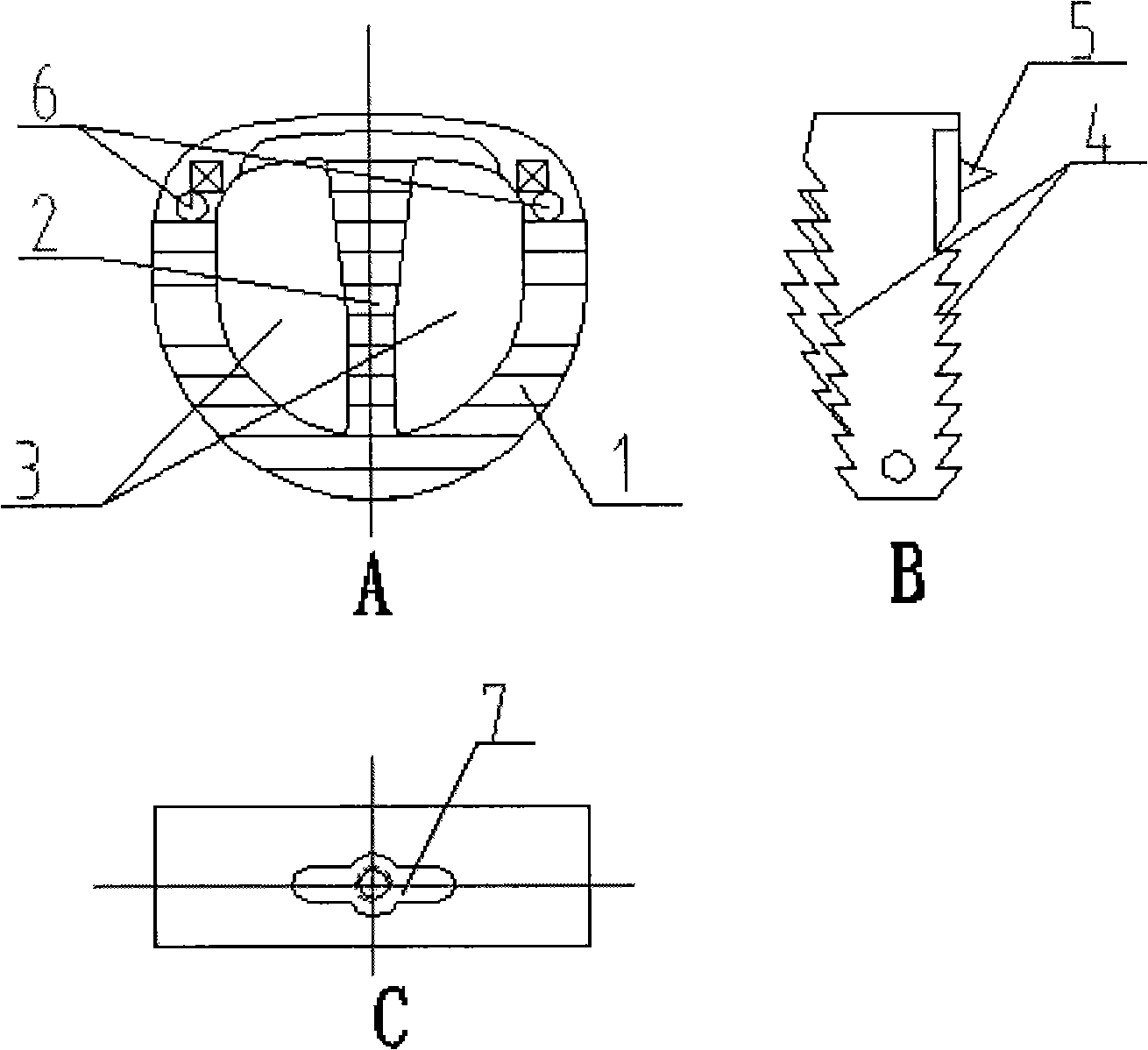

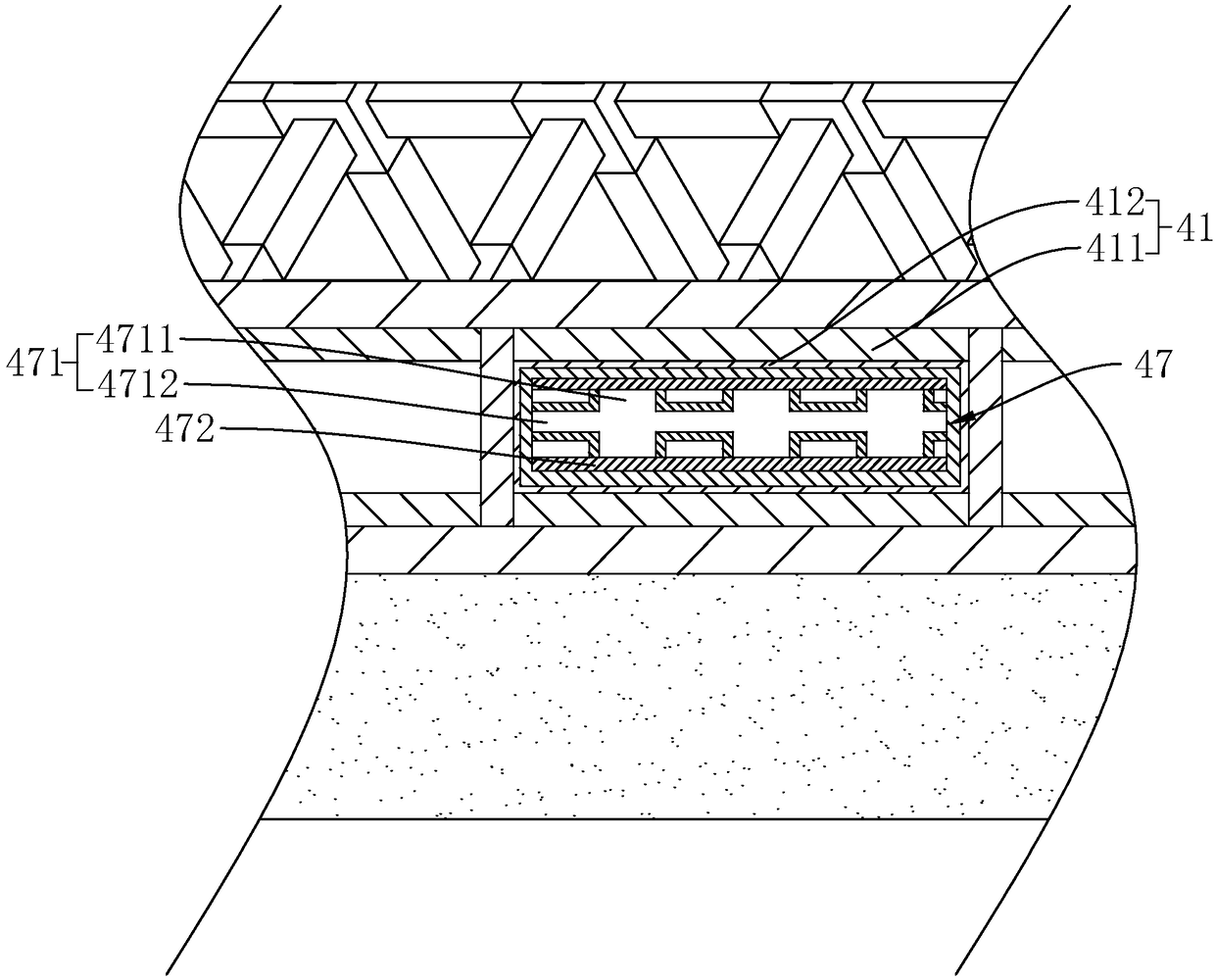

In vivo cervical vertebra fusion implant article

InactiveCN101406417AEliminate settlementEliminate height lossSpinal implantsCalcium biphosphateBiocompatibility Testing

The invention discloses an interbody vertebra fusion implant, which comprises a flat wedge-shaped frame, wherein the frame is separated by a reinforcing rib which is arranged in the frame to two inner cavities in which calcium phosphate is filled; and the upper surface of the reinforcing rib is arch-protrusion shaped, the upper surfaces and the lower surfaces of the frame and the reinforcing rib are provided with saw teeth respectively, and the lower surface of the frame is provided with two rectangular pyramids protruded outwards symmetrically. The interbody cervical vertebra fusion implant has the advantages of high intensity, good tenacity, no centrum collapse after operation, convenient implant, reliable and excellent biocompatibility.

Owner:杭州艾力康医药科技有限公司

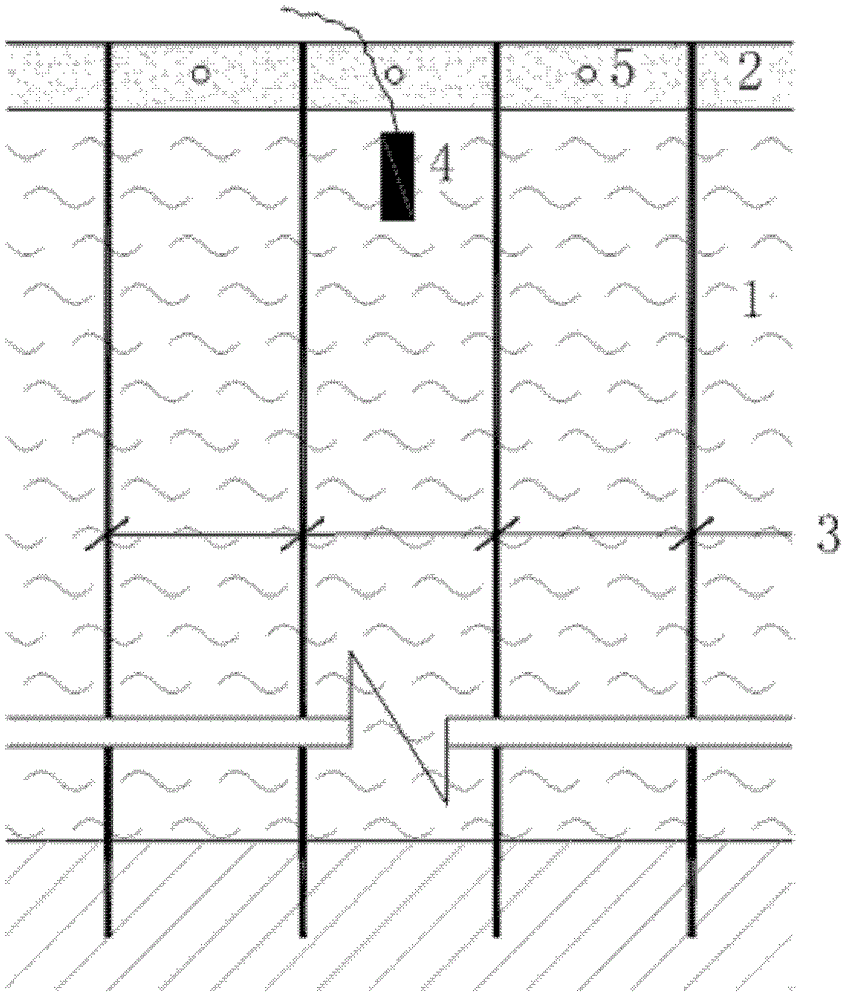

Method for consolidating hydraulically-filled soft clay in hydraulic filling process by using vacuum preloading method

The invention discloses a method for consolidating hydraulically-filled soft clay in the hydraulic filling process by using a vacuum preloading method. In the method, a drainage board with the length of 4-5m is artificially inserted in the original soft clay or hydraulically-filled soft clay, wherein the upper end of the drainage board is connected with a drain system which is connected with a water permeable pipe; soft clay is hydraulically filled, during which, the mode of hydraulically filling in blocks is adopted and a drain system is paved on the hydraulically-filled soft clay meeting the thickness requirement and is connected with the water permeable pipe; the drain system comprises a horizontal drainage board connected with the upper end of the drain board and a main drainage board connected with the horizontal drainage board; and the main drainage board is connected with the water permeable board. By using the invention, the thicker hydraulically-filled soft clay can be treated by vacuum preloading; by using loading upper-layer soft clay on lower-layer or original hydraulically-filled soft clay, so that the lower-layer hydraulically-filled soft clay starts to consolidate as early as possible and the settlement amount can be eliminated as early as possible; the drainage board can be reasonably inserted and paved in the hydraulically-filling process and the time is saved; and in addition, the invention saves money and reduces energy consumption.

Owner:TIANJIN COASTAL ZONE ENG

Post-grouting technology adopting manual hole digging and all-casing construction method, and adopting manner of installing rubber capsule (cavity) at bottom of cast-in-place pile

InactiveCN109056716AEliminate settlementIncrease ultimate bearing capacityBulkheads/pilesRebarUltimate tensile strength

The invention discloses a post-grouting technology adopting a manual hole digging and all-casing construction method, and adopting a manner of installing a rubber capsule (cavity) at the bottom of a cast-in-place pile. The post-grouting technology is applicable to the technical field of foundation and underground space engineering. The background technology is that with regard to a borehole usinga mud protection wall at present, if a steel plate capsule is installed at the bottom of a reinforcement cage, the collapse of the hole wall of the borehole is easily caused, so that the sediment of the bottom of the hole exceeds the standard, and silt collapsing from the hole wall is easily accumulated on a steel plate, so that the quality of the cast-in-situ bored pile is influenced. The post-grouting technology has the most prominent characteristic that the limit conditions and the application conditions of closed grouting adopting a manner of installing a grouting container at the bottom of a pile are found; and the main content is that a manual hole digging method or an all-casing construction method is utilized for hole formation for the cast-in-place pile, the mud protection wall isnot used in a hole formation process, a grouting pipe is bound on the reinforcement cage, the steel plate is installed at the bottom of the reinforcement cage, the rubber capsule is installed on thebottom surface of the steel plate, and the grouting pipe penetrates through the steel plate and communicates with the rubber capsule. After the hole is formed by virtue of the construction method, thereinforcement cage is descended to reach the bottom of the hole, then concrete starts to be poured, and after the strength of the body of the pipe meets requirements, pressure grouting is carried outon the rubber capsule at the bottom of the pile through the grouting pipe.

Owner:高永光 +1

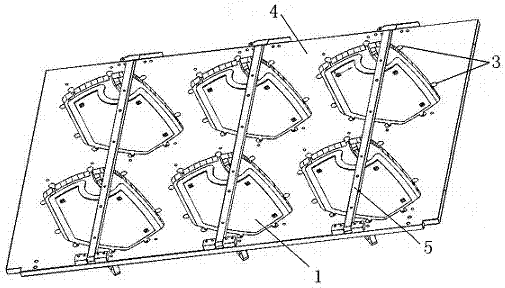

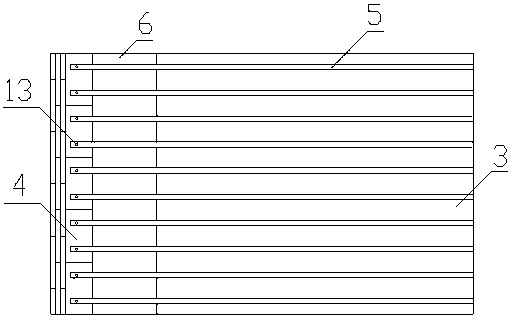

Process for coating strip with fully-closed outer edge by utilizing magnetron sputtering coating machine

ActiveCN103114273AImprove coating accuracyHigh precisionVacuum evaporation coatingSputtering coatingNumerical controlEngineering

The invention relates to a process for coating a strip with a fully-closed outer edge and is mainly applied to the technical field of physical vapor deposition (PVD) coating. The process comprises the following steps: performing computerized numerical control (CNC) machining on the coated film, wherein the profile tolerance is controlled to be 0.1, Cpk is controlled to be more than 1.33 through the SPC control means, and the no-return gauge inspection accords with +0.1 / -0.15; coating and cleaning the coated film; putting the coated film into a coating tool, and blocking a non-coated part on the coated film, so that the coated part on the coated film is exposed outside; putting the coating tool in a coating cavity of the magnetron sputtering coating machine, wherein the coating surface is arranged on one side at which a target is positioned; setting the coating process parameters according to the standard; and coating to obtain the coating film with the strip of which the outer edge is fully closed. According to the process, the strip with the fully closed outer edge can be coated, the coating accuracy is high, the film forming position is accurate, the edge is clean and is not shaded, and the cost is low.

Owner:ZHEJIANG LANTE OPTICS

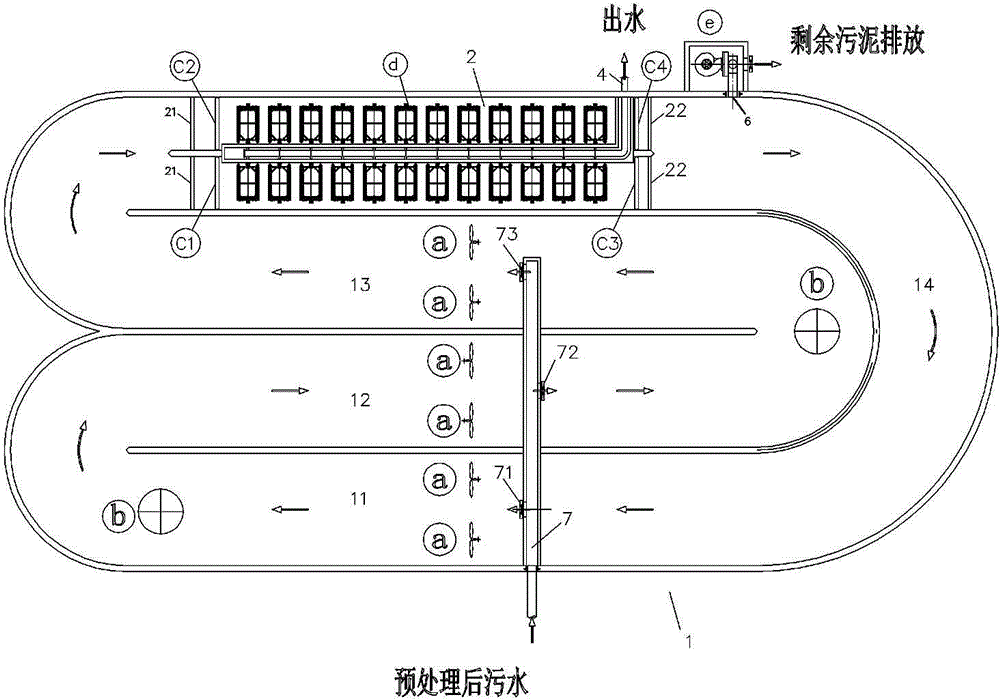

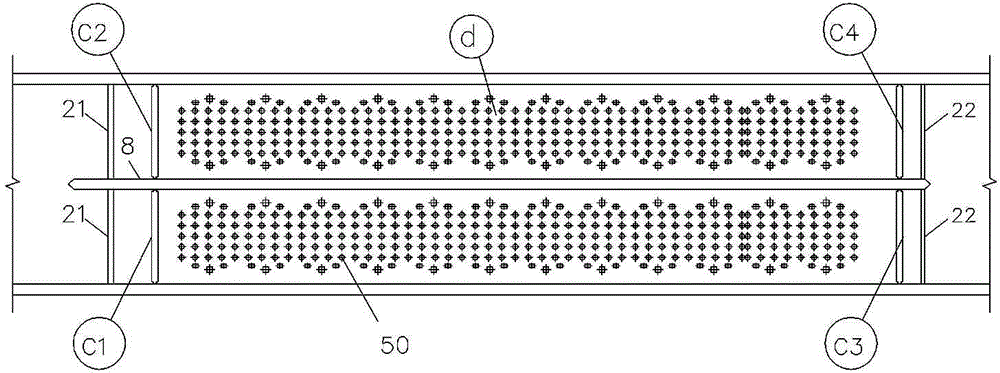

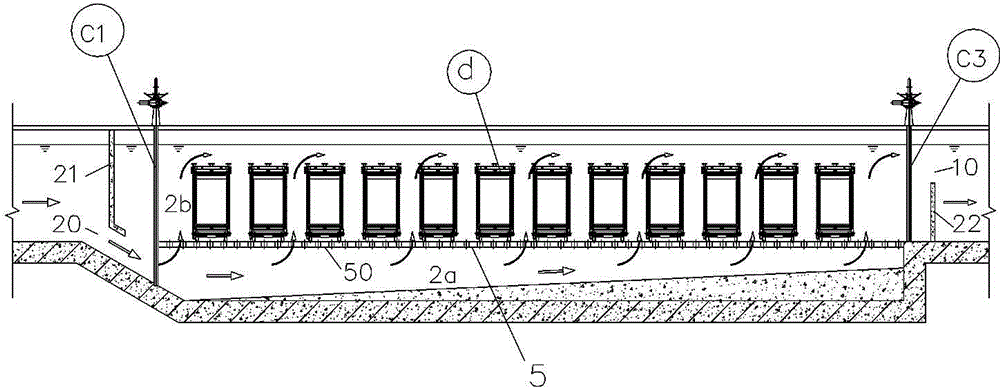

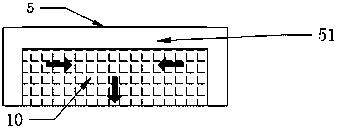

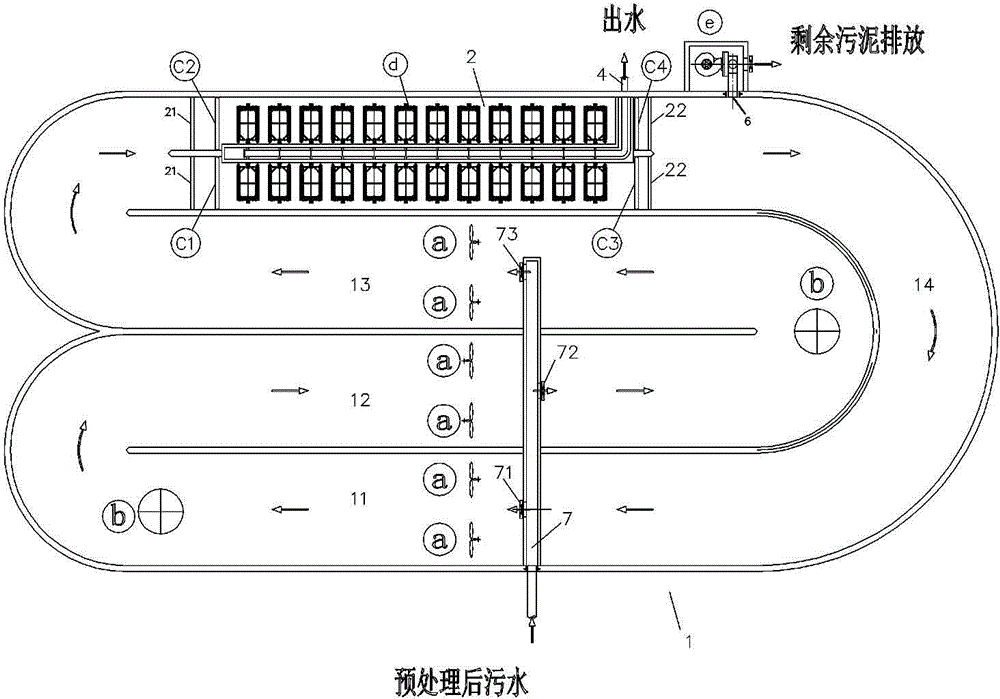

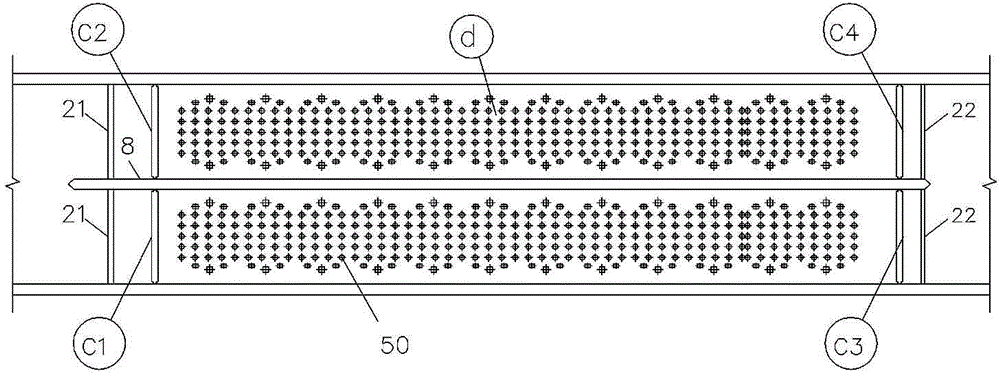

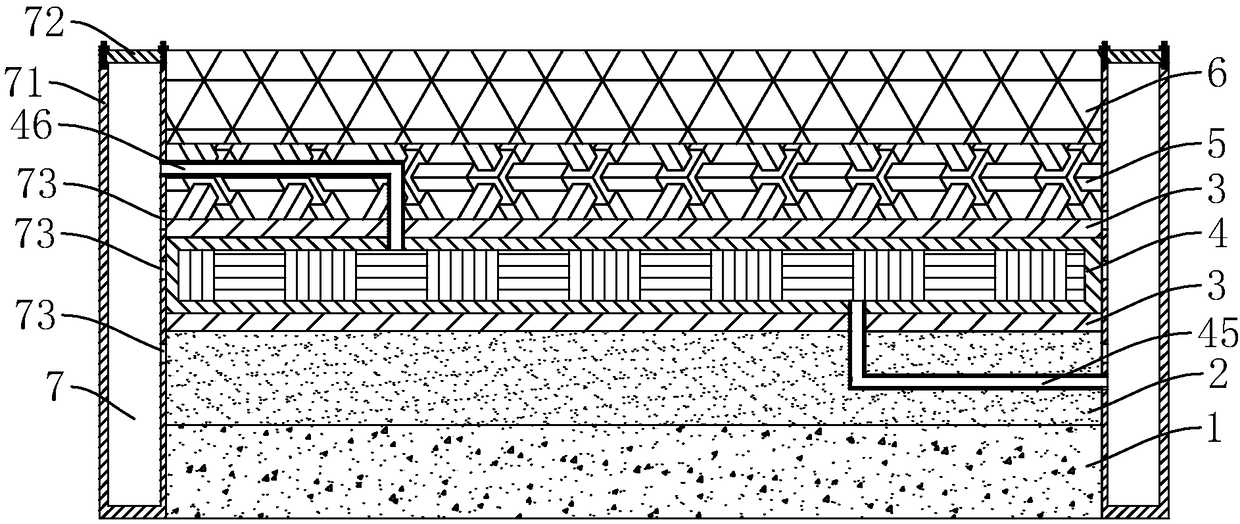

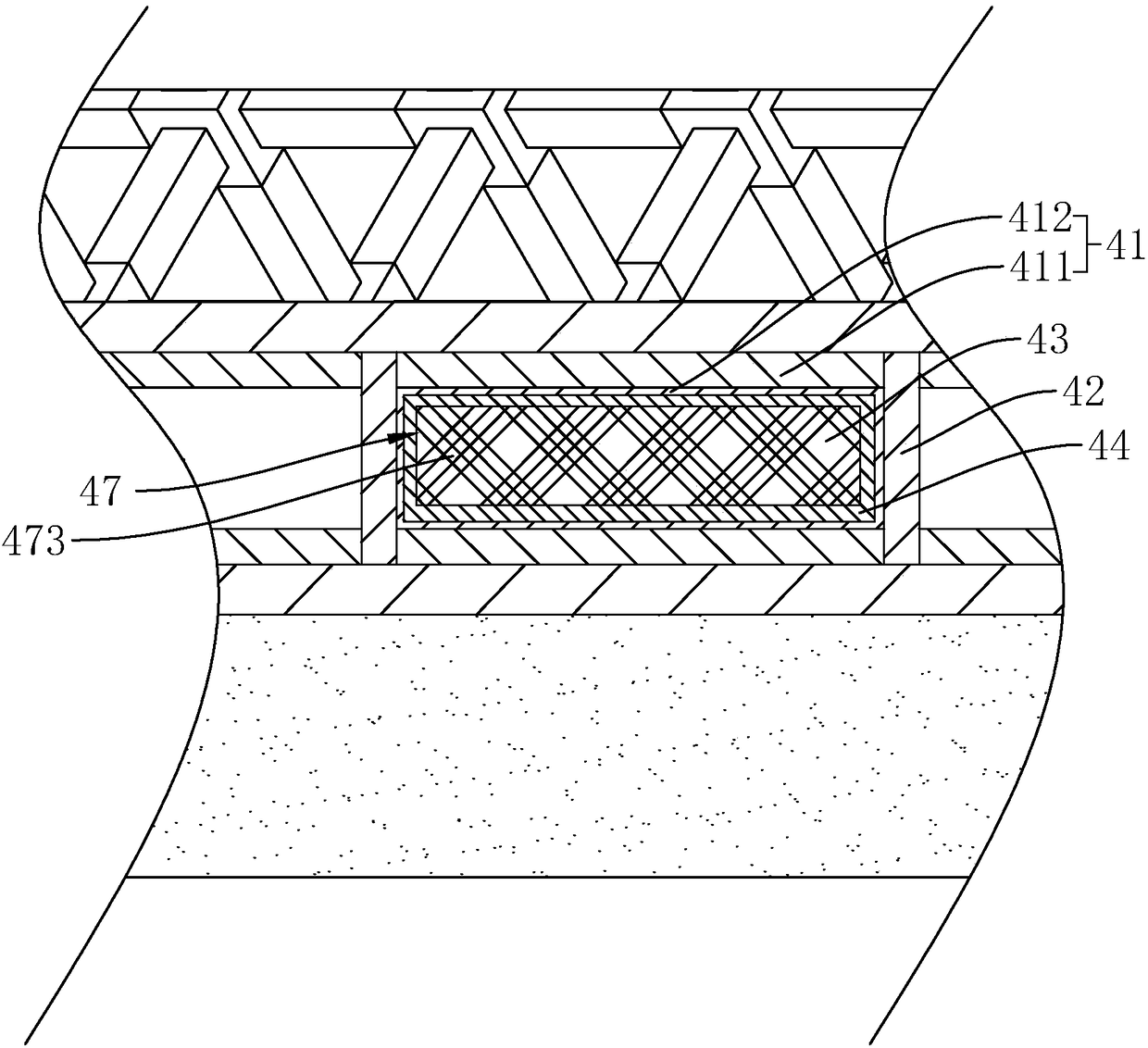

Energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage

ActiveCN103951063AEliminates adverse transverse shearExtended service lifeTreatment with aerobic and anaerobic processesButt jointSmall footprint

The invention relates to the technical field of treating sewage by utilizing a biological technology and discloses an energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage. The energy-saving type treatment device comprises an oxidization ditch biochemical reaction region and a membrane region, wherein a straight gallery of the membrane region and an S-shaped gallery of the oxidization ditch biological reaction region are in butt joint from the beginning to the end to form a circulating gallery; a penetrating tracery wall flat plate is overhead arranged on the bottom of the membrane region and used for dividing the membrane region into a membrane tank and a water distribution region from top to bottom; water distribution holes are uniformly distributed in the penetrating tracery wall flat plate; a membrane region water inlet is formed in the front end of the water distribution region; a membrane assembly and a water outlet tube are arranged in the membrane tank; the oxidization ditch biological reaction region is equipped with a water inlet device, a residual sludge outlet, a pushing device and an aeration device. According to the energy-saving type treatment device disclosed by the invention, the oxidization ditch process is organically combined with the membrane biological reactor; by utilizing hydraulic operation characteristics of large-flow circulating plug-flow state of the oxidization ditch process, mixed liquor in a groove is circulated and quickly flows through an MBR membrane set to realize solid-liquid separation, and therefore, the energy-saving type treatment device has the advantages of simple and compact structure, low operation energy consumption, small floor area, less investment, high pollutant removing efficiency and the like.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Low-energy-consumption lifting mixing barrel

ActiveCN104624097AUniform solid-liquid distributionReduce energy consumptionMixersStaringEngineering

The invention discloses a low-energy-consumption lifting mixing barrel. A mixing shaft is inserted into a barrel body, a motor and a reducer drive the mixing shaft to rotate, the mixing shaft is sequentially provided with a lower suspension spraying mixer and a bottom sweeping mixer from top to bottom, wherein the lower suspension spraying mixer is limited by an upper positioning step and a lower positioning step and can float up and down; the lower suspension spraying mixer comprises a mixing shaft, a shaft sleeve and a paddle, wherein the mixing shaft is a spline shaft, the shaft sleeve is also a spline shaft sleeve, the spline shaft sleeve can move on the spline shaft, and the paddle is welded on the spline shaft sleeve; the bottom sweeping mixer comprises a mixing shaft and an outer barrel, the mixing shaft and the outer barrel are welded into a whole by virtue of a paddle, the mixing shaft extends downward and forms a hollow cylinder, then the hollow cylinder extends to form a cone, and the outer wall of the cylinder is communicated with a jet pipe; and a blade tilt is gradually increased from top to bottom. The low-energy-consumption lifting mixing barrel has the characteristics that energy consumption is low, material circulation is good, deposition at the bottom is hardly caused, no mixing dead angle is formed, and light-load staring can be still realized even materials are sedimented due to long-time power failure, so that the low-energy-consumption lifting mixing barrel has a broad application prospect.

Owner:湖北省泽瀚实业有限公司

Construction method of collaborative backfill of hydraulic dynamic compaction machine and flat plate roadpacker

InactiveCN108867615AFlexible moving processRealize mechanized workSoil preservationDynamic compactionAbutment

The invention relates to the field of roadbed construction, in particular to a construction method of collaborative backfill of a hydraulic dynamic compaction machine and a flat plate roadpacker. Theprocess of collaborative backfill includes the following steps of check before backfill; backfill in layers and preliminary compaction; high-speed hydraulic dynamic compaction; detection, wherein in the step of high-speed hydraulic dynamic compaction, a bridge abutment back, a culvert table back, a retaining wall back and a pipe network groove are compacted in sequence. Compared with a traditionalmethod, the advantages that part movement is more flexible, the efficiency is higher, the consistency of the backfill compaction degree is further guaranteed while the backfill compaction construction quality is guaranteed, the safety performance is higher, and construction is more convenient and reliable are achieved. The flexibility advantage of the construction method is more obvious especially for some regions which are narrow and irregular and have certain depth.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

Concentrated eight-treasure porridge slurry stirring and cooking pot

InactiveCN104621422AGood suspensionWon't settleRotary stirring mixersFood preparationInlet valveSlurry

The invention discloses a concentrated eight-treasure porridge slurry stirring and cooking pot which comprises a pot body, a motor, a reducer and a stirring shaft, wherein the stirring shaft is inserted into the pot body; the motor and the reducer drive the stirring shaft to rotate; a bottom sweeping stirrer, a multistage serial bottom jet stirrer, a two-way jet stirrer and a suspended bottom jet stirrer are sequentially arranged on the stirring shaft from bottom to top; the suspended bottom jet stirrer is limited by upper and lower positioning steps and can float up and down; a jacket is arranged outside the pot body and is connected with a steam valve, a drain valve and a direct discharging valve; the jacket is also connected with a water inlet valve and a water return pipe control valve; and the bottom of the pot body is communicated with a steam valve and a medium-pressure blower. The stirring and cooking pot disclosed by the invention has the characteristics that the energy consumption is low, each processing step of the eight-treasure porridge can be finished, the materials circulate well and are difficult to sink to the bottom, and even if material settling is caused due to long-term power failure, light-load startup can be realized. Moreover, the application prospects are wide.

Owner:安徽省阜阳市海泉粮油工业股份有限公司

Pile end bottom grouting device, cast-in-place pile and construction method of cast-in-place pile

PendingCN113737786AEliminate settlementIncrease ultimate bearing capacityProtective foundationBulkheads/pilesSlurryUltimate tensile strength

The invention relates to the technical field of foundations, in particular to a pile end bottom grouting device, a cast-in-place pile and a construction method of the cast-in-place pile. The invention aims at overcoming the defect that in the prior art, the grouting cavity breaking opportunity and conditions are difficult to control. The pile end bottom grouting device comprises a fixing plate, and a grout storage bag fixed to the fixing plate, wherein the grout storage bag forms a containing cavity suitable for containing grout, or the grout storage bag and the fixing plate define the containing cavity suitable for containing the grout, and the grout storage bag has a full state in which the grout is filled to bear a pile body and a closed state inside which the grout is hollow, and a fixed ultimate pressure-bearing strength value is preset in the grout storage bag, and the volume of the grout storage bag is fixed in the full state.

Owner:高永光 +1

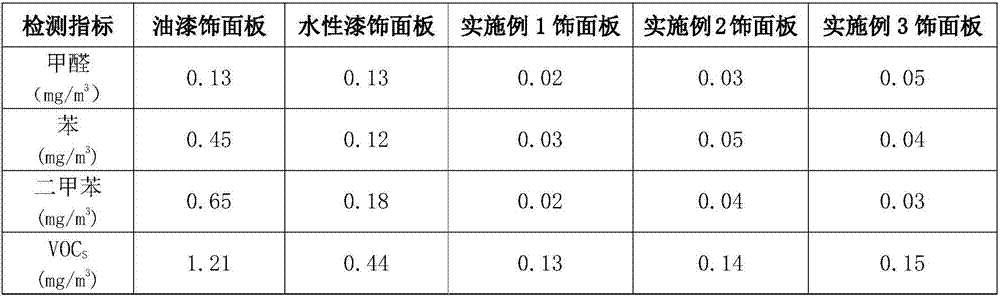

Paint-free healthy decoration panel capable of releasing anions and preparing method of paint-free healthy decoration panel

ActiveCN107088929AIncrease the concentration of negative ionsAchieve health benefitsSolid waste managementWood veneer joiningLacquerEngineering

The invention relates to the technical field of environment-friendly decoration materials, in particular to a paint-free healthy decoration panel capable of releasing anions and a preparing method of the paint-free healthy decoration panel. The paint-free healthy decoration panel capable of releasing the anions comprises a base material layer. An anion gluing layer, a veneer layer, a color matching agent layer and a transparent heat curing resin layer are sequentially arranged on the outer side of the base material layer from interior to exterior. The anion gluing layer is arranged on the base material layer in a roller painting or brush painting manner. The veneer layer is spliced to or covers the anion gluing layer. The color matching agent layer is arranged on the veneer layer in a roller painting or brush painting manner. The transparent heat curing resin layer is bonded to and covers the color matching agent layer. The paint-free healthy decoration panel capable of releasing the anions does not release harmful volatile matter, can overcome the defects of environment pollution caused by furniture and artificial panels in essence, and is capable of releasing the anions, safe and environment-friendly.

Owner:禹城福润德木业有限公司

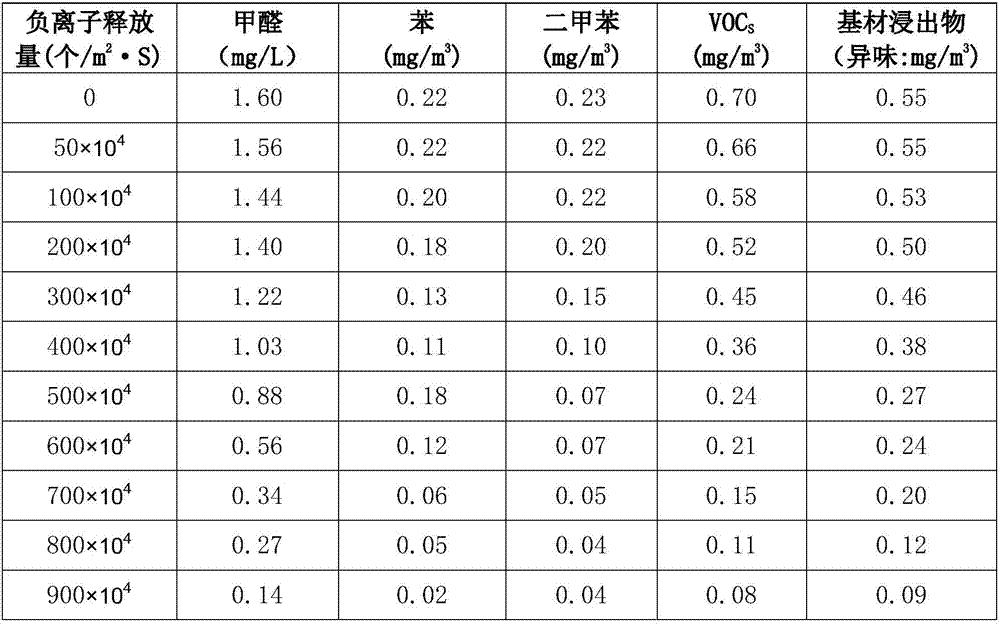

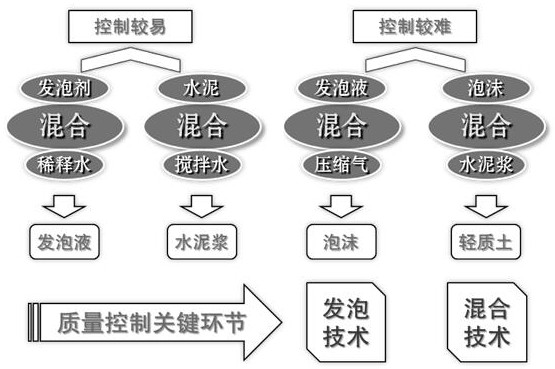

Silt-cement light building block, method for preparing same and application of silt-cement light building block

InactiveCN105712734AReduce additional stressSmall footprintCeramicwareFoaming agentUltimate tensile strength

The invention discloses a silt-cement light building block, a method for preparing the same and application of the silt-cement light building block. The silt-cement light building block comprises, by weight, 13-56 parts of cement, 17-19 parts of coal ash, 15-69 parts of silt, 0.7-3.6 parts of foaming agents, 1.2 parts of foam stabilizers and activators. The weight of the activators accounts for 6% of that of the foaming agents. The method includes metering the cement, the coal ash, the foam stabilizers, the activators, water and the saturated silt and then feeding the cement, the coal ash, the foam stabilizers, the activators, the water and the saturated silt into a stirring machine; uniformly stirring the cement, the coal ash, the foam stabilizers, the activators, the water and the saturated silt to obtain first mixtures, then metering the foaming agents and adding the foaming agents into the stirring machine; stirring the foaming agents and the first mixtures briefly to obtain second mixtures, pouring the second mixtures in molds and maintaining the second mixtures. The silt-cement light building block, the method and the application have the advantages that energy consumption can be reduced during production, and the building block can be lightened, has certain strength and is low in production cost.

Owner:SHANDONG UNIV

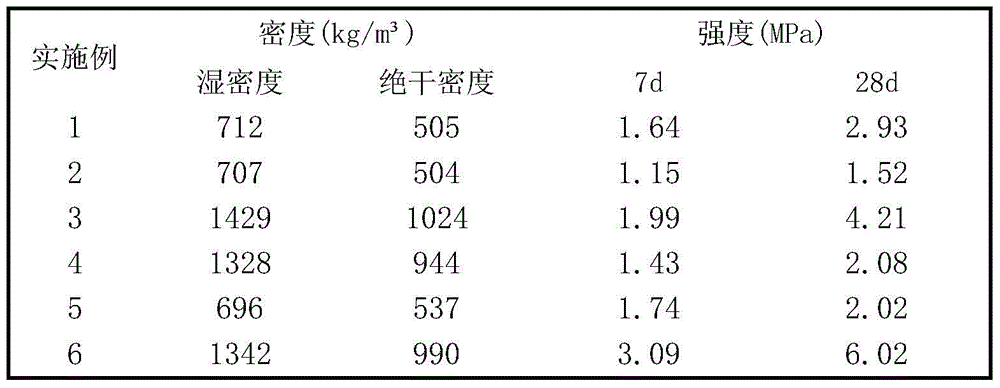

Replacement and repairing structure of sedimentation of railway station platform in soft soil area and construction method

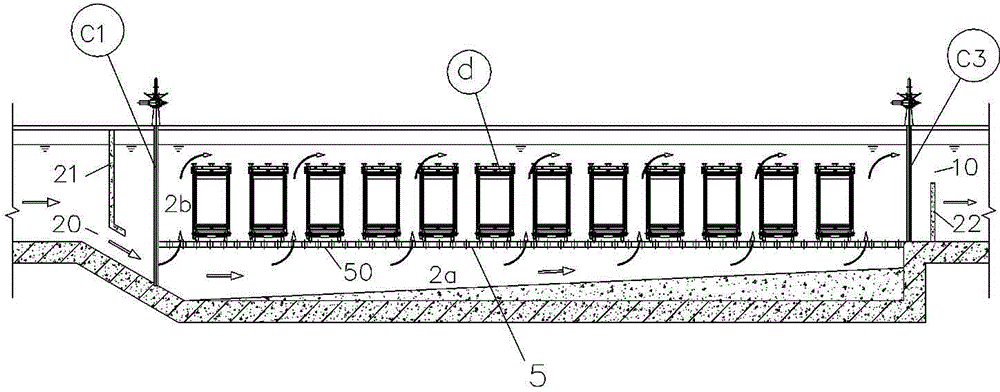

The invention discloses a replacement and repairing structure of sedimentation of a railway station platform in a soft soil area and a construction method. The structure comprises multiple layers of light soil, wherein the light soil is arranged on an area needed to be repaired in the railway station platform. A galvanized wire mesh anti-crack layer is arranged between every two layers of light soil, a medium-coarse-sand mix-pavement HDPE waterproof geomembrane is arranged on the top layer of the light soil, and a platform-surface pavement layer is arranged at the top of the medium-coarse-sand mix-pavement HDPE waterproof geomembrane. According to the replacement and repairing structure of sedimentation of the railway station platform in the soft soil area and the construction method, the filled soil of an original platform is replaced with foam light soil. Because the volume weight of the light soil is 6-10 kN / m3 (the volume weight of some light soil is lower, for example, the volume weight of EPS is only 2-4 kN / m3), the volume weight of the filled soil of the original platform is 18-19 kN / m3, and the loading of the platform can be greatly reduced through replacement by using the characteristics that the volume weight of the light soil is far smaller than the volume weight of the filled soil of the original platform; the light soil is different from the performance of granular substances of the filled soil, and has a little lateral pressure on a platform wall; and the effect of load-reducing is achieved, the sedimentation of the platform is eliminated, and excursion and limit-beyond of a platform wall can further be avoided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage

ActiveCN103951063BFast pushEliminate adverse effects of separationTreatment with aerobic and anaerobic processesEngineeringSmall footprint

The invention relates to the technical field of treating sewage by utilizing a biological technology and discloses an energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage. The energy-saving type treatment device comprises an oxidization ditch biochemical reaction region and a membrane region, wherein a straight gallery of the membrane region and an S-shaped gallery of the oxidization ditch biological reaction region are in butt joint from the beginning to the end to form a circulating gallery; a penetrating tracery wall flat plate is overhead arranged on the bottom of the membrane region and used for dividing the membrane region into a membrane tank and a water distribution region from top to bottom; water distribution holes are uniformly distributed in the penetrating tracery wall flat plate; a membrane region water inlet is formed in the front end of the water distribution region; a membrane assembly and a water outlet tube are arranged in the membrane tank; the oxidization ditch biological reaction region is equipped with a water inlet device, a residual sludge outlet, a pushing device and an aeration device. According to the energy-saving type treatment device disclosed by the invention, the oxidization ditch process is organically combined with the membrane biological reactor; by utilizing hydraulic operation characteristics of large-flow circulating plug-flow state of the oxidization ditch process, mixed liquor in a groove is circulated and quickly flows through an MBR membrane set to realize solid-liquid separation, and therefore, the energy-saving type treatment device has the advantages of simple and compact structure, low operation energy consumption, small floor area, less investment, high pollutant removing efficiency and the like.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

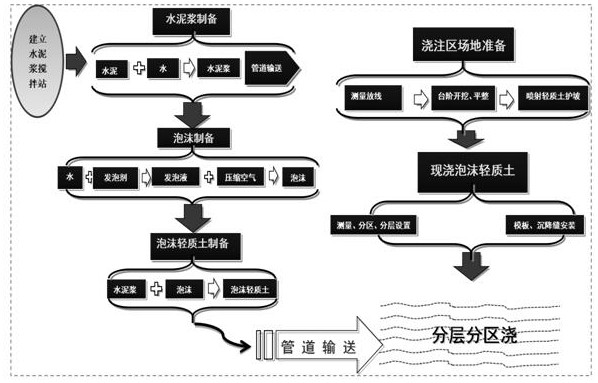

Construction method for filling intercommunication ramps with foam light soil

PendingCN112832094AImprove construction efficiencyEliminate settlementRoads maintainenceSoil preservationSoil scienceStructural engineering

The invention discloses a construction method for filling an intercommunication ramp by using foam light soil. The construction method comprises the following steps: (1) preparing cement paste; 2) preparing foam; (3) preparing foam light soil; (4) preparing a pouring area site; (5) casting foam light soil in situ, using the bottommost layer as the first layer for pouring, and arranging pouring areas every 10-15 m in the longitudinal direction of the roadbed; after slope excavation is completed, performing sequential construction from the bottom layer to the upper layer in a layered mode during filling, the single-layer pouring thickness is controlled to be 60 cm, the top layer pouring thickness is controlled to be 0.3-1.0 m according to the designed elevation, and when pouring is conducted towards the upper layer, performing 90 cm construction; filling the edge covering lime soil layer by layer from bottom to top according to the ultra-width of 1 m, the compaction degree meets the design requirement, and after the edge covering lime soil is filled to the top elevation, performing slope brushing on the edge covering lime soil; performing roadbed lime soil filling after the strength of the foam light soil meets the requirement, performing filling layer by layer, the compaction degree meets the design requirement, and adjusting transverse and longitudinal slopes of a roadbed; and 6), performing maintenance, according to the method, the load of the roadbed base can be obviously reduced, post-construction settlement of the roadbed is eliminated, and the diseases such as bumping at the bridgehead are solved.

Owner:THE SECOND CONSTR OF CTCE GROUP

Low energy consumption lifting mixing bucket

The invention discloses a low-energy-consumption lifting mixing barrel. A mixing shaft is inserted into a barrel body, a motor and a reducer drive the mixing shaft to rotate, the mixing shaft is sequentially provided with a lower suspension spraying mixer and a bottom sweeping mixer from top to bottom, wherein the lower suspension spraying mixer is limited by an upper positioning step and a lower positioning step and can float up and down; the lower suspension spraying mixer comprises a mixing shaft, a shaft sleeve and a paddle, wherein the mixing shaft is a spline shaft, the shaft sleeve is also a spline shaft sleeve, the spline shaft sleeve can move on the spline shaft, and the paddle is welded on the spline shaft sleeve; the bottom sweeping mixer comprises a mixing shaft and an outer barrel, the mixing shaft and the outer barrel are welded into a whole by virtue of a paddle, the mixing shaft extends downward and forms a hollow cylinder, then the hollow cylinder extends to form a cone, and the outer wall of the cylinder is communicated with a jet pipe; and a blade tilt is gradually increased from top to bottom. The low-energy-consumption lifting mixing barrel has the characteristics that energy consumption is low, material circulation is good, deposition at the bottom is hardly caused, no mixing dead angle is formed, and light-load staring can be still realized even materials are sedimented due to long-time power failure, so that the low-energy-consumption lifting mixing barrel has a broad application prospect.

Owner:湖北省泽瀚实业有限公司

Method for consolidating hydraulically-filled soft clay in hydraulic filling process by using vacuum preloading method

The invention discloses a method for consolidating hydraulically-filled soft clay in the hydraulic filling process by using a vacuum preloading method. In the method, a drainage board with the length of 4-5m is artificially inserted in the original soft clay or hydraulically-filled soft clay, wherein the upper end of the drainage board is connected with a drain system which is connected with a water permeable pipe; soft clay is hydraulically filled, during which, the mode of hydraulically filling in blocks is adopted and a drain system is paved on the hydraulically-filled soft clay meeting the thickness requirement and is connected with the water permeable pipe; the drain system comprises a horizontal drainage board connected with the upper end of the drain board and a main drainage boardconnected with the horizontal drainage board; and the main drainage board is connected with the water permeable board. By using the invention, the thicker hydraulically-filled soft clay can be treated by vacuum preloading; by using loading upper-layer soft clay on lower-layer or original hydraulically-filled soft clay, so that the lower-layer hydraulically-filled soft clay starts to consolidate as early as possible and the settlement amount can be eliminated as early as possible; the drainage board can be reasonably inserted and paved in the hydraulically-filling process and the time is saved; and in addition, the invention saves money and reduces energy consumption.

Owner:TIANJIN COASTAL ZONE ENG

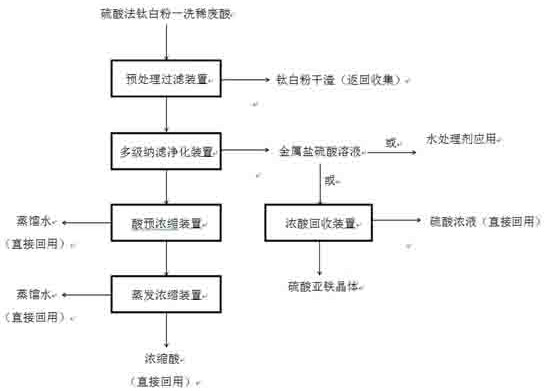

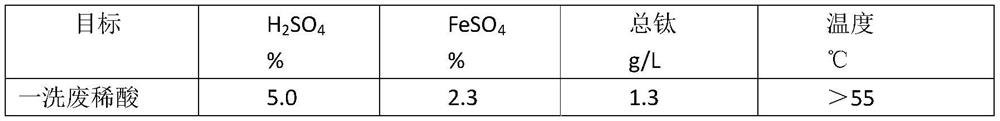

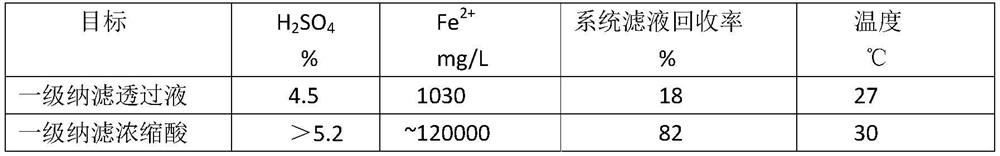

Sulfuric acid process titanium dioxide primary washing dilute waste acid membrane integrated recycling zero-discharge treatment method

PendingCN114057167AAdjustable filter precisionSatisfy the influent water quality requirement of influent SDI<3Sulfur-trioxide/sulfuric-acidProcess engineeringNanofiltration

The invention discloses a sulfuric acid process titanium dioxide primary washing dilute waste acid membrane integrated recycling zero-discharge treatment method which comprises the following steps: (1) carrying out solid-liquid separation on titanium dioxide primary washing dilute waste acid to obtain first filtrate; (2) carrying out heat exchange cooling on the first filtrate through a heat exchanger; (3) performing separation and concentration treatment on the cooled first filtrate through a multi-stage nanofiltration membrane system to obtain a first-stage nanofiltration concentrated solution, and treating the first-stage nanofiltration concentrated solution through the multi-stage nanofiltration system to obtain a final nanofiltration membrane purified dilute acid solution; (4) pre-concentrating the final nanofiltration purified dilute acid solution to obtain a pre-concentrated sulfuric acid solution; and (5) evaporating and concentrating the pre-concentrated sulfuric acid solution to obtain a high-concentration sulfuric acid solution which can be directly recycled. According to the invention, a full-physical separation method, namely a membrane integrated treatment process, is adopted, no extra chemical agent is added, and the method is environment-friendly and high in filtering precision.

Owner:NANTONG SUNSHINE GRAPHITE EQUIP TECH

Soft foundation road structure and quick settlement repairing technology adopting road structure

The invention discloses a soft foundation road structure and a quick settlement repairing technology adopting the road structure. According to the technical scheme, the soft foundation road structureis characterized in that the structure comprises a tamped soil layer, a concrete broken stone cushion layer, a bituminous basic layer and a bituminous pavement layer, all of which are sequentially laid from bottom to top, an expansion layer is arranged between the concrete broken stone cushion layer and the bituminous basic layer and comprises multiple expansion cushion bodies and diaphragms for dividing the adjacent expansion cushion bodies, each expansion cushion body comprises a rubber coat and reinforced fiber cloth attached to the rubber coat, inner cavities filled with resin adhesive areformed between the rubber coats and the diaphragms, the inner walls of the inner cavities are coated with a curing agent in advance, the curing agent can cure the resin adhesive, a grouting pipe communicating with the inner cavities penetrates through the concrete broken stone cushion layer, an exhaust pipe communicating with the inner cavities penetrates through the bituminous basic layer, and the structure is used for quick repair conducted in the later period of settlement of a soft foundation road.

Owner:温州伟国建设有限公司

A method for strengthening soft soil foundation by temperature-increasing vacuum preloading method

InactiveCN103255761BImprove bearing capacityDrain fastSoil preservationVacuum pressureVacuum extraction

The invention relates to a method for reinforcing a soft soil foundation by using a calescence type vacuum preloading way. The method comprises the steps of: introducing a foundation heating system on the basis of a regular vacuum preloading way; and keeping an under-film vacuum pressure and a temperature of shallow-layer soft soil in a reinforcing region respectively above 80 kPa and 62 DEG C within a period of time of a reinforcing period so as to rapidly vaporize pore water of foundation soil and pump the vaporized pore water by vacuum extraction equipment to cause sedimentation of the foundation. Compared with the prior art, the method for reinforcing the soft soil foundation by using the calescence type vacuum preloading way has the advantages of shorting the construction period, improving reinforcing effects, reducing settlement after the construction, increasing the bearing capacity of foundation soil and the like.

Owner:TONGJI UNIV

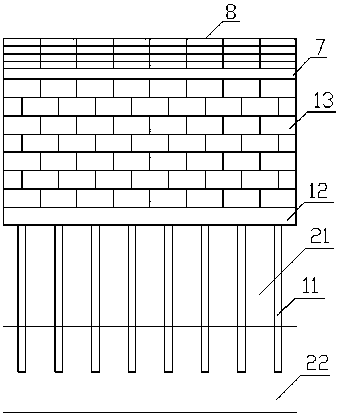

A Reinforced Soil Bank Wall Structure Based on Tidal Flat Soft Foundation

ActiveCN105804007BImprove integritySpeed up the consolidationDamsDykesFilling materialsStructure of the Earth

The invention discloses a reinforced soil bank wall structure suitable for beach zone soft soil foundation conditions, namely a reinforced soil bank wall structure based on a beach soft foundation. The reinforced soil bank wall structure comprises plastic drainage plates arranged in soft soil, drainage under layers paved on the surface of the soft soil, a bagged sand quilt cofferdam, prefabricated wall panels used for protection and soil blocking, reinforced belts previously buried in the bagged sand quilt cofferdam, a filling material between the wall panels and the bagged sand quilt cofferdam, pile foundations below the panels, copestone above the panels and reverse filtering geotextile behind the bagged sand quilt cofferdam. The structure is implemented step by step, and the deformation of the soft soil foundation and the cofferdam is basically finished before the wall panels are constructed, so that post-construction settlement and uneven settlement are reduced. The bagged sand quilt cofferdam can also be used as the construction platform of the wall panels and the pile foundations, so that intertidal zone construction is changed into land construction, and construction conditions are improved. The structure can adapt to the bearing capacity and deformation of the soft soil foundation, is simple in construction technology, can be constructed by stages, and saves investment.

Owner:CCCC THIRD HARBOR CONSULTANTS

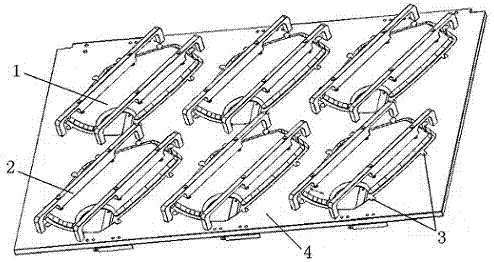

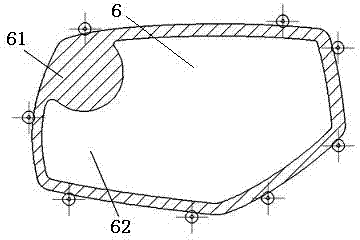

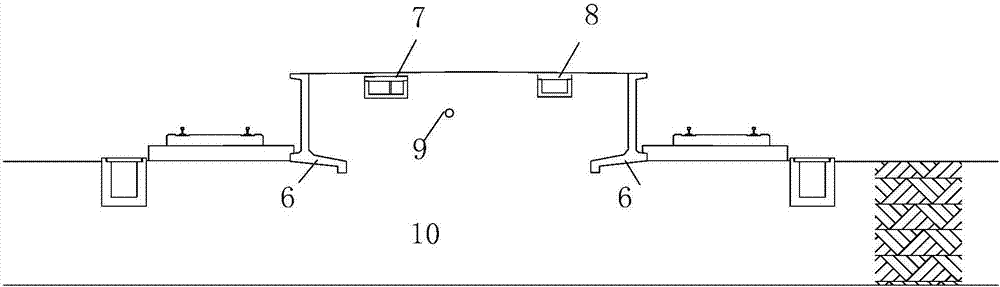

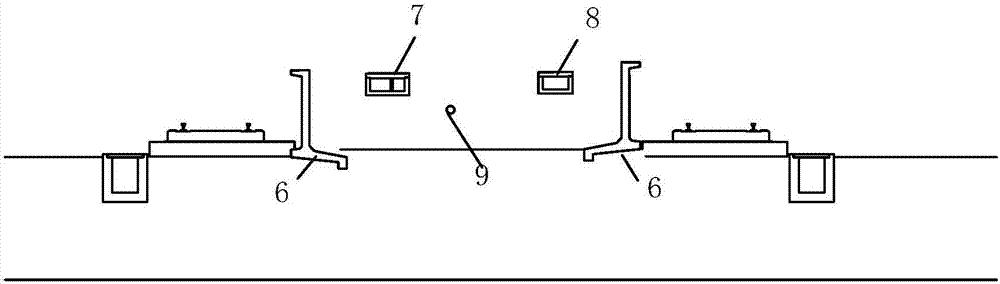

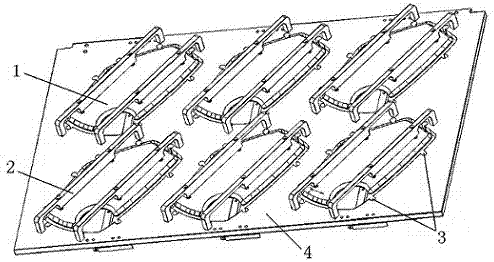

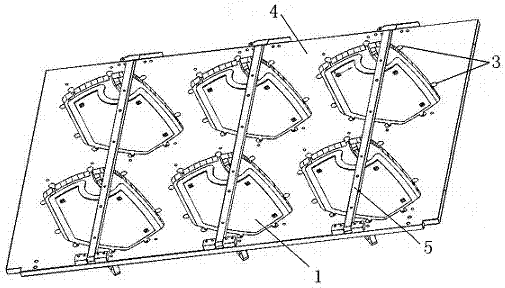

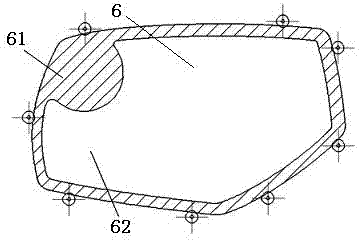

Film-coating tool for coating outer edge totally-closed zone

ActiveCN103132017BPrevent movementEliminate settlementVacuum evaporation coatingSputtering coatingSputteringFixed frame

The invention relates to a film-coating tool for coating an outer edge totally-closed zone, and is mainly suitable for the technical field of magnetic-control sputtering film-coating equipment. The film-coating tool comprises a main frame, wherein the main frame is provided with at least one erection unit used for erecting a substrate; the erection unit comprises a shielding sheet, a shielding sheet fixing beam and a film-coated sheet supporting and fixing frame; both ends of the shielding sheet fixing beam are fixed on the main frame; the shielding sheet is fixed with the shielding sheet fixing beam through a fixing hole; the film-coated sheet supporting and fixing frame is positioned at the same side of the film-uncoated surface of the main frame; one end of the film-coated sheet supporting and fixing frame is movably connected with the main frame through a rotating shaft; and a circle of gap is positioned between the edge of the shielding sheet and the edge of the erection unit. The film-coating tool disclosed by the invention has the advantages of reasonability in structural design, convenience for use, high film-coating accuracy, accurate film-forming position, clear edge without a shadow and lower cost, can realize that the outer edge totally-closed zone is coated and can be used for coating the outer edge totally-closed film-coating zone in any shape.

Owner:ZHEJIANG LANTE OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com