Droplet injection device and nozzle recovery method for droplet injection device

A recovery method, droplet technology, applied in printing and other directions, can solve unsolved problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

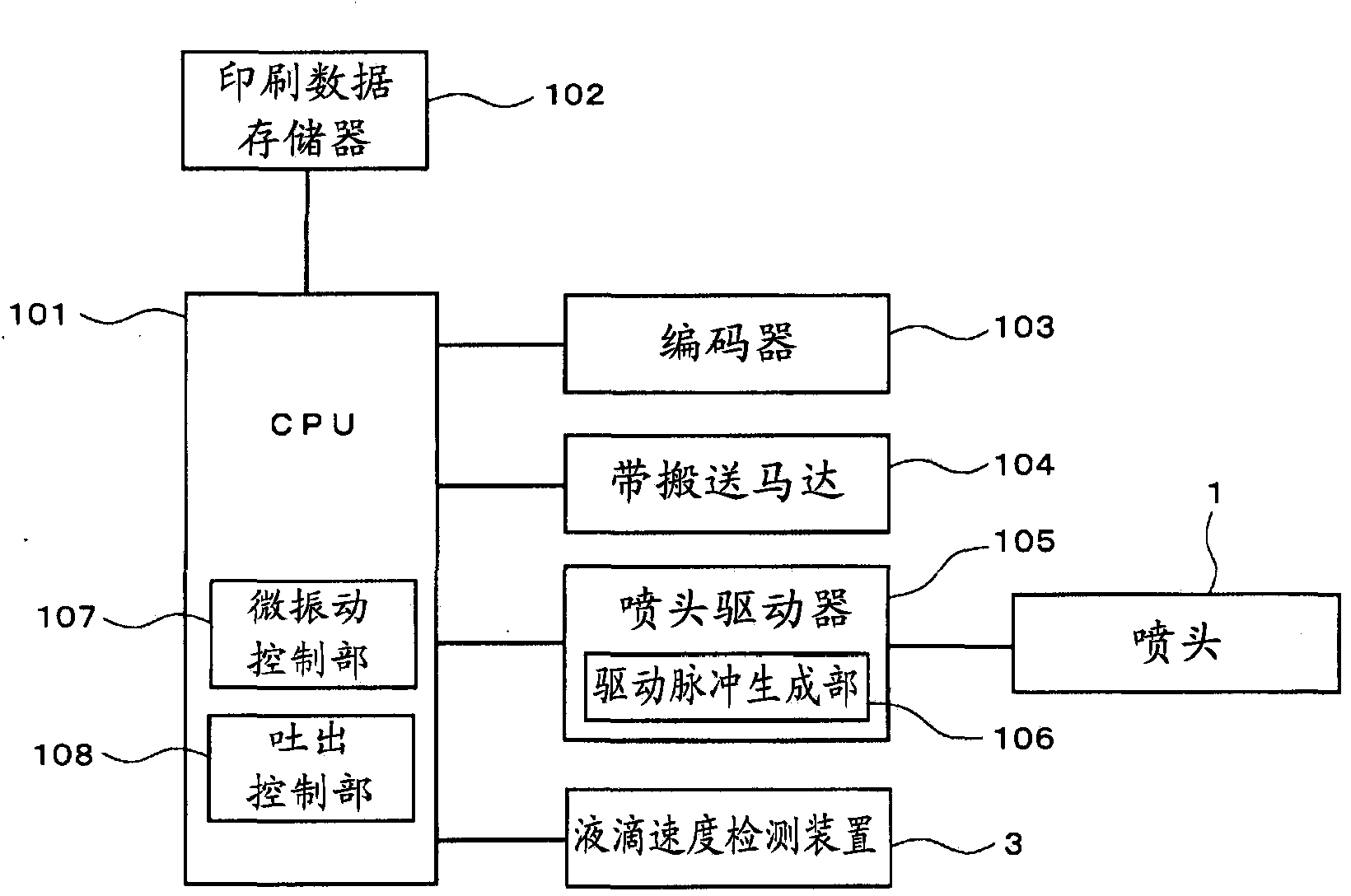

[0183] Such as Figure 15 As shown, using a scanning type droplet ejection device in which ink receiving parts are respectively arranged in the non-printing areas on both sides of the recording medium, from a UV liquid that uses titanium oxide containing a dispersant and a solid particle whose specific gravity is larger than that of the dispersant Ink (the specific gravity difference between the dispersant and solid particles: 0.25, the content of the substance whose vapor pressure is greater than water at room temperature: 5%), performs specified printing in the printing area of the recording medium, and the nozzle is in the main scanning direction. Since the end portion is folded back, every time it reaches a non-printing area, after applying a micro-vibration pulse at a frequency half of the droplet ejection frequency during printing, the ink receiving portion ejects droplets at the same frequency as the ejection frequency.

[0184] As a result, no nozzle clogging occurs ...

Embodiment 2

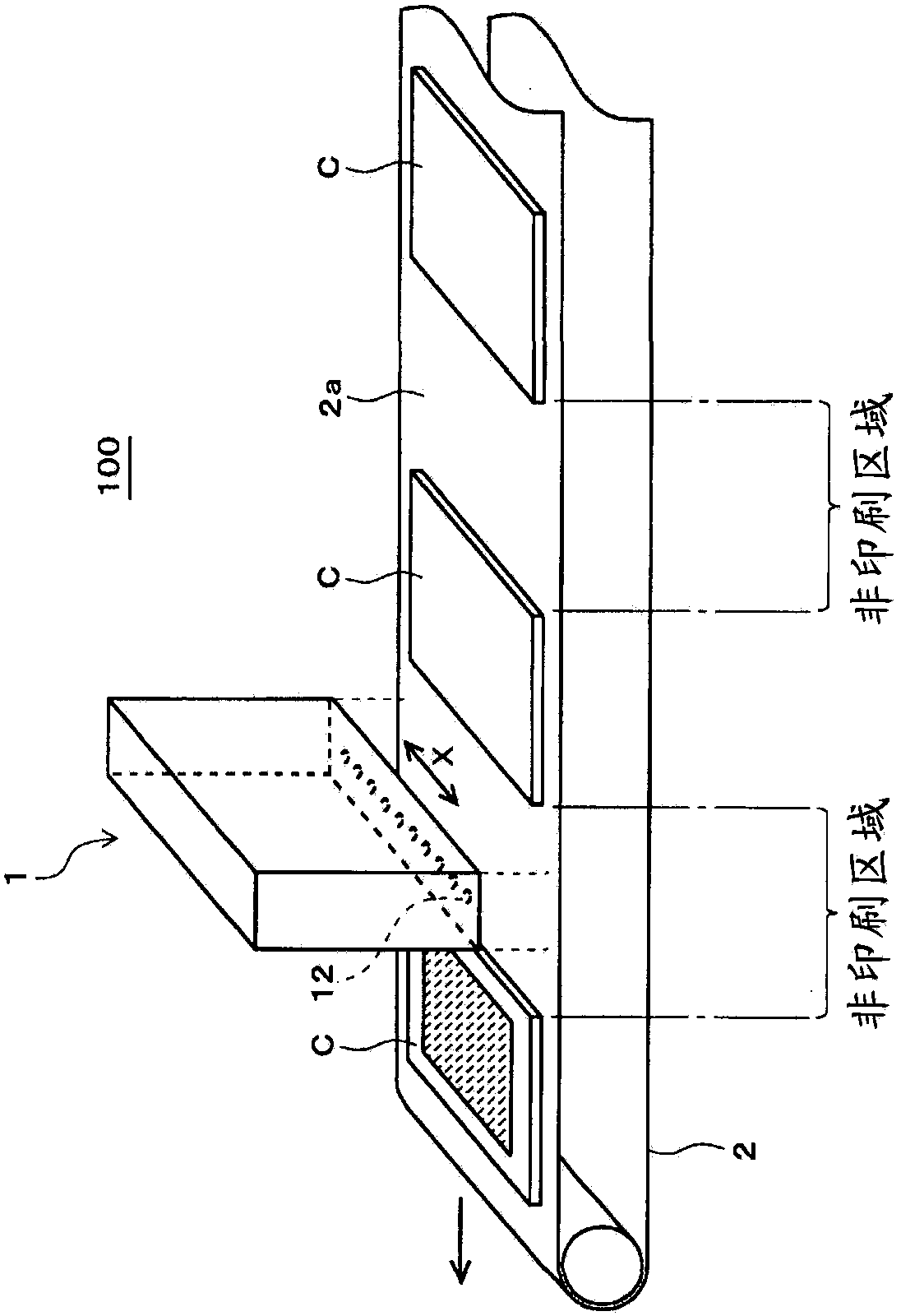

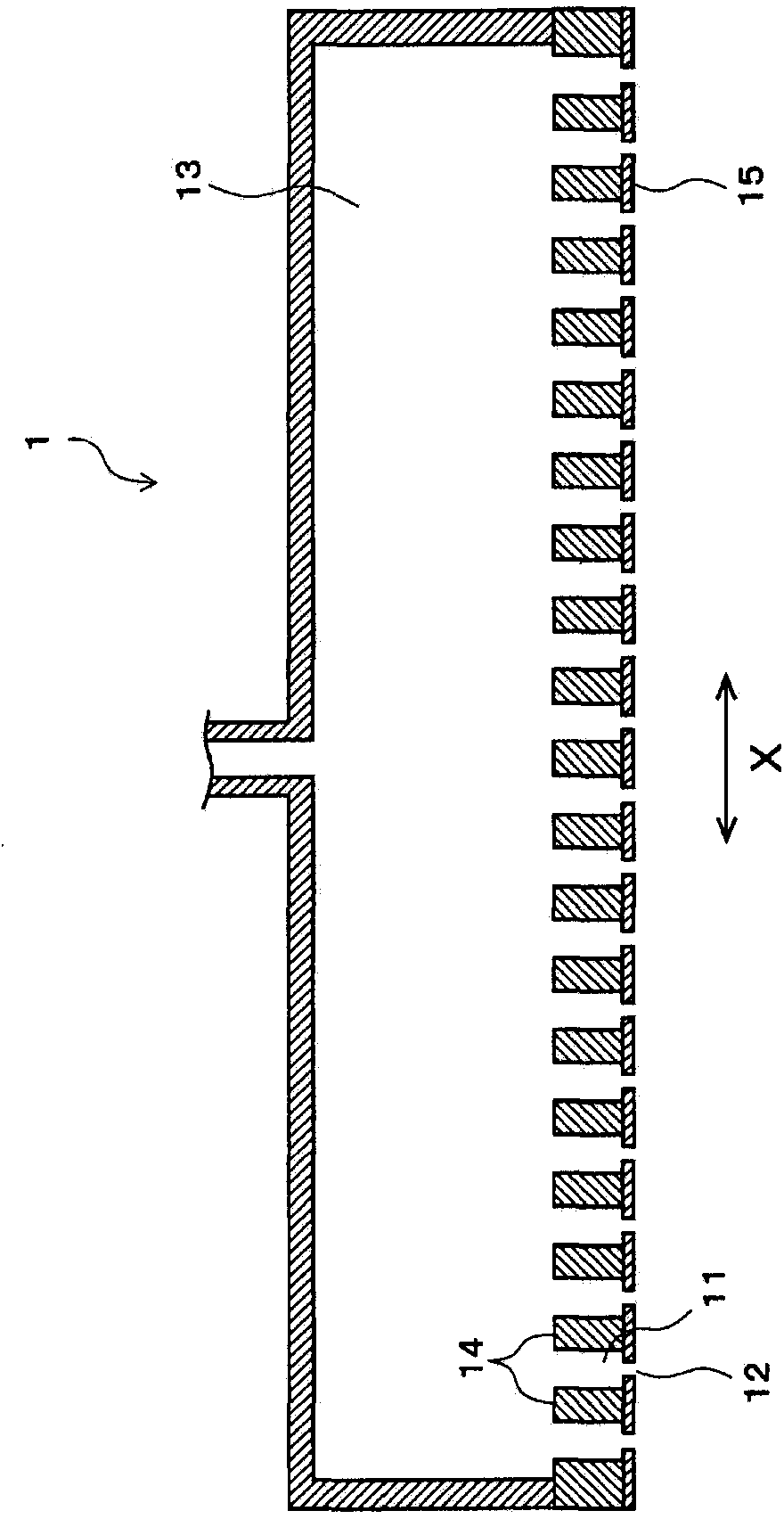

[0192] Such as figure 1 As shown, using a line-type droplet ejection device that prints on the surface of ceramic tiles conveyed by a conveyor belt through a single channel from the nozzle, from ink using a dispersant and yellow pigment particles as solid particles (The specific gravity difference between the dispersant and the solid particles: 0.30, the content of the substance whose vapor pressure is greater than water at room temperature: 3%), the specified printing was performed in the printing area on the surface of the ceramic tile. The ink used for ceramic tiles has a high density, and the pigment particles are easy to settle, so whenever the nozzle comes to the non-printing area between the ceramic tiles, after applying a micro-vibration pulse with the same frequency as the droplet ejection frequency during printing, Droplet discharge at the same frequency as the discharge frequency was performed in the ink receiving unit.

[0193] As a result, no nozzle clogging occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com