Film-coating tool for coating outer edge totally-closed zone

A fully enclosed, outer edge technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve problems such as inability to perform coating, and achieve elimination of film sedimentation, improvement of uniformity, and coating accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

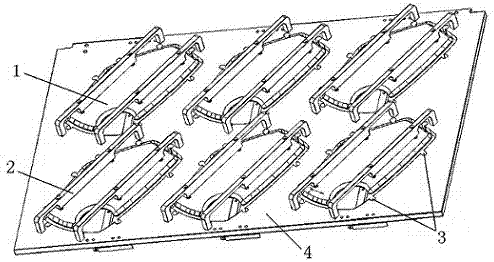

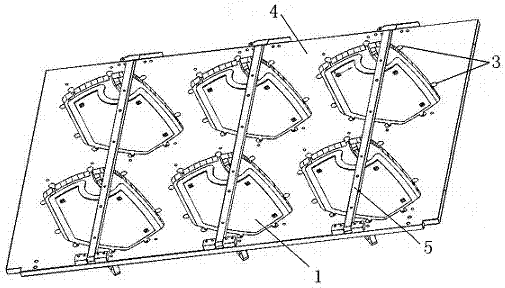

[0019] see Figure 1 to Figure 3 , this embodiment includes a backbone frame 4 and three supporting and fixing frames 5 for coated sheets, six erection units are arranged on the backbone frame 4, and the six erection units are arranged in a form of 2×3.

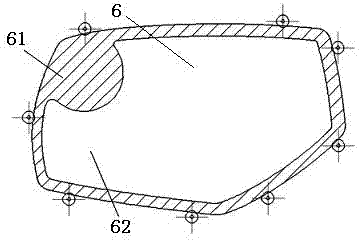

[0020] An erection unit in this embodiment includes a shielding sheet 1 , a shielding sheet fixing beam 2 , and a reference positioning support point 3 for the film to be coated.

[0021] In this embodiment, each erection unit corresponds to two shielding sheet fixed beams 2, and the two shielding sheet fixed beams 2 are arranged in parallel. On the coating surface, the shielding sheet 1 is provided with four fixing holes, the shielding sheet 1 is fixed with the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com