Sulfuric acid process titanium dioxide primary washing dilute waste acid membrane integrated recycling zero-discharge treatment method

A treatment method and technology for titanium dioxide, applied in chemical instruments and methods, sulfur compounds, sulfur trioxide/sulfuric acid, etc., can solve the problems of uneven distribution of water production, high energy consumption, and difficulty in recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

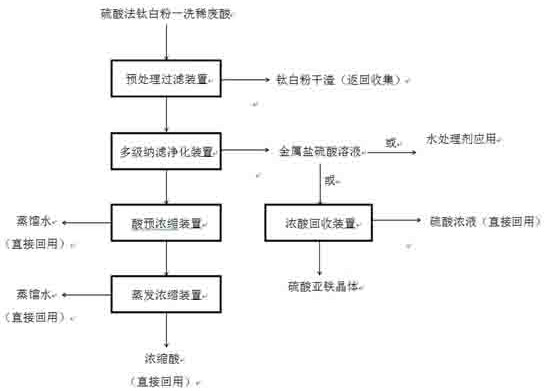

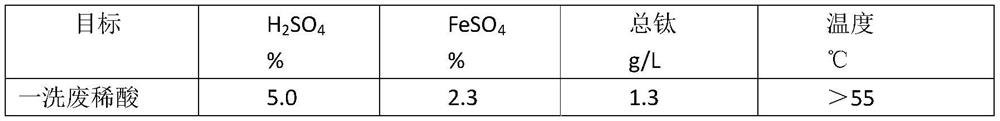

[0043] A zero-discharge treatment method for sulfuric acid-process titanium dioxide once washed and diluted waste acid film integrated resource utilization, comprising the following steps:

[0044] (1) For solid-liquid separation of waste dilute acid after washing titanium dioxide, first add filter aid to circulate and filter backflow to pre-coat the surface of the filter element to form a certain thickness of filter cake layer, and then switch to normal filtration to remove insoluble hydrolyzed TiO 2 Colloid, and get the qualified first filtrate; when the water production efficiency drops and the filter cake layer reaches a certain thickness, then use compressed air to blow forward and back blow to get titanium dioxide dry residue, and finally use water to wash the filter element in reverse and forward direction, Then re-enter the next cycle to use;

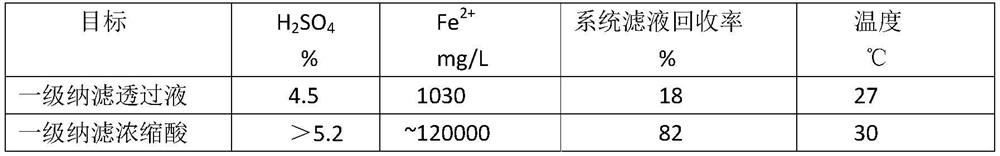

[0045] (2) The first filtrate is subjected to heat exchange and cooling through a heat exchanger to reach a suitable temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com