Polyether-ether-ketone hollow fiber porous membrane and preparation method thereof

A polyetheretherketone and porous membrane technology, which is applied in the field of polyetheretherketone hollow fiber porous membrane and its preparation, can solve the problems of low flux, poor permeability, difficult pore formation of PEEK hollow fiber membrane, etc. Good capacitance, improved membrane permeability, and the effect of solving the problem of porosity caused by melt spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

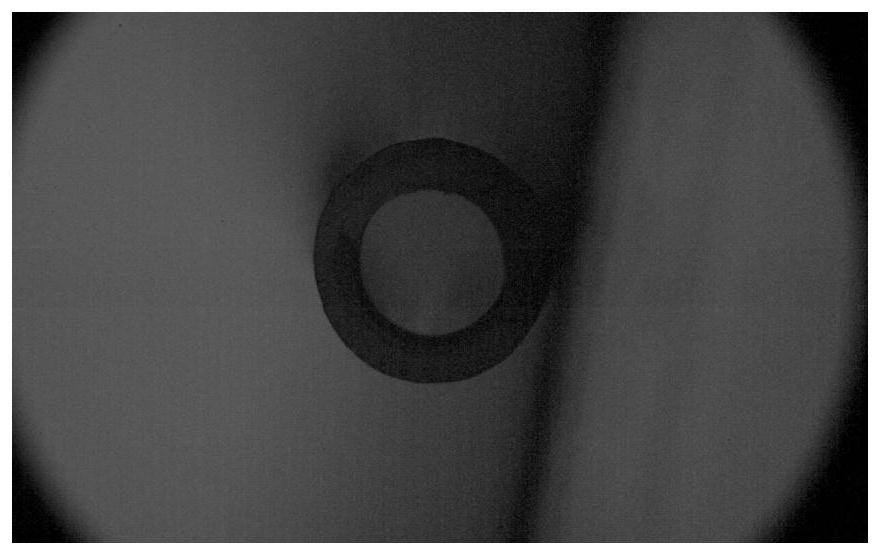

Image

Examples

specific Embodiment approach

[0032] Specific embodiments of the present invention are given below. The specific embodiments are only used to further illustrate the present invention in detail, and do not limit the protection scope of the claims of the present application.

[0033] The invention provides a preparation method of a polyetheretherketone hollow fiber porous membrane, comprising the following steps:

[0034] Step 1. Preparation of special pellets for polyetheretherketone hollow fiber membrane spinning:

[0035] The polymer porogen and inorganic porogen are compounded into a composite porogen, which is premixed with PEEK resin and additives using a high-speed mixer, fully mixed in an extruder, cooled and pelletized to obtain PEEK hollow fiber membrane spinning Special pellets. The special pellet formulation is: PEEK resin 30-60 wt%, composite porogen 35-65 wt%, additive 0-3 wt%, the sum of each component is 100%, and the polymer in the composite porogen causes porosity The ratio of agent to i...

Embodiment 1

[0048] Step 1. After 52 wt% PEI and 2 wt% nano-silica were ball-milled for 6 h, the temperature was raised to 350 °C, the mixture was uniformly mixed at a high speed, cooled and cooled, and a uniformly mixed composite porogen was obtained by a pulverizer and a grinder. 45 wt% PEEK resin and 1 wt% silicone pellets were premixed with a high-speed mixer, fully kneaded in an extruder, cooled and pelletized to obtain pellets for PEEK hollow fiber membrane spinning.

[0049] Step 2. Set the heating temperature from zone 1 to zone 10 with a temperature gradient of 10 °C, from 280 °C to 370 °C, fully melt the pellets for spinning in the extruder, and spray them through a 3 / 2 mm hollow through a metering pump. The silk assembly was extruded. The inside of the assembly was fed with nitrogen at 100°C at 100ml / min, and stretched twice through the spinneret. After the hollow melt was solidified, it was stretched and wound online at 16 m / min. The PEEK hollow fiber membrane was obtained by s...

Embodiment 2

[0053] Step 1. After ball-milling 50 wt% PEI, 7 wt% potassium chloride, and 2 wt% nano-silica for 6 h, the temperature was raised to 310 °C, and the mixture was uniformly mixed at a high speed. After compounding the porogen, 40wt% PEEK resin and 1wt% silicone particles were premixed with a high-speed mixer, fully kneaded in an extruder, cooled and pelletized to obtain PEEK hollow fiber membrane spinning pellets.

[0054] Step 2. Set the heating temperature from zone 1 to zone 10 with a temperature gradient of 10°C, from 270°C to 360°C, fully melt the pellets for spinning in the extruder, and spray them through a 3 / 2 mm hollow through a metering pump. The silk component was extruded. The inside of the component was injected with nitrogen gas at 150°C at 100ml / min, and stretched by 1 times through the spinneret. After the hollow melt was solidified, it was stretched and wound online at 16 m / min. The PEEK hollow fiber membrane was obtained by soaking in N-methylpyrrolidone solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com