Patents

Literature

83results about How to "Increase gas output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing coal bed gas yield through indigenous bacteria

InactiveCN106285581AIncrease gas outputImprove porosity and permeabilityBacteriaPreparing sample for investigationFermentationCoal

The invention provides a method for increasing the coal bed gas yield through indigenous bacteria. The method comprises the steps of (1) a methanogens community is enriched and cultured, specifically, a coal sample and a water sample are collected from a target zone, enrichment culture and fermentation of the methanogens community are conducted, and fermentation liquor is obtained; (2) ultrasonic coupling supercritical CO2 treatment is conducted, specifically, a laboratory operation and maintenance management system is used, the optimal condition for ultrasonic coupling supercritical CO2 treatment on the coal seam sample is analyzed in a laboratory, and a target coal seam is treated under the optimal condition; and (3) coal degradation through microorganism is conducted, specifically, the fermentation liquor obtained in the step (1) is injected into the target coal seam, changes of injection wellhead gas components and the methane concentration are detected continuously, and methane is gathered in drainage, pressure lowering and recovering modes. The treatment time is effectively shortened through the ultrasonic coupling supercritical CO2 treatment, the coal bed gas generation speed is increased, and meanwhile the working efficiency is effectively improved through the laboratory operation and maintenance management system.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

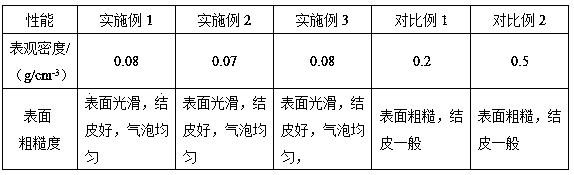

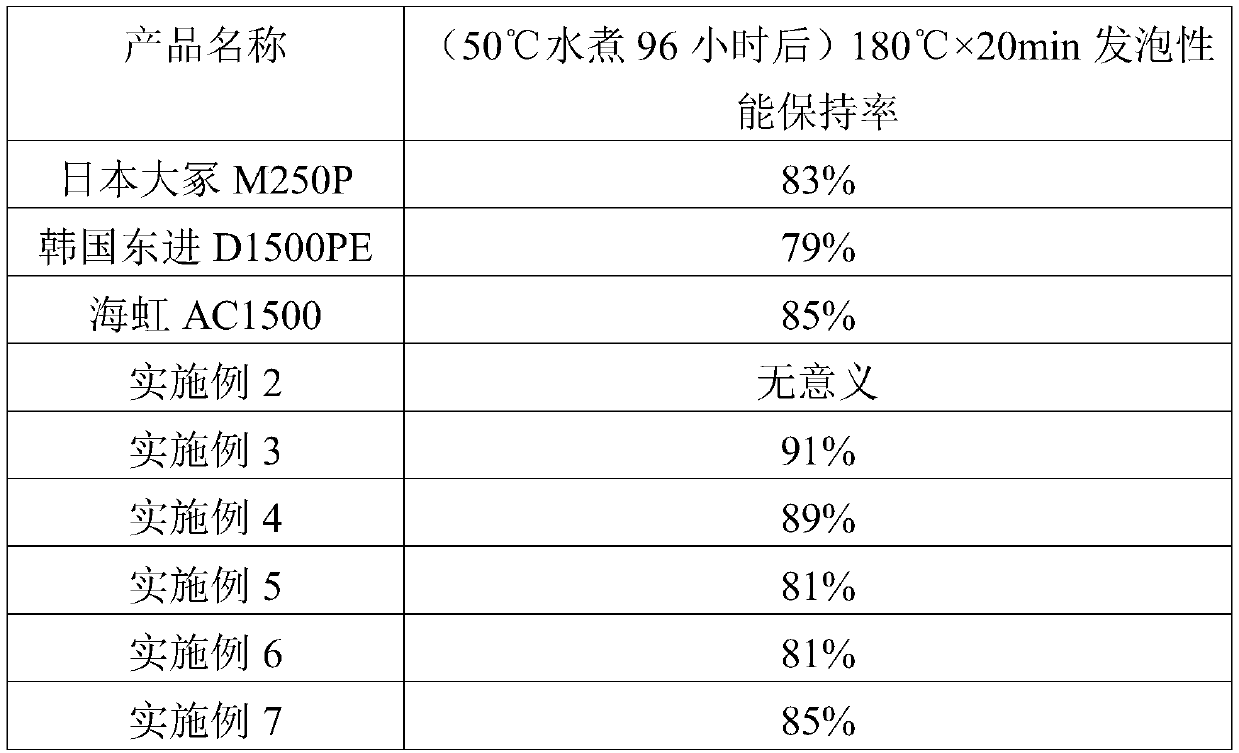

Low-density ethylene propylene diene monomer extruded sponge material and preparation method thereof

The invention relates to a low-density ethylene propylene diene monomer extruded sponge material and a preparation method thereof. The sponge material disclosed by the invention is prepared from the following components in parts by weight: 100 parts of raw rubber matrix, 20-50 parts of carbon black; 50-100 parts of a plasticizer, 100-200 parts of an inorganic filler, 1-3 parts of a vulcanizing agent, 15-30 parts of a blowing agent, 5-10 parts of a vulcanization accelerator, 5-10 parts of an activator, 5-10 parts of calcium oxide; wherein the raw rubber matrix is ethylene propylene diene monomer rubber, the ethylene content of the raw rubber matrix is 40-55%, the Mooney viscosity (ML(1 + 4)125 DEG C) of the raw rubber matrix is 40-80, and the content of a third monomer ENB of the raw rubbermatrix is 7-10%. The low-density ethylene propylene diene monomer extruded sponge material has the advantages of light density, smooth surface, excellent weather resistance, ozone resistance and coldresistance, the preparation method is simple and convenient to operate and low in cost, and the sponge material can be applied to the fields of pipeline or building insulation, fitness products and the like.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

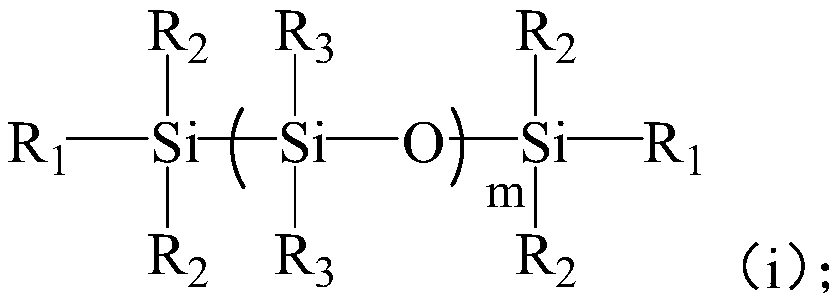

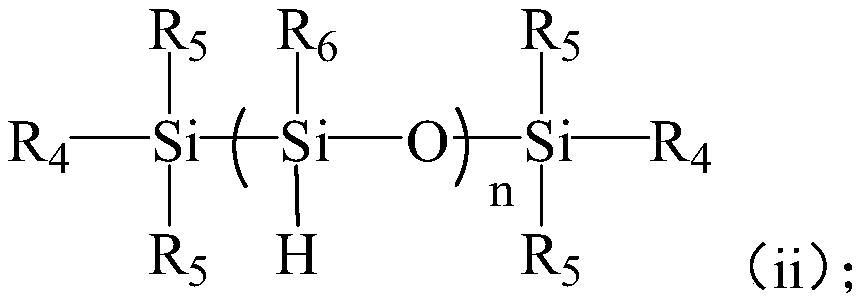

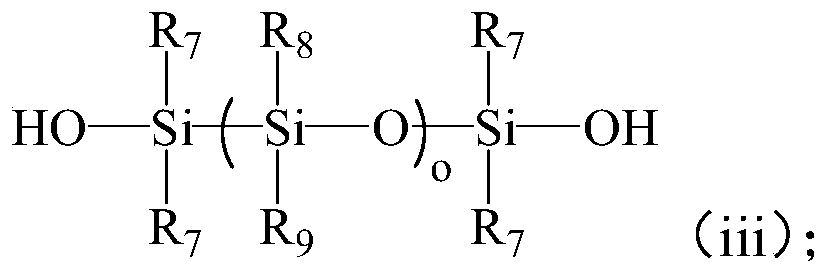

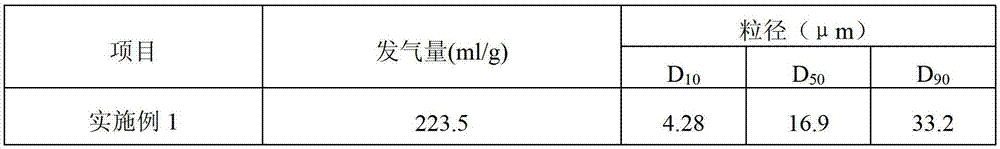

Pre-foamed organic silicone foam material as well as preparation method and application thereof

The invention provides a pre-foamed organic silicone foam material as well as a preparation method and application thereof. The pre-foamed organic silicone foam material disclosed by the invention comprises the following raw materials: methyl and / or vinyl-terminated organopolysiloxane, hydrogen-containing polysiloxane, hydroxyl silicone oil, a pre-foaming agent, an alcohol substance, a surfactant, a filler, a catalyst and a vulcanization inhibitor. According to the pre-foamed organic silicone foam material disclosed by the invention, the pre-foaming agent and the alcohol substance are adopted for performing auxiliary foaming on the basis of dehydrogenation foaming of hydroxyl silicone oil, foaming can be performed before a dehydrogenation reaction, tiny bubble nucleuses are formed, gas volumes and foaming ratios can be effectively increased, the dosage of the hydroxyl silicone oil is reduced, thixotropy is reduced, and processability is improved. Meanwhile, by adding aids such as the surfactant, compatibility of the components can be improved, and stability in the foaming process is improved, so that the prepared foam material is fine and uniform in pore and low in density.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Low-temperature type ADCA (Azodicarbonamide) foaming agent and preparation method as well as application thereof

The invention relates to a low-temperature type ADCA (Azodicarbonamide) foaming agent. The low-temperature type ADCA foaming agent is formed by combining one or more activating agents and ADCA according to a certain proportion, wherein the activating agent can be selected from metallic compounds such as chromium, zinc and lead, urea derivatives, nitroguanidine and the like. The lowest decomposition temperature of the foaming agent provided by the invention can reach 150 DEG C-112 DEG C; the forming agent is a novel heat absorption type forming agent and has a stable, compact and regular foam structure; and the foaming agent can be widely used for rolling leathers and rubbers and is simultaneously used for foaming medicines.

Owner:ZAOZHUANG ZHONGKE CHEM

Calcium carbide powder shaping binder, preparation method thereof and calcium carbide powder shaping method

InactiveCN104140686AImprove adhesionRaw materials are easy to obtainOther chemical processesHydrocarbonsActive agentCalcium carbide

The invention discloses a calcium carbide powder shaping binder, a preparation method thereof and a calcium carbide powder shaping method. The calcium carbide powder shaping binder comprises, by weight, 1-20 parts of calcium lignin sulphonate, 1-10 parts of calcium carbonate, 1-5 parts of an activator, 1-10 parts of calcium chloride and 1-15 parts of calcium oxide. The calcium carbide powder shaping binder has the advantages of simple and easily available raw materials, and good calcium carbide powder binding effect. Calcium carbide powder pellets made by using the calcium carbide shaping method through using the binder can be directly used in acetylene gas production without reconstructing an acetylene generator and introducing components harmful to the acetylene generator.

Owner:ELION RESOURCE GROUP +1

Method for producing ADC (azodicarbonamide) foaming agent by chlorine dioxide biurea

InactiveCN103193685AQuality improvementReduced particle size distribution widthOrganic chemistryPartial oxidationChemical oxygen demand

The invention discloses a method for producing an ADC (azodicarbonamide) foaming agent by chlorine dioxide biurea. The method concretely comprises the following steps of A, adding a part of water to biurea, recovering a part of oxidized mother liquor to prepare 20-40% biurea slurry containing acid, adding an oxide additive of which the mass ratio of the biurea is 0.3-10%; B, adding the biurea slurry into an oxidizing kettle, exhausting by an exhaust fan, keeping micro-negative pressure inside the oxidizing kettle, namely -1 to -10kPa; C, opening a chlorine valve, leading chlorine, and controlling the reaction temperature at 20-60 DEG C by a refrigerant, oxidizing until the reaction is finished; keeping the micro-negative pressure inside the oxidizing kettle in an oxidizing process; D, separating, washing and drying the slurry to prepare the product ADC foaming agent after the reaction is finished; recycling a part of oxidizing mother liquor, and carrying out wastewater treatment on a part of oxidizing mother liquor. The method has the beneficial effects that the quality of the ADC product is improved by adopting these methods; the particle size distribution width is reduced; the gas forming amount is improved; a reaction terminal point is easier to control; the peroxide phenomenon is reduced; the product yield is improved; the peroxide side reaction is reduced; and the COD (chemical oxygen demand) content of the waste liquid is also reduced.

Owner:HANGZHOU HI TECH FINE CHEM

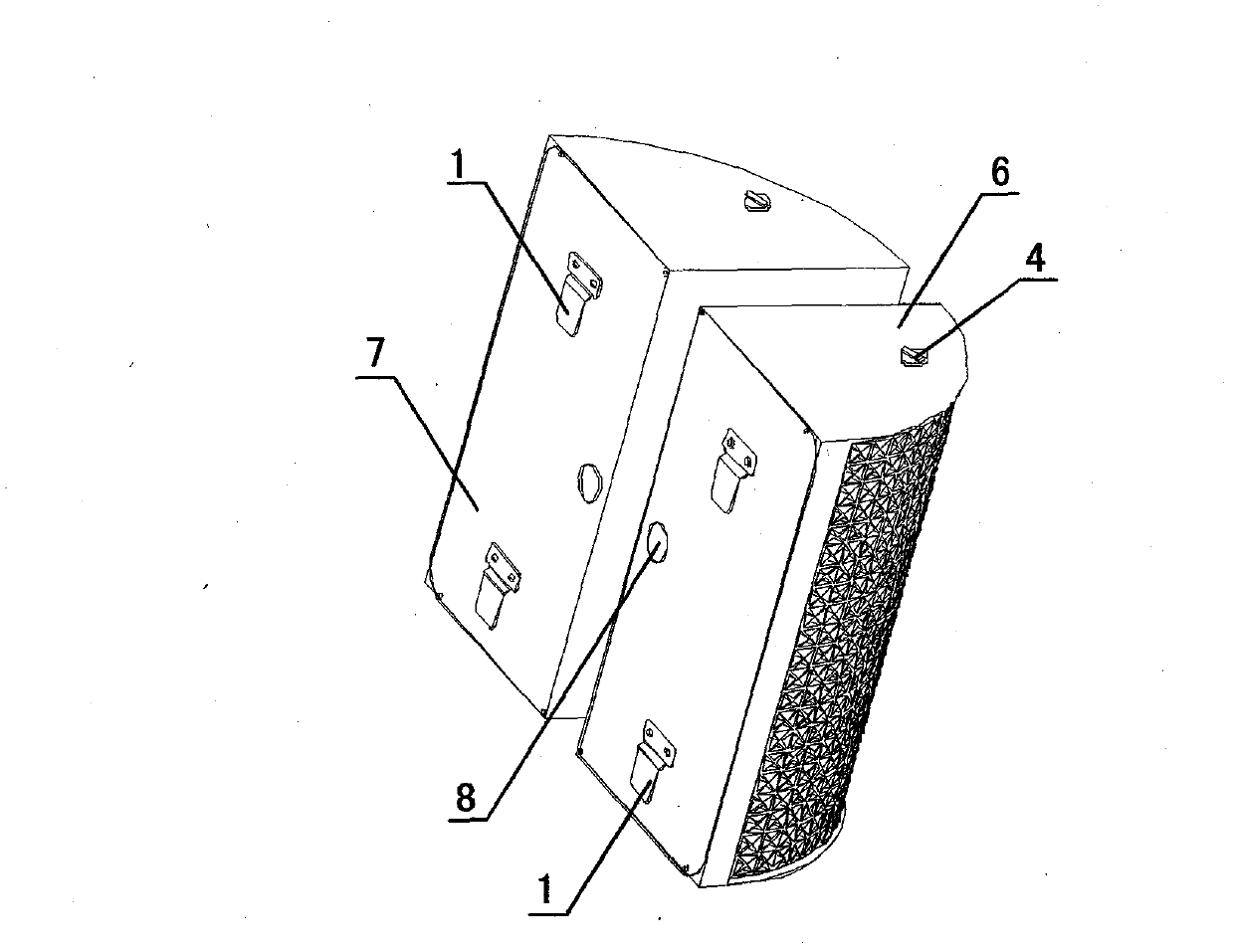

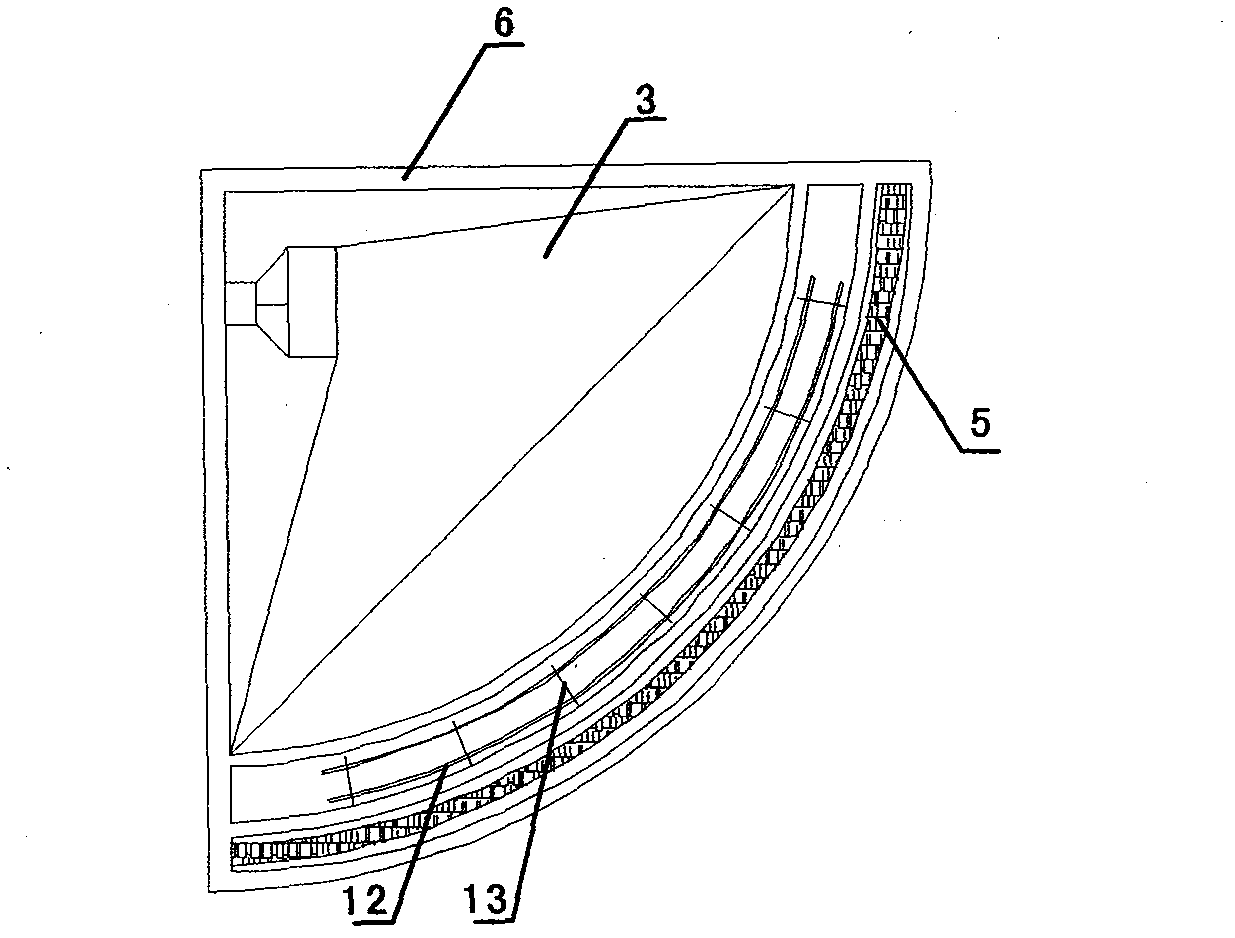

Air inlet and outlet device of house ventilator

InactiveCN102563792AEasy to installFully adjustable air intake directionLighting and heating apparatusAir-flow control membersEngineeringFan blade

The invention discloses an air inlet and outlet device of a house ventilator, which comprises an air inlet device and an air outlet device. The air inlet device and the air outlet device are structurally symmetric and respectively comprise a shell, a filter, fan blades, a ventilation opening, a ventilation pipe and a lower cover, the shell is of a sector structure, an adjustment opening is arranged at the upper end of the shell, the filter is mounted inside the shell, the fan blades are mounted inside the shell close to the filter, a holder and an external hole are arranged on the lower cover, the external hole corresponds to an external opening of the ventilation pipe, and the lower cover is mounted on one sector side of the shell. The air inlet and outlet device has the advantages that air inlet and outlet amount can be increased for a house, short-term air outlet directions are optionally controlled, and filterability is enhanced.

Owner:SHANGHAI NICHOLS ELECTRONICS TECH INC

High thermal stability synthetic ammonia gasification moulded coal and preparation method thereof

ActiveCN101555427AIncrease cold strengthDoes not add ashSolid fuelsAmmonia preparation/separationCarbonizationAnthracite

The invention provides a high thermal stability synthetic ammonia gasification moulded coal, which is made from the following components by weight: 76.0-84.7 of anthracite powder, 0.3-1.0 of added modified starch, 4-10 of fat coal powder processed by low temperature carbonization and 11-13 of water. Due to the added modified starch, the synthetic ammonia gasification moulded coal effectively enhances the cold strength of moulded coal and effectively improves the thermal stability of moulded coal with the added fat coal processed by low temperature carbonization.

Owner:SHANXI UNIV

Flame retardant rigid polyisocyanurate foam and preparation method thereof

InactiveCN108395515AEasy to prepareThe preparation method is simple, and the performance of the prepared rigid foam is simpleFoaming agentNitrogen

The invention relates to flame retardant rigid polyisocyanurate foam and a preparation method thereof. The flame retardant rigid polyisocyanurate foam is prepared from the following components in parts by weight: 150-170 parts of polyisocyanate, 5-8 parts of polyether polyol, 15-20 parts of flame retardant, 2-3 parts of catalyst, 1-2 parts of stabilizer, and 15-20 parts of foaming agent. The flameretardant is prepared by mixing a nitrogen-containing flame retardant and a phosphorus-containing flame retardant at the mass ratio of 1:1. The preparation method comprises the following steps: S1, mixing an additive; and S2, preparing rigid polyurethane foam. The flame retardant rigid polyisocyanurate foam has the advantages of being good in flame retardant effect, high in rigid foam performanceand suitable for industrial production.

Owner:江苏中昌绝热技术工程有限公司

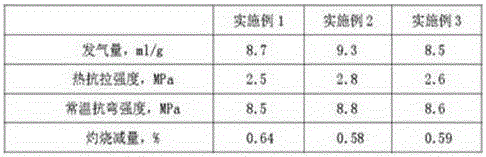

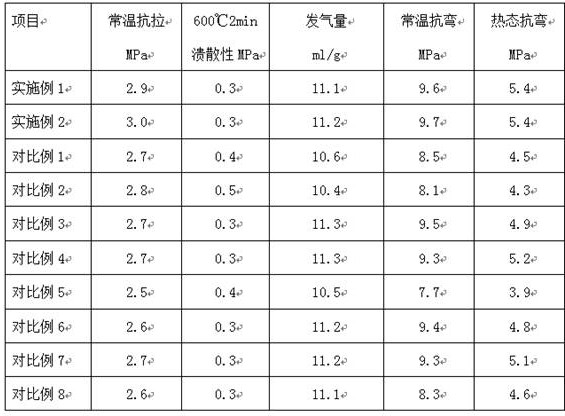

Coated core sand for casting train steel casting and preparation method of coated core sand

The invention discloses coated core sand for casting a train steel casting and a preparation method of the coated core sand. The coated core sand is prepared from, by weight, 170-180 parts of hill sand, 30-40 parts of zircon sand, 20-30 parts of emery, 15-20 parts of ceramsite, 15-20 parts of montmorillonite, 2-4 parts of phenolic resin, 2-3 parts of BT resin, 1-2 parts of diethoxy-methyl-[3-(oxiran-2-ylmethoxy)propyl]silane, 0.6-0.8 part of urotropine, 0.5-0.7 part of rosin pentaerythrityl ester, 5-7 parts of tephra, 6-8 parts of quartz crucible waste, 2-3 parts of salty mud, 0.3-0.5 part of paratoluensulfonyl chloride, 0.2-0.4 part of (H2NCH2C6H4)2O , 1-2 parts of trioctyl trimellitate, 3-5 parts of bismuth oxide, 4-7 parts of ferronickel slag and 20-30 parts of ethyl alcohol. The coated core sand has very high sand burning resisting capacity and veining resisting capacity, has the beneficial effects of being high in strength, small in gas generating amount, good in heat resistance and the like and is suitable for producing the steel casting, and the defects such as veining, sand burning and pores can be remarkably reduced.

Owner:江阴联华铸造有限公司

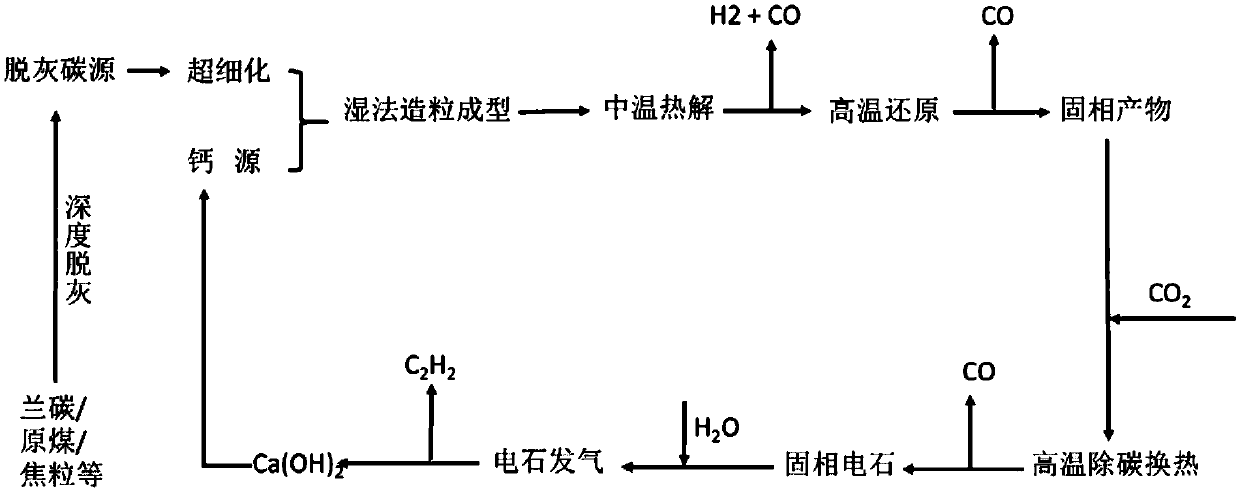

Calcium carbide acetylene production technology capable of reducing generation of calcium carbide slag

ActiveCN108675911AIncrease the deep deashing processAdd carbon removal processHydrocarbon from carbon oxidesCalcium carbideSource materialSlag

The invention discloses a calcium carbide acetylene production technology capable of reducing generation of calcium carbide slag. The calcium carbide acetylene production technology comprises the following reaction steps: S1, preparing an ultrafine deashed carbon source material and a calcium source material; S2, adding mixture of the ultrafine deasehd carbon source material and the calcium sourcematerial into a binding agent, feeding in a pelletizer, and forming by adopting wet granulation, thus obtaining calcium carbide raw material balls in certain size; S3, putting the obtained raw material balls in a calcium carbide synthetic furnace for heating and smelting; S4, introducing CO2 gas in certain concentration in a high-temperature solid-phase product obtained through reaction, and carrying out decarbonization and heat exchange; merging a produced gas into furnace gas, separating and purifying the mixed gas after carrying out heat exchange and dedusting, and feeding the treated gasinto a storage tank or to next process; S5, developing gas by calcium carbide, thus obtaining an acetylene gas and calcium hydroxide slurry; S6, recycling the calcium source material; S7, stopping recycling of the calcium source material when the amount of impurities in the calcium hydroxide slurry exceeds 20 weight percent of calcium groups, and removing the calcium hydroxide slurry, thus obtaining calcium carbide slag. According to the calcium carbide acetylene production technology disclosed by the invention, the calcium source material is recycled, and meanwhile, no scorification / less scorification during a calcium carbide process and great improvement of quality of the calcium carbide can be realized.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

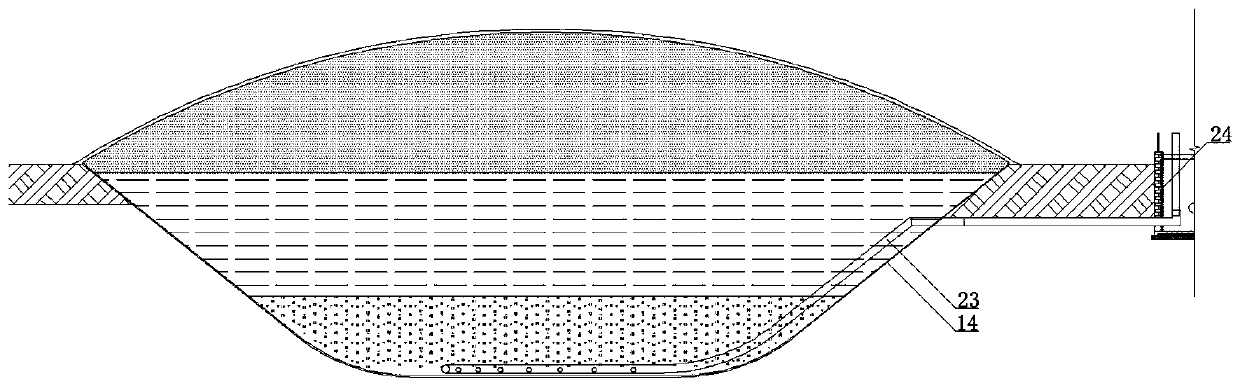

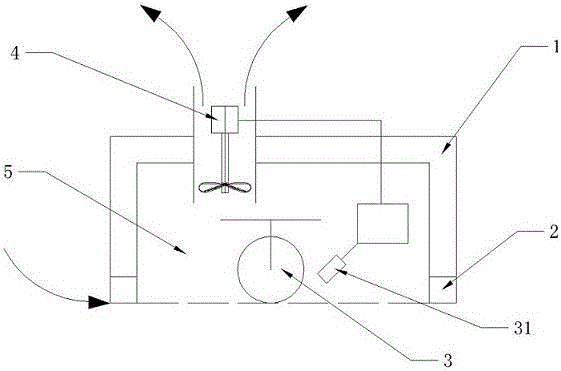

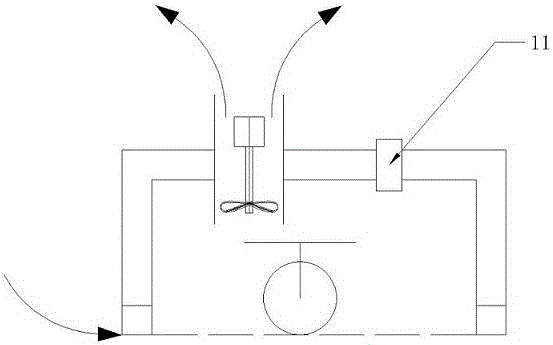

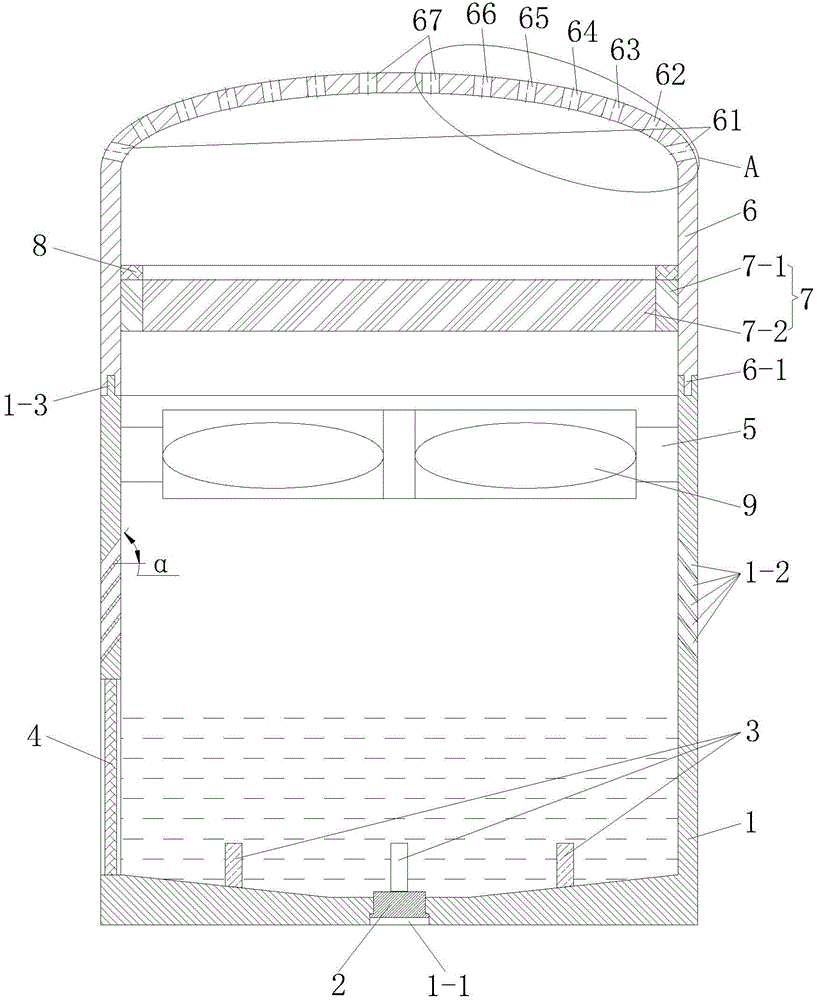

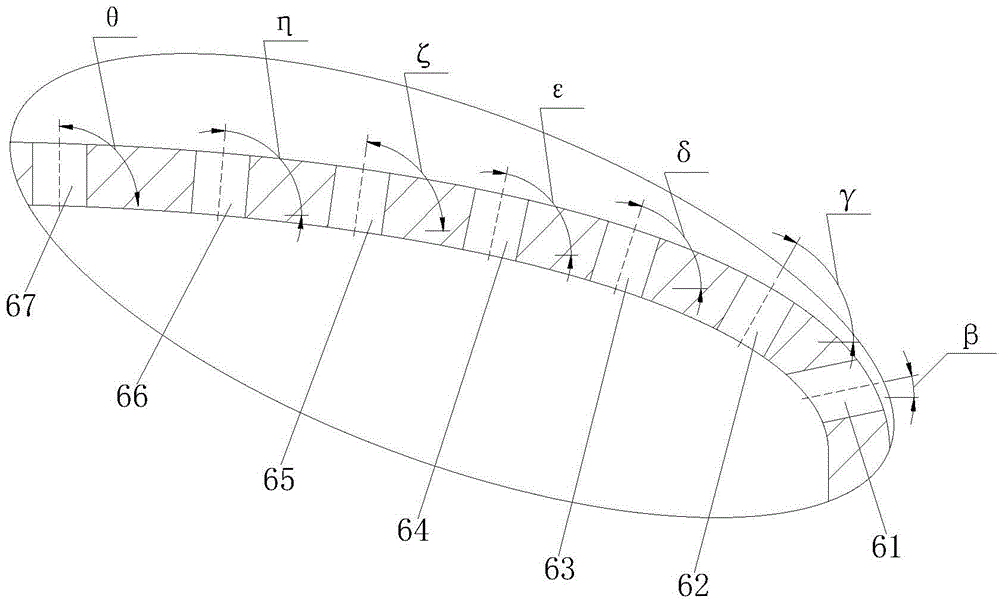

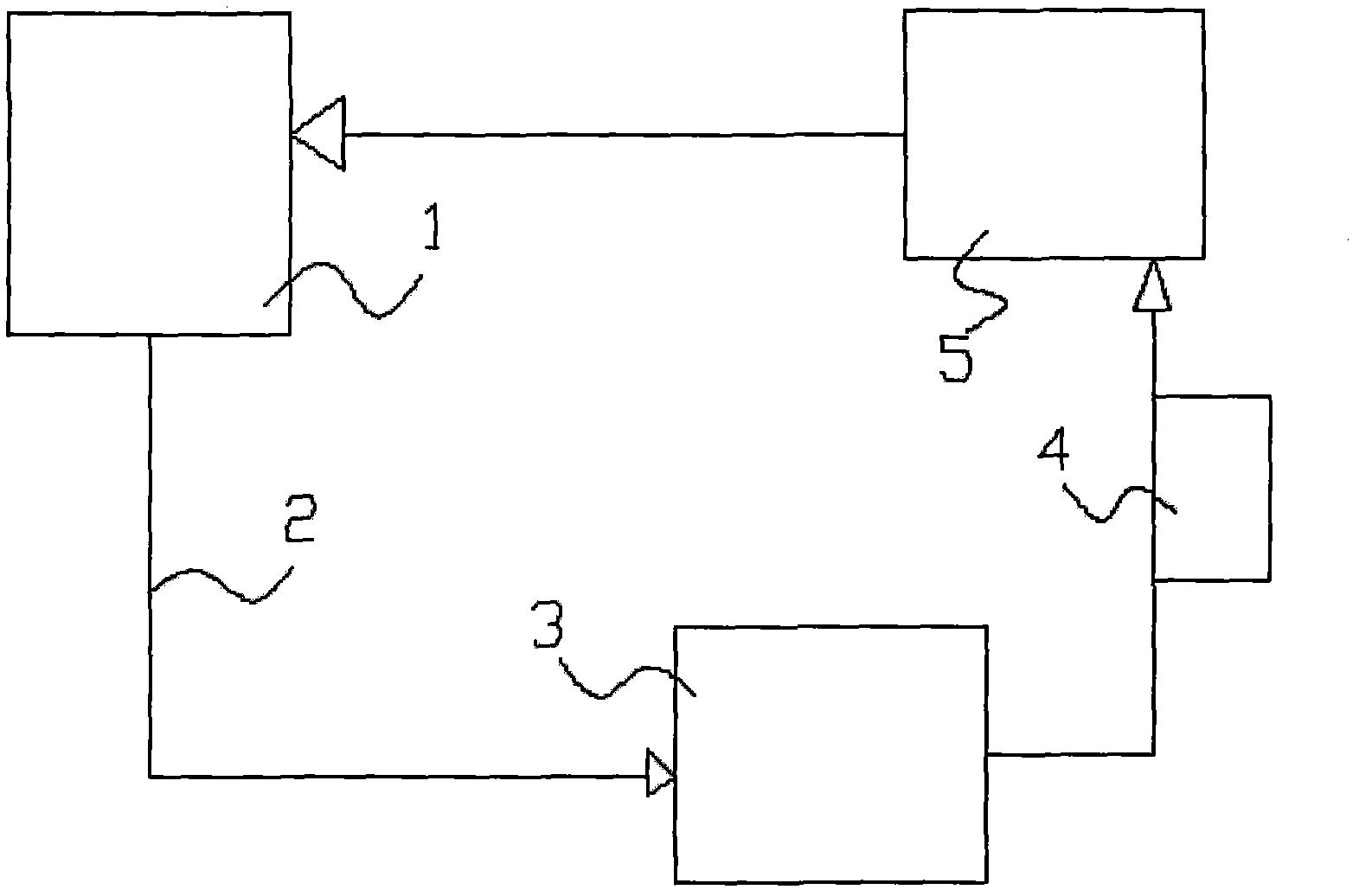

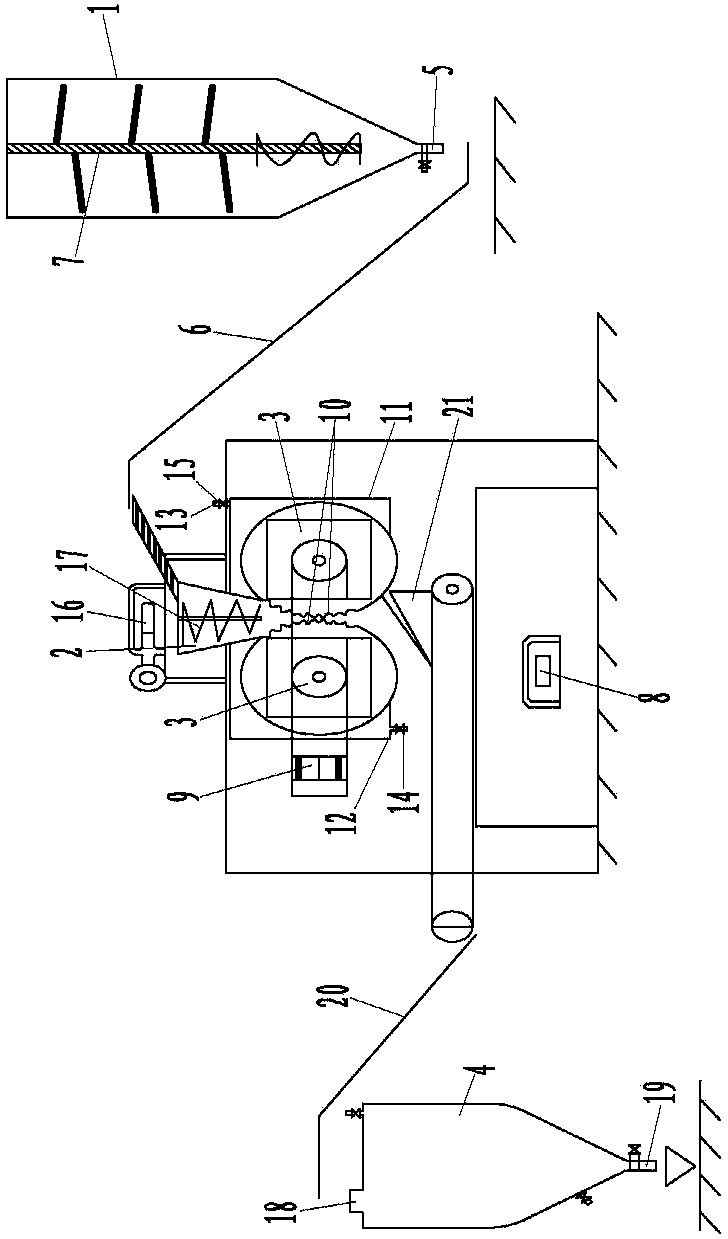

Circulating system and method for improving biogas yield of biogas digester

InactiveCN110862208AIncrease gas productionSolve the problem of difficult operation and high operating costProductsReagentsAnimal fecesProcess engineering

The invention discloses a circulating system for improving the biogas yield of a biogas digester. The circulating system comprises an original dung liquid pool, a backflushing pool, a feeding well, abiogas digester, a liquid outlet pipe well, a biogas taking well and a plurality of slag discharging wells. Film pressing ditches are disposed on both sides of the biogas digester, a filter unit is arranged between the original dung liquid pool and the backflushing pool, and an adding device is arranged between the backflushing pool and the feeding well. The invention also provides a circulating method for improving the biogas yield of the biogas digester. According to the invention, during use, slag and floating objects can be removed, the biogas digester does not need to be stopped for cleaning, the waste heat generated by biogas power generation can be used for keeping running in supercold weather, so that the system can achieve cycle running continuously all year round, animal dung ofbreeding plants can be continuously cleaned so as to solve the environmental problem brought about by animal dung, the fermented biogas residue can be used for making organic fertilizer, thus reachingcyclic utilization of animal dung, also the biogas yield is high, and biogas can be continuously provided for power generation.

Owner:宁夏金宇浩兴农牧业股份有限公司

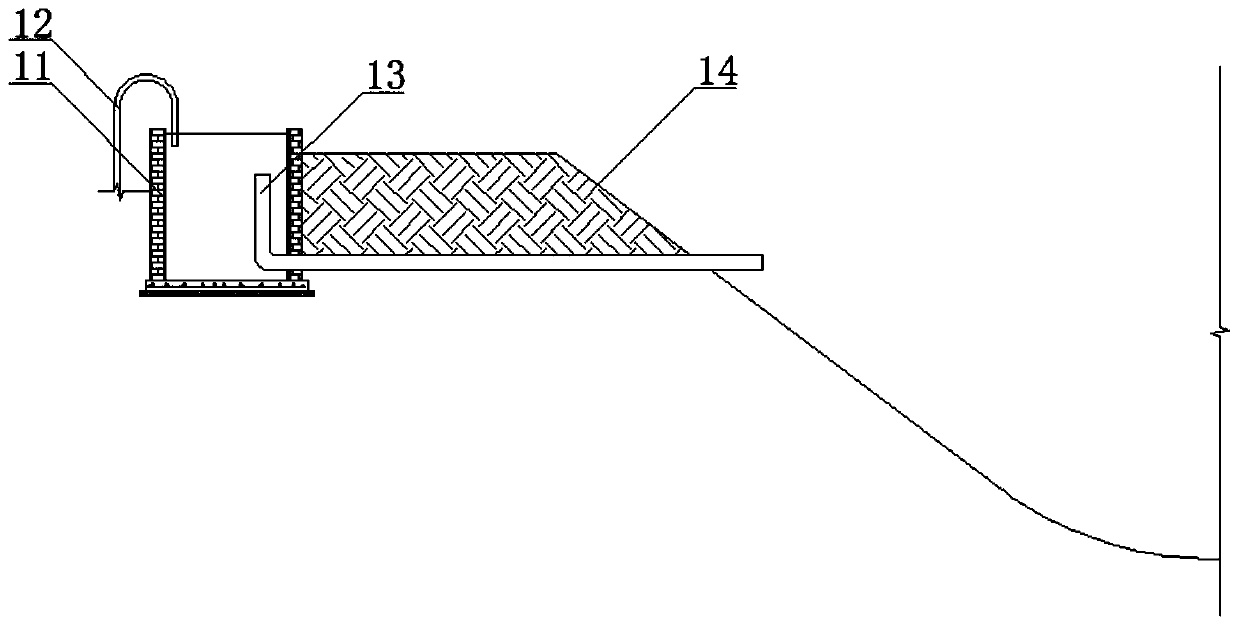

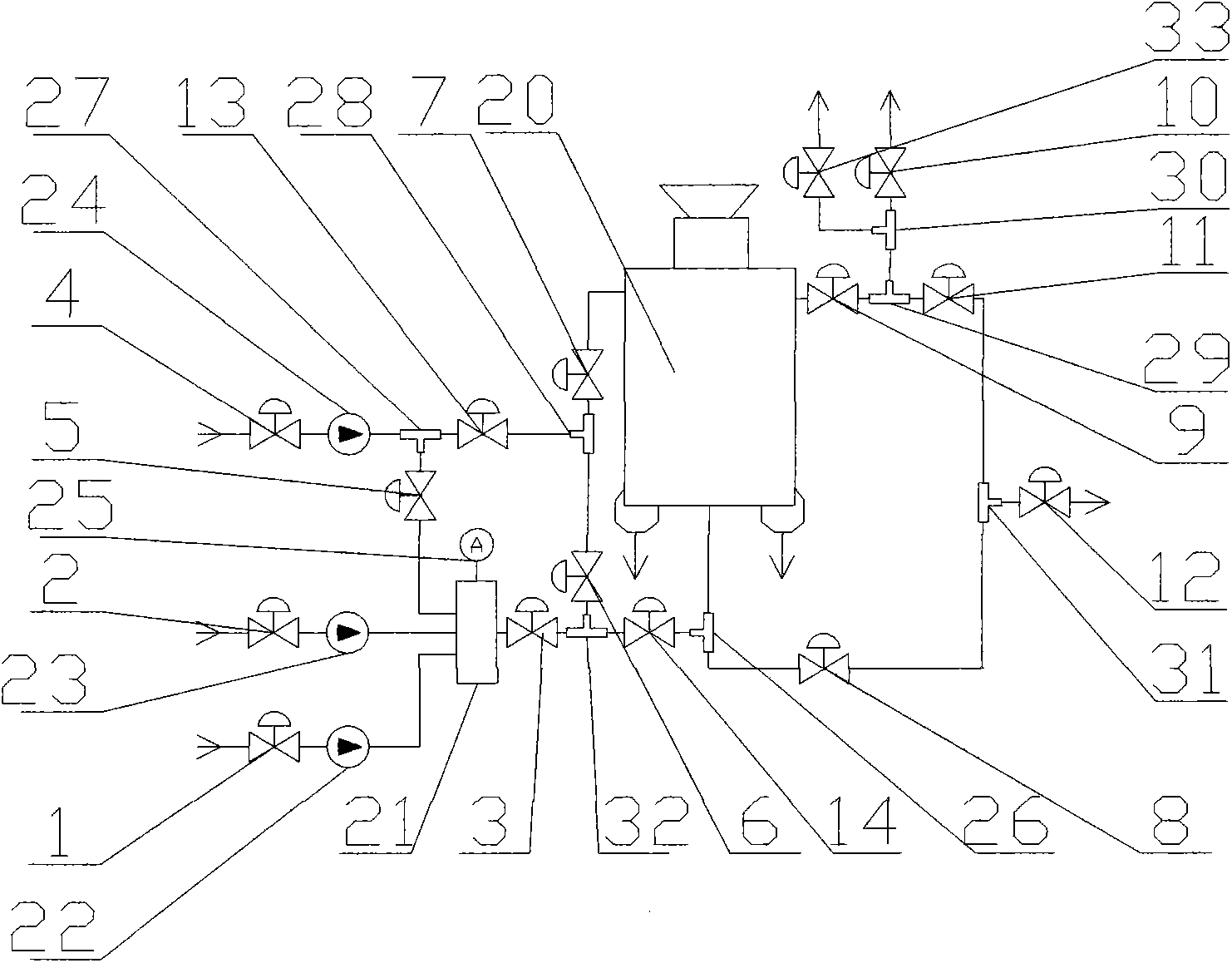

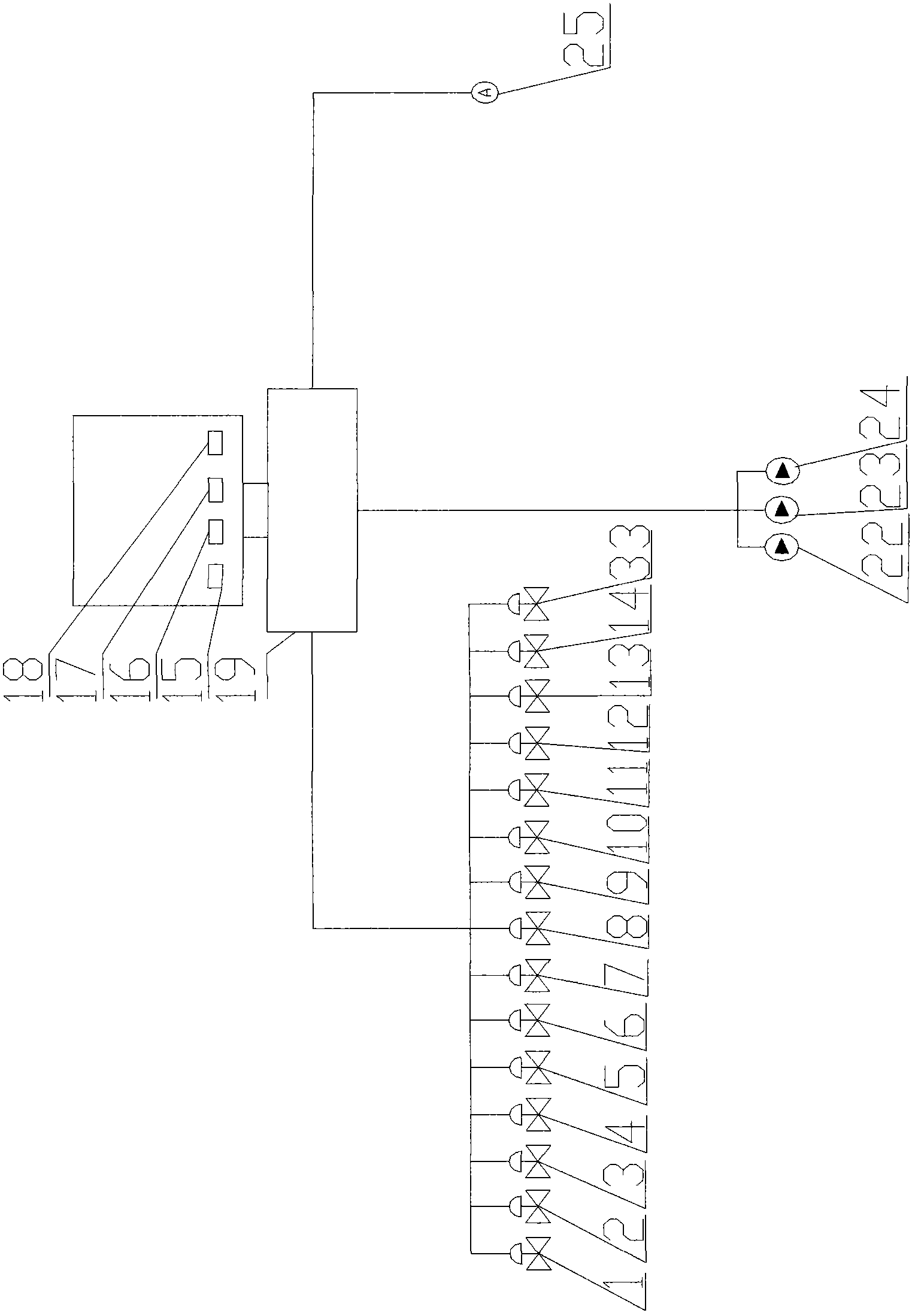

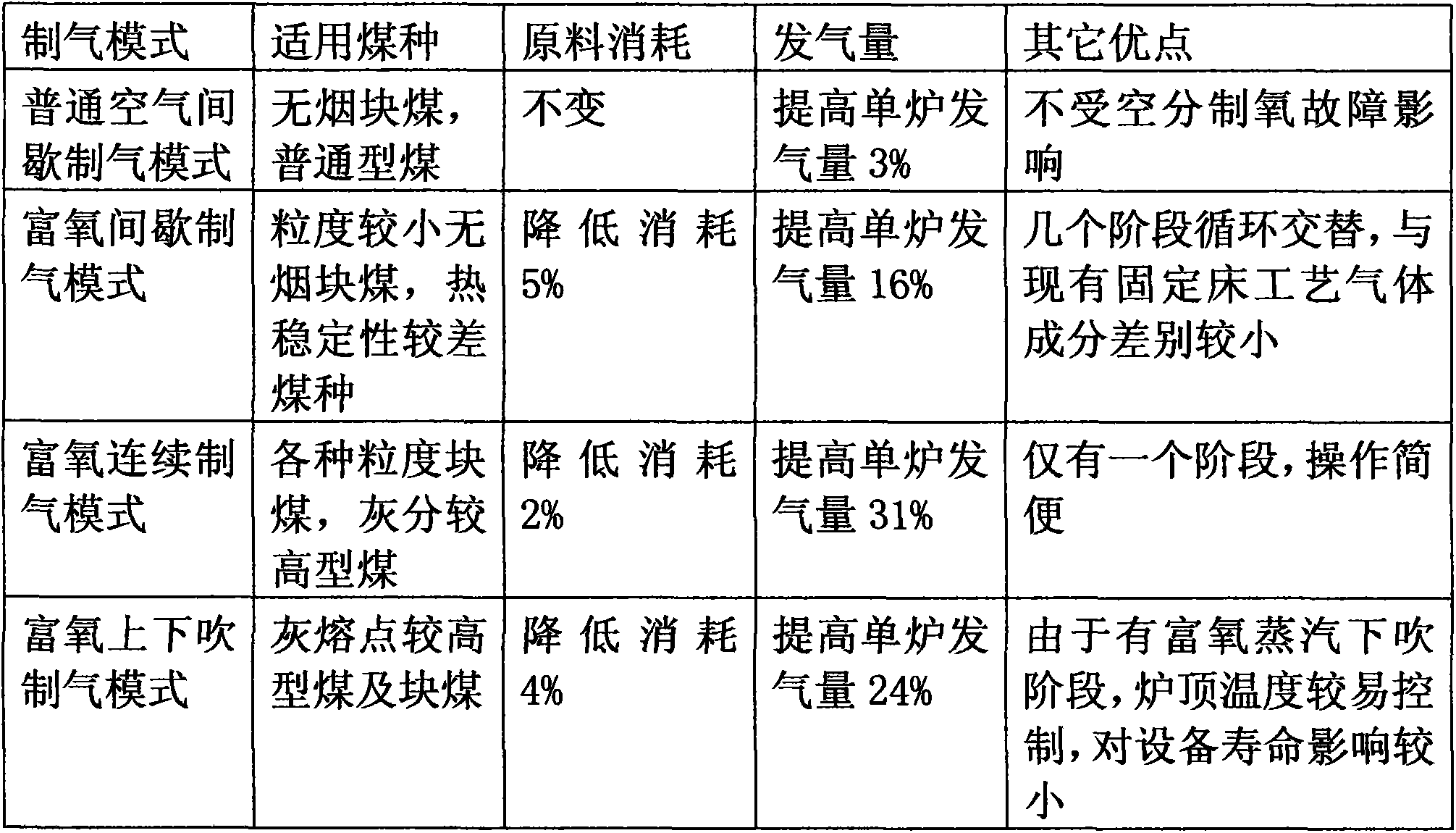

Multifunctional fixed bed gasification furnace gas making device and gas making process

The invention belongs to the technical field of gas making of fixed bed gasification furnaces, and specifically relates to a multifunctional fixed bed gasification furnace gas making device and a gas making process. The multifunctional fixed bed gasification furnace gas making device comprises a gasification furnace the top of which is provided with a coal inlet and slag holes which are respectively arranged on the two sides of the bottom of the gasification furnace, wherein an oxygen pipeline is connected with the inlet of a buffer tank through a first program control valve, the outlet of the buffer tank is sequentially connected with a third program control valve, a fourteenth program control valve and the bottom of the gasification furnace through a pipeline; a first tee joint is arranged on the pipeline arranged between the fourteenth program control valve and the bottom of the gasification furnace, a third end of the first tee joint is sequentially communicated with an eighth program control valve and a twelfth program control valve through the pipeline, and the twelfth program control valve is communicated with a gas cabinet. The multifunctional fixed bed gasification furnace gas making device and the gas making process provided by the invention have the advantages that the raw material coal adaptability is widened, the consumption of raw material coal is reduced, a resource is saved, the gas yield of a single furnace is improved, the cost is reduced, the multifunctional fixed bed gasification furnace gas making device is free from the influence of a space division gas making fault, the operation is simple and convenient, the multifunctional fixed bed gasification furnace gas making device is stable and safe, and the enterprise competitive power is improved.

Owner:HENAN XINLIANXIN FERTILIZER +2

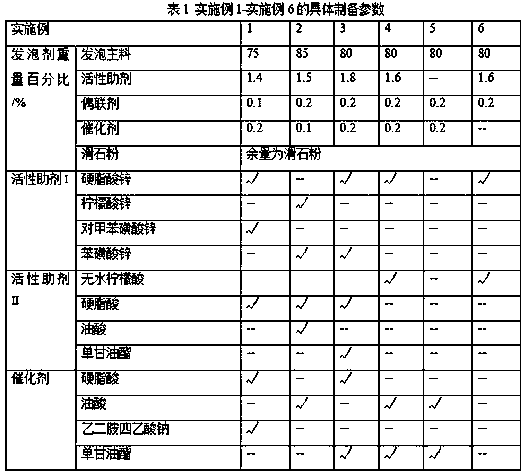

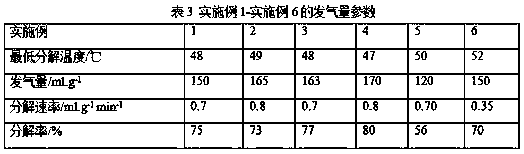

Solid environment-friendly foaming agent and preparation method thereof

ActiveCN108409998AEnvironmental protection is goodImprove foaming efficiencyDecompositionSodium bicarbonate

The invention relates to a solid environment-friendly foaming agent and a preparation method thereof. The foaming agent is prepared from the following components in percentage by weight: 75 to 85 percent of foaming main material, 1.4 to 1.8 percent of active auxiliary agent, 0.1 to 0.2 percent of coupling agent, 0.1 to 0.2 percent of catalyst, and the balance of talc, wherein the foaming main material is sodium bicarbonate. The preparation method comprises the following steps: S1, preparing raw materials; S2, mixing and stirring; S3, crushing and coating: after crushing the raw materials mixedin step S2 twice, adding the catalyst to stir for 2 to 3 minutes, and then adding the coupling agent and stirring for 8 to 10 minutes to obtain the finished product. The solid environment-friendly foaming agent has the advantages of environmental protection, low cost, stable gas generation and high decomposition rate.

Owner:福建灿辉环保科技股份有限公司

Negative-pressure self-adaptive adjusting device for negative-pressure type wall-climbing robot

Disclosed is a negative-pressure self-adaptive adjusting device for a negative-pressure type wall-climbing robot. Through the negative-pressure self-adaptive adjusting device, the technical problems that an existing negative-pressure self-adaptive adjusting device is high in energy consumption, low in wall-climbing efficiency, poor in stability and low in usability are mainly solved. According to the main points of the technical scheme of the negative-pressure self-adaptive adjusting device, the negative-pressure self-adaptive adjusting device comprises a robot outer wall (1), a seal gasket (2), a driving device (3) and a centrifugal fan (4); the robot outer wall is provided with an opening, and thus the robot outer wall and a robot working plane form a negative-pressure cavity; and the robot is provided with a pressure controlling device. The negative-pressure self-adaptive adjusting device is mainly applied to the fields of robot technology and automatic control.

Owner:湖南千智机器人科技发展有限公司

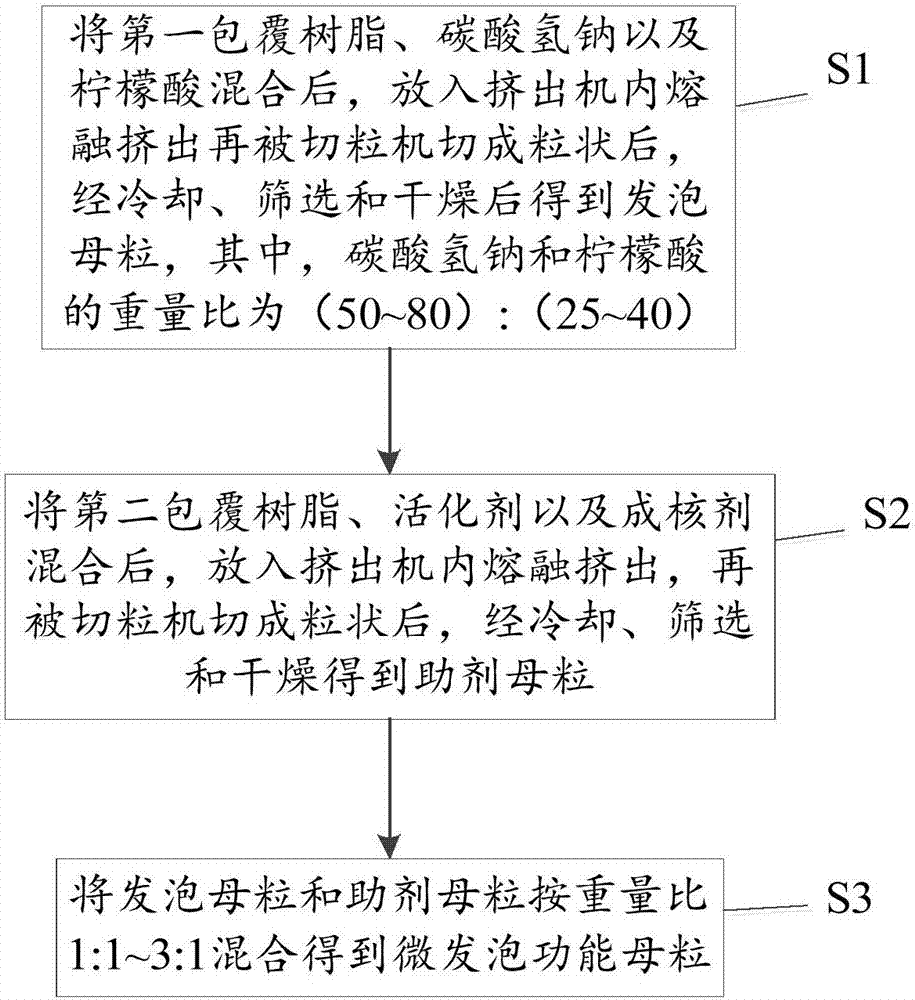

Micro foaming functional masterbatch composition and preparation method thereof, and refrigerator foam board

The invention discloses a micro foaming functional masterbatch composition and a preparation method thereof, and a refrigerator foam board. The micro foaming functional masterbatch composition is formed by mixing a foaming masterbatch and an additive masterbatch according to the weight ratio of 1:1-3:1; the foaming masterbatch comprises a first coating resin, and sodium bicarbonate and citric acid which are dispersed in the first coating resin, and the weight ratio of sodium bicarbonate to citric acid is (50-80) to (25-40); the additive masterbatch comprises a second coating resin, and an activating agent and a nucleating agent which are dispersed in the second coating resin. The two endothermic foaming agents comprising environmental-protection food-grade inorganic foaming agents sodium bicarbonate and citric acid are compounded in proper proportion, environmental protection and no pollution are achieved, and the foaming process can absorb heat in the environment, so that the temperature of a structural member as a substrate is reduced and the deformation of the structural member is prevented; at the same time, citric acid can facilitate improvement of the gas generation amount of sodium bicarbonate, foaming is allowed to be more uniform and stable, and smaller foam aperture is achieved.

Owner:HEFEI HUALING CO LTD +2

Efficient energy-saving humidification air purifier

InactiveCN106016480AIncrease the air intakeLow powerLighting and heating apparatusHeating and ventilation casings/coversAir cleaningAir volume

The invention relates to the technical field of air purifying, in particular to an efficient energy-saving humidification air purifier. The efficient energy-saving humidification air purifier comprises a lower shell body and an upper shell body; four electric heating bars are annularly arranged on the bottom surface of an inner cavity of the lower shell body; the side wall of the lower shell body is axially provided with a plurality of air inlet sets; the inner cavity of the lower shell body is fixedly provided with an axial flow fan through a fixed framework, and air inlets are located below the axial flow fan; and a filter is fixedly arranged on the wall of an inner cavity of the upper shell body, and a top cover of the upper shell body is radially provided with seven rows of air outlet hole sets. The efficient energy-saving humidification air purifier has the beneficial effects that the air inlet amount and the air outlet amount are increased by optimizing the structure of the air inlets and the structure of air outlet holes, and the power of the fan is greatly reduced, so that the electricity energy is saved, and noise is lowered; humidification air is filtered through a filtering element, and not only can various harmful substances and heavy metal be adsorbed, but also deodorization and sterilization effects are achieved; and accordingly the quality of the humidification air is ensured. The efficient energy-saving humidification air purifier has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:DIQIUCUN TONGYI TECH SHENZHEN CO LTD

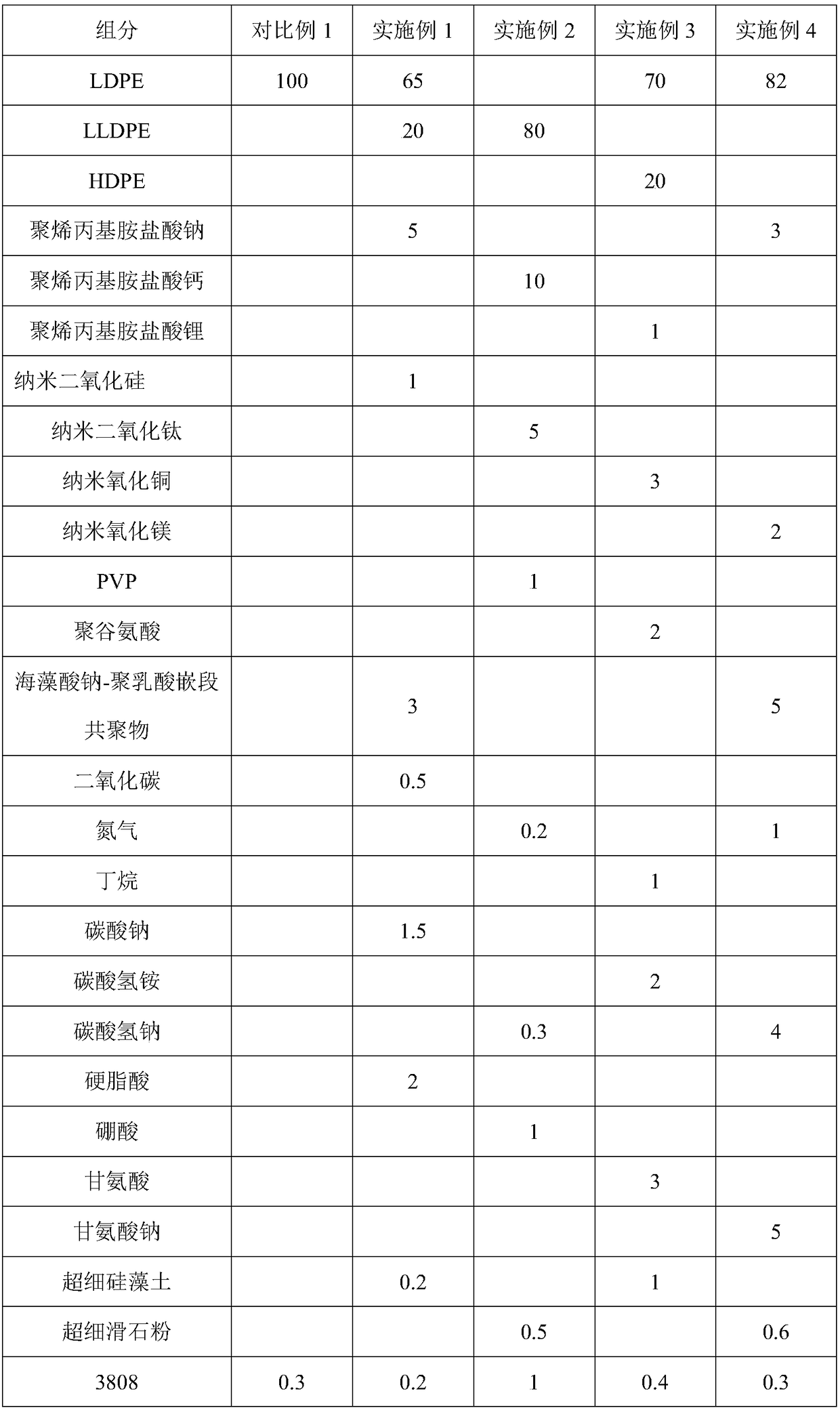

Easy-care micro-foam film packaging paper material and preparation method thereof

The invention relates to film packaging paper and a preparation method thereof, in particular to an easy-care micro-foam film packaging paper material and a preparation method thereof. The easy-care micro-foam film packaging paper material is made from, by weight, 80-90 parts of polyethylene, 1-10 parts of polyallyamine hydrochloride, 1-5 parts of nano oxides, 1-5 parts of an amphiphilic block copolymer, 0.5-5 parts of a foaming agent, 0.2-1 part of an anti-adhesion agent, 1-5 parts of a foaming aid, and 0.5-2 parts of other aids. The preparation method of the easy-care micro-foam film packaging paper material is also disclosed. The easy-care micro-foam film packaging paper material has the advantages of good melt forming tensile property, small foam cell diameter, high cell density, foamfilm thickness reaching 20 micrometers and below, light weight, high tensile strength, high tear resistance, and excellent heat resistance, and is applicable to the field of packaging having the requirement on the temperature of 80 DEG C and above; the easy-care micro-foam film packaging paper material is environmentally friendly and biodegradable, has excellent oil barrier property and has good adhesion with paper, and production efficiency is high as film surface post-treatment is omitted.

Owner:NANJING JULONG SCI&TECH CO LTD

Calcium carbide powder molding equipment

The invention discloses calcium carbide powder molding equipment. The calcium carbide powder molding equipment comprises a taper hopper, wherein two extrusion dies which are driven by power equipment to rotate in opposite directions and are extruded mutually are arranged below the taper hopper; an outlet in the lower end of the taper hopper directly faces the extruded parts of the two extrusion dies; a plurality of concave dies are arranged on the outer surfaces of the two extrusion dies; the two extrusion dies are both mounted in a protection casing provided with an inner cavity filled with nitrogen. The calcium carbide powder molding equipment can be used for safely preparing calcium carbide balls or calcium carbide blocks and inhibits flying of calcium carbide powder dust, the prepared calcium carbide balls or calcium carbide blocks are put into an acetylene production kettle for recycling, the reaction rate is uniform, the amount of gas evolution is high, and the economic benefit is increased.

Owner:郭蓉

Preparation method of durable liquid silica gel

The invention discloses a preparation method of durable liquid silica gel, and belongs to the technical field of silica gel. The durable liquid silica gel comprises the following components of vinyl-terminated side-chain vinyl silicone oil and a catalyst are used as a component A, vinyl-terminated side-chain vinyl silicone oil and a cross-linking agent are used as a component B, and low-molecular-weight polyethylene glycol is added into the component B as a stabilizer to ensure the stability and transparency of a product, and gamma-aminopropyl triethoxy silane, modified sodium bicarbonate and hydrogen-containing silicone oil are added. The preparation method of the durable liquid silica gel comprises the following steps: mixing the component A and the component B according to a ratio of 1: 1, volume ratio or weight ratio, and then directly using. Through the synergistic effect of the gamma-aminopropyl triethoxy silane, the modified sodium bicarbonate and the hydrogen-containing silicone oil, the tensile strength and the tensile elongation at break of the liquid silica gel are improved.

Owner:深圳精灿材料技术有限公司

Flame retardant foam plastic and preparation method thereof

ActiveCN108559193AReduce the temperatureSuppress generationDimethyl methylphosphonatePolymer science

The invention discloses flame retardant foam plastic and a preparation method thereof, and relates to the technical field of foam plastic preparation. The plastic is prepared from, by weight, 76-84 parts of polystyrene, 12-16 parts of flame retardants, 5-8 parts of binder, 6-9 parts of lubricant, 4-8 parts of foaming agent and 0.5-0.8 part oftalc, the flame retardant is formed by mixing a mixtureA and a mixture B according to the mass ratio of 1:2, the mixture A is formed by mixing anhydrous phosphoric acid, tris(2-chloroethyl) phosphate and dimethyl methylphosphonate at a mass ratio of 2:1:1, and the mixture B is obtained by mixing decabromodiphenylethane and magnesium hydroxide at a mass ratio of 1:2. The plastic solves the problem that foam plastic has poor flame retardancy, and the flame retardant which is a mixture of the mixture A and the mixture B is added to raw materials, thereby improving the flame retardancy of the foam plastic.

Owner:青岛文宝泡塑包装有限公司

Preparation method of XPE foaming agent

The invention discloses a preparation method of XPE foaming agent, which comprises the steps of S1, mixing 100 parts by weight of azodicarbonamide, 1 part by weight of zinc stearate and 1 to 5 parts by weight of foaming activator, and grinding until the median particle size is 3 to 15 microns; S2, mixing 100 parts by weight of the auxiliary foaming agent and 1 part of zinc stearate, and grinding to a powder with a median particle size of 3-15 microns; S3, stirring and mixing 40 parts by weight of gaseous phase silica and 60 parts by weight of auxiliary crosslinking agent for 10 to 20 minutes;S4, respectively taking 100 parts of the finished product obtained in the step S1, 0-20 parts of the finished product obtained in the step S2 and 4-10 parts of the finished product obtained in the step S3 and mixing for 5-10 minutes, then adding 0-10 parts by weight of liquid oil to continue mixing for 5-10 minutes. The XPE foaming agent prepared by the preparation method of the invention has widefoaming temperature range and large operability elasticity; after foaming, the cell fineness is good, and the product surface is smooth and delicate and the foaming rate is high.

Owner:浙江杰上杰新材料股份有限公司

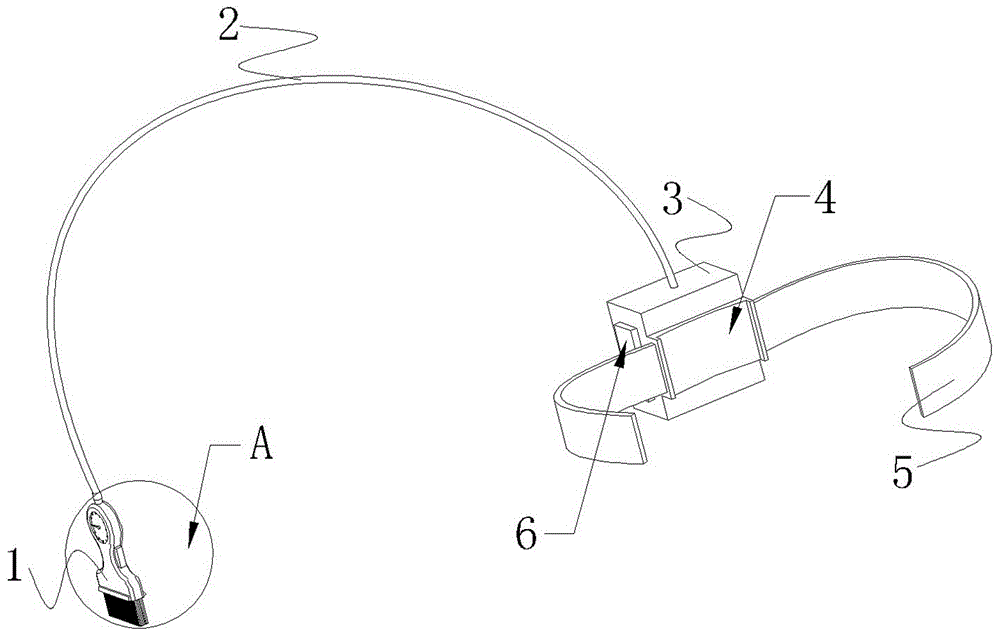

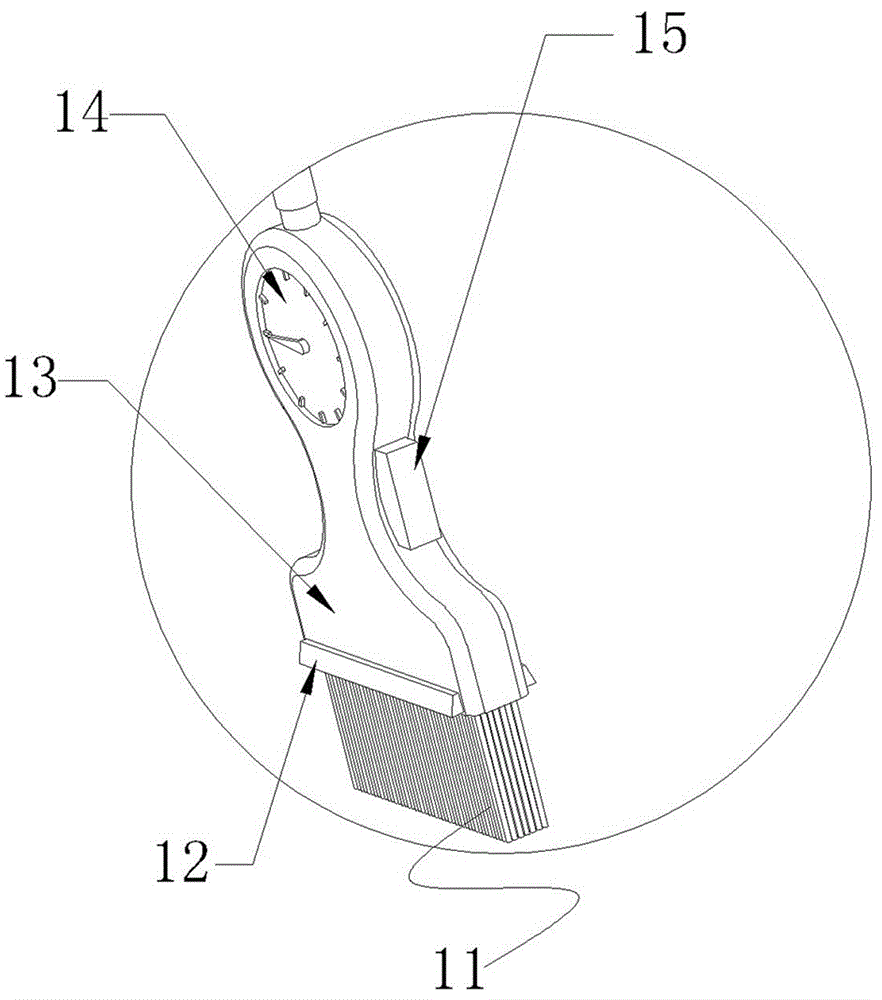

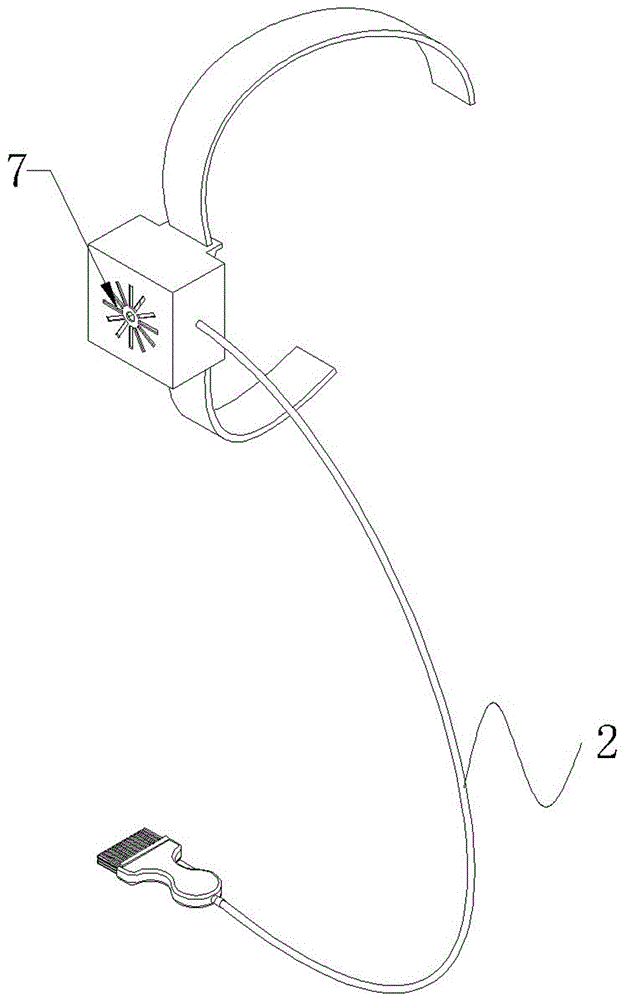

Portable archaeological cleaning device

The invention discloses a portable archaeological cleaning device of a field of archaeological appliance, including a hand-held brush, an air tube and an air-supply device. The hand-held brush includes a brush holder, a brush body and bristles; an end of the brush body is connected with bristles, and the other end of the brush body is connected with the brush holder fixedly; cavities are arranged in the brush body and the brush holder; an air valve is arranged on the brush holder; air holes are provided through the brush bristles, and the air holes are connected with the cavities. The air-supply device comprises of a shell body, wherein a gas compressor and a battery are arranged in the shell body; the gas compressor is connected with the brush holder through the air tube; a ventilated window is arranged on the shell body; a control switch is arranged on the outer wall of the shell body; the output end of the battery is connected with the control switch in a series way, and the output end of the control switch is connected with the gas compressor in a series way; a belt is connected with the outer wall of the shell body. The portable archaeological cleaning device combines the hand-held brush and high pressure air, which not only remains the function of loosening impurities by using brush bristles to rub surfaces of cultural relics, but increases the function of quickly cleaning loose impurities by using high pressure air.

Owner:务川仡佬族苗族自治县文化遗产保护中心

Preparation method of high-strength centrifugal casting precoated sand

InactiveCN111957879ASimple preparation processGood value for moneyFoundry mouldsFoundry coresPtru catalystSlurry coating

The invention discloses a preparation method of high-strength centrifugal casting precoated sand and belongs to the technical field of casting materials. The high-strength centrifugal casting precoated sand prepared through the preparation method is low in gas evolution amount requirement and low in gas evolution speed, and has the characteristics of high temperature resistance, high strength, lowexpansion, low gas evolution, slow gas evolution, easy collapsibility, oxidation resistance, heat resistance and the like. The high-temperature-resistant precoated sand is formed by centrifugal slurry coating and precoating of a polyphosphazene derivative, polydivinyl acetylene and poly-2,6-dibromophenyl ether in the presence of a polymerization catalyst and a curing accelerator, the preparationmethod is simple and convenient, raw materials are wide in source, and the prepared centrifugal casting precoated sand with excellent high-temperature performance and comprehensive casting performanceis suitable for being applied to casting of seamless steel tubes, roller ways, cylinder sleeves, rollers, bearing bushes and the like.

Owner:和县华顺铸造有限公司

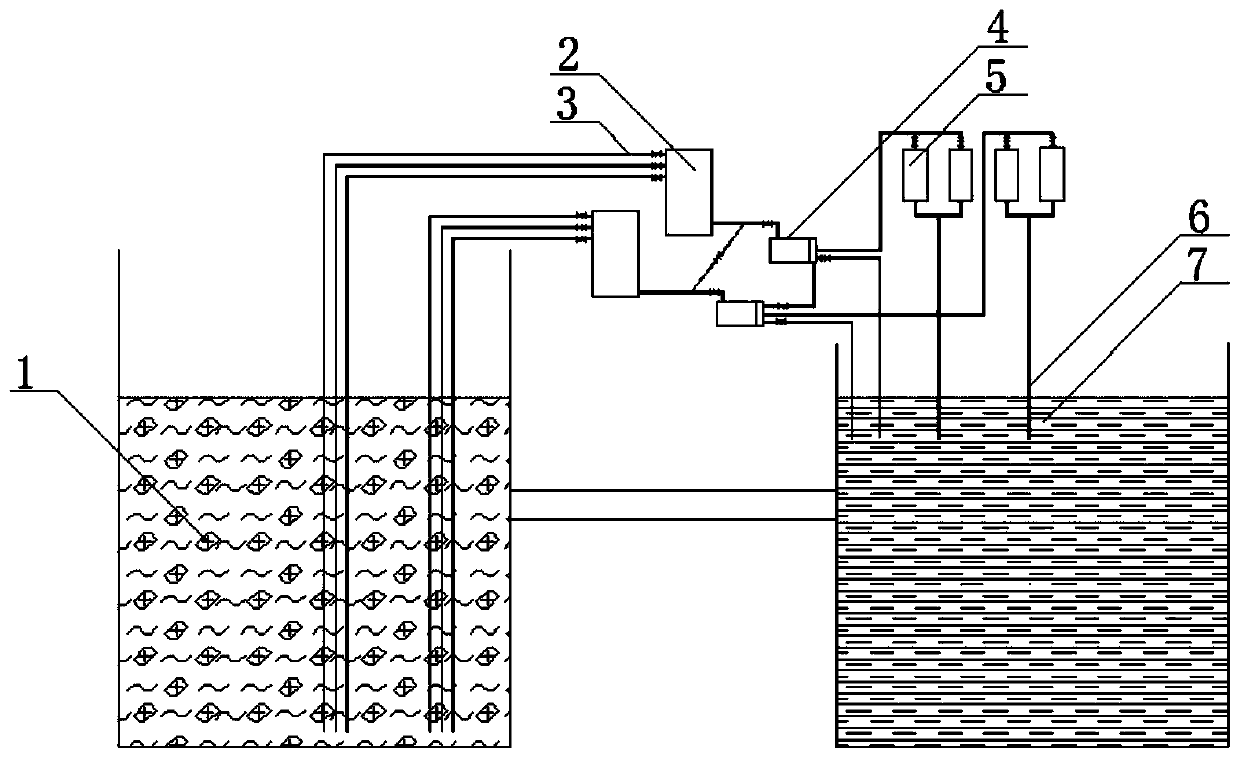

Heat energy reutilization system of methane generator

InactiveCN102367753AIncrease contact areaEfficient use ofLiquid coolingGas production bioreactorsWater dischargeEngineering

The invention discloses a heat energy reutilization system of a methane generator and relates to the technical field of energy reutilization. The heat energy reutilization system of the methane generator is characterized in that the generator, a methane tank and a radiator are mutually connected through a water circulation pipeline, cold water in the radiator enters into an engine for taking out heat in the engine and further enters into the methane tank through the water circulation pipeline, hot water in the water circulation pipeline can perform heat release on the methane tank and further flows into the radiator for completing the circulation process, a fan is arranged on the water circulation pipeline between the radiator and the methane tank, if the temperature of the water discharged from the methane tank is higher, the fan is started for performing fast cooling, and a power supply of the fan is from electric energy emitted by the generator. The heat energy reutilization system of the methane generator can effectively utilize the heat emitted by the generator, increase the temperature in the methane tank, greatly improve the gas output, effectively and reasonably utilize resources, avoid pollution and be in line with the development needs of a harmonious society.

Owner:安徽汇展热交换系统股份有限公司

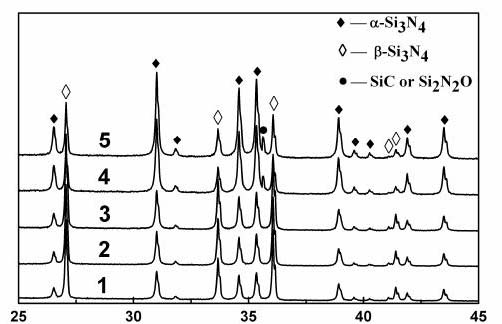

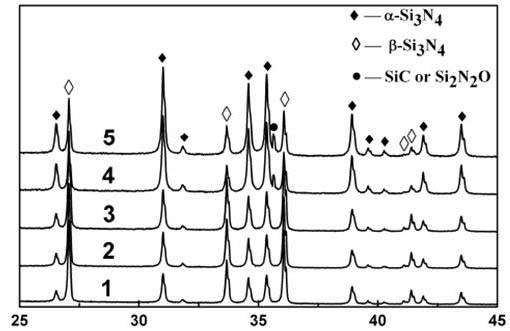

Method for rapidly combusting and synthesizing silicon nitride powder by using foaming agent capable of producing nitrogen while decomposing as additive

The invention discloses a method for rapidly combusting and synthesizing silicon nitride powder by using a foaming agent capable of producing nitrogen while decomposing as an additive, which comprises the following steps: in the rapid combustion and synthesis process of silicon nitride, the foaming agent capable of producing nitrogen while decomposing is taken as an auxiliary agent; the foaming agent possesses the purity greater than 99% and comprises an azo compound, a nitroso compound, a sulfohydrazide compound and the like. The method of the invention has the following beneficial effects: 1) the used foaming agent has the advantages of no toxicity, constant color, no odor, no pollution and insolubility in common solvents; 2) the foaming agent of the invention has the advantages of highgas evolution, small particles and good dispersibility; 3) the foaming agent is selected as nitrogen source, so that production security is increased, and the raw material cost is reduced; and 4) thefoaming agent discharges a lot of heat while decomposing, so that the combustion and synthesis reaction can be carried out with a faster reaction rate, the instability problem during the combustion process can be solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

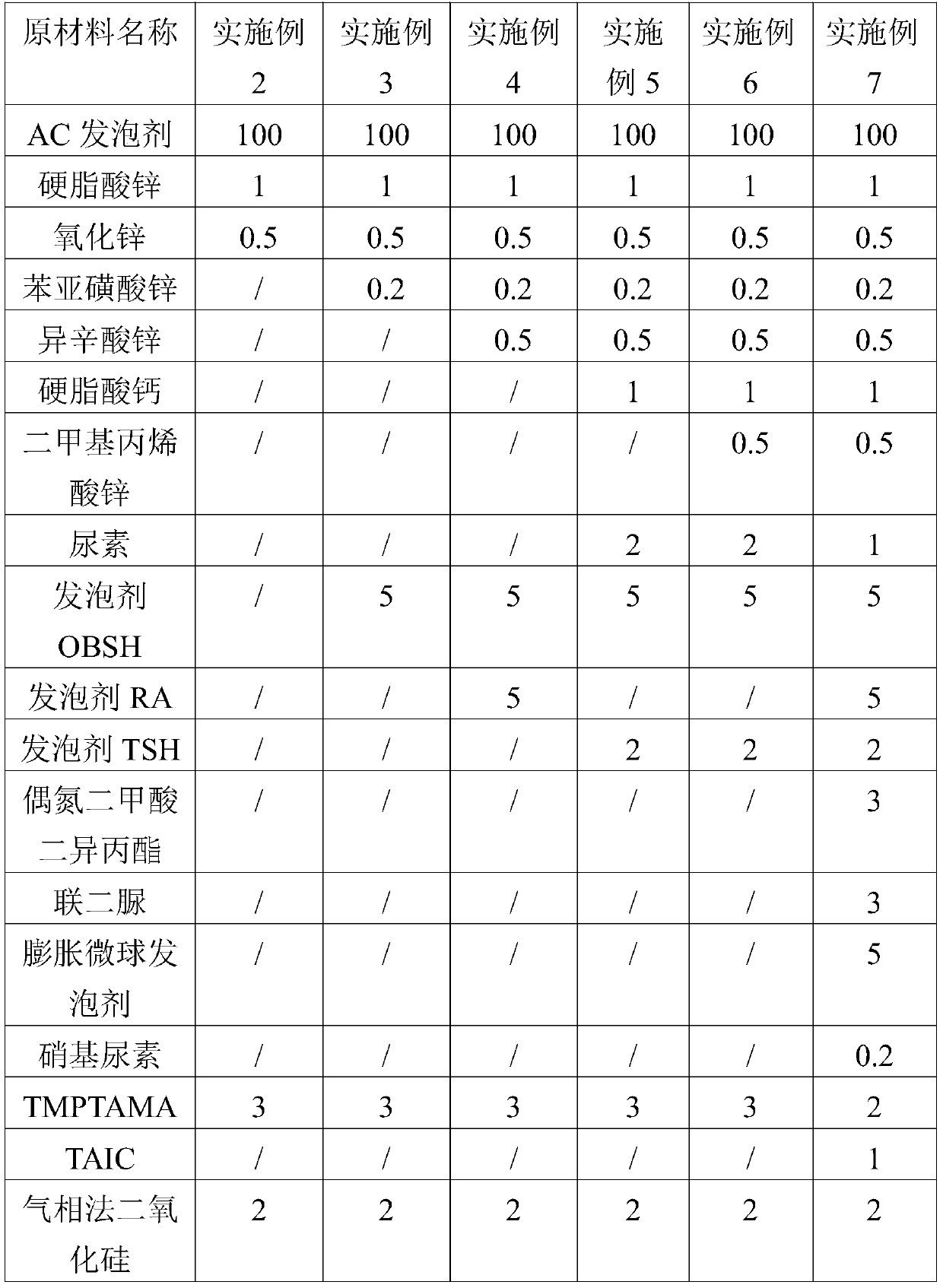

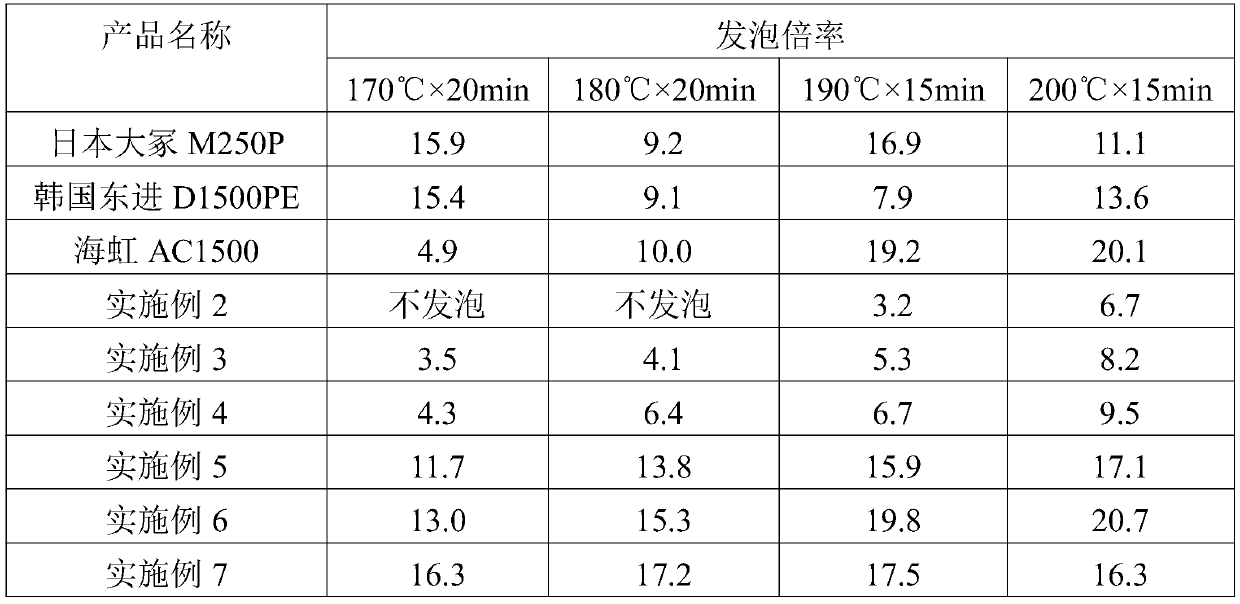

Foaming agent compound for low-temperature decomposition of expanding rubber and preparation method of foaming agent compound

The invention discloses a foaming agent compound for low-temperature decomposition of expanding rubber, the foaming agent compound comprises a foaming component and an activating auxiliary agent, the foaming component is composed of one or more of an AC foaming agent, an OBSH foaming agent, an H foaming agent, a TSH foaming agent and a sodium bicarbonate foaming agent, the activating auxiliary agent is composed of one or more of a zinc compound, a weak acid salt of sodium, a treated urea auxiliary agent, aromatic sulfinate and stearic acid; according to the invention, azodicarbonamide and the low-temperature foaming agent are compounded, a plurality of activators are matched, and the foaming agent compound which is suitable for industrial application at 150 DEG C, is completely decomposed within 5 minutes and has the gas generation amount higher than 180ml / g is prepared through blending and grinding processes, so that the expanding rubber can reach a higher foaming ratio at a lower temperature, and sagging and foaming height are considered. Meanwhile, bubbles in the expanding rubber are uniformly dispersed, the surface of the expanding rubber is smooth and fine, and the cost performance is high.

Owner:WUHU HAICHENG RUBBER & PLASTIC

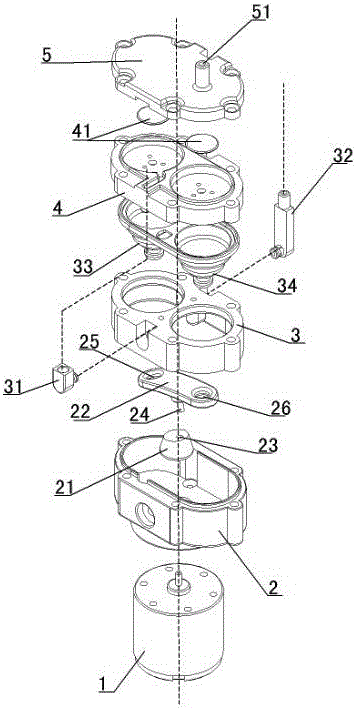

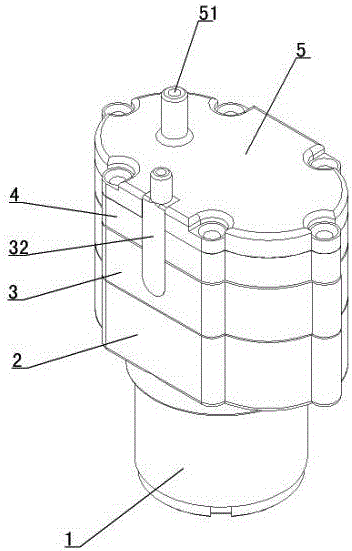

Electronic wobble pump

InactiveCN106286205AEasy to swing and rotateIncrease vacuumPositive displacement pump componentsPiston pumpsCylinder blockValve seat

The invention relates to an electronic wobble pump. The electronic wobble pump comprises a motor, a motor seat, a cylinder body, a valve seat and a pump cover as well as an eccentric wheel which is arranged on the motor seat, wherein the eccentric wheel is connected with wobble support; the cylinder body is provided with a valve, an air inlet, a first piston and a second piston; the valve seat is provided with two valve plates, and the pump cover is provided with an air outlet. When in work, the motor provides power to drive the eccentric wheel to rotate, the eccentric wheel drives the wobble support to rotate and swing, the wobble support first pushes the first piston in the swinging process, so that air enters the cylinder body via the air inlet to be primarily compressed by the first piston, then the wobble support pushes the second piston, the air is secondarily compressed by the second piston, and finally the compressed air is discharged from the air outlet via the valve seat and the pump cover; and the two valve plates mainly play an intermediate obstruction role in air suction and exhaustion, so that the air orderly circulates, the air output is increased, the noise is low, and safety and reliability can be realized. The appearance size of a real product is only 85mm*61mm*36mm, the principle is ingenious and unique, and the electronic wobble pump is particularly suitable for an oxygen generator to use.

Owner:周纪昌

Calcium carbide powder forming equipment and process for machining calcium carbide powder into calcium carbide balls or blocks

InactiveCN104228110AConvenient mixing and conveyingEasy to transportShaping pressPowder mixtureNitrogen

The invention discloses calcium carbide powder forming equipment and a process for machining calcium carbide powder into calcium carbide balls or blocks. The equipment comprises a taper hopper. A pair of extrusion dies is disposed below the taper hopper. The extrusion dies are driven by power equipment to rotate along opposite directions and extrude each other. The lower-end outlet of the taper hopper faces directly to the extruding part of the two extrusion dies. A plurality of female dies are disposed on the outer surface of each extrusion die. The two extrusion dies are mounted in the cavity, filled with nitrogen, of a protective shell. Collected calcium carbide powder and mixed materials are mixed and then fed into the taper hopper, and the calcium carbide powder mixture enters the extrusion dies and is extruded by the female dies of the two extrusion dies to form the calcium carbide balls or blocks. By the calcium carbide powder forming equipment, the calcium carbide balls or blocks can be manufactured safely, calcium carbide powder dust flying is inhibited, the manufactured calcium carbide balls or blocks can be reused in acetylene generating kettles, even reaction speed and high gas generating quantity, and economical benefits are increased.

Owner:亿绿兰德(北京)技术有限公司

Process for producing high-gloss melamine veneer with solid wood effect

ActiveCN103465337AImprove bindingIncrease the number ofNon-fibrous pulp additionWood working apparatusSolid woodMelamine formaldehyde resin

The invention relates to the technical field of machining of decorative plates, in particular to a process for producing a high-gloss melamine veneer with a solid wood effect. According to the process, a part of silane coupling agent is introduced into a modified melamine formaldehyde resin, so that the bonding capability of an inorganic matter such as a resin adhesive and a fibrous layer is improved, the capability of bonding with a finishing varnish also is improved, a lifelike texture effect is achieved, and the problems of weak adhesive force and high cracking rate after the finishing varnish is sprayed onto the melamine veneer also are solved.

Owner:天津市瑞鸿装饰材料销售有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com