Micro foaming functional masterbatch composition and preparation method thereof, and refrigerator foam board

A technology of functional masterbatch and foaming masterbatch, which is applied in the field of refrigerator foam board, microfoaming functional masterbatch composition and its preparation, which can solve the problems of microfoaming material stress, substrate thermal deformation, etc., and achieve The effect of uniform and stable foaming, reducing internal stress, and small foaming pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

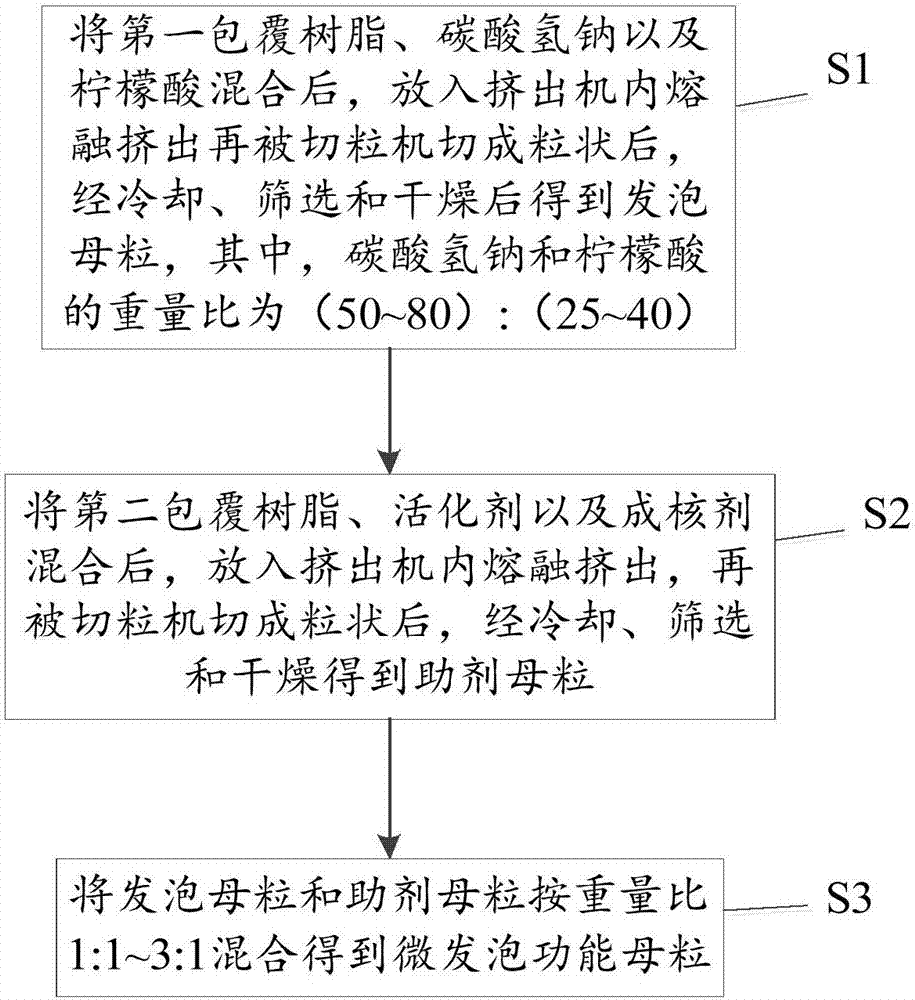

[0034] In addition, the present invention also provides a preparation method of a micro-foaming functional masterbatch composition, the preparation process of the micro-foaming functional masterbatch composition adopts mixing, extrusion, cutting and cooling methods, and adopts the method of melt extrusion, The compound form of twin-screw extruder and single-screw extruder is used, that is, twin-screw extrusion feeds, and single-screw extrusion pelletizes. Specifically, see figure 1 , the preparation method of micro-foaming functional masterbatch composition comprises the following steps:

[0035] S1. After mixing the first coating resin, sodium bicarbonate and citric acid, put them into the extruder to melt and extrude, then cut into pellets by a pelletizer, cool, screen and dry to obtain foam masterbatches, Wherein, the weight ratio of sodium bicarbonate and citric acid is (50~80):(25~40);

[0036] S2. After mixing the second coating resin, activator and nucleating agent, p...

Embodiment 1

[0041] A micro-foaming functional masterbatch composition, which is formed by mixing a foaming masterbatch and an auxiliary masterbatch at a weight ratio of 2:1, and the raw materials of the foaming masterbatch include 35 parts by weight of LDPE resin, sodium bicarbonate 65 parts and 35 parts of citric acid, the raw materials of the additive master batch include 35 parts of POE, 0.6 parts of stearic acid, 0.7 parts of talcum powder and 0.6 parts of siloxane in parts by weight.

[0042] The preparation method of this micro-foaming functional master batch composition comprises the following steps:

[0043] S1. After mixing 35 parts of LDPE resin, 65 parts of sodium bicarbonate and 35 parts of citric acid in a mixer at high speed for 25 minutes, put them into a twin-screw extruder and melt them under the technological conditions of 135°C and main screw speed of 30r / min Extrusion, the molten material extruded from the twin-screw flows into the single-screw extruder, and the molten...

Embodiment 2

[0047] A micro-foaming functional masterbatch composition, which is formed by mixing a foaming masterbatch and an auxiliary masterbatch at a weight ratio of 1:1, and the raw materials of the foaming masterbatch include 20 parts by weight of LDPE resin, sodium bicarbonate 50 parts and 25 parts of citric acid, the raw materials of the additive master batch include 20 parts of POE, 0.2 parts of stearic acid, 0.5 parts of talcum powder and 0.1 part of siloxane in parts by weight.

[0048] The preparation method of this micro-foaming functional master batch composition comprises the following steps:

[0049] S1. After mixing 20 parts of LDPE resin, 50 parts of sodium bicarbonate and 25 parts of citric acid in a mixer at high speed for 15 minutes, put them into a twin-screw extruder and melt them under the technological conditions of 120°C and main screw speed of 20r / min Extrusion, the molten material extruded from the twin-screw flows into the single-screw extruder, and the molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com