Patents

Literature

93results about How to "High refractory temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof material, preparation method thereof and fireproof door

The invention discloses a fireproof material. The fireproof material is prepared from the following raw materials in parts by weight: 35 to 70 parts of black mud powder or 10 to 45 parts of furnace slag or mixture of the black mud powder and the furnace slag, 10 to 50 parts of red silica powder or quartzitic sandstone power, 5 to 15 parts of kyanite powder or andalusite powder or sillimanite powder, 1 to 4 parts of zirconium silicate powder or yttrium-stabilized zirconia powder, 5 to 15 parts of cement, 3 to 5 parts of sodium hexametaphosphate, 3 to 5 parts of fibers, 0.5 to 1 part of aluminum sol or yttrium sol, and the balance being water and animal composite foaming agent. The invention also provides a preparation method for the fireproof material, and a fireproof door made from the fireproof material. The fireproof material is high in refractory temperature, low in manufacturing cost and simple in preparation method. The fireproof door is simple in structure, easy to produce, longin refractory time, high in refractory temperature, low in production cost and stable in quality.

Owner:汪洋

Fireproof and pressure-resistant artificial quartz stone plate and preparation method thereof

The invention discloses a fireproof and pressure-resistant artificial quartz stone plate and a preparation method thereof. The fireproof and pressure-resistant artificial quartz stone plate is composed of the following components in parts by weight: 30-80 parts of 8-100-mesh quartz stone, 20-50 parts of 325-1250-mesh quartz powder, 5-15 parts of broken glass, 5-10 parts of unsaturated polyester resin, 10-20 parts of 50-100-mesh white afrodite powder, 10-20 parts of 100-150-mesh andalusite powder, 3-8 parts of fibers, 0.3-0.5 part of an adjuvant and 0.1-2 parts of pigment. The artificial quartz stone plate disclosed by the invention not only has excellent fireproof performance, but also has stronger breaking strength, compressive strength and bending strength; in addition, the preparation cost is low, and the preparation method is simple and is suitable for industrial production.

Owner:田忠和

Artificial quartz stone sheet and preparation method thereof

The invention discloses an artificial quartz stone sheet and a preparation method thereof. The artificial quartz stone sheet comprises the following components in parts by weight: 30-90 parts of 6-80mesh calcined quartz sand, 30-70 parts of 325mesh quartz powder, 5-15 parts of broken glass, 3-10 parts of 30-50mesh tourmaline, 3-12 parts of 50-100mesh sillimanite powder, 3-12 parts of 100-200mesh zirconium silicate powder, 5-10 parts of unsaturated resin, 0.3-2 parts of a silane coupling agent, 0.3-2 parts of a curing agent and 0.1-1 part of a pigment. By the calcined quartz sand, the hardness of the artificial quartz stone sheet is increased so that the artificial quartz stone sheet resists wear and is difficult to be scratched; tourmaline is added so as to increase the antimicrobial property of the artificial quartz stone sheet and meanwhile, sillimanite powder and zirconium silicate powder are added to improve the fireproof performance of the artificial quartz stone sheet.

Owner:田忠和

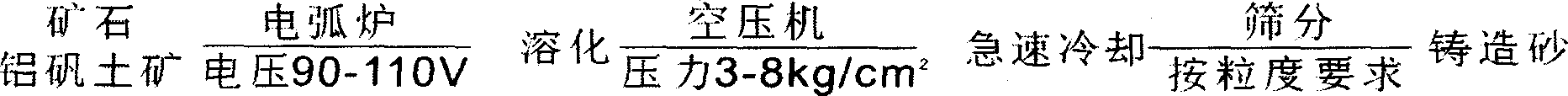

Novel artificial casting sand and its preparing method

InactiveCN1899722ASatisfy the refractory temperature requirementHigh refractory temperatureFoundry mouldsFoundry coresElectric arc furnaceCoesite

The present invention is technological process of producing artificial casting sand and its application. The artificial casting sand is produced with bauxite ore containing Al2O3 in 45-90 % as material in an arc furnace. Bauxite ore material is first smelted in an arc furnace, and the outflow liquid is applied with air pressure of 3.0-8.0 kg / sq cm to be crushed, so that spherical casting sand with smooth surface is obtained. The artificial casting sand may be used for molding together with furan resin, phenolic resin, water glass, etc. The present invention has the features of environment friendship, high heat resistance, high strength, low heat expansion, low production cost, etc.

Owner:刘满对 +1

Fireproof door core plate and making method thereof

InactiveCN107162633AImprove fire resistanceImprove thermal insulationFireproof doorsCeramicwareFiberThermal insulation

The invention discloses a fireproof door core plate and a making method thereof, and relates to the technical field of door cores. The fireproof door core plate comprises 55-65 parts of a polymer matrix, 45-55 parts of desulfurized gypsum, 40-43 parts of borax, 37-38 parts of anhydrous magnesium chloride, 32-34 parts of cenosphere, 30-32 parts of a filler material, 26-28 parts of refractory particles, 20-23 parts of reinforcing fibers, 17-19 parts of wood powder, 16-18 parts of phosphonate, 10-15 parts of an assistant, 4-10 parts of stearic acid and 60-63 parts of water. The fireproof door core plate has the advantages of good fire resistance, good thermal insulation resistance, light weight, high strength and easiness in fragmentation.

Owner:合肥市旺友门窗有限公司

Artificial quartzite plate and manufacturing method thereof

InactiveCN104496273AImprove antioxidant capacityImproves UV protectionAntioxidantAntibacterial property

The invention discloses an artificial quartzite plate and a manufacturing method thereof. The artificial quartzite plate is composed of the following components in parts by weight: 30-90 parts of 3-80-mesh quartzite, 30-70 parts of 325-mesh quartz powder, 5-15 parts of cullet, 3-10 parts of 30-50-mesh tourmaline, 3-12 parts of 50-100-mesh sillimanite powder, 3-12 parts of 100-200-mesh zirconium silicate powder, 0.1-2 parts of antioxidant, 5-10 parts of unsaturated resin, 0.3-2 parts of silane coupling agent, 0.3-2 parts of curing agent and 0.1-1 part of pigment. The antioxidant is added to the raw materials, thereby enhancing the oxidation resistance and ultraviolet resistance of the artificial quartzite plate. The tourmaline is added to the raw materials to effectively enhance the antibacterial property of the artificial quartzite plate, and thus, the artificial quartzite plate has long antimicrobial effect. The sillimanite powder and zirconium silicate powder, which are favorable refractory materials with very high melting point and hardness, can enhance the refractory temperature of the artificial quartzite plate, prolong the refractory time and increase the compression strength.

Owner:田忠和

Fireproof manmade quartz stone slab with superhardness and manufacturing method of fireproof manmade quartz stone slab

The invention discloses a fireproof manmade quartz stone slab with superhardness and a manufacturing method of the fireproof manmade quartz stone slab. The manmade quartz stone slab is manufactured from the following components in parts by weight: 30-80 parts of 6-80-mesh calcined quartz stones, 30-60 parts of 325-mesh quartz powder, 5-10 parts of cullet, 10-20 parts of 50-100-mesh red-silica powder or quartzitic sandstone powder, 5-15 parts of 100-150-mesh kyanite powder or andalusite powder or sillimanite powder, 1-10 parts of 100-200-mesh zirconium silicate or yttria-stabilized zirconia powder, 5-10 parts of unsaturated resins, 0.3-0.5 part of auxiliary, and 0.3-0.8 part of pigment. According to the fireproof manmade quartz stone slab, the red-silica powder, quartzitic sandstone powder, kyanite powder or andalusite powder or sillimanite powder, and zirconium silicate or yttria-stabilized zirconia powder is added in a manufacturing process, so that the compressive property and the fireproof flame retardant performance of the manmade quartz stone slab are improved; meanwhile, by using the calcined quartz stones, the hardness of the manmade quartz stone slab is improved, so that the fireproof manmade quartz stone slab with superhardness is relatively wearproof, difficult to scratch and long in service life.

Owner:田忠和

Method for preparing corundum-mullite saggers

The invention discloses a method for preparing corundum-mullite saggers. The method includes 1), preparing raw materials; 2), preparing pug; 3), carrying out forming and drying; 4), carrying out sintering. The method has the advantages that the corundum-mullite saggers prepared by the aid of the method are excellent in strength, high in applicable temperature and long in service life and are corrosion-resistant, and the problems in the prior art can be effectively solved.

Owner:浙江招通高温材料有限公司

Vulnerable part of welding gun and surface treatment method of vulnerable part

InactiveCN105108403AHigh refractory temperatureSmall specific heat and thermal conductivityMolten spray coatingWelding/cutting auxillary devicesSurface finishingAluminium oxide

The invention discloses a vulnerable part of a welding gun and a surface treatment method of the vulnerable part. The vulnerable part of the welding gun is of a hollow structure and comprises an outer surface and an inner surface. A metal oxide coating is arranged on the outer surface. Metal oxide powder of the metal oxide coating includes 89%-91% of zirconium dioxide powder and 9%-11% of aluminum oxide powder. According to the vulnerable part of the welding gun and the surface treatment method of the vulnerable part, metal oxide powder is sprayed onto the surface of the vulnerable part of the welding gun, zirconium dioxide is high in fire-resistant temperature, small in specific heat coefficient and heat conductivity coefficient, good in comprehensive mechanical property and high in chemical stability, the abrasion resistance of the coating can be improved through aluminum oxide, and the thermal shock resistance is improved; in this way, the surface materials of the vulnerable part can be changed, the coating has a good heat dissipation effect, the temperature of a workpiece can be decreased, the durability and fire resistance of the high-temperature part are remarkably improved, the probability of slag hanging of the workpiece is greatly lowered, and the problem that an airflow path is blocked or wire feeding cannot be achieved due to the fact that the workpiece is burn down or slag hanging occurs is solved.

Owner:常州特尔玛科技股份有限公司

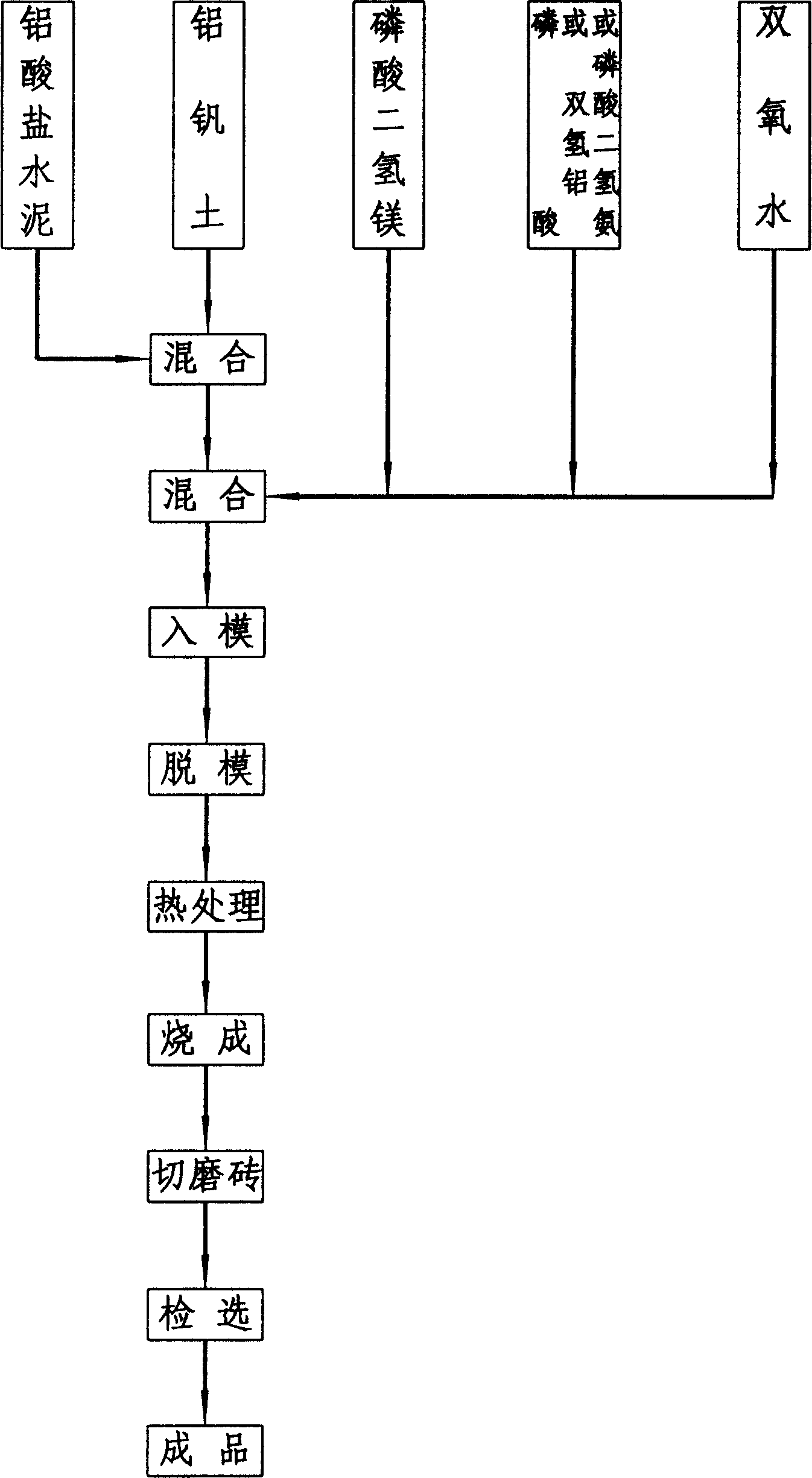

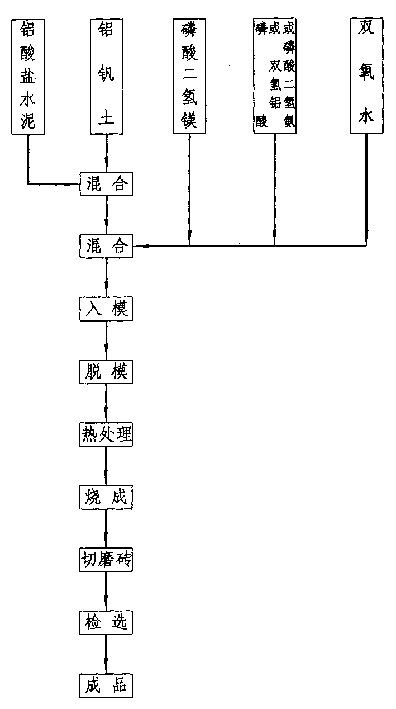

Light fire brick and preparing method thereof

A light-weight refractory brick burnt in tunnel kiln and oil-burning vertical kiln is prepared from bauxite, phosphoric acid, magnesium bihydrogen phosphate, aluminate cement, and H2O2. Said bauxite contains Al2O3 (more than 80%), magnesium oxdie (less than 0.25%), potassium oxide (less than 0.25%), sodium oxide (less than 0.25%), and calcium oxide (less than 0.25%). Its advantages are low cost, high resistance to high temp, high insulating effect, high strength, and long service life.

Owner:李作范

Artificial quartz stone panel and preparation method thereof

The invention discloses an artificial quartz stone panel and a preparation method thereof. The artificial quartz sand panel is prepared from the following components in parts by weight: 30-90 parts of 3-80mesh quartz stones, 20-60 parts of 325mesh quartz powder, 5-15 parts of cullet, 3-10 parts of shells, 3-10 parts of fibers, 3-10 parts of 30-50mesh tourmaline, 3-12 parts of 50-100mesh sillimanite powder, 3-12 parts of 100-200mesh zirconium silicate powder, 5-10 parts of unsaturated resin, 0.3-0.5 part of auxiliaries and 0.3-0.8 part of pigments. According to the artificial quartz stone panel disclosed by the invention, in the preparation process, the fibers and tourmaline are added, so that the compressive property and the antibacterial property of the artificial quartz stone panel are improved and meanwhile, the sillimanite powder and the zirconium silicate powder are added, so that the fireproof performance of the artificial quartz stone panel is improved.

Owner:田忠和

Lines of refractory ceramics fiber and fabricating method

A kind of refractory ceramics fibre line that raw material weight components are high-aluminium mineral cotton 70-80 and nickel sliver 20-25 or high-aluminium mineral cotton 70-80 and stainless steel sliver 20-25. Prodn. method is that said material is composed to ceramics fibre line with diameter 2.5-2.5 mm by common spinning machine.

Owner:李现堂

Zircon mullite saggar

The invention relates to a zircon mullite saggar, belonging to the field of refractory materials, and being used for effectively preventing acid corrosion and alkali corrosion of a lithium solution on a saggar body. For solving the technical problem, the invention adopts the technical scheme that the zircon mullite saggar comprises the following components in percentage by weight: 68-79% of Al2O3, 0.65-18.5% of SiO2, 10-12.7% of ZrO2, 0.2-0.5% of Fe2O3, 0.05-0.1% of CaO and 0.1-0.2% of MgO.

Owner:浙江立鑫高温耐火材料有限公司

Waterproof plastering gypsum and production method thereof

The invention discloses waterproof plastering gypsum and a production method thereof, which relate to the technical field of a plastering material. The waterproof plastering gypsum comprises the following raw materials by parts: 55-65 parts of desulfurized gypsum, 42-44 parts of cement, 38-40 parts of modified kaolin, 32-33 parts of fireproof particles, 26-28 parts of anhydrous magnesium chloride, 24-26 parts of a crystal growth stimulator, 21-23 parts of floating beads, 18-19 parts of an organosilicon water repellent, 15-16 parts of an auxiliary agent, and 65-70 parts of water. The waterproof plastering gypsum has excellent waterproof performance, is not easily damped and shed, and has high stability.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Filled magnesium oxide mineral insulated cable and preparation method thereof

ActiveCN112700930AImprove bearing strengthInsulation performance is not affectedClimate change adaptationApparatus for heat treatmentOxide mineralsMagnetic separator

The invention discloses a filled magnesium oxide mineral insulated cable and a preparation method thereof. The preparation method comprises the following steps of: (1) calcining heavy magnesium oxide powder at a high temperature of 850-950 DEG C to remove impurities, then uniformly mixing the calcinated heavy magnesium oxide powder with potassium tetrafluoroaluminate powder, and placing the mixture in a heat preservation furnace for heat preservation; (2) putting a required wire core material into a copper pipe on an assembly table for blank assembly, and fixing one end of the copper pipe; (3) before filling, adopting a magnetic separator to remove magnetic metal inclusions, then pouring the mixed powder into a gap around the copper core in the copper pipe, and using a tamping mechanism for tamping the mixed powder until the mixed powder is filled well while pouring is conducted; and (4) subjecting the wire core copper pipe filled with the mixed powder to stretching, annealing, stretching again and annealing again until a wire core copper pipe meeting the design specification and size is stretched out. The problems that an existing magnesium oxide powder automatic filling method is low in compactness and poor in impact resistance and uniformity are solved.

Owner:重庆科宝电缆股份有限公司 +1

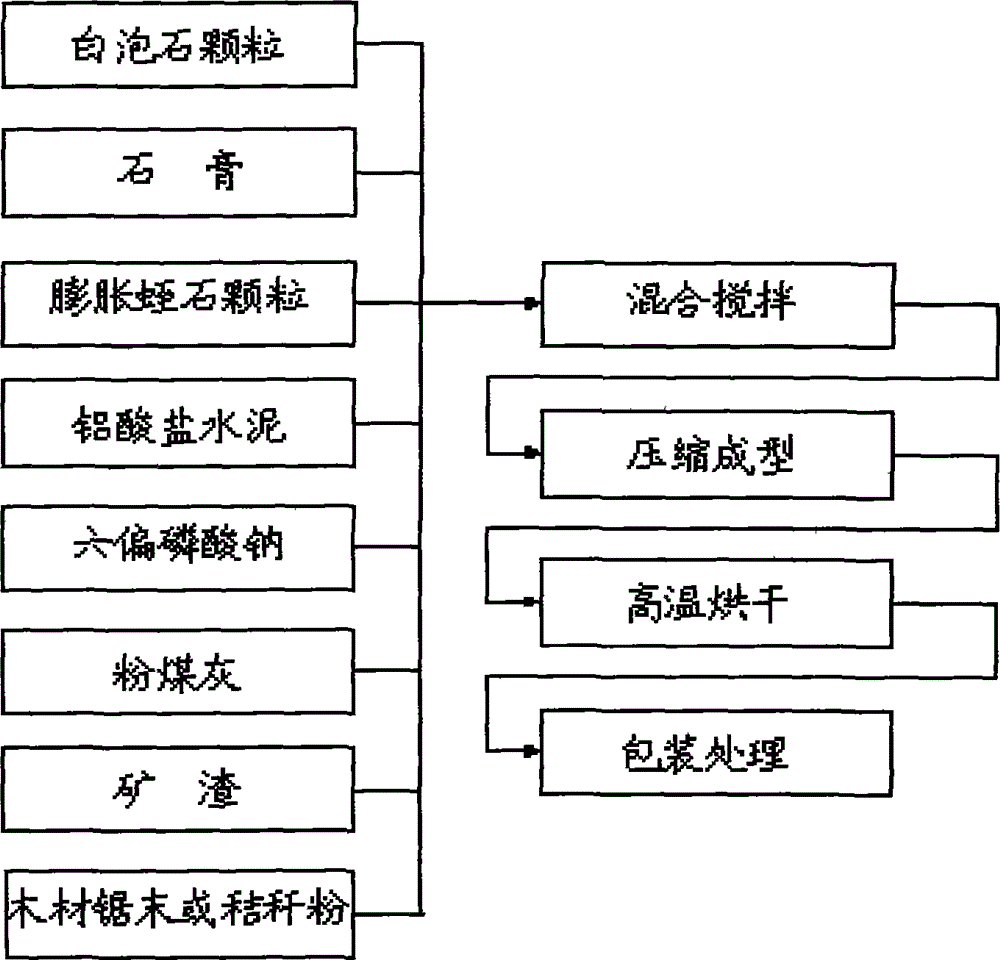

Environmentally-friendly and fireproof door panel and making method thereof

The invention relates to a construction fireproof member, and concretely relates to an environmentally-friendly and fireproof door panel and a making method thereof. The door panel is made through mixing white afrodite particles, gypsum, expanded vermiculite particles, aluminate cement, sodium hexametaphosphate, fly ash, mineral slag, and wood shavings or straw powder, and through molding. The door panel has lightweight and a fireproof function, and is in favor of realizing environmental protection due to use of recovered resources.

Owner:宋伟滨

Porous ceramic with straw as pore forming agent and preparation method of porous ceramic

InactiveCN105732087AIncrease demandIncrease profitCeramicwareClaywaresKaolin clayUltimate tensile strength

The invention provides porous ceramic with straw as a pore forming agent and a preparation method of the porous ceramic. The method comprises the following steps: weighing 47 to 54 parts of kaolin, 10 to 13 parts of industrial alumina, and 36 to 40 parts of talc in parts by weight, mixing with water to prepare a premixed liquid, drying the premixed liquid and sieving to obtain powder, taking 10 to 50 parts of the straw which is pulverized to be mixed with the powder uniformly so as to be pressed into a green body, drying the green body and firing. The method disclosed by the invention not only develops a new way to use crop straw, and reduces the pollution caused by burning the straw to the environment, but also reduces the production cost of porous ceramic material products; produced products are high in apparent porosity, low in volume density, and high in bending strength and fire resistant temperature.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

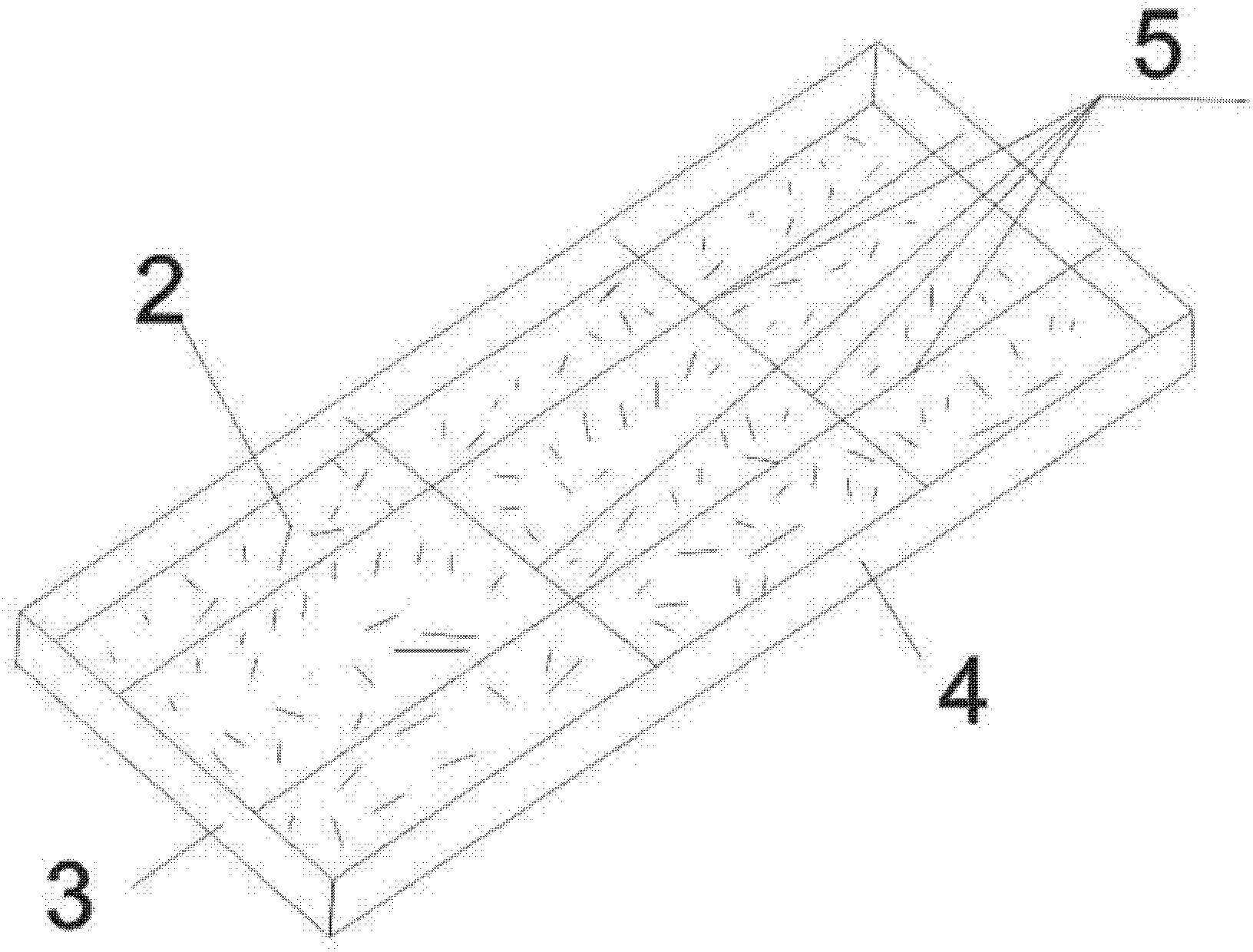

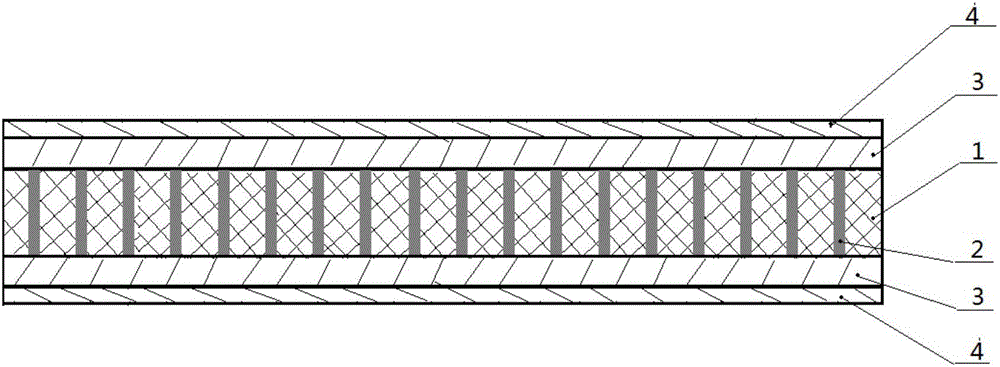

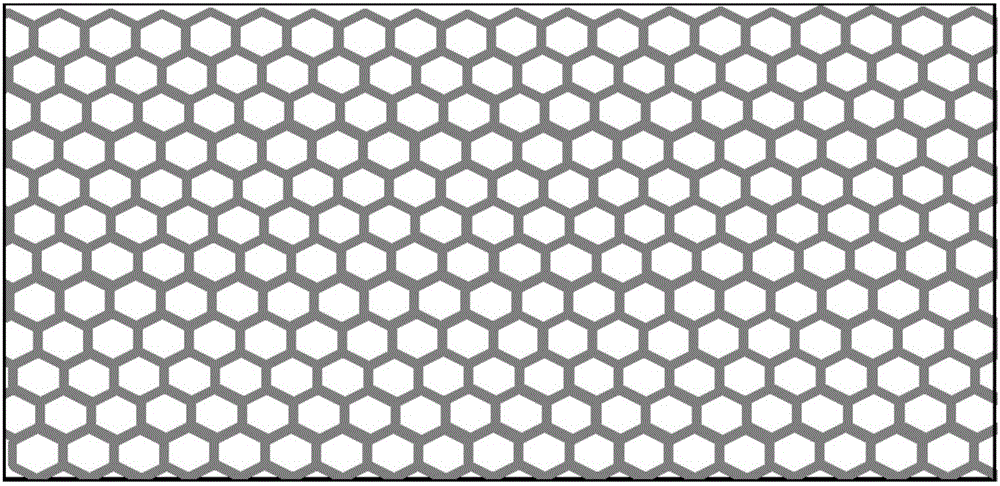

Production method of high-strength thermal-insulation board

InactiveCN105019562AHigh refractory temperatureLow thermal conductivityHeat proofingFire proofingFiberThermal insulation

The invention relates to a high-strength thermal-insulation board. The high-strength thermal-insulation board is of a sandwich structure. A middle layer is formed by framework support material and refractory fiber material. Gaps of the framework support material are filled with the refractory fiber material in order to form the structure of the middle layer adopting the framework support material as a framework and having continuous distribution of the refractory fiber material. Two sides of the middle layer are provided with fiber protection layers, outer layers of which are provided with anti-radiation layers. The production method of the high-strength thermal-insulation board has following beneficial effects: the problem that conventional aluminum silicate thermal-insulation material has poor strength and thermal shock resistance at high temperature is solved so that heat efficiency of a cement rotary kiln is improved, energy is saved and manufacturing cost is decreased.

Owner:王建春

Composite fireproof material

The invention relates to the technical field of fireproof materials, particularly a composite fireproof material which comprises the following components in parts by mass: 3.6-5.4 parts of aluminum oxide, 45-60 parts of cement, 8-15 parts of silicon dioxide, 15-20 parts of polyester fiber, 5.6-7.2 parts of furnace slag powder, 5-10 parts of sodium hexametaphosphate, 3-9 parts of magnesium hydroxide, 6-14 parts of citric acid, 1.5-3.8 parts of aluminum silicate fiber and 12-18 parts of maleimide. By adopting the formula, the fireproof material has the advantages of high fire-resistant temperature, low manufacturing cost and simple preparation method. Besides, the composite fireproof material has the characteristics of simple and accessible components, long fire-resistant time, low production cost and stable quality, and is easy to produce.

Owner:魏忠

Low-cost fireproof material

InactiveCN106699075AImprove flame retardant performanceHigh refractory temperatureSolid waste managementCelluloseFoaming agent

The invention belongs to a fireproof material and relates to a low-cost fireproof material which comprises the following raw materials in parts by weight: 20-25 parts of black mud powder or black mud particles or 55-70 parts of furnace slag powder or furnace slag particles or a mixture of black mud powder or black mud particles and furnace slag powder or furnace slag particles, 7-10 parts of industrial magnesium chloride, 7-10 parts of sillimanite powder, 7-10 parts of sepiolite, 7-10 parts of high-aluminum cement, 1-4 parts of polypropylene fibers, 3-5 parts of asbestos cellulose, 1-3 parts of a foaming agent and 1-3 parts of an AES active agent. The material is good in fireproof performance, is low in cost, is small in density and can be used for manufacturing fireproof equipment such as a fireproof door.

Owner:江苏东钢新材料有限公司

ASA co-extruding material with flame resistance and high weather resistance

InactiveCN109233131AImprove anti-blocking performanceImprove surface propertiesWater basedHigh resistance

The invention provides an ASA co-extruding material with flame resistance and high weather resistance and relates to the technical field of macromolecules. The ASA co-extruding material with flame resistance and high weather resistance provided by the invention comprises the following components in parts by weight: 20-32 parts of ASA powder, 62-70 parts of medium flow styrene acrylonitrile resin,8-12 parts of low flow styrene acrylonitrile resin, 20-30 parts of ethylene ditetrabromide phthalimide, 6.2-9.3 parts of auxiliary fire retardant and 10-15 parts of water-based wear-resisting agent. The ASA co-extruding material has excellent flame resistance, high wearing resistance, high surface evenness and high heat stability; ASA powder, medium flow styrene acrylonitrile resin and low flow styrene acrylonitrile resin are compounded and prepared into a base stock resin, so that liquidity is moderate, impact property is excellent and melt strength is higher; an anti-flaming plasticizer is added, so that fire-resistant temperature and capacity of resisting against high-temperature corrosion deformation of the product are promoted; the water-based wear-resisting agent is added for obviously improving the surface performance of system, so that the wearing resistance, smoothness and anti-adhesion property of the coating can be obviously promoted.

Owner:ZHEJIANG HONGBO NEW BUILDING MATERIALS

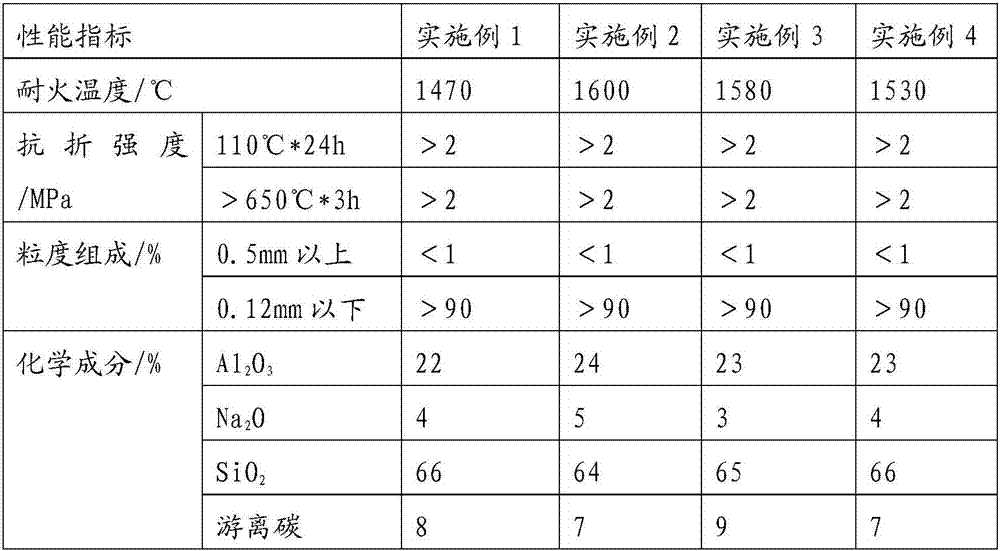

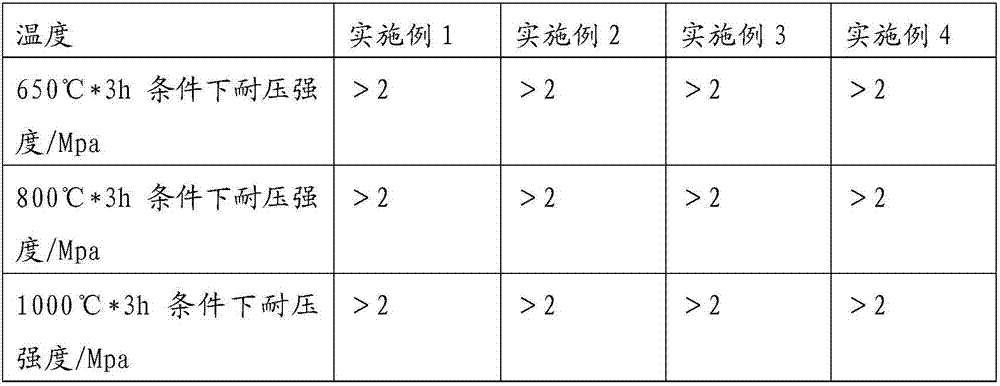

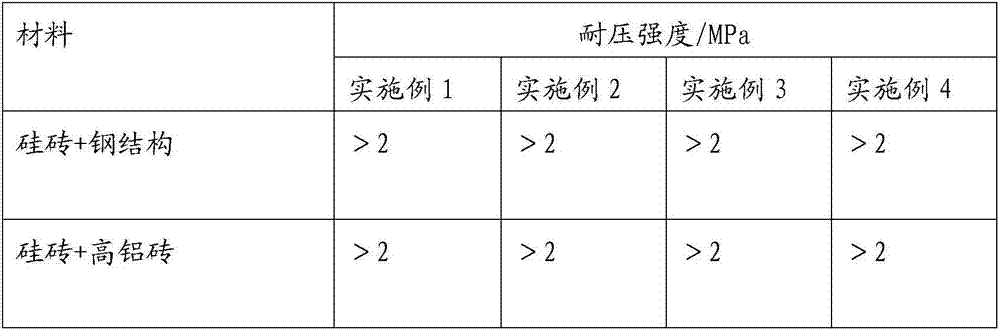

High-temperature-resistant binder

ActiveCN106867415AHigh refractory temperatureHigh bonding strengthNon-macromolecular adhesive additivesInorganic adhesivesKyaniteFire resistance

The invention relates to a high-temperature-resistant binder. The high-temperature-resistant binder comprises the following components in percentage by weight: 35-40% of a sodium silicate water solution, 50-57% of kaolin with ultralow alkali metal content and 8-10% of kyanite powder. The preparation method comprises the following steps: adding the high-modulus sodium silicate and water into a high-speed dispersing machine according to a ratio, and fully dispersing; then adding kaolin with ultralow alkali metal content, and dispersing for 10 minutes at a high speed; finally adding the kyanite powder, slowly stirring for 1 minute, discharging, and finally sealing and packaging. The high-temperature-resistant binder disclosed by the invention is non-toxic and harmless, is friendly to a human body and environment, and is high in fire resistance and high in bonding strength, the bonding strength in any one temperature interval between the normal temperature and the highest use temperature is more than 2 MPa, the defect that most binders have no bonding strength at the temperature between 650 DEG C and 1000 DEG C is overcome, bonding between different materials can be realized; compared with an existing binder, the binder is more convenient to use, and the construction efficiency is improved.

Owner:洛阳欧斯特节能科技有限公司

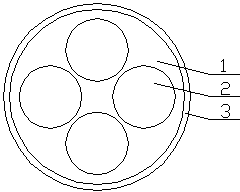

Flexible inorganic insulating fire-resisting cable

InactiveCN103219078ASolve the disadvantages of being susceptible to moistureImprove thermal conductivityFlexible cablesFlexible conductorsElectrical conductorMetallic materials

The invention discloses a flexible inorganic insulating fire-resisting cable. The flexible inorganic insulating fire-resisting cable is composed of one piece or a plurality of pieces of conductors, an inorganic substance packing layer and a sheathing layer from inside to outside in sequence, wherein the sheathing layer is made of metal materials and provided with ripples. According to the flexible inorganic insulating fire-resisting cable, conventional organic substances of plastics, rubber and the like are not adopted as an insulating sheath, inorganic substances with good insulating performance are adopted as an insulating layer instead, metal materials of copper, aluminum or aluminum and the like are used as conductors and adopted by the sheathing layer, and the defects that a metal sheath is uneasy to bend, install and transport are overcome through rippling process.

Owner:ANHUI RUIKAN SCI CABLE

White ground black fancy glazed porcelain and preparation method thereof

White-ground black fancy glazed porcelain comprises a green body, engobe, black fancy glaze and protection glaze, the engobe is prepared from the following raw materials: dolomite, borax, clam meal, talc, anorthite, bentonite and wollastonite; and according to the fired vitreous enamel, white serves as the ground color, the black floral patterns are formed on the surface of the ground color, the black floral patterns and the ground color form a distinct contrast, the expressive force of the black floral patterns is greatly improved, and the white-ground black fancy glazed porcelain has a unique artistic effect so as to meet more market requirements.

Owner:福建省德化县奇丽工艺有限公司

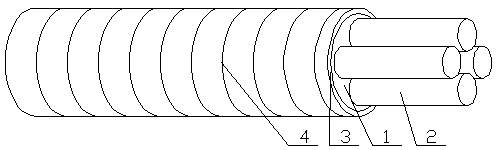

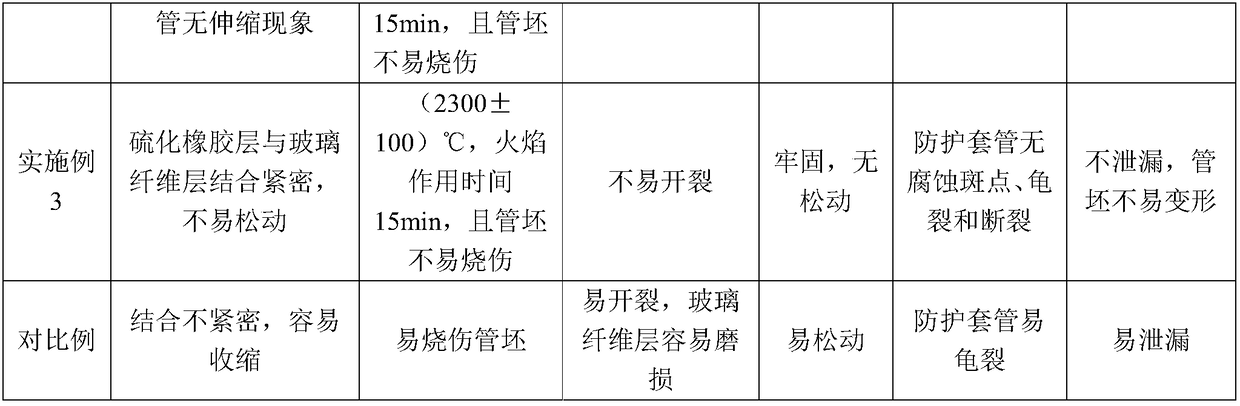

Flexible mineral insulated cable and production method thereof

InactiveCN105655011AHigh refractory temperatureImprove fire performanceNon-insulated conductorsInsulated cablesGlass fiberEngineering

The invention discloses a flexible mineral insulated cable and a production method thereof. The flexible mineral insulated cable comprises cable core conductors, insulated layers and a sheath. An inner calcined mica insulated tape wraps every cable core conductor tightly, an outer calcined mica insulated tape wraps every inner calcined mica insulated tape, and the insulated layer wraps every outer calcined mica insulated tape by extruding so as to form one insulated wire. A glass fiber filling rope is arranged in a gap among the insulated wires which are stranded into a cable body, mineral oxygen-insulated fireproof filling mud is extruded outside the stranded insulated wires, a fire-resistant layer is arranged outside the mineral oxygen-insulated fireproof filling mud, and the sheath is extruded outside the fire-resistant layer. The flexible mineral insulated cable has the advantages of high flexibility, excellent insulating and fire-resisting performance, simple production technology, low cost and long service life.

Owner:JIANGSU JIANGYANG CABLE

High-strength heat insulating refractory material preparation method

The invention discloses a high-strength heat insulating refractory material preparation method, and belongs to the technical field of heat insulating refractory material preparation. Waste building potteries and glass are crushed and ball-milled into powder, waste battens are prepared into wood pellets, the wood pellets, the potteries, the glass powder, potassium carbonate, sodium carbonate, aluminum oxide, sodium carbonate, potassium hydroxide and deionized water are grinded and poured into a mold, drying and demolding are performed after aging mixture to prepare dry blanks, the dry blanks are sintered and then cooled, calcined materials obtained by heat insulating calcination are shifted into an oil bath for reaction, half-cooled calcined materials are filtered, collected, shifted into ice-water mixed liquid, cooled and naturally aired, and a high-strength heat insulating refractory material can be prepared. Examples prove that raw materials are easily obtained, the preparation process is simple, and the prepared heat insulating refractory material is uniform in pore distribution and high in strength and has a wide application market.

Owner:吴迪

Fireproof artificial quartz stone sheet and manufacturing method thereof

InactiveCN104478273AEasy to prepareSuitable for industrial productionSillimaniteCompressive strength

The invention discloses a fireproof artificial quartz stone sheet and a manufacturing method thereof. The artificial quartz stone sheet comprises the following components in parts by weight: 30-80 parts of 6-100mesh quartz stone, 30-60 parts of 325mesh quartz powder, 5-10 parts of broken glass, 10-20 parts of 50-100mesh red-silica powder or white afrodite powder, 5-15 parts of 100-150mesh kyanite powder or andalusite powder or sillimanite powder, 1-10 parts of 100-200mesh zirconium silicate powder or yttrium-stabilized zirconium oxide powder, 5-10 parts of unsaturated resin, 0.3-0.5 part of an additive and 0.3-0.8 part of a pigment. During the preparation, by adding red-silica powder or white afrodite powder, kyanite powder or andalusite powder or sillimanite powder and zirconium silicate powder or yttrium-stabilized zirconium oxide powder, the compressive strength and fireproof and fire-retardant properties of the artificial quartz stone sheet disclosed by the invention are increased and meanwhile, the manufacturing method is simple and is suitable for industrial production and has broad market prospects.

Owner:田忠和

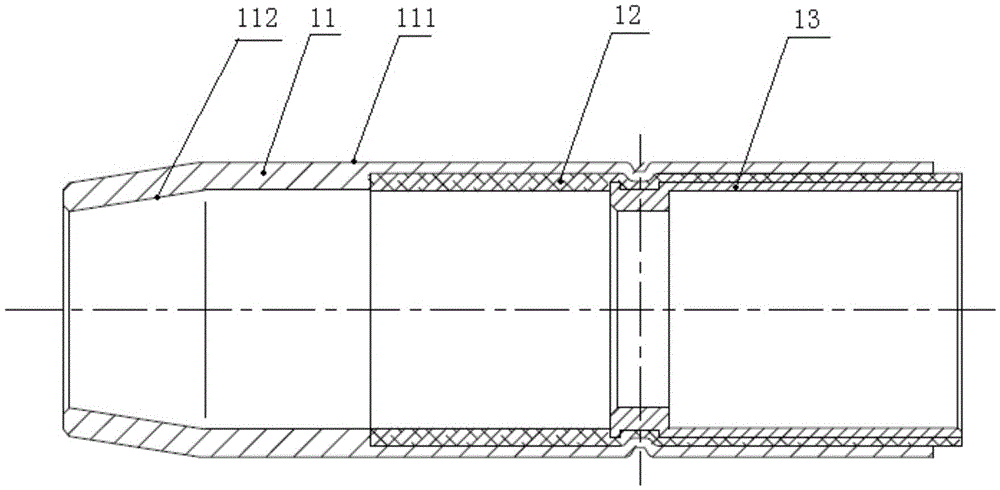

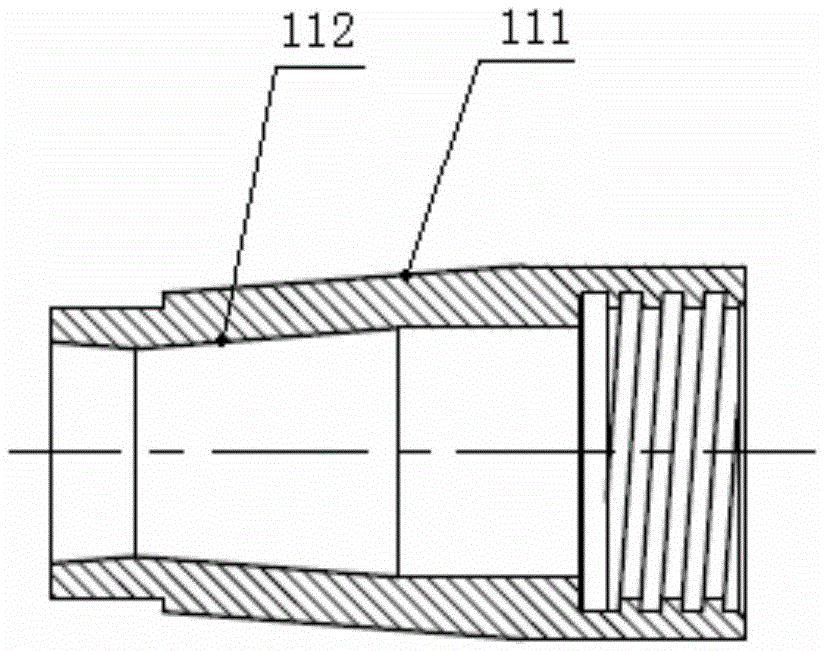

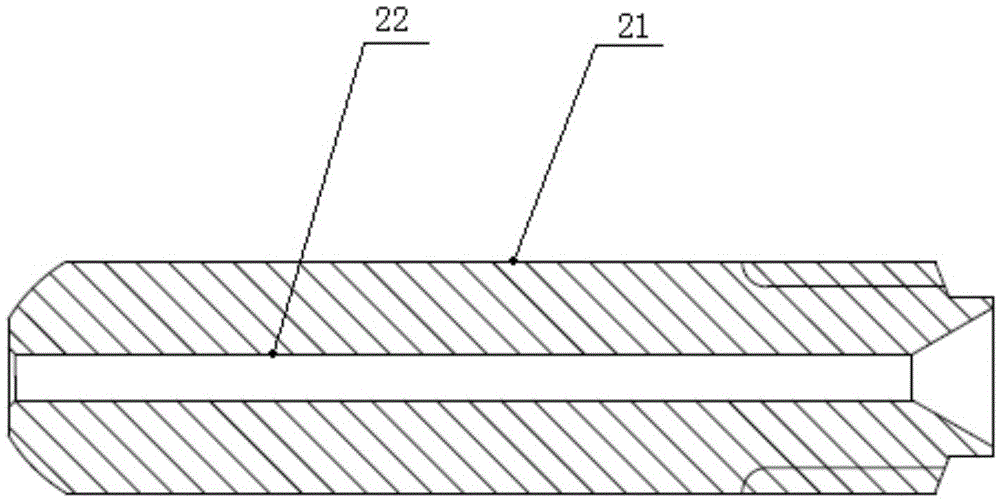

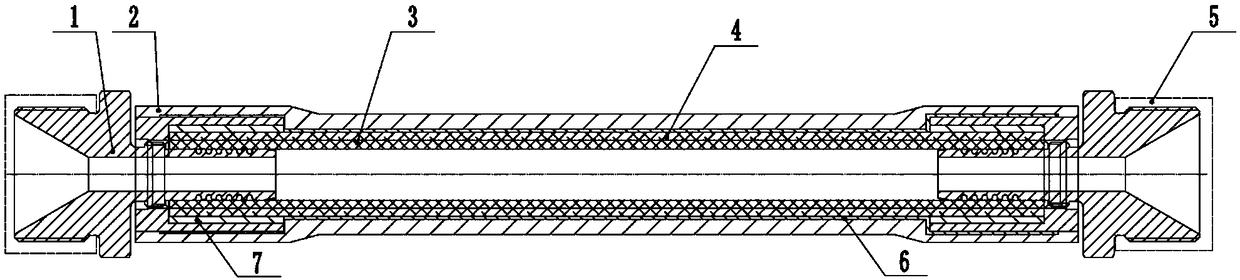

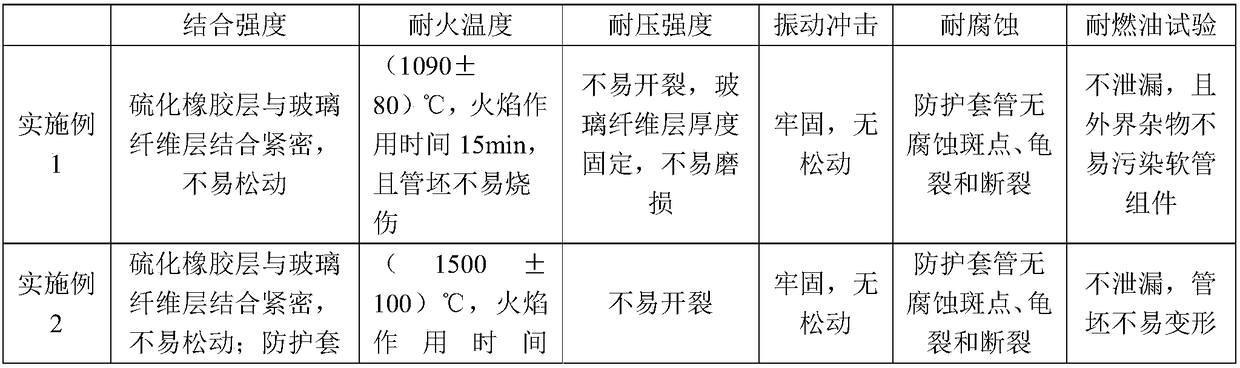

Vulcanizing-packaging method for polytetrafluoroethylene hose assembly and vulcanizing-packaged polytetrafluoroethylene hose assembly

InactiveCN109080116ANot easy to looseHigh refractory temperatureFlexible pipesGlass fiberEngineering

The invention relates to a vulcanizing-packaging method for a polytetrafluoroethylene hose assembly and a vulcanizing-packaged polytetrafluoroethylene hose assembly, and belongs to the technical fieldof rubber vulcanizing. The vulcanizing-packaging method for the polytetrafluoroethylene hose assembly disclosed by the invention comprises the following steps: (1) coating the surface of glass fibrefabric which is coated with insulating paint with a bonding agent, then, wrapping a polytetrafluoroethylene hose assembly with the glass fibre fabric with the surface, which is coated with the bondingagent, inward, and forming a glass fibre layer; (2) wrapping the outer side of the glass fibre layer with rubber to form a rubber layer; and (3) vulcanizing to obtain the vulcanizing-packaged polytetrafluoroethylene hose assembly. According to the vulcanizing-packaging method for the polytetrafluoroethylene hose assembly disclosed by the invention, a vulcanized rubber layer is formed by adoptingthe method of directly vulcanizing after the glass fibre layer outside a polytetrafluoroethylene hose is wrapped with the rubber. According to the vulcanizing-packaged polytetrafluoroethylene hose assembly obtained by the method, an outer layer is not likely to loose when the vulcanizing-packaged polytetrafluoroethylene hose assembly is used; the refractory temperature is high; and the vulcanizing-packaged polytetrafluoroethylene hose assembly is suitable to be used in all places.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

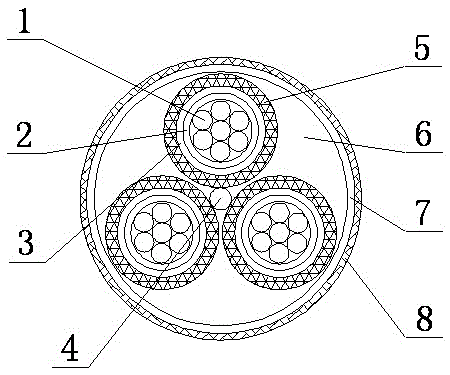

Silicon carbon doped insulated fire-resisting cable and preparation method thereof

InactiveCN107103952AHigh refractory temperatureSolve the real problemRubber insulatorsNon-insulated conductorsGlass fiberEngineering

The invention relates to a silicon carbon doped insulated fire-resisting cable and a preparation method thereof. Four cable cores, a metal sheath, an insulating layer, a first wrapping tape, a fire-resisting layer, a second wrapping tape and an outer sheath are sequentially arranged inside the cable from inside to outside; and center filling layers are arranged at the centers of the four inner cable cores. Silicon rubber filling layers are arranged among the inner cores, the center filling layer and the metal sheath. The center filling layer is made of glass fibers; and the metal sheath is made of metal aluminium. Flexibility of the cable is improved. The aluminium metal can be continuously extruded, so that the aluminium metal is an ideal metal sheath material of the flexible mineral insulated cable. The first wrapping tape and the second wrapping tape are respectively lapped outside the insulating layer and the fire-resisting layer without being twisted, and are both formed by lapping glass fibers. The fire-resisting cable disclosed by the invention is reasonable in structural design, low in manufacturing cost, simple in manufacturing process, stable in chemical performance, high in flexibility at the normal temperature and high in mechanical intensity at a high temperature, is not limited to a production length and is good in flame retardance and fire resistance.

Owner:CHINA THREE GORGES UNIV

A fireproof coating for lithium-ion power battery pack and preparation method thereof

ActiveCN108165126BSuitable for large-scale productionImprove performanceFireproof paintsEpoxyDimethylaniline N-oxide

The invention belongs to the technical field of lithium ion battery, and in particular, relates to a fireproof coating layer for a lithium ion power battery pack and a preparation method thereof. Thefireproof coating layer consists of the following components by the weight percentage: 15 to 55% of sodium phosphate, 5% to 15% of modified amino resin, 2 to 6% of titanium dioxide, 2 to 8% of dimethyl phthalate, 1 to 5% of dimethylaniline, 1 to 5% of epoxy chloroethane, and 30 to 70% of a solvent. Compared with the prior art, the inner wall or an outer shell of the battery pack is coated with thespecially prepared fireproof coating layer, therefore, when the battery pack is burned, the fireproof coating layer can isolate the battery pack and a shell body for as long as two hours or more under a condition of open fire, the combustion is prevented from spreading quickly to other parts of a vehicle, enough time is left for the personnel on the vehicle to safely withdraw, malignant personnelcasualty accidents are avoided from being generated and the safety performance of the lithium ion battery pack is effectively improved.

Owner:DONGGUAN LILONG BATTERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com