Production method of high-strength thermal-insulation board

A heat insulation board, high-strength technology, applied in the direction of building components, heat preservation, fire protection, etc., can solve the problems of poor strength, poor thermal shock resistance, etc., and achieve the effects of reducing production costs, high refractory temperature, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

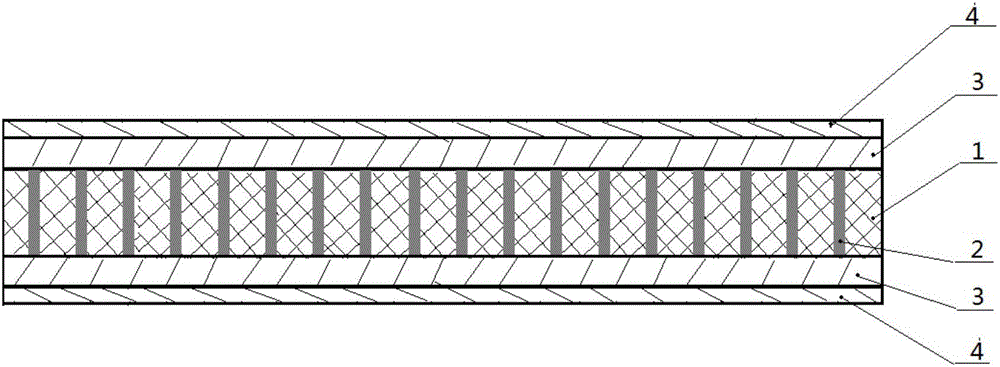

[0023] The preparation method step of above-mentioned high-strength heat insulation board is as follows:

[0024] (1) Put the refractory fiber into the water, add an appropriate amount of sodium fluorosilicate, put the raw material, water and sodium fluorosilicate in the stirring tank, stir for 10-30 minutes and disperse evenly;

[0025] (2) Place the skeleton support material in a metal tray with mesh, put the metal tray into the stirring tank, connect the vacuum pipe, absorb the refractory fiber in the liquid, until the refractory fiber covers the entire support material, stop vacuuming;

[0026] (3) Take the tray out of the mixing tank, turn it over to the wooden tray, put it on the baking rack, push the semi-finished product on the baking rack into the drying room, and dry it at 110-300 ° C for 10-24 hours;

[0027] (4) Plane and trim the dried semi-finished product from the baking rack, paste the processed semi-finished product on the front and back, fiber paper and alumi...

Embodiment 1

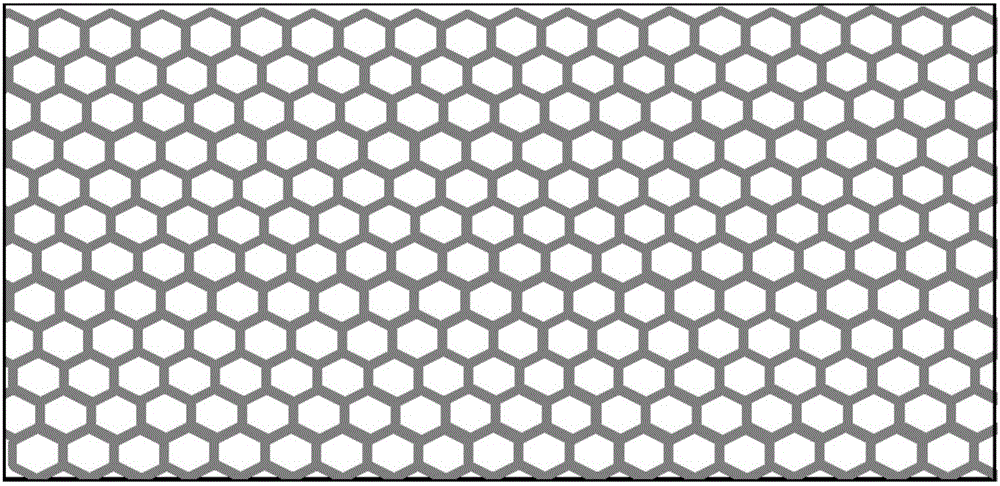

[0029] Put the refractory aluminum silicate fiber into the water, the weight ratio of refractory fiber and water is 1:5, then add 1% by weight of sodium fluorosilicate, put the raw material, water and sodium fluorosilicate in the stirring tank, stir Disperse evenly after 20 minutes, place the hexagonal grid stainless steel 304 skeleton support material in a metal tray with mesh, put the metal tray into the stirring tank, connect the vacuum pipeline, and absorb the refractory fiber in the liquid until the refractory fiber is covered Fill the entire support material, stop vacuuming, take the tray out of the mixing tank, turn it over to the wooden tray, place it on the baking rack, push the semi-finished product on the baking rack into the drying room, and dry it at 150°C for 20 hours Plane and trim the dried semi-finished products from the baking rack, paste the processed semi-finished products on the front and back, fiber paper and aluminum film, put them on wooden brackets, pas...

Embodiment 2

[0031] Put the refractory alumina fiber into the water, the weight ratio of refractory fiber and water is 1:8, then add 2% by weight of sodium fluorosilicate, put the raw material, water and sodium fluorosilicate in the stirring tank, stir for 30 Disperse evenly after 1 minute, place the pentagonal grid stainless steel 304 skeleton support material in a metal tray with mesh, put the metal tray into the stirring tank, connect the vacuum pipeline, and absorb the refractory fiber in the liquid until the refractory fiber is covered. Stop vacuuming the entire support material, take the tray out of the mixing tank, turn it over to the wooden tray, place it on the baking rack, push the semi-finished product on the baking rack into the drying room, and dry it at 200 ° C for 15 hours; Plane and trim the dried semi-finished product from the baking rack, paste the processed semi-finished product on the front and back, fiber paper and aluminum film, put it on a wooden bracket, paste it sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com