Silicon carbon doped insulated fire-resisting cable and preparation method thereof

A fire-resistant cable and silicon carbon technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of difficult to meet market demand, large capital investment, high equipment requirements, etc., to extend the effective use time, change The effect of simple production process and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

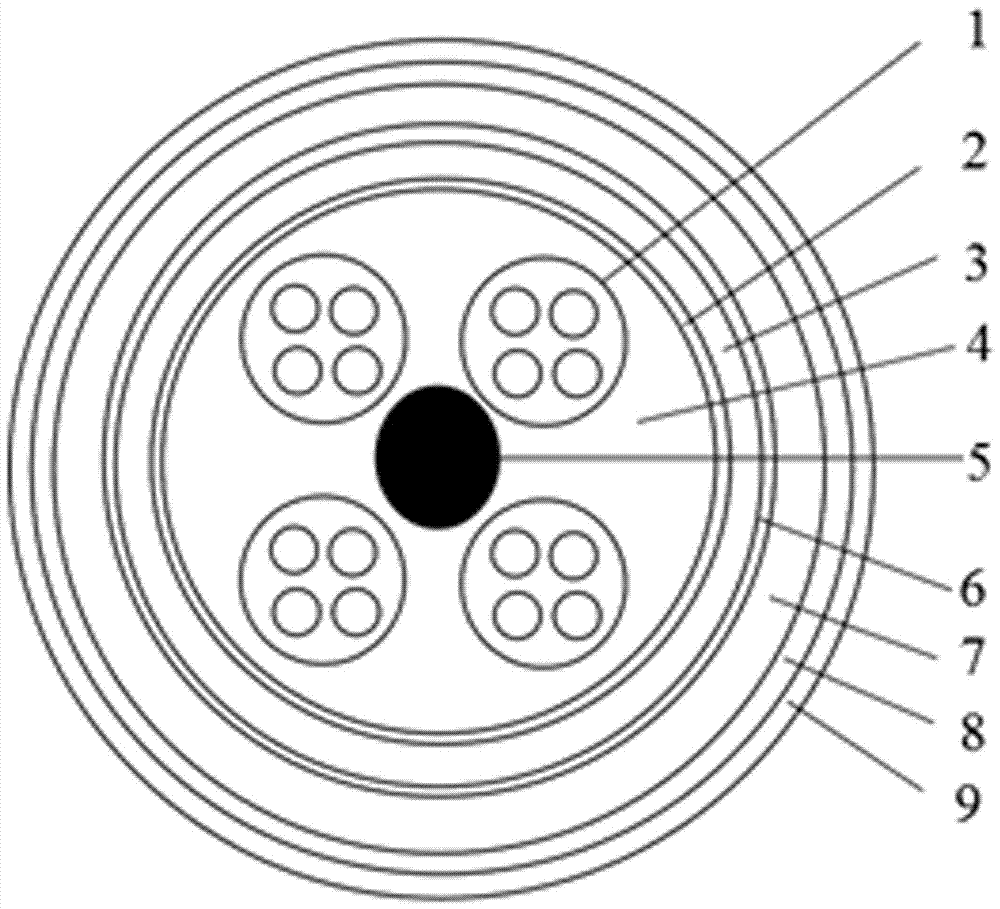

[0034] Such as figure 1 As shown, in the doped insulated fire-resistant cable provided by the present invention, a cable inner core 1, a metal sheath 2, an insulating layer 3, a filling layer 4, a central filling layer 5, a first wrapping tape 6, a fire-resistant Layer 7, Second Tape 8, and Outer Sheath 9. The layers of the structure are tightly fitted, and the cross-section forms a concentric circle.

[0035] The inner core 1 of the cable is metal copper, aluminum alloy, multi-core copper stranded wire or multi-core aluminum stranded wire, and the length does not need to be limited.

[0036] The thickness of the insulating layer 3 is 1-2 mm, and the thickness of the refractory layer 7 is 2-3 mm.

[0037] Preferably, the material of the insulating layer 3 and the refractory layer 7 is a mixture of magnesium oxide, carbon-silicon composite, silicon dioxide, mica powder, and kaolin. It makes the insulating layer and refractory layer have a higher melting point, and it is not ...

Embodiment 2

[0052] A silicon-carbon-doped insulated fire-resistant cable, the inside of the cable is sequentially provided with four cable cores 1, a metal sheath 2, an insulating layer 3, a first tape 6, a fire-resistant layer 7, and a second The tape 8 and the outer sheath 9 are provided with a central filling layer 5 in the center of the four inner cores 1 .

[0053] Preferably, there is a silicone rubber filling layer 4 between the inner core 1 , the central filling layer 5 and the metal sheath 2 . Silicone rubber forms another filling layer between the metal inner core and the metal wrapping layer. In case of fire, this filling layer can form a ceramic structure, thereby preventing the heat generated by the flame from being transferred to the metal inner core and extending the effective life of the cable. Using time, it can also prevent moisture from contacting the inner core of the cable during fire extinguishing, and play an isolation role.

[0054] Preferably, the material of the...

Embodiment 3

[0071] A silicon-carbon-doped insulated fire-resistant cable, the inside of the cable is sequentially provided with four cable cores 1, a metal sheath 2, an insulating layer 3, a first tape 6, a fire-resistant layer 7, and a second The tape 8 and the outer sheath 9 are provided with a central filling layer 5 in the center of the four inner cores 1 .

[0072] Preferably, there is a silicone rubber filling layer 4 between the inner core 1 , the central filling layer 5 and the metal sheath 2 . Silicone rubber forms another filling layer between the metal inner core and the metal wrapping layer. In case of fire, this filling layer can form a ceramic structure, thereby preventing the heat generated by the flame from being transferred to the metal inner core and extending the effective life of the cable. Using time, it can also prevent moisture from contacting the inner core of the cable during fire extinguishing, and play an isolation role.

[0073] Preferably, the material of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com