Environmentally-friendly and fireproof door panel and making method thereof

A technology for a fireproof door core board and a manufacturing method, which is applied in the field of building fireproof components, can solve the problems of inability to form specialized production, complicated production process, increased production cost, etc., and achieves comprehensive utilization of waste, simple production process, and high fire resistance temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

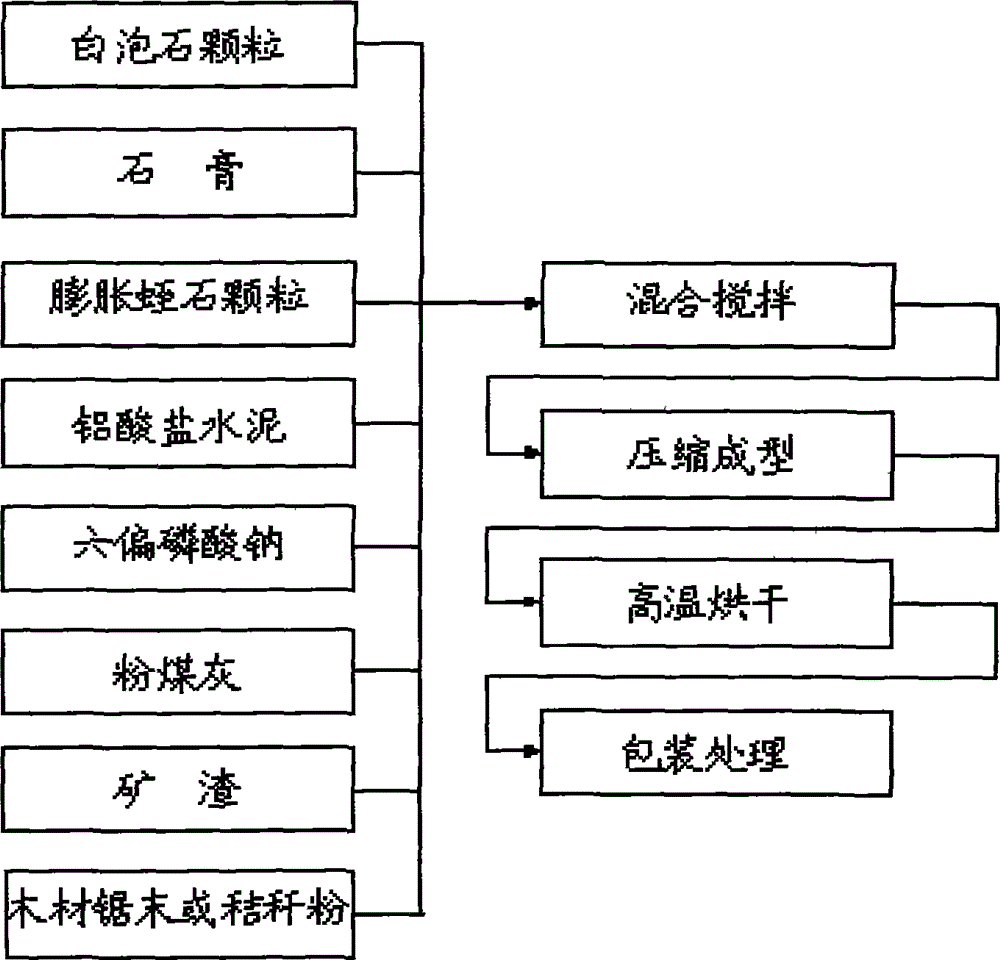

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: respectively by weight percentage is white foam stone particle 50%: Gypsum 5%: Expanded vermiculite particle 2%: Aluminate cement 10%: Sodium hexametaphosphate 0.2%: Fly ash 10%: Slag 1% , and the rest add wood sawdust or straw powder.

Embodiment 2

[0026] Embodiment two is respectively by weight percent white foam stone particle 55%: Gypsum 8%: Expanded vermiculite particle 3%: Aluminate cement 15%: Sodium hexametaphosphate 0.3%: Wood sawdust or straw powder 8%: Slag 1 %, and the rest is fly ash.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com