Patents

Literature

59results about How to "Meet the requirements of safety and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

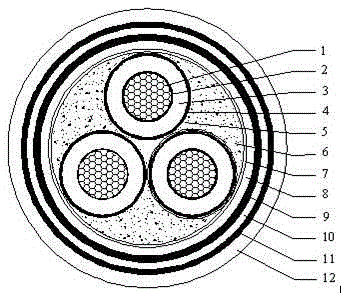

Ceramifying polyolefin fireproof cable material

InactiveCN105348627ALow priceSimple processing technologyPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

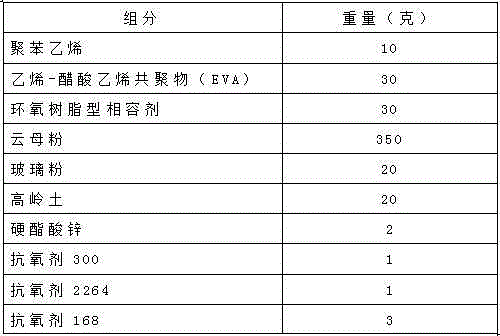

The invention provides a ceramifying polyolefin fireproof cable material. The material is prepared by the following components in parts by weight: 40-100 parts of polyolefin; 1-30 parts of a compatilizer; 350-450 parts of ceramifying powder; 20-200 parts of a flux; 20-90 parts of a fire retardant; 2-20 parts of a lubricant; and 1-10 parts of an anti-oxidant. Polyolefin is selected from one or more of an ethane-vinyl acetate copolymer, polypropylene, polystyrene, polyethylene and a polyolefin elastomer. The ceramifying powder is selected from one or more of pottery clay, powdered steatile, mica powder, pyrophillite, ascharite, datolite, calcite, limestone, spodumene and clay. The ceramifying polyolefin fireproof cable material has the advantages of good fireproof performance, environmental protection, low cost, easy processing and good application prospect.

Owner:SUZHOU CPLUS NEW MATERIAL

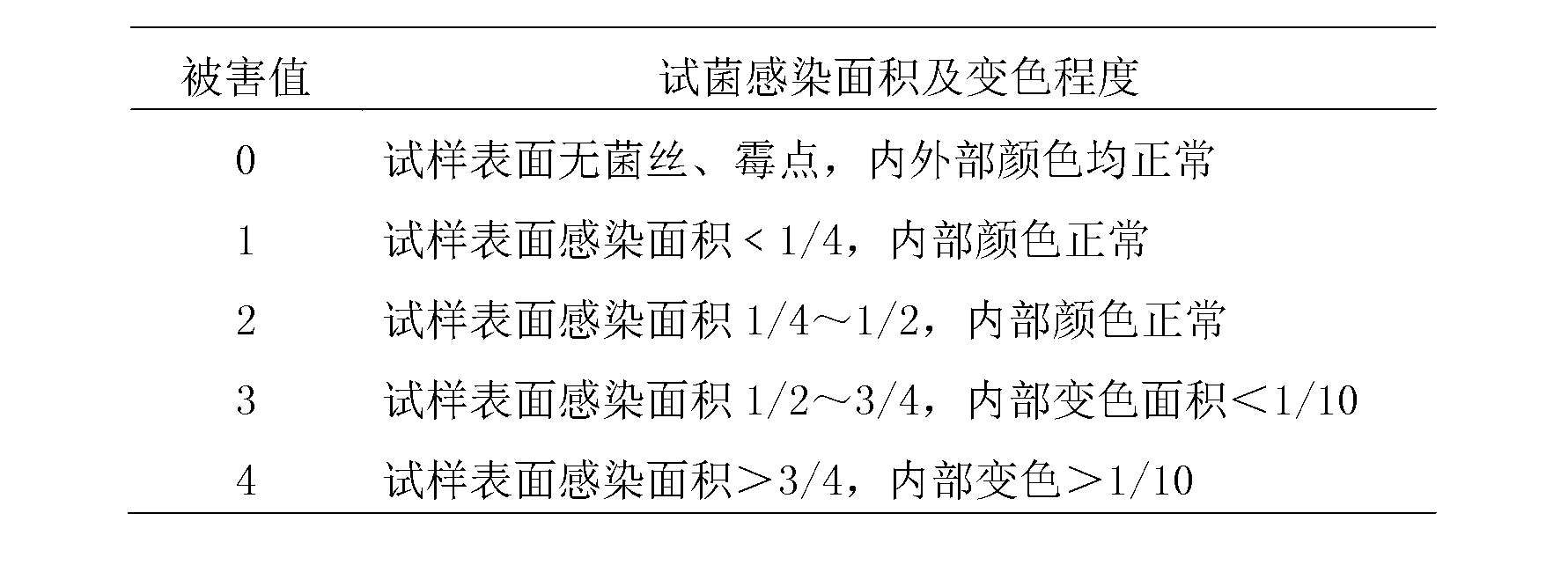

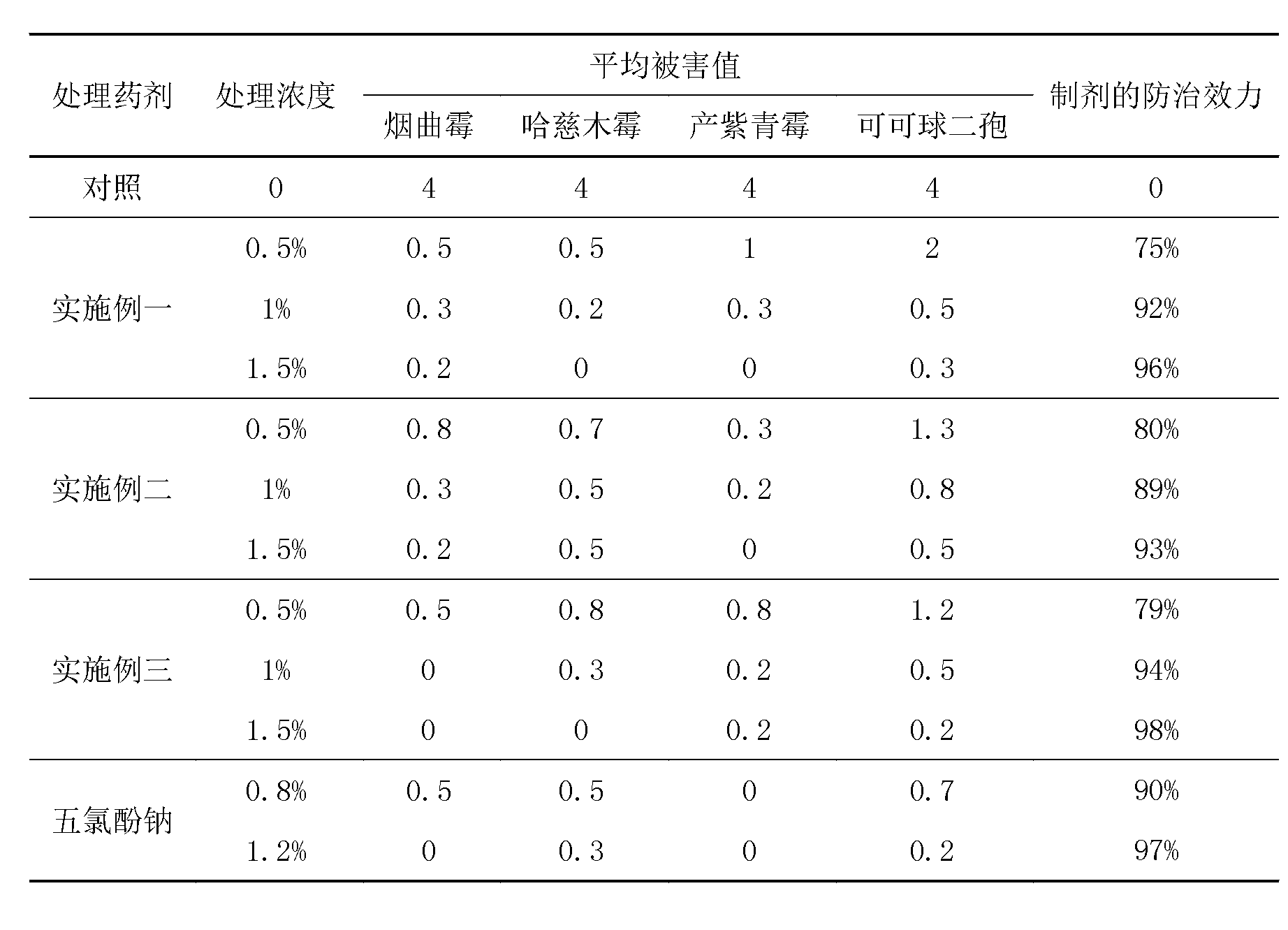

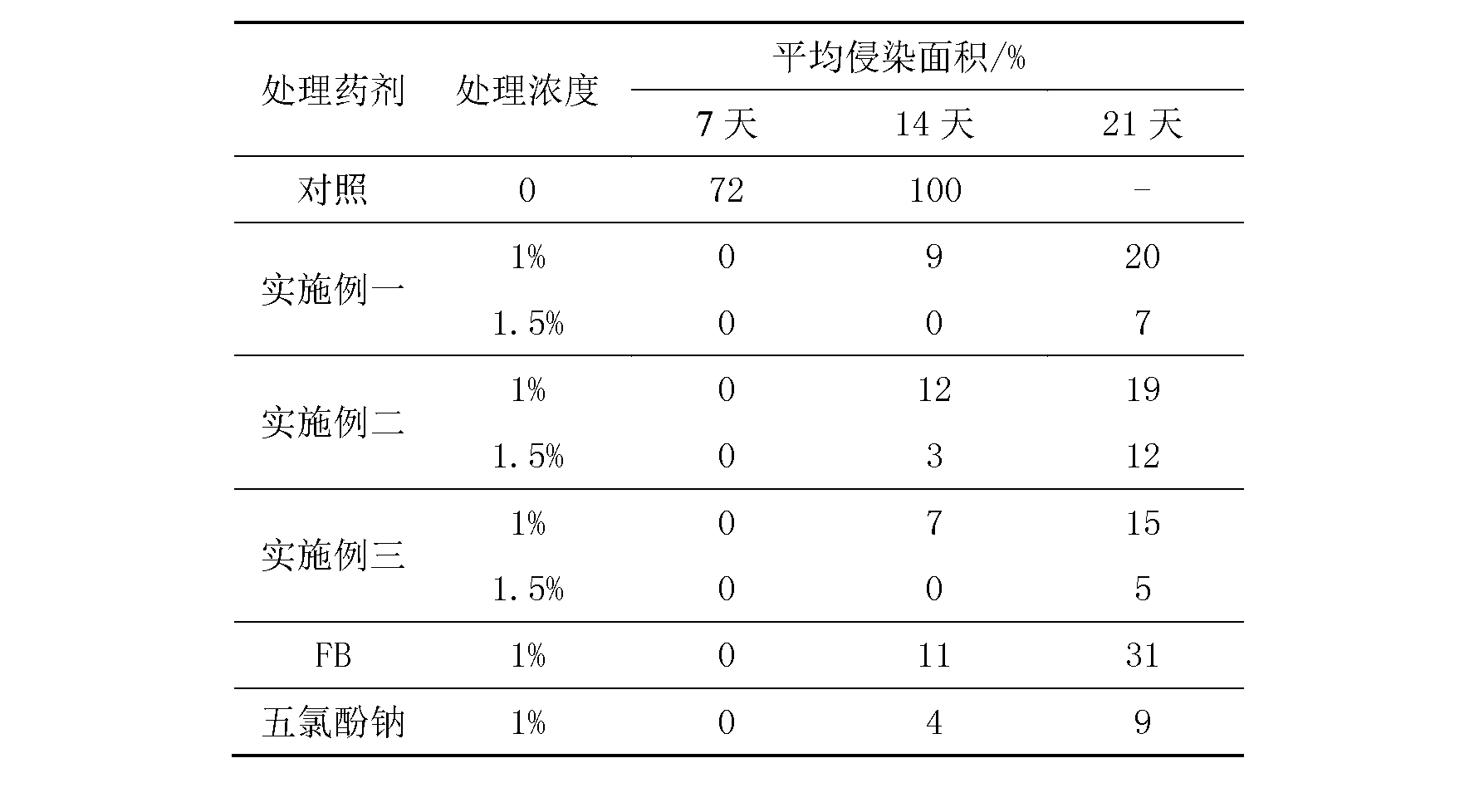

Environment-friendly mould-proof and anti-discoloration protective agent for rubber wood

ActiveCN102934635AApplicable short-term protectionLess drug intakeBiocideFungicidesSolubilityBotryodiplodia theobromae

The invention relates to an environment-friendly mould-proof and anti-discoloration protective agent for rubber wood. Iodopropynyl butylcarbamate ester, an isothiazolinone compound, an organic solvent, a solubility promoter A, a solubility promoter B and water are uniformly mixed to prepare the environment-friendly mould-proof and anti-discoloration protective agent; the solubility promoter A is one of an advanced fatty acid salt surfactant, a quaternary ammonium salt surfactant and a polyhydric alcohol surfactant or a combination of the advanced fatty acid salt surfactant, the quaternary ammonium salt surfactant and the polyhydric alcohol surfactant; and the solubility promoter B is one of a sulphosalts surfactant and an isothiazolinone surfactant or a combination of the sulphosalts surfactant and the isothiazolinone surfactant. The iodopropynyl butylcarbamate ester and the isothiazolinone compound are compounded, stable treatment solution can be formed, and the environment-friendly mould-proof and anti-discoloration protective agent has the advantages of environmental protection, broad spectrum and high efficiency, is good in water solubility and stability, realizes excellent effects for preventing and treating botryodiplodia theobromae, alternaria alternata and the like which severely damage the rubber wood, is applicable to various rubber wood treatment processes such as vacuum-pressure processes, hot and cold bath processes and soaking processes, and can be directly applied to existing production processes conveniently.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Preparation method of ceramic polyolefin fire-resistant cable material

InactiveCN108841072AEnvironmentally friendlyLow costPlastic/resin/waxes insulatorsPolyolefinAntioxidant

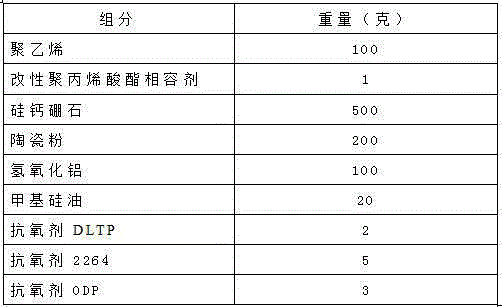

The invention provides a preparation method of a ceramic polyolefin fire-resistant cable material. The cable material comprises the following components in parts by weight: 40-100 parts of polyolefin,1-30 parts of a compatibilizer, 350-500 parts of porcelain powder, 20-200 parts of a fluxing agent, 20-100 parts of a flame retardant, 2-20 parts of a lubricant and 1-10 parts of an antioxidant; andthe preparation method sequentially comprises the following steps: (1) adding the polyolefin, the compatibilizer, the flame retardant and the antioxidant to an internal mixer and internally mixing to90-110 DEG C in 5-15 min; (2) adding the porcelain powder and the lubricant and internally mixing to 115-135 DEG C in 2-8 min; (3) then adding the fluxing agent, internally mixing to 165-185 DEG C in20-40 min and stopping the internal mixing; and (4) performing twin-screw extrusion molding on materials obtained in the step (3) to obtain the ceramic polyolefin fire-resistant cable material. The preparation method of the invention is simple in operation and low in raw material cost; and the obtained cable material has good fire resistance and good application prospects.

Owner:南通智达光缆材料有限公司

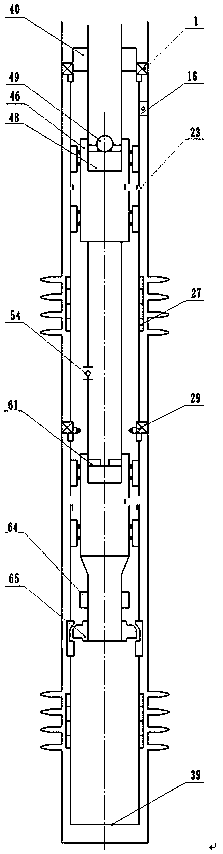

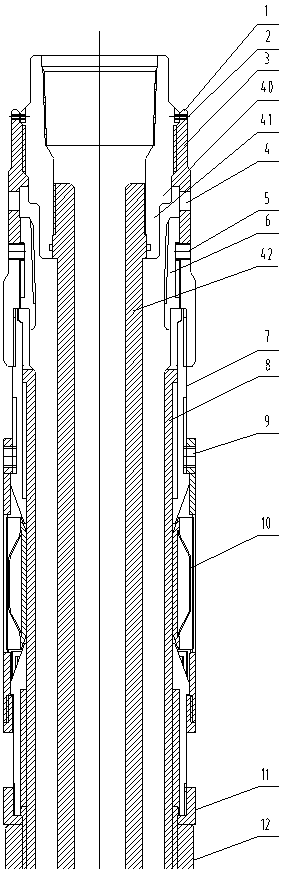

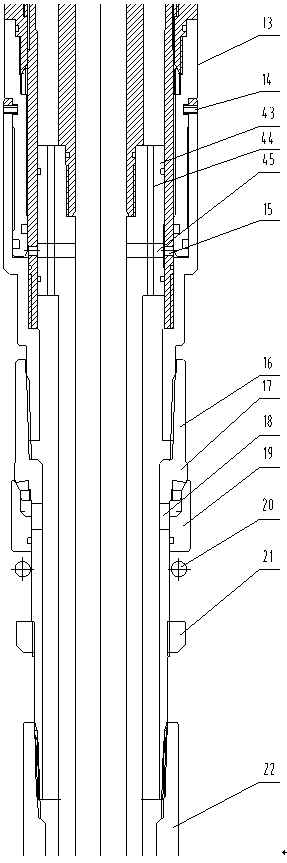

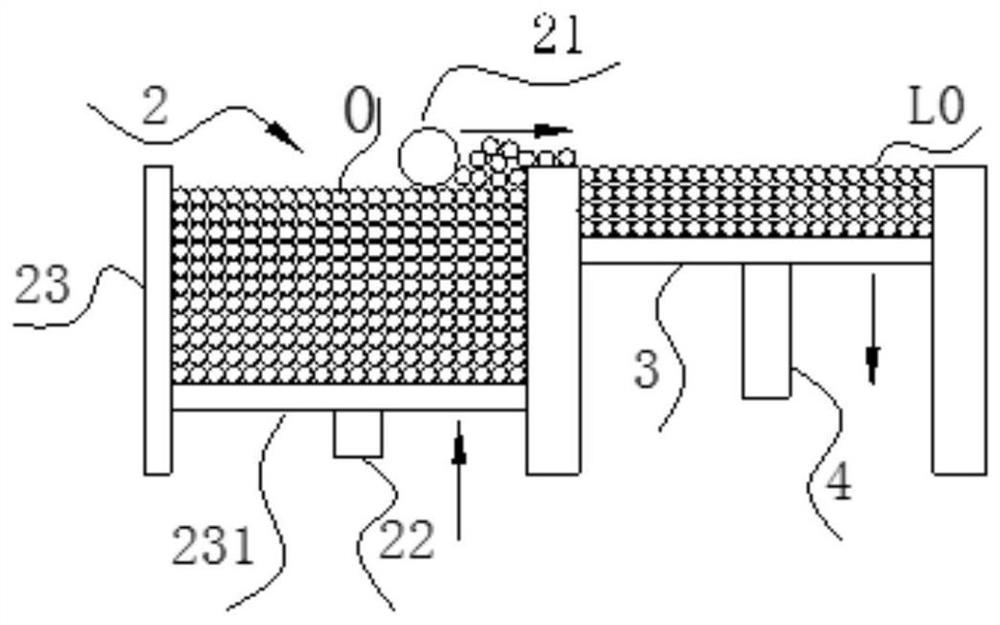

Ball-throwing type layered sand control process pipe column and method thereof

ActiveCN108625830AEfficient use ofEffective transformationGeothermal energy generationFluid removalProduction effectEngineering

The invention discloses a ball-throwing type layered sand control process pipe column and a method thereof. The pipe column comprises a sand control outer pipe and a sand control inner pipe placed inside the sand control outer pipe, wherein the sand control outer pipe comprises a top suspension setting mechanism, a reverse well-flushing device, external filling devices, screen tubes and a pipe plug from top to bottom, and the top suspension setting mechanism, the reverse well-flushing device, the external filling devices, the screen tubes and the pipe plug are connected in sequence. The sand control inner tube includes a releasing mechanism, inner filling devices, a switch mechanism and a bottom positioning device from top to bottom, wherein the releasing mechanism, the inner filling devices, the switch mechanism and the bottom positioning device are connected in sequence. The number of the inner filling devices is consistent with that of the external filling devices in each oil reservoir, and the inner filling devices and the external filling devices correspond to each other in the radial direction. Internal well-flushing valves are installed between every two inner filling devices. The ball-throwing type layered sand control process pipe column and the method thereof can realize completion of layered sand control construction of a multiple zone by one-trip pipe column, ensureindependence between layers, and give full play to the productivity of each small layer to achieve the best sand control production effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

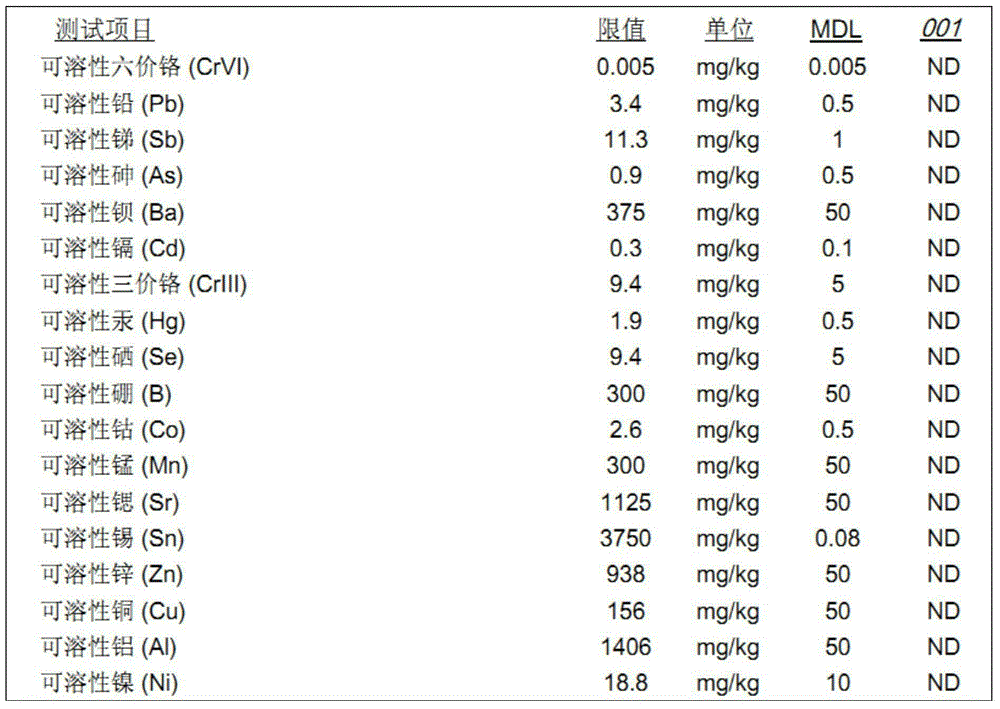

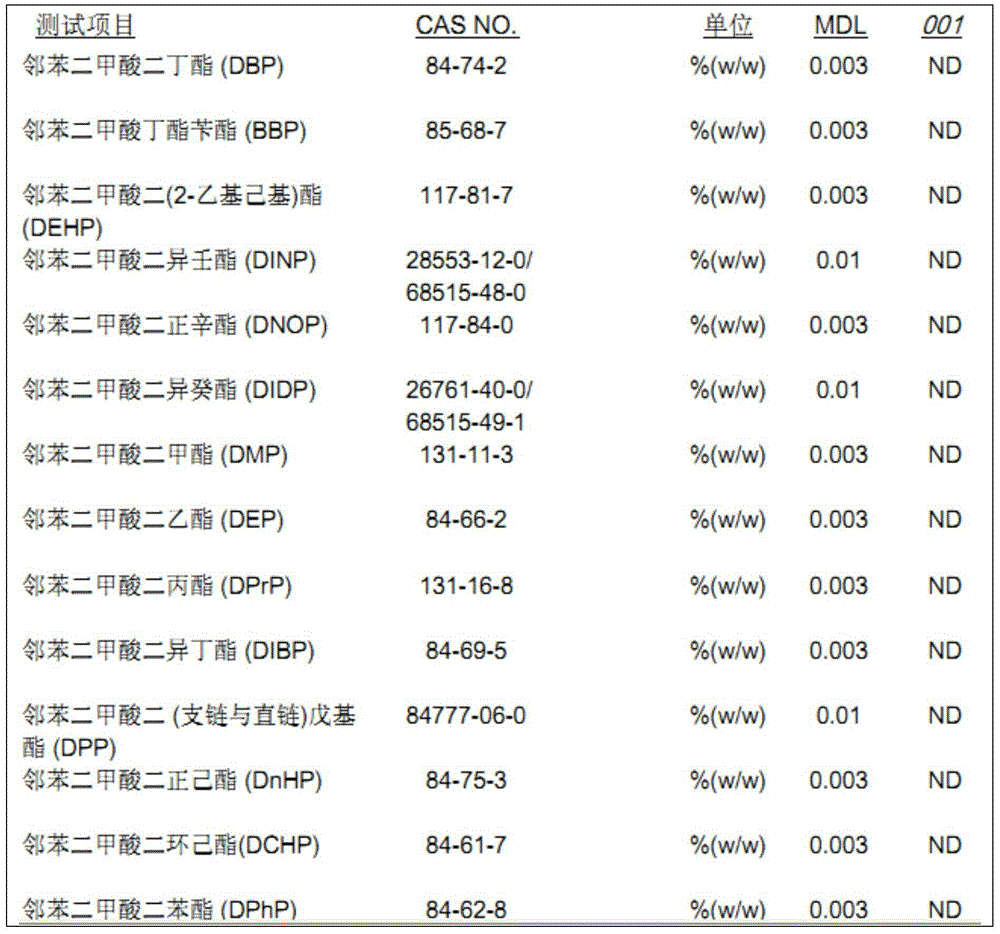

Pitted polyvinyl chloride dipping plastic fluid and preparation method thereof

InactiveCN104910553AEliminate the possibility of harmMeet the requirements of safety and environmental protectionPlasticizerPolyvinyl chloride

The invention relates to a pitted polyvinyl chloride dipping plastic fluid and a preparation method thereof. The invention solves the problem that existing plasticizers are toxic. The pitted polyvinyl chloride dipping plastic fluid is composed of the following materials: PVC suspension resin powder, PVC paste resin, a plasticizer, a stabilizer, a viscosity reducer, calcium carbonate, a defoamer, and a pigment. The invention also provides a preparation method of the pitted polyvinyl chloride dipping plastic fluid. The pitted polyvinyl chloride dipping plastic fluid disclosed by the invention can be applied to the preparation of PVC products.

Owner:山东万图高分子材料股份有限公司

Method for preparing pre-vulcanized natural latex based slow release fertilizer

InactiveCN101531548AWill not polluteMeet the requirements of safety and environmental protectionFertilizer mixturesCross-linkOrganic solvent

The invention relates to a method for preparing pre-vulcanized natural latex based slow release fertilizer. Natural amylose chitosan and sodium alginate as wrapping materials are used for wrapping and molding fertilizer. By adopting pre-vulcanized natural latex as a wrapping material and controlling the cross-linking density of the pre-vulcanized natural latex, various slow release fertilizers with different slow release speeds can be obtained within a definite range. The raw materials adopted by the method are all natural high molecular materials, the operation process does not use organic solvent, and water source and soil pollution is not generated during use, so the method accords with the requirement of safety and environmental protection, and is particularly applicable to the production in saline districts by directly using local brine.

Owner:GUANGDONG OCEAN UNIVERSITY

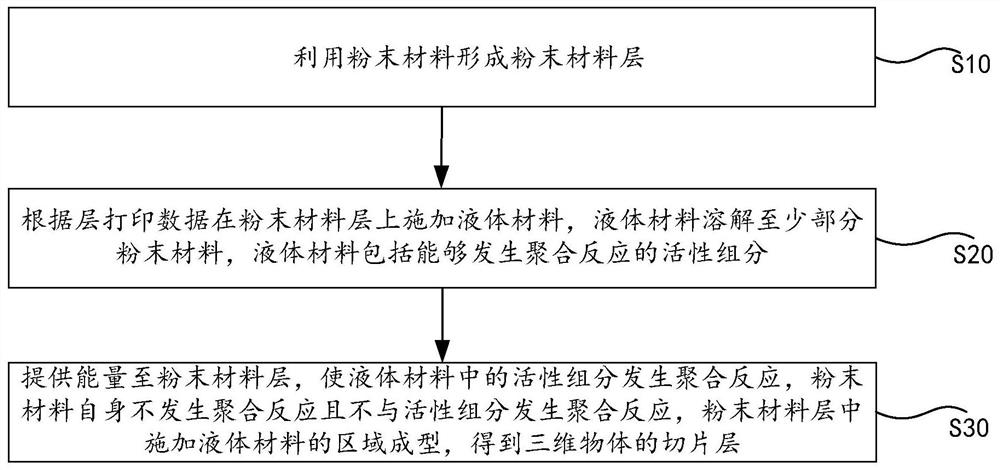

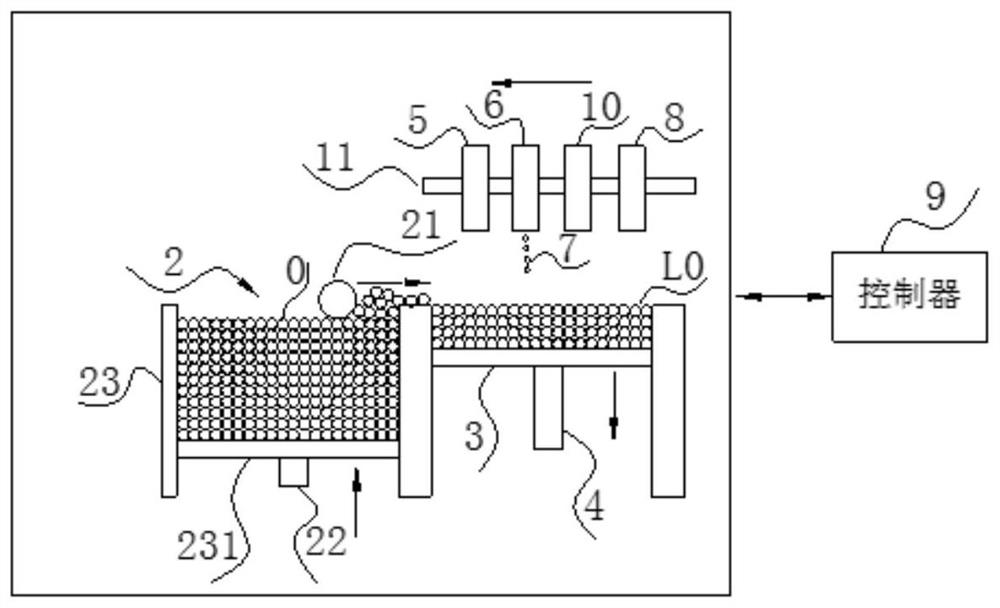

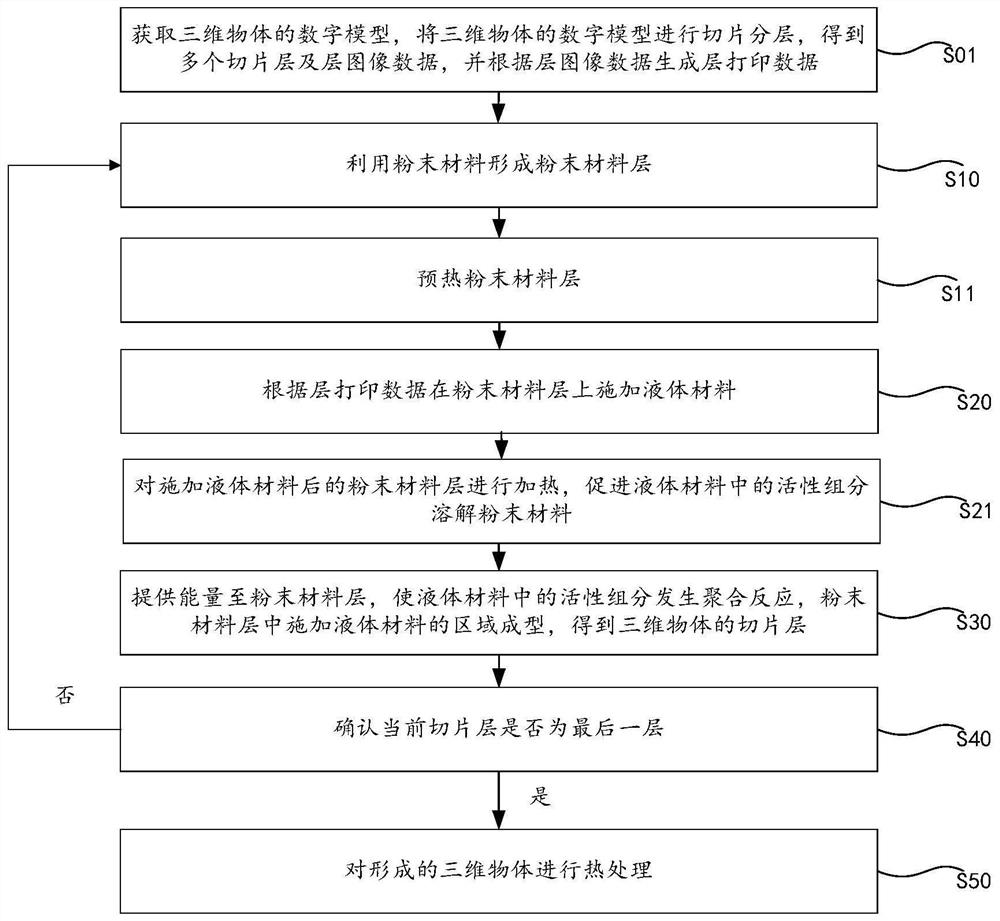

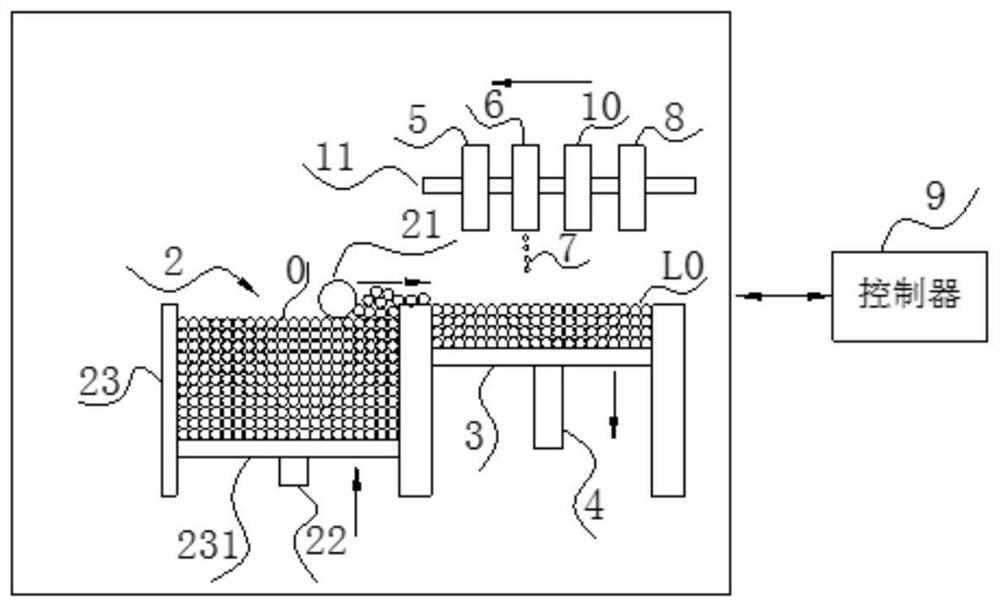

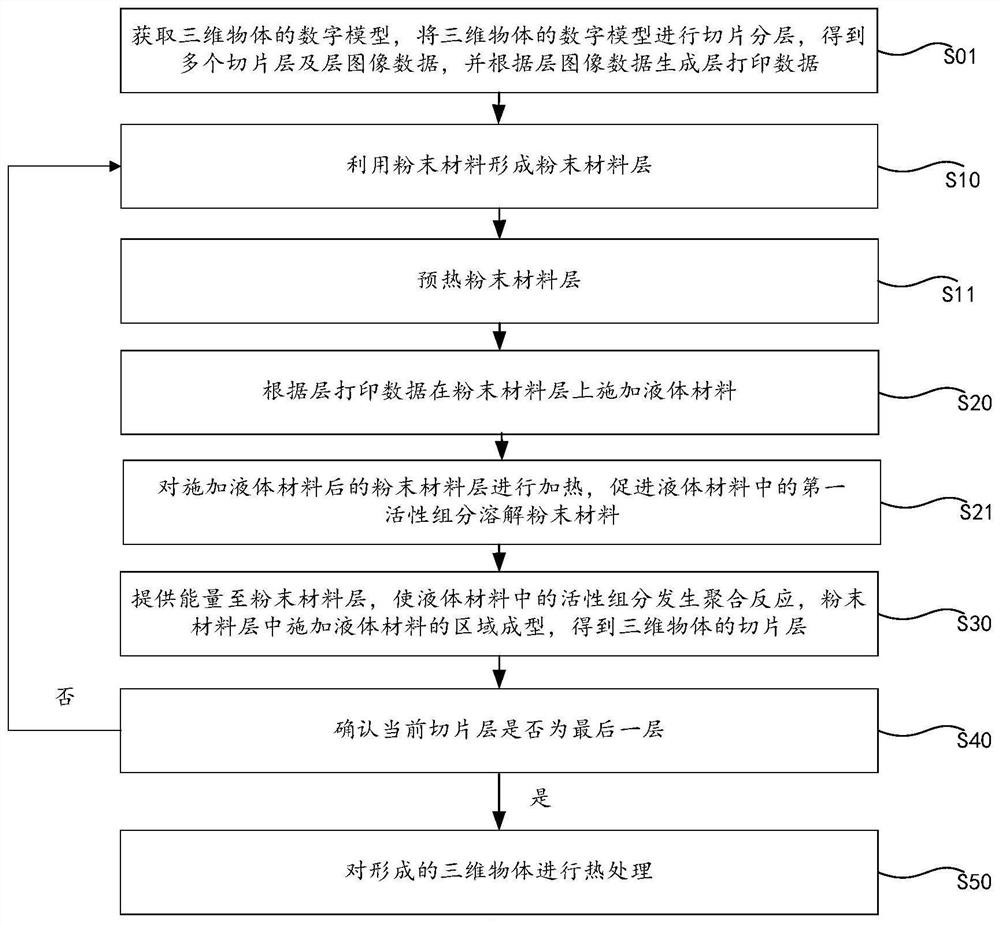

Three-dimensional object additive manufacturing method and device, storage medium and computer equipment

ActiveCN111976134AHigh mechanical strengthFirmly connectedManufacturing platforms/substratesManufacturing heating elementsAdditive layer manufacturingPolymerization

The invention provides a three-dimensional object additive manufacturing method and device, a storage medium and computer equipment. The method comprises the following steps of forming a powder material layer by using a powder material; applying a liquid material to the powder material layer according to layer print data, wherein the liquid material is dissolved to part of powder material and comprises an active component capable of performing a polymerization reaction; and providing energy to the powder material layer, wherein the active component in the liquid material is subjected to the polymerization reaction, the powder material itself is not subjected to polymerization reaction and is not subjected to polymerization reaction to the active component, and an area where the liquid material is applied to the powder material layer is formed to obtain a section layer of the three-dimensional object. According to the three-dimensional object additive manufacturing method and device, the storage medium and the computer equipment, the mechanical strength of the three-dimensional object can be improved effectively, the porosity of the three-dimensional object can be reduced effectively, and the compactness of the three-dimensional object can be improved effectively.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Airtight removing method for harmful gas in drilling fluid

The invention discloses an airtight removing method for harmful gas in a drilling fluid and relates to the technical field of petroleum drilling airtight drilling processes. The drilling fluid containing the harmful gas returns to the ground from a downhole and subjected to three-stage separation treatment, the harmful gas in the drilling fluid is separated. Different forms of the harmful gas such as sulfureted hydrogen in the drilling fluid can be subjected to staged treatment in a drilling fluid ground treatment system completely isolated from the atmosphere, harm to personnel, equipment and the environment due to the fact that the toxic and harmful gas cut drilling fluid is exposed in the atmosphere environment and then volatilized is completely avoided, accidents are avoided, and the urgent demands for drilling safety and environmental protection are met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Single-component non-toxic stain-resisting paint based on quinones

InactiveCN101121857ASolve the emission problemGood antifoulingAntifouling/underwater paintsPaints with biocidesQuinoneOrganism

A one-component non-toxic antifouling paint based on quinones, which is composed of base material, functional filler, extender pigment and filler, nontoxic antifouling agent and auxiliary agent. The base material is silicone-acrylic compound emulsion, the functional fillers are nano-TiO2 and nano-ZnO, the body pigments and fillers are iron red, talcum powder, and CaCO3, and the antifouling agent is quinone non-toxic antifouling agent. The paint is not only completely non-toxic, does not emit toxic gas during production and painting, and has good adhesion to the anti-corrosion primer, but also has a strong inhibitory effect on the most harmful and most frequently occurring barnacles among marine fouling organisms , It also has obvious control effect on the adhesion of other fouling organisms. The coating can be widely used in the antifouling of ships and submarines, cage culture, bay construction, offshore platforms, underwater facilities, etc.

Owner:大连华乌科技转化有限公司

Washable graffiti crayon and preparation method thereof

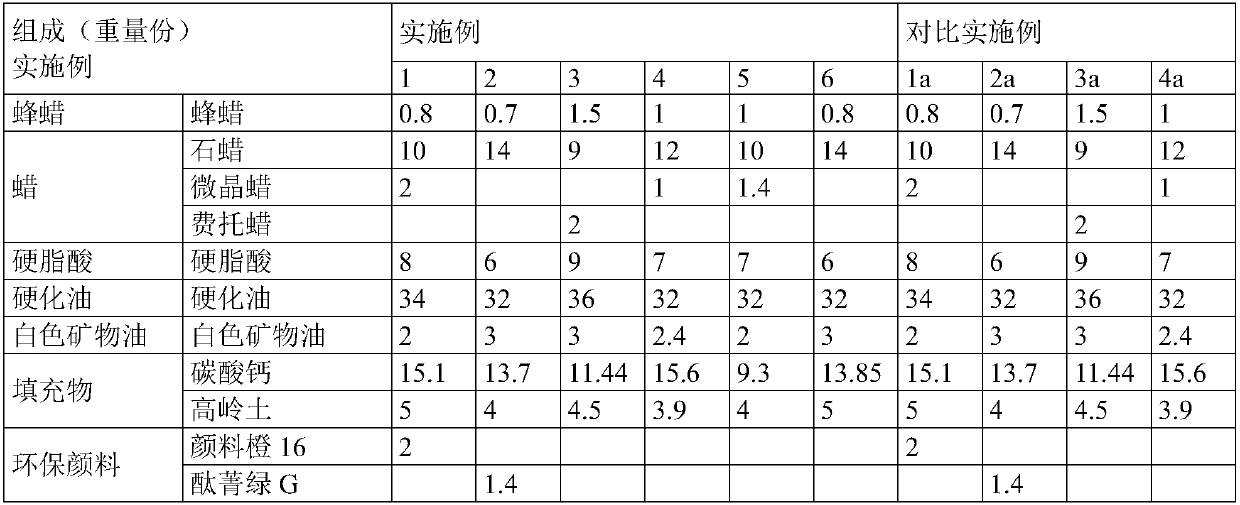

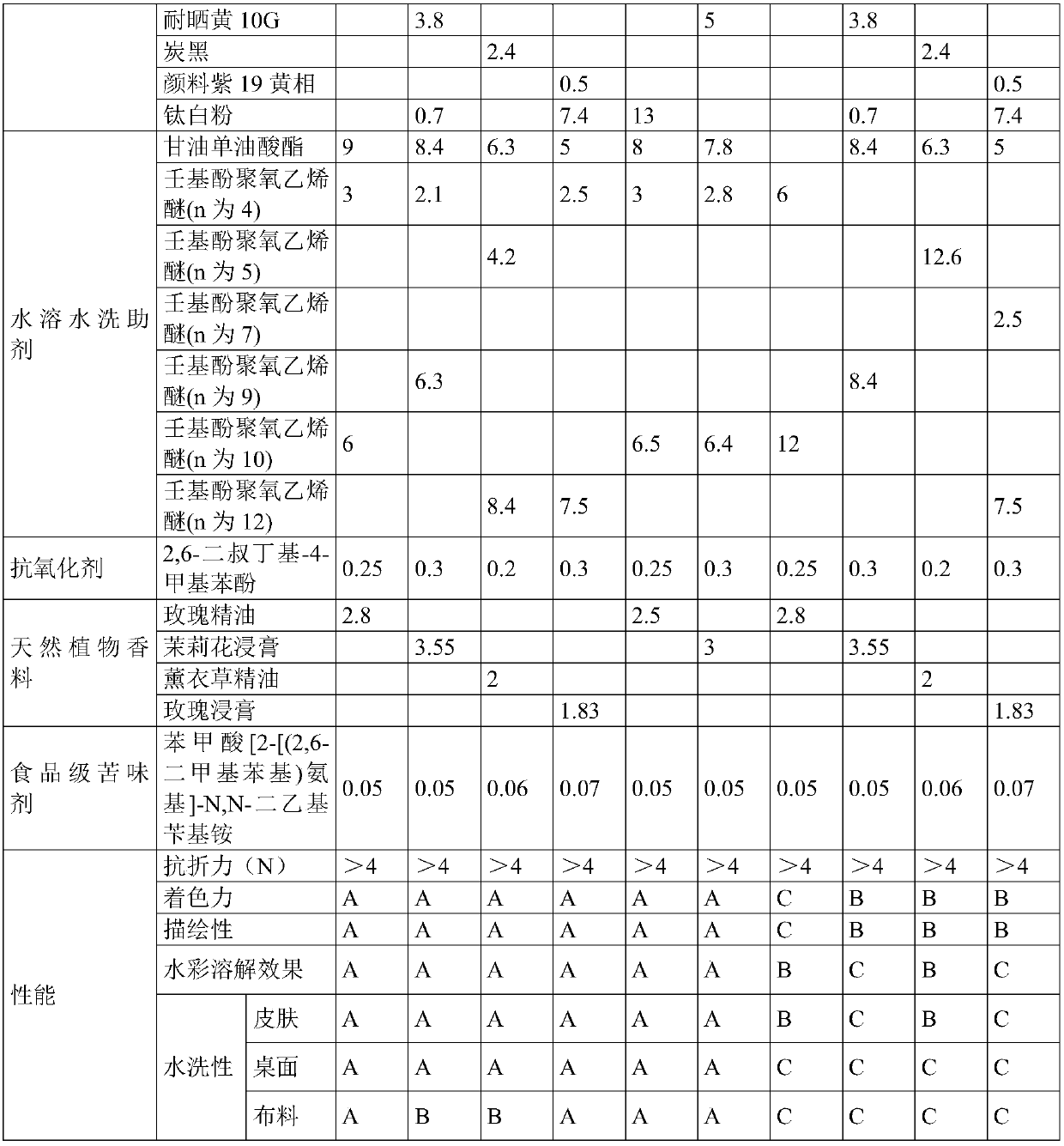

The invention provides a washable graffiti crayon and a preparation method thereof. The washable graffiti crayon comprises the following components in parts by weight: 5-15 parts of wax, 0.5-2 parts of bee wax, 3-10 parts of stearic acid, 30-40 parts of hardened oil, 1-4 parts of white mineral oil, 15-30 parts of filler, 1-15 parts of environment-friendly pigment, 15-25 parts of water-soluble washing auxiliaries, 0.01-1.5 parts of antioxidant, 0.1-5 parts of natural plant perfume material and 0.001-0.3 part of food grade bitter agent. The washable graffiti crayon provided by the invention hasthe advantages of environmental protection, non-toxicity, anti-microbial property, safety, fresh flavor, bright color, smooth and non-sticky crayon body, fine and smooth graffiti without dreg falling,capability of drawing on various interfaces and capability of being removed by washing with water. After the washable graffiti crayon is used for drawing on paper, a watercolor-similar art effect canbe achieved by using a writing brush for polishing the painting with water.

Owner:SHANGHAI M&G STATIONERY INC

Aluminum product cleaning agent and preparation method thereof

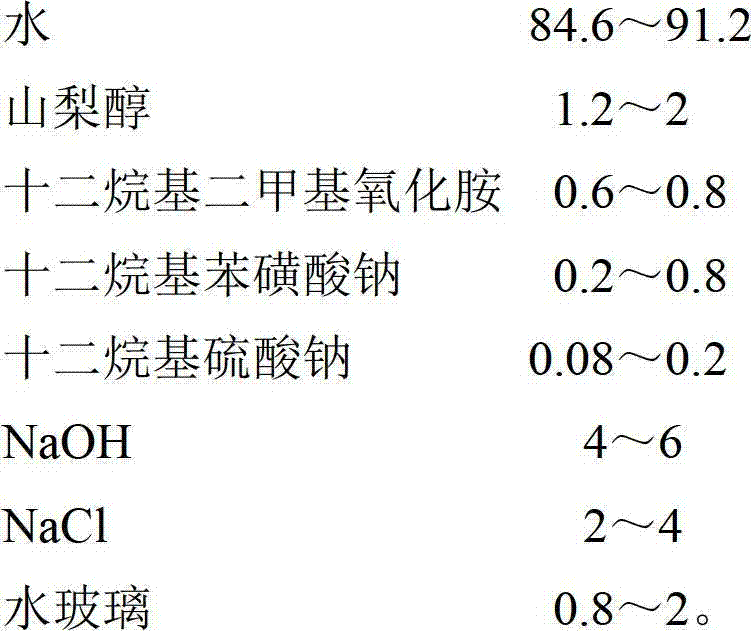

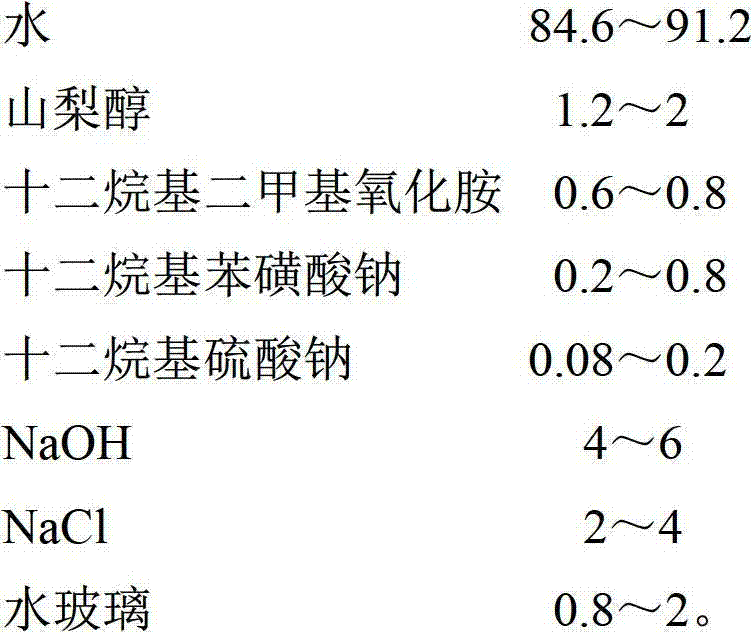

The invention relates to an aluminum product cleaning agent and a preparation method thereof. The preparation method includes: (1) sequentially putting partial of water, sorbitol, dimethyl dodecyl amine oxide, sodium dodecyl benzene sulfonate and lauryl sodium sulfate into a reaction kettle, and fully stirring the solution until the mixture is totally dissolved to obtain mixture A for spare; (2) sequentially putting the remaining water, NaOH, NaCl and sodium silicate into the reaction kettle, stirring the solution until the mixture is totally dissolved to obtain mixture B; and (3) cooling the mixture B to the room temperature, adding the mixture A in the mixture B, and fully stirring until the solution is even to obtain the finished product of the aluminum product cleaning agent. The aluminum product cleaning agent has strong cleaning capability and can thoroughly clean oil dirt, the oil dirt is small in corrosion, an oxidation film on the surface of an aluminum product cannot be damaged, the glossiness of an aluminum part is maintained, and the aluminum part is free of watermarks, spots and residual dirt and is non-discoloring.

Owner:TIANJIN CHEM REAGENT RES INST

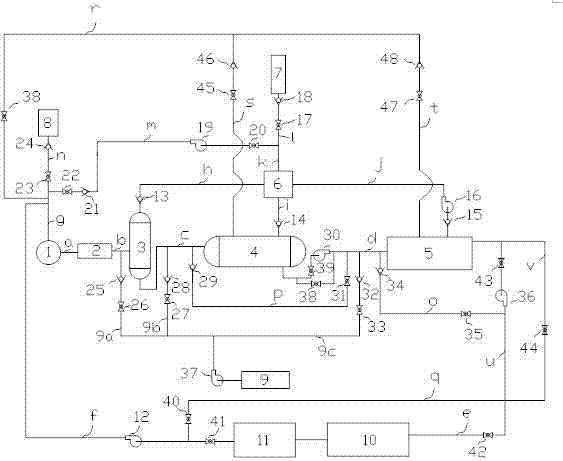

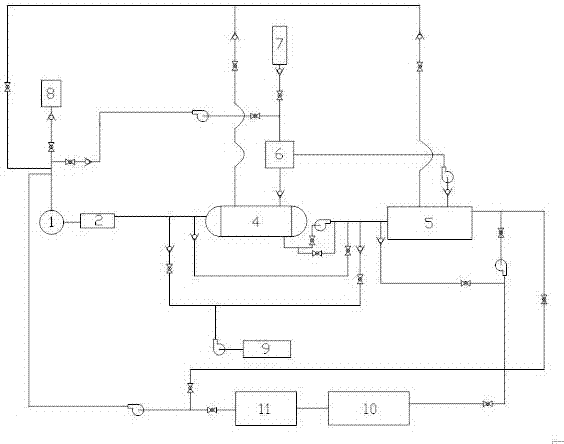

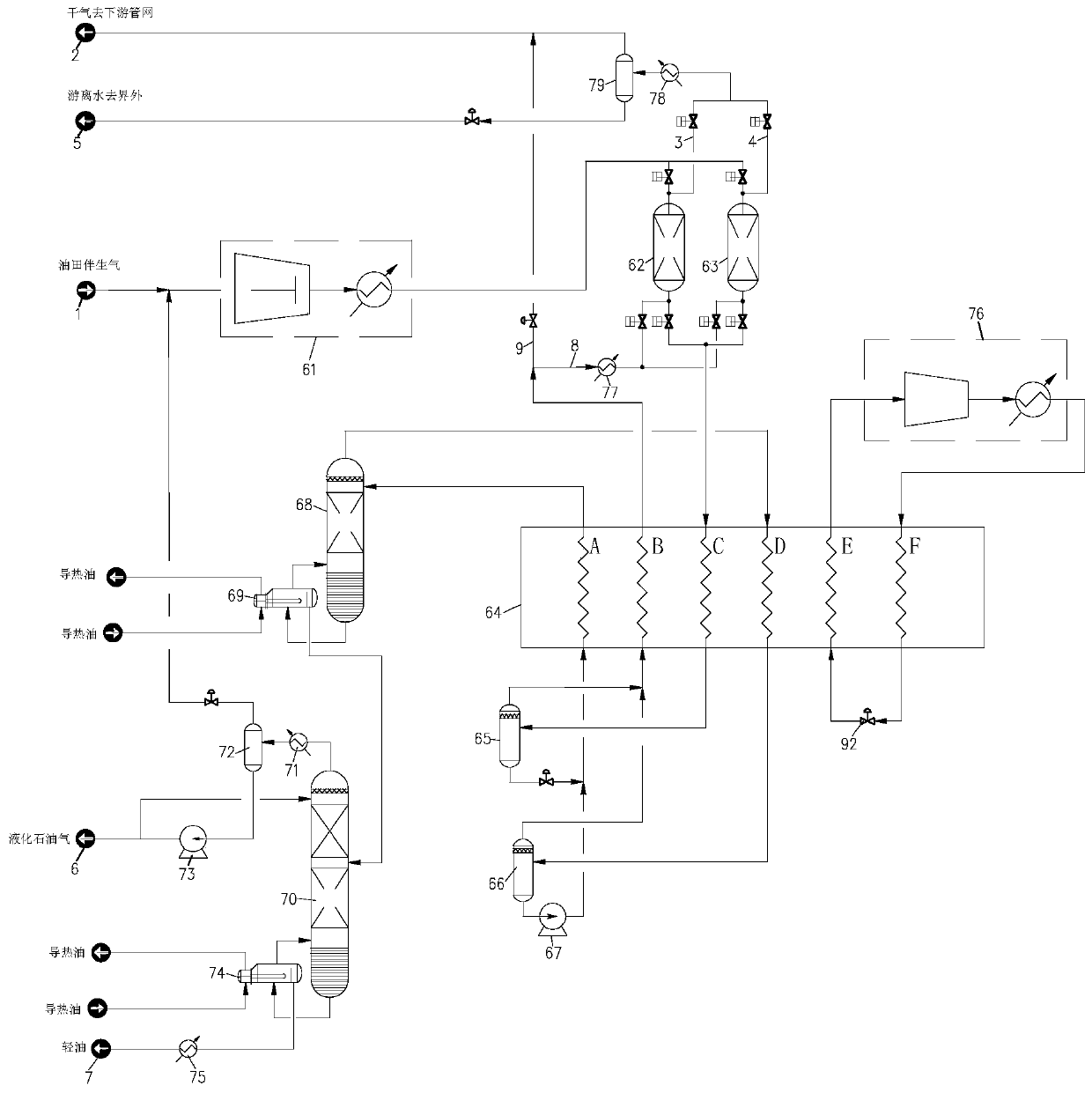

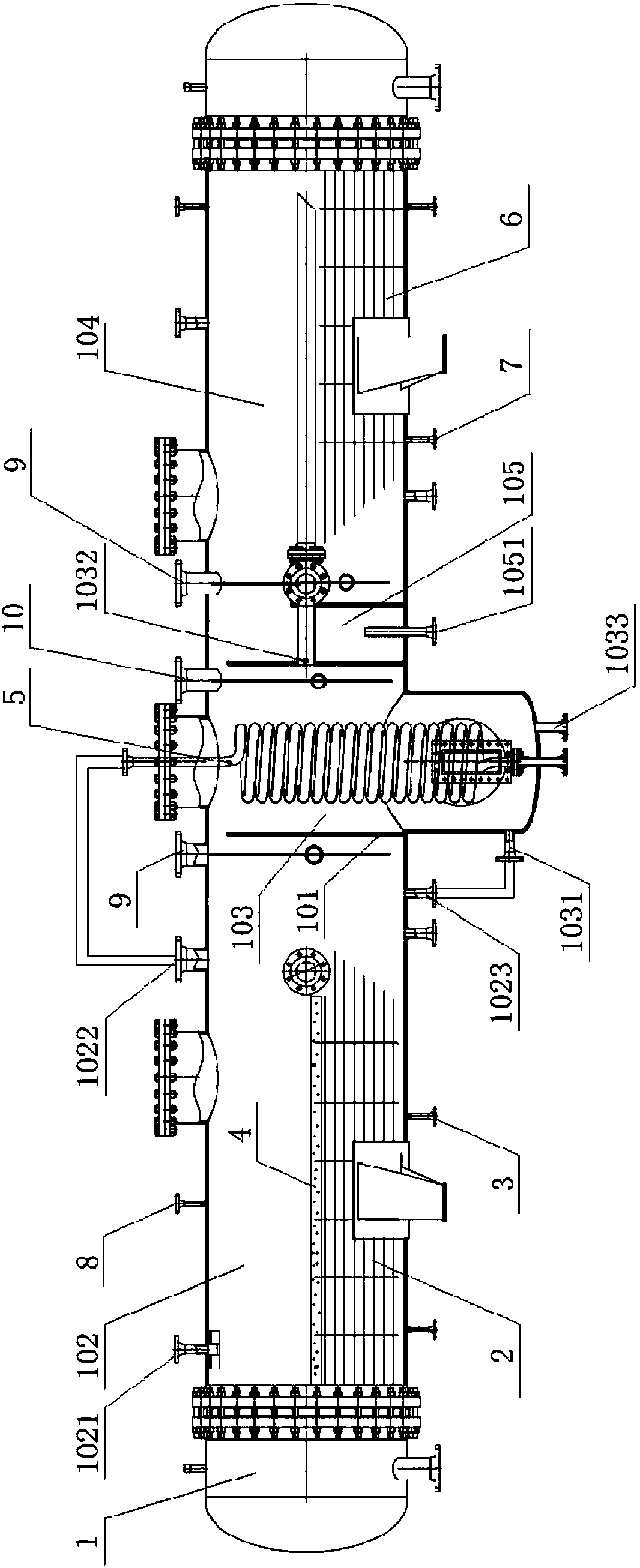

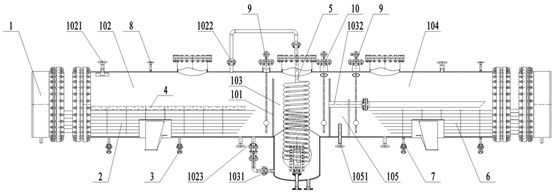

Low-temperature flash evaporation and light hydrocarbon recovery system and method used for oilfield associated gas

PendingCN110538476AHigh recovery rateReduce adsorptionGas treatmentDispersed particle separationGas compressorReboiler

The invention relates to a low-temperature flash evaporation and light hydrocarbon recovery system and method used for oilfield associated gas. The recovery system comprises a raw material gas compressor, a first adsorption column, a low-temperature heat exchanger, a first-stage flash separator, a second-stage flash separator, a dethanizing column, a dethanizing column reboiler, a liquefied gas column, a reflux drum and a liquefied gas column reboiler; and a channel A, a channel B, a channel C and a channel D are arranged in the low-temperature heat exchanger. In the low-temperature flash evaporation and light hydrocarbon recovery system used for the oilfield associated gas, gas from the top of the dethanizing column enters the second-stage flash separator after running through the low-temperature heat exchanger again and being cooled to certain temperature, separated gas meets the requirements of dry gas exportation, after the separated gas and gas separated from the first-stage flashseparator are mixed, and are reheated by the low-temperature heat exchanger, obtained mixed gas goes to a dry gas downstream pipe network, liquid separated from the second-stage flash separator is boosted by a liquid booster pump, then obtained boosted liquid and liquid separated from the first-stage flash separator are mixed, and obtained mixed liquid goes to the dethanizing column after being reheated by the low-temperature heat exchanger, so that the recovery rates of heavy components of propane, butane, pentane and the like are improved.

Owner:HANGZHOU HONGSHENG ZHONGHONG NEW ENERGY CO LTD

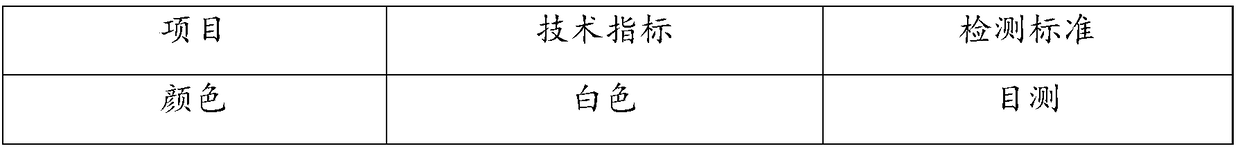

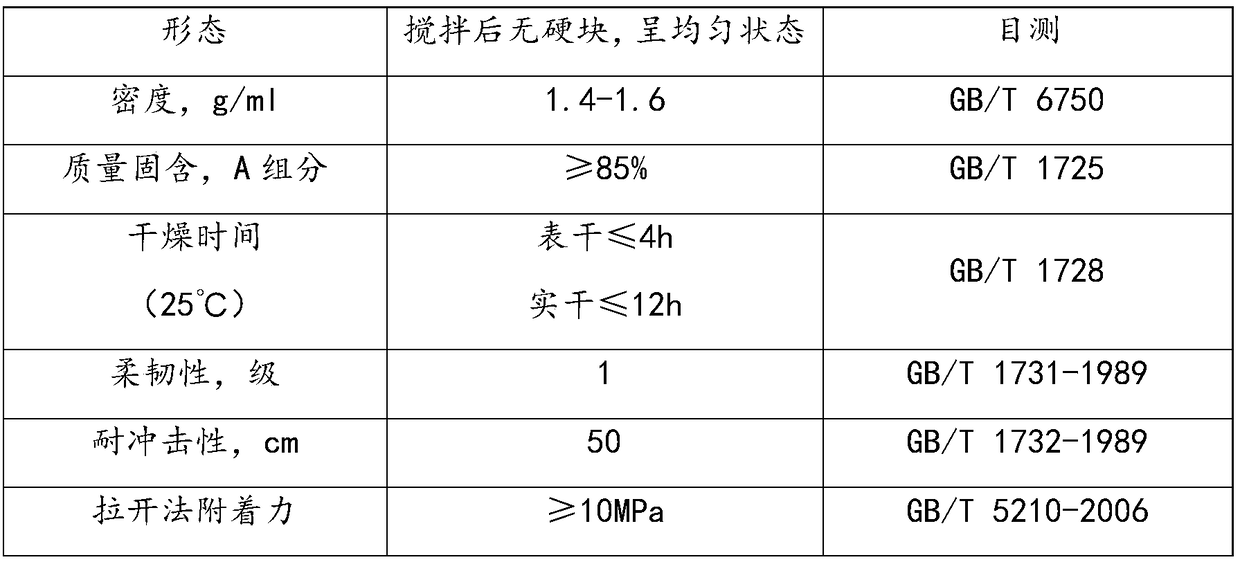

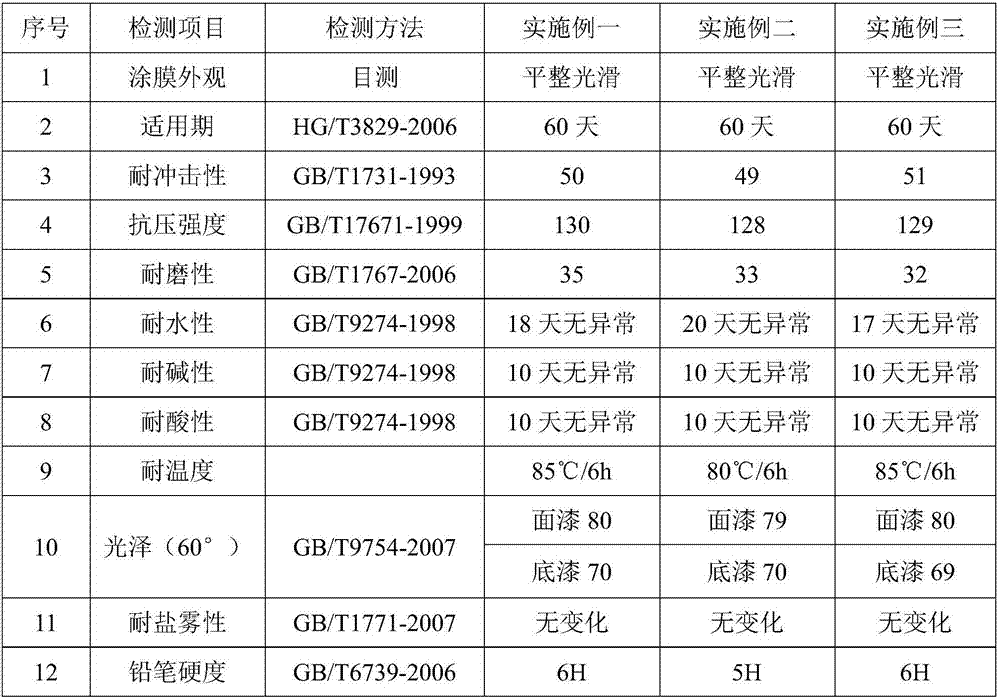

Chemical-resistant epoxy inner lining coating and preparation method thereof

InactiveCN109504234AImprove shielding effectReduce internal stressEpoxy resin coatingsSolventChemistry

The invention relates to the technical field of coatings, and particularly relates to a chemical-resistant epoxy inner lining coating and a preparation method thereof. The chemical-resistant epoxy inner lining coating provided by the invention is prepared from a component A and a component B, wherein the component A is prepared from the following components in parts by weight: 29 to 36 parts of bisphenol F epoxy resin, 0.4 to 0.6 part of a wetting dispersant, 0.3 to 0.5 part of an antifoaming agent, 0.4 to 0.6 part of a thixotropic agent, 10 to 18 parts of pigment, 30 to 32 parts of a filler a, 10 to 16 parts of a filler b and 6 to 10 parts of a mixed solvent; the component B is prepared from the following components in parts by weight: 70 to 75 parts of an aliphatic amine additive product, 22 to 27 parts of an organic solvent, 1.5 to 2 parts of a curing accelerator and 1 to 2 parts of an adhesion promoter; and the weight ratio of the component A to the component B is (3 to 4) to 1. The chemical-resistant epoxy inner lining coating provided by the invention is sufficiently cured in a normal-temperature condition, does not contain any active thinners or plasticizers, and has excellent chemical resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Recovery method for electrolytically extracting metal from catalyst after synthesizing diamonds from powder

InactiveCN103361672AReduce labor intensityImprove working conditionsPhotography auxillary processesProcess efficiency improvementRecovery methodMaterials science

The invention discloses a recovery method for electrolytically extracting metal from a catalyst after synthesizing diamonds from powder. The recovery method comprises the following steps of: (a) putting broken diamond synthesis bar powder into an anode bag, simultaneously putting an anode plate into the anode bag, and putting the anode bag into an electrolytic cell; (b) injecting water into the electrolytic cell until the anode bag is completely soaked in the water, then adding conducting salt, adding a buffer agent which is 3-10% of weight of the added water, so as to obtain electrolyte; and (c) circularly heating the prepared electrolyte to 51-65 DEG C, putting a cathode plate into the prepared electrolyte after maintaining the temperature for 3-5 hours, sealing the electrolytic cell, electrifying, and depositing metal ions on the cathode plate to realize electrolytic recovery, wherein the cathode-current density is controlled at 1-8 A / am<2>, and the temperature of the electrolyte in the electrifying process is maintained at 51-65 DEG C all the time. The invention is suitable for a recovery method for electrolytically extracting noble metals in the catalyst after synthesizing the diamonds from the powder.

Owner:河南金六方超硬材料有限公司

Waterborne bicomponent epoxy iron red shop primer and preparation method thereof

InactiveCN107974166APoisonousFlame retardant and explosion-proofEpoxy resin coatingsPriming paintsEpoxyNano al2o3

The invention discloses waterborne bicomponent epoxy iron red shop primer and a preparation method thereof, and relates to a coating composition. The waterborne bicomponent epoxy iron red shop primerprovided by the invention comprises a component A and a component B, wherein the component A is prepared from waterborne epoxy resin, an iron red pigment, nano alumina, a dispersant, a filling material, a waterborne antifoaming agent, a waterborne preservative, negative ion distilled water and a waterborne amine curing agent; the component B is prepared from a waterborne epoxy resin emulsion, a waterborne antifoaming agent, a waterborne wetting and flatting agent, a waterborne preservative, a water-soluble active thinner and water. The component A and the component B adopted by the waterbornebicomponent epoxy iron red shop primer provided by the invention are both waterborne products, and are easily mixed; a sufficient curing purpose can be achieved. The waterborne bicomponent epoxy ironred shop primer has higher impact resistance, cannot generate foaming and stripping phenomena, meanwhile, has advantages of nontoxicity, flame retarding effect, explosion-proof effect, long application period, high hardness of film and high toughness, has uniform color and cluster, and can be used for meeting requirements of safety and environmental protection.

Owner:YIXING JUREN PAINT

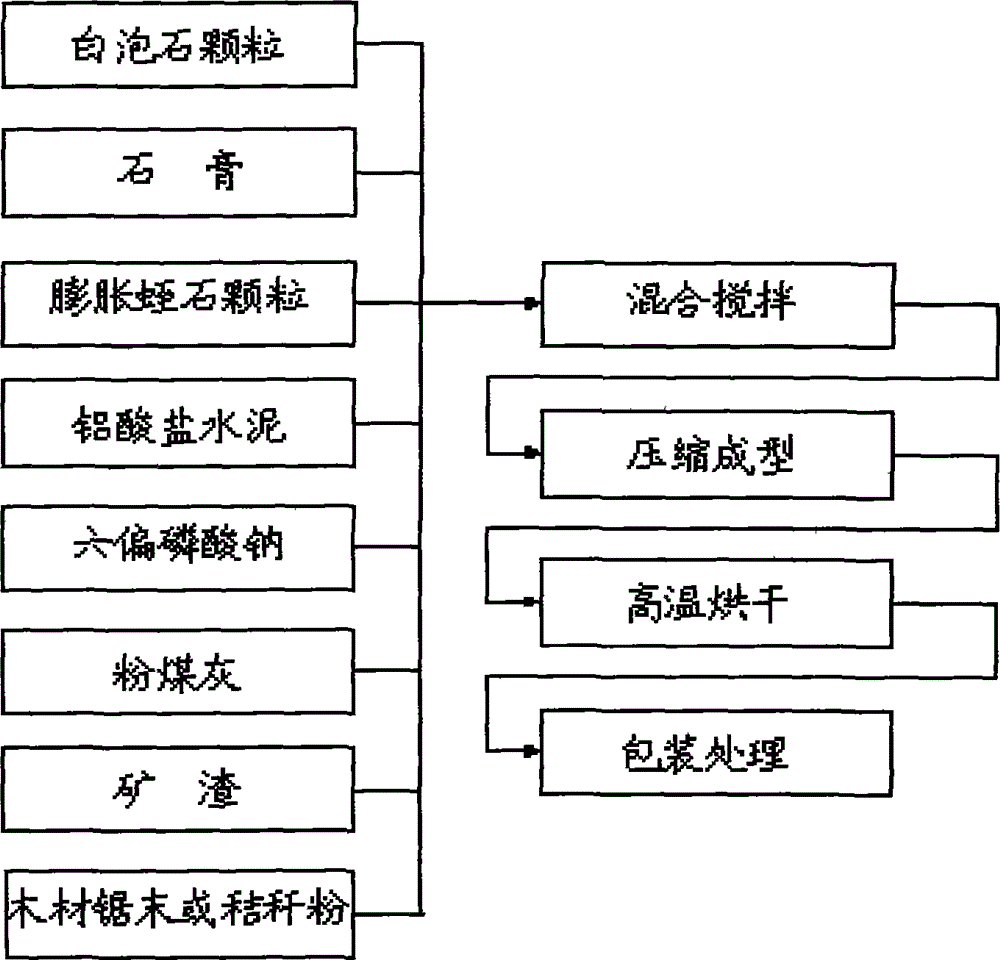

Environmentally-friendly and fireproof door panel and making method thereof

The invention relates to a construction fireproof member, and concretely relates to an environmentally-friendly and fireproof door panel and a making method thereof. The door panel is made through mixing white afrodite particles, gypsum, expanded vermiculite particles, aluminate cement, sodium hexametaphosphate, fly ash, mineral slag, and wood shavings or straw powder, and through molding. The door panel has lightweight and a fireproof function, and is in favor of realizing environmental protection due to use of recovered resources.

Owner:宋伟滨

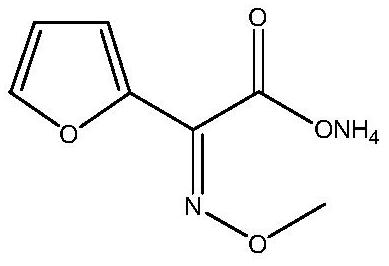

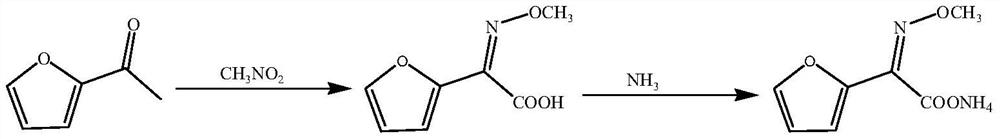

Synthetic method of furan ammonium salt

The invention particularly relates to a synthetic method of furan ammonium salt, and belongs to the technical field of synthesis of medical intermediates. The synthesis method of the furan ammonium salt comprises the following steps: under the catalytic action of a metal salt, reacting acetylfuran with methyl nitrite to obtain 2-imino-2-furan acetic acid, introducing ammonia gas, and carrying outafter-treatment to obtain the furan ammonium salt. The synthesis method of the furan ammonium salt is simple and feasible, reduces the production cost, improves the product yield, is safe and environment-friendly, and has remarkable economic benefits and environment-friendly benefits.

Owner:YIYUAN XINQUAN CHEM

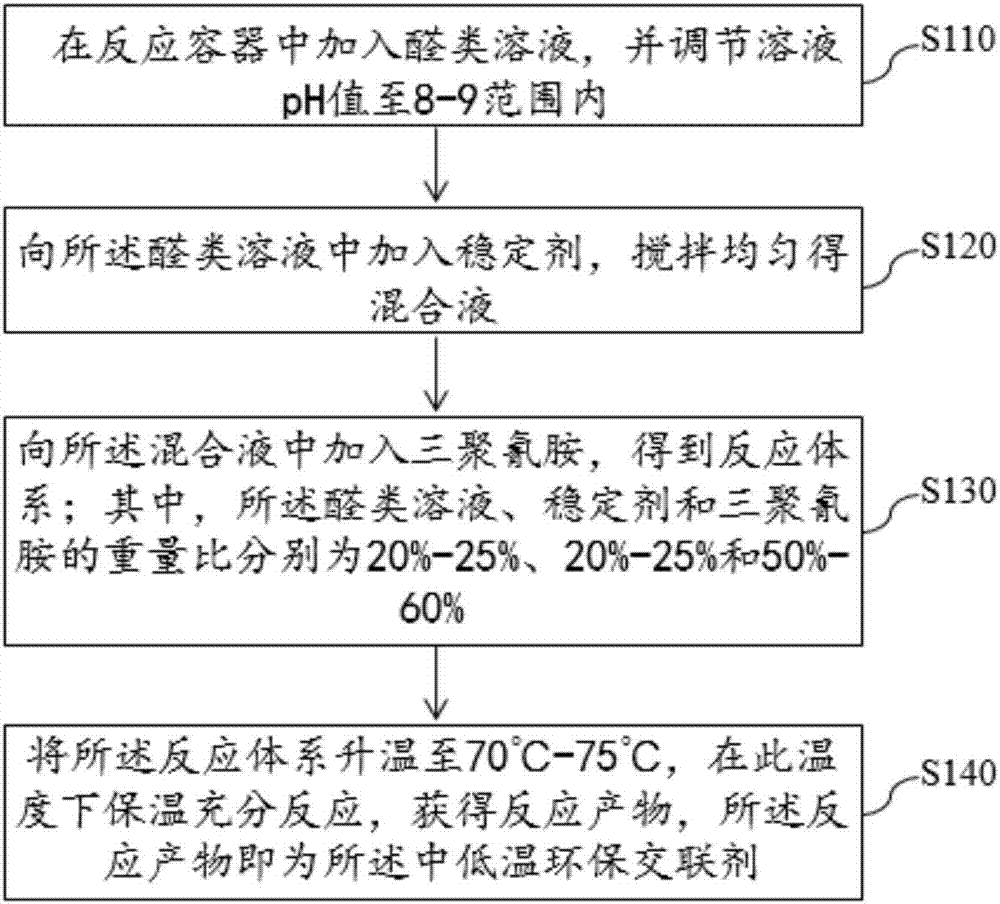

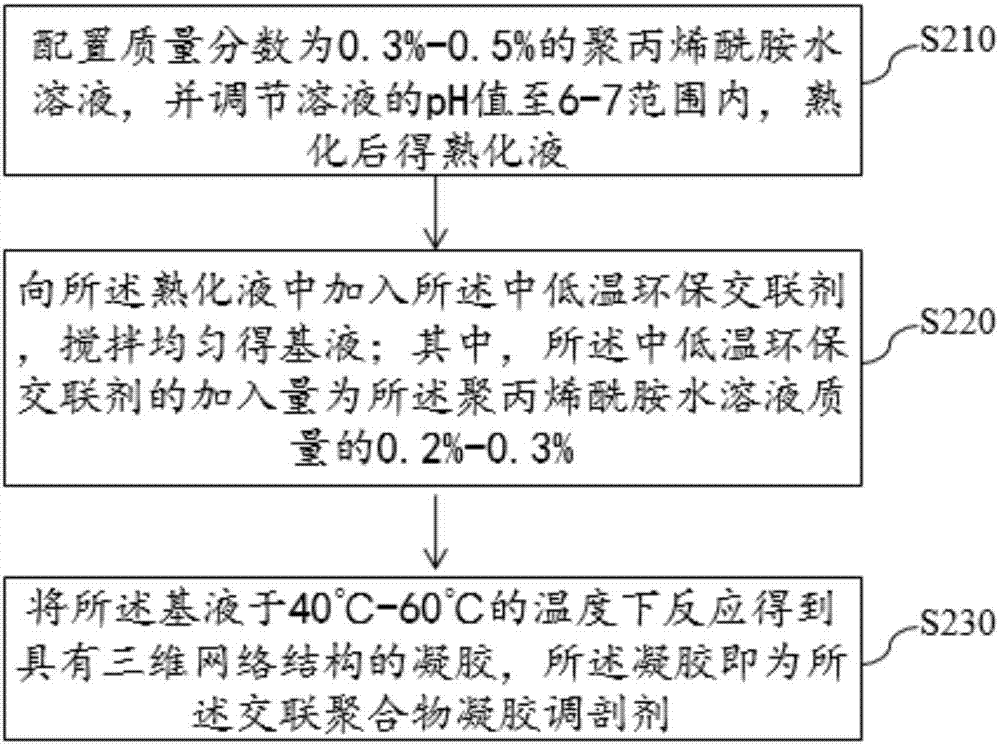

Preparation method and application of medium/low-temperature environment-friendly crosslinking agent

ActiveCN107365573ANo irritating smellReduce typesOrganic chemistryDrilling compositionCrosslinked polymersMelamine

The invention discloses a preparation method and application of a medium / low-temperature environment-friendly crosslinking agent, belonging to the technical field of oilfield chemistry. The preparation method of the crosslinking agent comprises the following steps: adding an aldehyde solution into a reaction vessel, and regulating the pH value of the solution to 8-9; adding a stabilizer, and performing uniform stirring; and finally, adding melamine, performing heating to 70-75 DEG C, and performing a sufficient reaction while keeping at such temperature, thereby obtaining the medium / low-temperature environment-friendly crosslinking agent, wherein the mass percents of the aldehyde solution, stabilizer and melamine are respectively 20-25%, 20-25% and 50-60%. When being used for preparing a crosslinked polymer gel profile control agent, the medium / low-temperature environment-friendly crosslinking agent prepared by the method can form a gel at 40-60 DEG C, and the gel formation time is controllable within the range of 12 hours to 7 days; the formed gel system is stable, and the gel viscosity can reach 8000 mPa.s or above; and the crosslinking agent is safe and nontoxic, has small pollution to the oil reservoir, and satisfies the requirements for safety and environment friendliness in the production process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

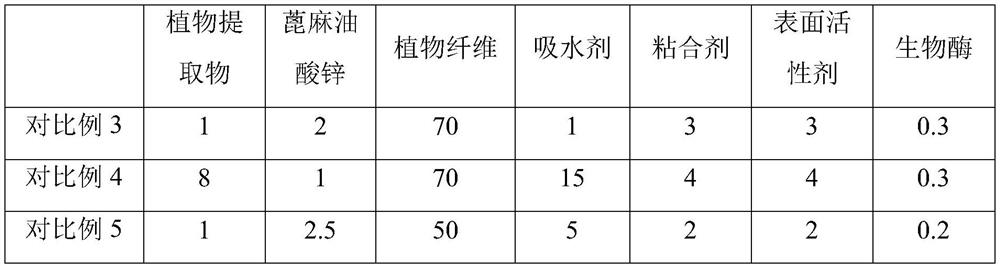

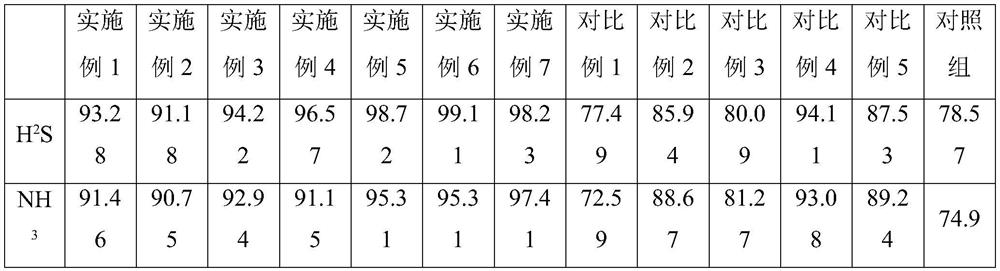

Cat litter with deodorization and disinfection functions and preparation method thereof

The invention relates to a cat litter with deodorization and disinfection functions and a preparation method thereof, and relates to the field of pet supplies, the cat litter comprises the following raw materials by weight: 3-5 parts of a plant extract, 1-5 parts of zinc diricinoleate, 60-90 parts of plant fiber, 5-10 parts of a water absorbent, 3-7 parts of an adhesive, 2-5 parts of a surfactant, and 0.3-0.5 part of a biological enzyme; based on the total amount of the plant extract, the plant extract is prepared from the following raw materials in parts by weight: 1-3 parts of celastrus angulatus, 2-4 parts of coptis chinensis, 1-3 parts of melaleuca bracteata and 2-3 parts of yucca. The cat litter with the deodorization and disinfection functions, provided by the invention, has the effects of environmental protection, safety, high water absorption, efficient deodorization and bacteriostasis and the like, and is lower in cost.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

A car interior cleaning agent

ActiveCN103710178BImprove decontamination abilityNot corrosiveSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsCarboxylate

The invention provides a cleaning agent for automotive interior ornaments. The cleaning agent comprises the following raw materials by weight: 0.1-0.4 part of alcohol ether carboxylate, 0.1-0.4 part of alkyl glycoside, 0.1-0.3 part of a terpene compound, 50 ppm of an antibacterial agent, 0.01-0.02 part of dispersant, 5-15 parts of low molecular alcohol and 80-150 parts of water. The cleaning agent has the characteristics of environment protection, high security and strong decontamination capability.

Owner:CHINA PETROLEUM & CHEM CORP

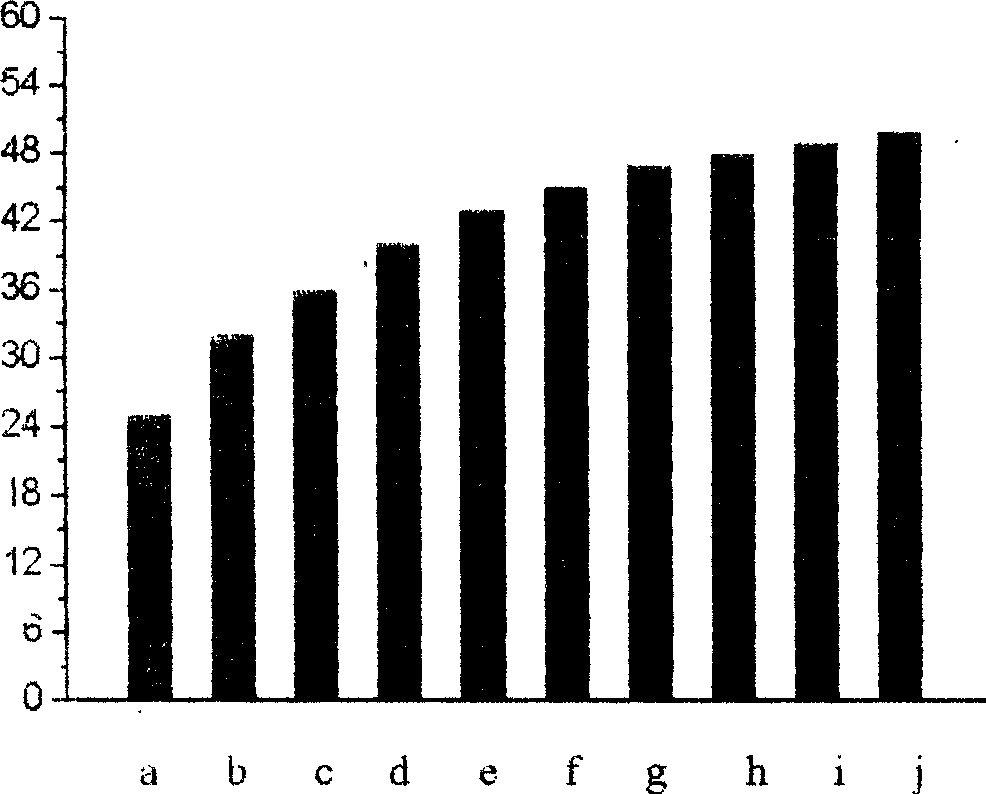

Preparation method of amphoteric comb-shape polyacrylamide by synthesis of quaternary ammonium salt functional monomer

ActiveCN102432750AConvenient heat transferUniform distribution of reaction temperatureFunctional monomerAmmonium sulfate

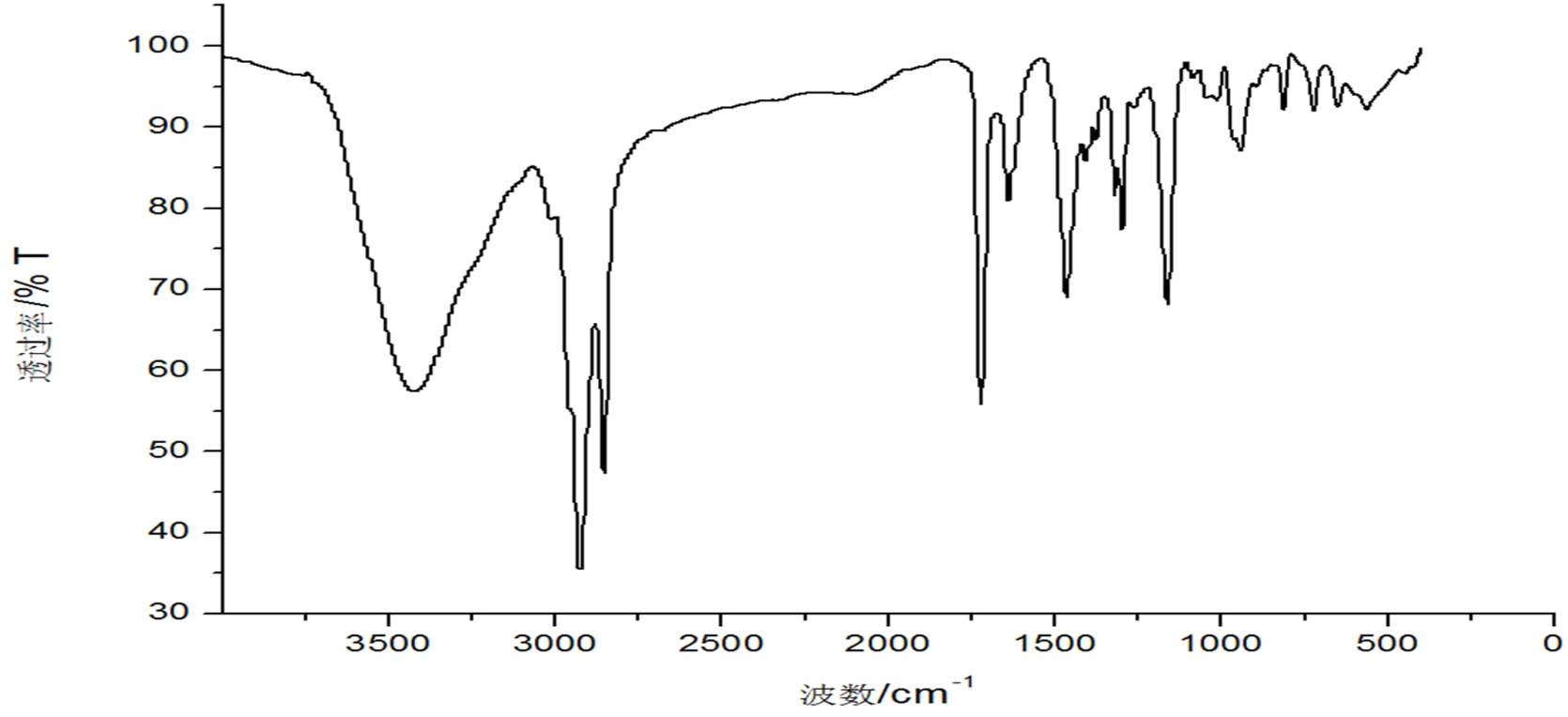

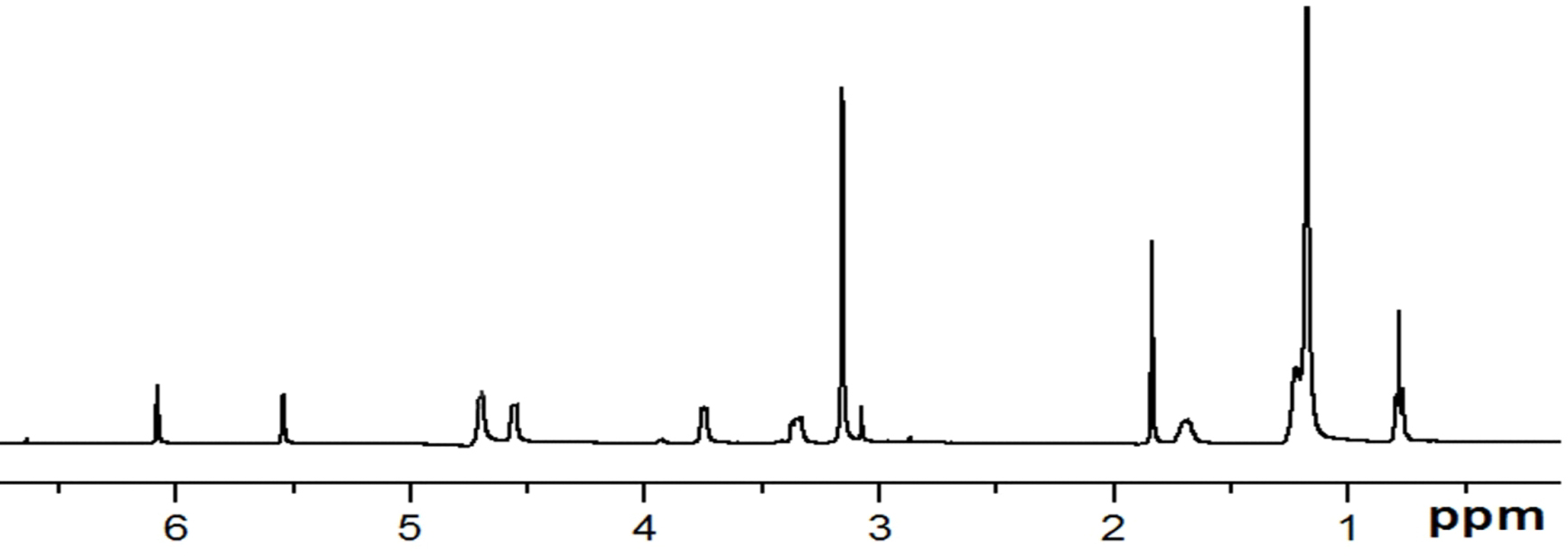

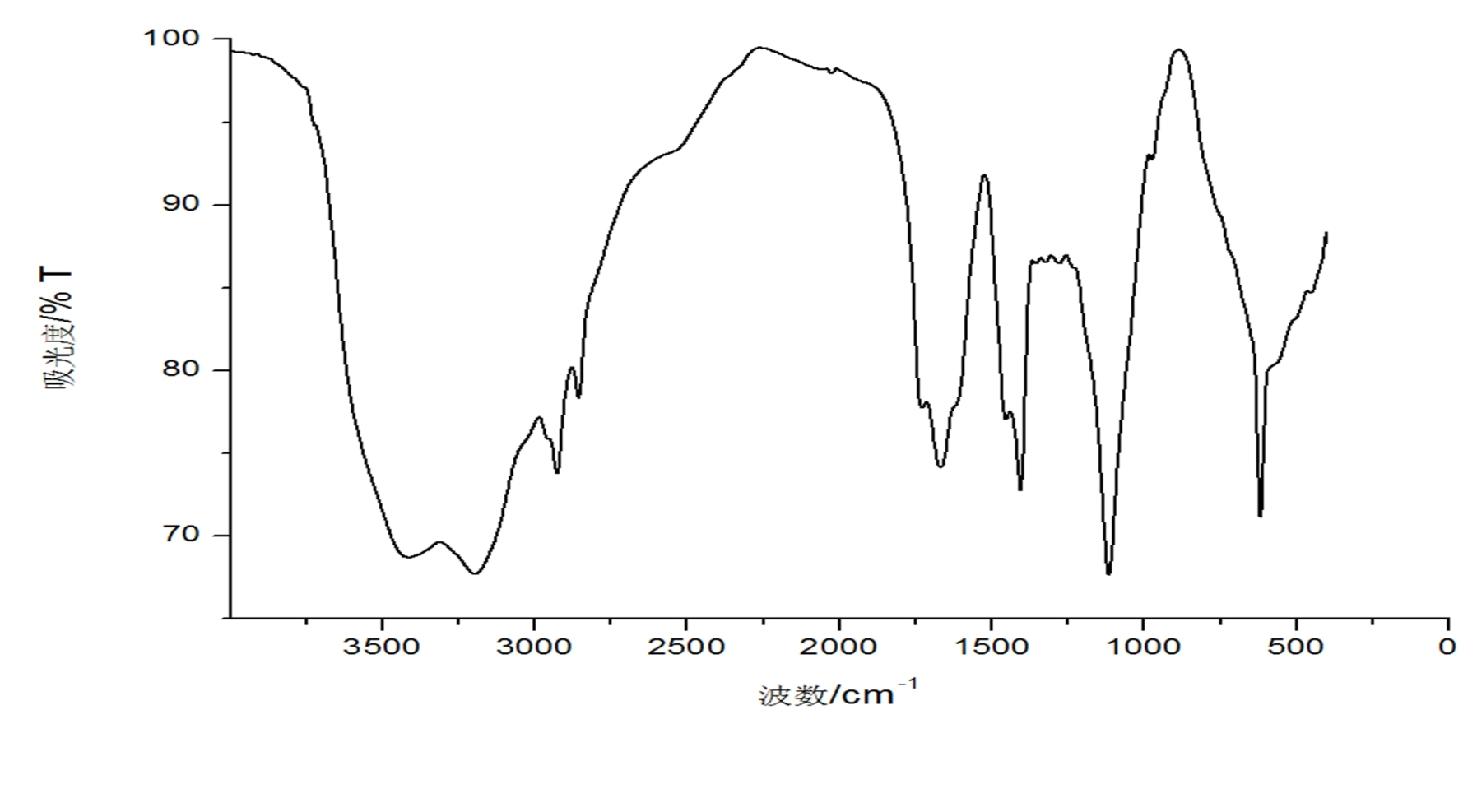

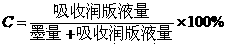

The invention relates to a preparation method of amphoteric comb-shape polyacrylamide by the synthesis of a quaternary ammonium salt functional monomer, comprising the following steps of: dissolving dimethylaminoethyl methacrylate and 1-n alkyl bromide in equimolar ratio with a certain amount of hydroquinones in acetone, and preparing quaternary ammonium salt under the protection of nitrogen; dissolving quaternary ammonium salt, acrylamide and acrylic acid in an ammonium sulfate dispersive aqueous solution, adding a certain amount of span 80, stirring, heating up to the initiation temperature, adding dropwisely ammonium persulfate, and initiating polymerization under the protection of nitrogen so as to finally obtain quaternary ammonium salt functional monomer synthesized amphoteric comb-shape polyacrylamide. Through the synthesis of the quaternary ammonium salt functional monomer, the obtained novel polyacrylamide has amphoterism and a long-chain comb-shaped structure, and is endowedwith high viscoelasticity, anti-shearing performance, temperature resistance and pH resistance. The attached graph is the infrared spectra of the synthesized quaternary ammonium salt 1 in the embodiment 1.

Owner:EAST CHINA UNIV OF SCI & TECH

Environment-friendly fountain solution and preparing method of environment-friendly fountain solution

InactiveCN104139627AMeet the requirements of safety and environmental protectionImprove hard water resistancePrinting pre-treatmentAdditive ingredientPhosphate

The invention discloses an environment-friendly fountain solution, which is characterized by being prepared from the following ingredients in parts by weight: 2 to 10 parts of polyoxyethylene isooctyl ether phosphate, 2 to 8 parts of corn starch, 1 to 3 parts of ammonium bicarbonate, 0.5 to 1.5 parts of trihydroxymethyl aminomethane, 1 to 3 parts of nicotinamid, 1 to 3 parts of sodium octane sulfonate, 1 to 3 parts of castor oil, 2 to 8 parts of castor oil maleic acid ester, 0.5 to 1.5 parts of tea polyphenol, 1 to 5 parts of lactic acid, 1 to 4 parts of L-Aspartyl-L-phenylalanine methyl ester, 1 to 2 parts of tea tree essential oil, 5 to 10 parts of auxiliaries and 30 to 50 parts of water. The fountain solution disclosed by the invention has the advantages that the raw material resource is rich, the cost is low, the wetting effect is good, volatile and irritant substances are not contained, the cost is reduced, the fountain solution is mild and harmless to human bodies and environments, and the requirements of energy saving and environment protection are met.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

Material for three-dimensional forming, three-dimensional object, and slice layer of three-dimensional object

ActiveCN111978479AFirmly connectedImprove bindingAdditive manufacturing apparatusPolymer sciencePolyamide

The present application provides a material for three-dimensional forming, a three-dimensional object and a slice layer of the three-dimensional object. The material comprises a powder material and aliquid material, wherein the powder material comprises polyamide powder and / or modified polyamide powder; the liquid material comprises a first active component, and the first active component can besubjected to a polymerization reaction; the first active component dissolves at least part of the polyamide powder and / or the modified polyamide powder, and the powder material itself does not undergoa polymerization reaction and does not undergo a polymerization reaction with the first active component. According to the material for three-dimensional forming, the three-dimensional object and theslice layer of the three-dimensional object, the mechanical strength and density of the three-dimensional object can be effectively improved.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Low base weight high-strength food grade unbleached waxing raw paper

ActiveCN105019297AReduce absorptionReduce air permeabilityWater-repelling agents additionReinforcing agents additionBursting strengthToxic material

The invention relates to a low base weight high-strength food grade unbleached waxing raw paper. The base weight of the waxing raw paper is 20-25g / m<2>, the tightness is 0.7-0.8g / m<2>, the opacity is 60-65%, the air permeability is 0.4-0.5micrometer / Pa.s, the vertical and horizontal tearing strength is 130-140mN, the bursting strength is 85-100KPa, the evenness is 900-925, and the vertical and horizontal average fracture length is 5-8Km. The slurry adopted by the waxing raw paper comprises, by weight, 47-60 parts of softwood pulp, 36-48 parts of hardwood pulp, and 4-6 parts of china clay. The food grade unbleached waxing raw paper provided by the invention has the advantages of low base weight, high strength, high evenness, low absorption, low air permeability and certain opacity, the adopted wood pulp raw materials are not bleached and are not added with fluorescent agent or other toxic ingredients. The obtained waxing raw paper is safe and non-toxic, the production waste liquor has no toxic substance emission. Therefore, the low base weight high-strength food grade unbleached waxing raw paper is in line with the requirements of safety and environmental protection.

Owner:浙江佳维康特种纸有限公司

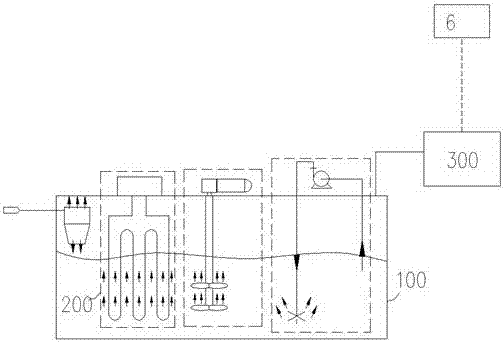

Aging oil dehydration device and method

ActiveCN109135813ALow costEasy to useTreatment with plural serial refining stagesMoistureWater vapor

The invention discloses an aging oil dehydration device and method. The aging oil dehydration device comprises a shell body, an inner cavity is divided into a heating demulsification area, a settlingdehydration area, a selected up-to-standard area and an external discharge oil area communicated with the selected up-to-standard area through an overflow port, wherein the upper portions of the heating demulsification area, settling dehydration area, selected up-to-standard area and external discharge oil area are communicated in sequence; the heating demulsification area is internally provided with a first heat conduction oil tube connected with a heat conduction oil furnace, the top of the heating demulsification area is provided with an aging oil inlet and a steam outlet, and the bottom ofthe heating demulsification area is provided with a first oil outlet; the settling dehydration area is internally provided with a steam delivery pipeline, the side wall of the lower portion of the settling dehydration area is provided with an oil inlet communicated with the first oil outlet, and a partition plate where the side wall of the settling dehydration area is located is provided with a second oil outlet communicated with the selected up-to-standard area; an inlet of the steam delivery pipeline is communicated with a steam outlet, and an outlet of the steam delivery pipeline is connected with a drainage pipeline; the selected up-to-standard area is internally provided with a second heat conduction oil tube connected with the heat conduction oil furnace; and the bottom of the external discharge oil area is provided with a cleaned oil outlet. The aging oil dehydration device has the advantages that the moisture content of the aging oil is reduced to less than 5%, the device is safe and environmentally-friendly, the cost is low, and the use is convenient.

Owner:PETROCHINA CO LTD

Energy-saving aged oil dehydration device

InactiveCN112011358AImprove heat transfer effectReduce consumptionDewatering/demulsification with mechanical meansHydrocarbon dewateringWater vaporHeater Rod

The invention belongs to the technical field of oil field production equipment, and particularly relates to an energy-saving aged oil dehydration device. The device comprises a shell, and a heating demulsification area, a settling dehydration area, a fine selection standard area and an outer oil discharge area communicated with the fine selection standard area through an overflow port are arrangedin the shell. An anti-explosion electric heating rod is arranged in the heating demulsification area, and an aged oil inlet and a water vapor outlet are formed in the top of the heating demulsification area. A water vapor conveying pipeline is arranged in the settling dehydration area, an oil inlet communicated with a first oil outlet is formed in the side wall of the lower portion, and a secondoil outlet communicated with the fine selection standard area is formed in the partition plate where the side wall of the lower portion is located. And an adjustable flow rate control valve is arranged at the oil inlet / outlet. The inlet of the water vapor conveying pipeline is communicated with a water vapor outlet, and the outlet of the water vapor conveying pipeline is connected with a drain pipe. THE explosion-proof electric heating rod is arranged in the selection standard area. A purified oil outlet is formed in the bottom of the external oil drainage area. According to the device, the energy consumption in the actual dehydration treatment process can be reduced, meanwhile, the moisture content of the aged oil is reduced to 0.5% or below, and the device is safe and environmentally friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

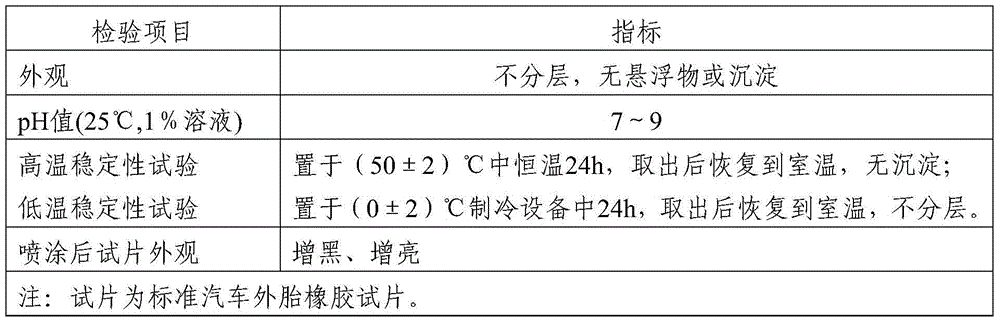

Tyre care agent

ActiveCN105567158ANot corrosiveMeet the requirements of safety and environmental protectionOther chemical processesOrganic solventWear resistant

The invention provides a tyre care agent. The tyre care agent comprises, by weight, 0.5-1 part of a wear resistant reinforcing agent, 0.5-1 part of a silane coupling agent, 0.5-1 part of water-soluble silicone oil, 0.5-1 part of an anionic surfactant, 0.5-1 part of a chelating-type surfactant, 3-10 parts of an organic solvent and 80-150 parts of water. The tyre care agent has the characteristics of environmental friendliness, blackening, brightening and no tyre corrosion.

Owner:CHINA PETROLEUM & CHEM CORP

Plaster board

InactiveCN102505796ASimple structureGood energy saving effectConstruction materialEnergy analysisFiber layer

The invention discloses a plaster board, comprising a board material and plaster layers, wherein the board material comprises a front side and a back side; the plaster layers are uniformly coated on the front side and the back side; and fiber layers are arranged below the plaster layers. According to one embodiment of the invention, the fiber layers are irregular gridding cloths. A foam layer is arranged inside the board material. Furthermore, the board material has a uniform specification and the size of the board material is 1200mm*2400mm. The plaster board provided by the invention is simple in structure and high in energy saving performance, and meets the requirements of safety and environmental friendliness; the plaster board is good in flexibility and is suitable for being used as a partition; the specification is uniform so that the plaster board is convenient to machine; the use cost is saved; and the plaster board is suitable for production on a large scale.

Owner:常熟市华夏建筑节能材料有限公司

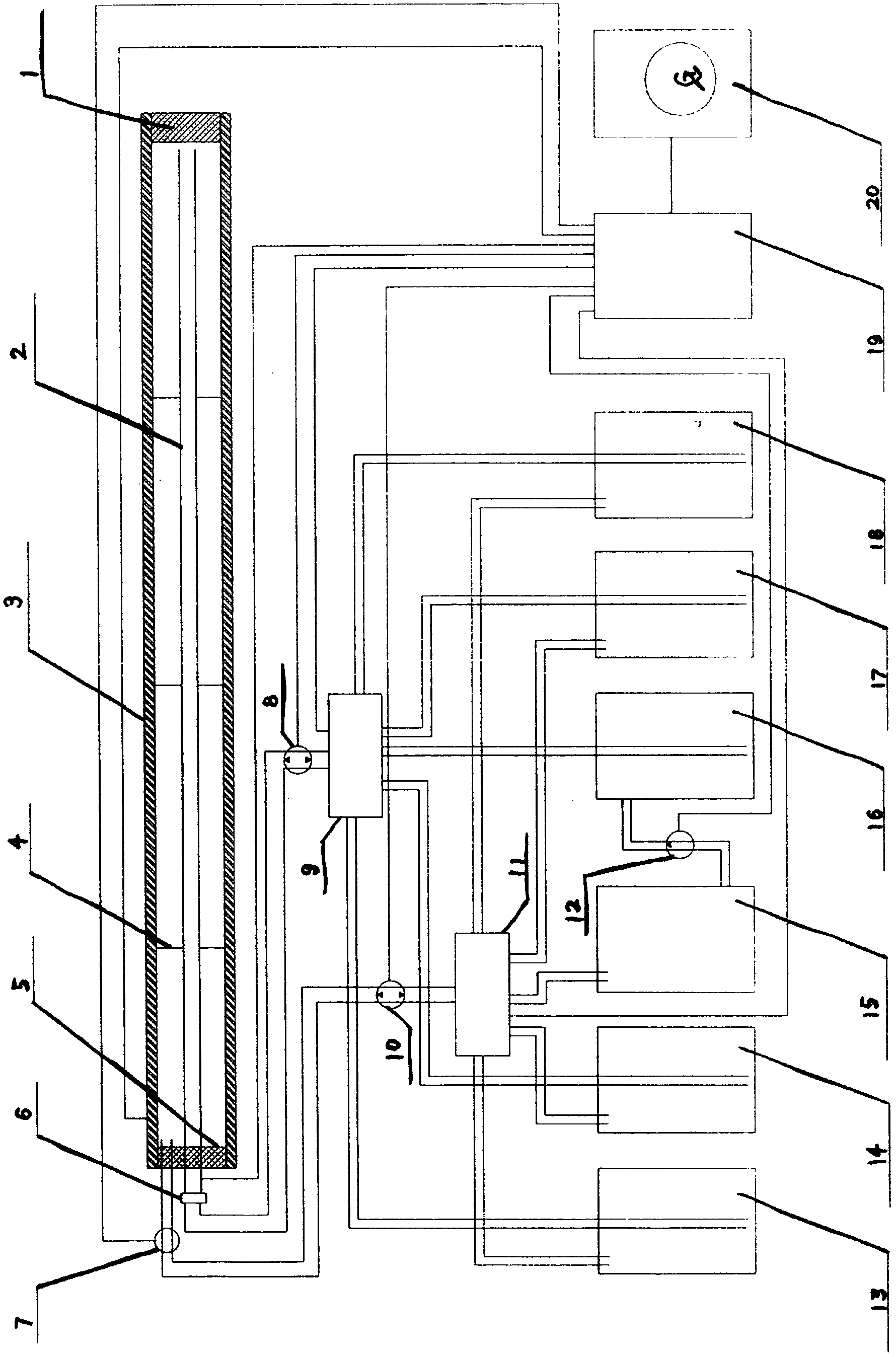

Cannon Electrochemical Copper Removal System

ActiveCN106134424BReduce labor intensityGuaranteed not to leakVentillation systemsWeapon cleaningExhaust valveAutomatic control

The invention relates to a artillery electrochemical copper removal system, which is composed of a wooden plug or a rubber plug, an electrode, a barrel, an insulating support, a rubber plug, a two-way, an exhaust valve, a two-way pump, a solenoid valve, a one-way pump, and a solenoid valve. , one-way pump, degreasing liquid storage tank, degreasing water washing liquid storage tank, electrolyte storage tank, electrolyte recovery storage tank, electrolytic primary washing liquid storage tank, electrolytic secondary washing liquid storage tank, control power supply, generator composition , the use of the present invention not only reduces the labor intensity of gun wiping, but also ensures that the solution does not leak outside, meets the requirements of safety and environmental protection, does not damage the chrome layer in the gun hall, prolongs the service life of the gun, and can increase the copper removal speed of the gun. It is a fully enclosed, environmentally friendly electrochemical copper removal system that can be automatically controlled by a program. This system can be used for copper removal from fixed-position artillery, and it can also be installed on vehicles for field training and artillery copper removal on the battlefield. .

Owner:INNER MONGOLIA FIRST MACHINERY GRP

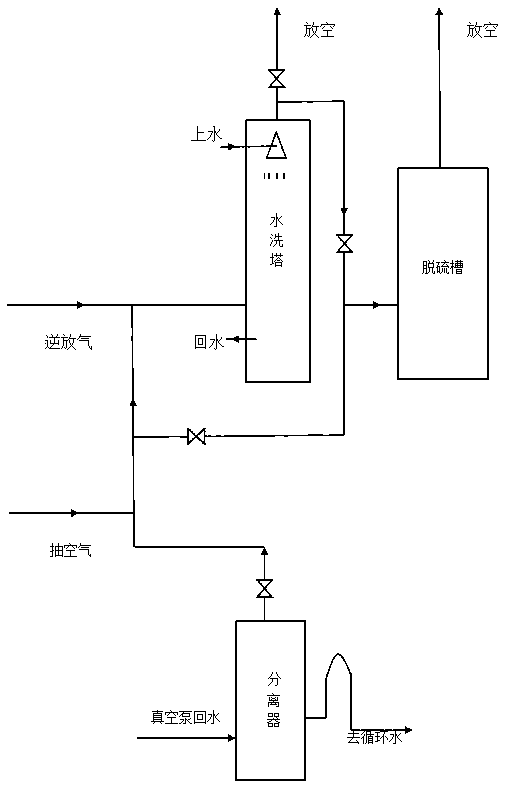

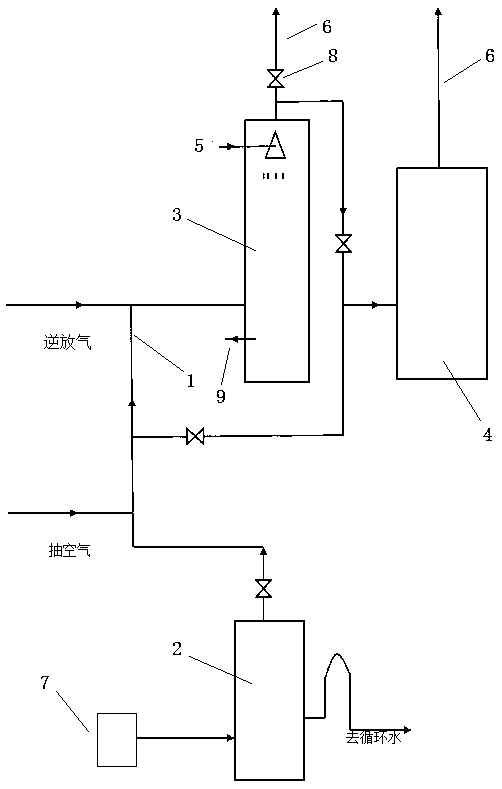

Purification method for pressure swing adsorption decarbonized evacuated gas and purification device thereof

InactiveCN109589743AEfficient purificationNo increased loadGas treatmentDispersed particle separationActivated carbonPurification methods

The invention discloses a purification method for pressure swing adsorption decarbonized evacuated gas and a purification device thereof. The evacuated gas is purified effectively by adding a washingstep behind an original gas evacuating step, carrying out gas-liquid separation on return water of a vacuum pump, controlling the liquid level of a water seal pipe through a U-shaped bend of a separator, ejecting the evacuated gas after gas-water separation from the top of the separator, feeding the evacuated gas into a post-section washing tower and a desulfurizer successively together, feeding the evacuated gas into a washing tower to be washed and purified and adsorbing and purifying acidic gas such as H2S in the evacuated gas by activated carbon, so that the environmental influence is reduced.

Owner:ANHUI JINGHE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com