Environment-friendly fountain solution and preparing method of environment-friendly fountain solution

A dampening solution, an environmentally friendly technology, applied in the field of printing dampening solution, can solve the problems of harm to the human body, pollution of the environment, etc., and achieve good hard water resistance, stable product quality, and good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Preparation of fountain solution

[0019] An environment-friendly dampening solution prepared from the following components by weight (kg): isooctyl alcohol polyoxyethylene ether phosphate 8, corn starch 6, ammonium bicarbonate 2, trishydroxymethylaminomethane 1, smoke Amide 2, sodium octyl sulfonate 2, castor oil 2, castor oil maleate 6, tea polyphenol 1, lactic acid 4, aspartame 3, tea tree essential oil 1.5, additive 8, water 40;

[0020] Among them, the auxiliary agent is made of the following raw materials by weight (kg): gum arabic 7, phosphatidylethanolamine 2, triethanolamine 3, sodium gluconate 6, Tween 20 4, citric acid 3, sodium citrate 10, olive oil 2 , vitamin E 0.3, water 50; under the condition of 70-80°C water bath, add gum arabic, phosphatidylethanolamine, triethanolamine, Tween 20 and olive oil to the water at 200rpm, stop the water bath after 1 hour, cool to room temperature and Add the rest of the raw materials and stir at 200rpm unti...

Embodiment 2

[0025] Embodiment 2: Fountain solution performance test

[0026] Fountain solution mainly affects the balance performance of water and ink in the printing process, and the emulsification rate of ink is an important parameter. The nature of the fountain solution has an important influence on the ink emulsification rate. According to the principle of offset printing, it is feasible for the ink emulsification rate to be lower than 26% during the offset printing process.

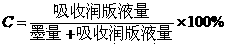

[0027] Determination of ink emulsification rate C: by weight method.

[0028] Dilute the dampening solution described in Example 1 to 3% with distilled water, add 50 g of black ink and 50 g of the diluted dampening solution to the container at one time, stir at 100 r / min for 1 hour and then let it stand for 10 minutes, remove the unabsorbed dampening solution The liquid and the ink are separated in layers, and the emulsification rate of the ink is calculated according to the following formula:

[0029]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com