Energy-saving aged oil dehydration device

A dehydration device and aging oil technology, which is applied in the direction of hydrocarbon oil dehydration, mechanical dehydration/demulsification, etc., can solve the problems of large energy loss, aging oil moisture content can not meet the use requirements, etc., to achieve low cost and reduce energy use The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

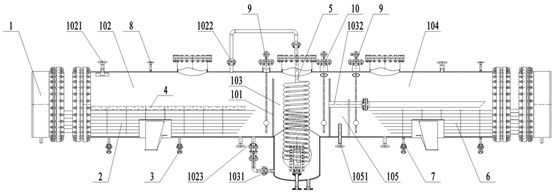

[0025]Referencefigure 1 , An energy-saving aging oil dehydration device, the dehydration device includes a housing 1, a first explosion-proof electric heating rod 2, a first temperature detection element 3, a water vapor transmission pipeline 4, a second explosion-proof electric heating rod 6, a second The temperature detection element 7, the pressure gauge 8, the float level gauge 9 and the oil-water interface instrument 10; the inner cavity of the casing 1 is divided into a heating demulsification zone 102 and a sedimentation dehydration zone 103 which are connected to each other by a partition 101. , Selected standard area 104 and external drain oil area 105, the external drain oil area 105 is located between the sedimentation dehydration area 103 and the selected standard area 104; the first explosion-proof electric heating rod 2 and the second explosion-proof electric heating rod 6 are set On the bottom cavity of the heated demulsification zone 102 and the selected standard-rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com