Patents

Literature

157results about How to "Increase heat exchange intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

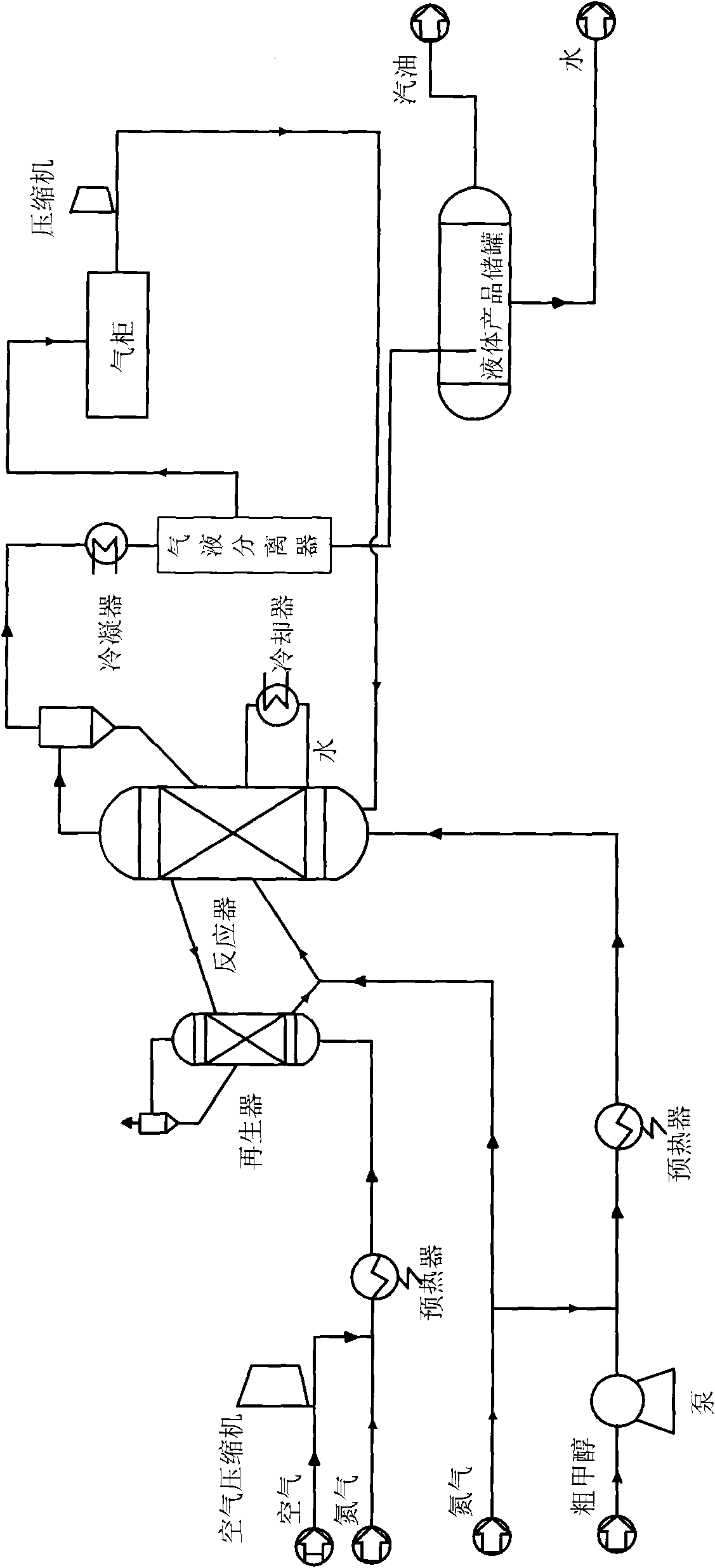

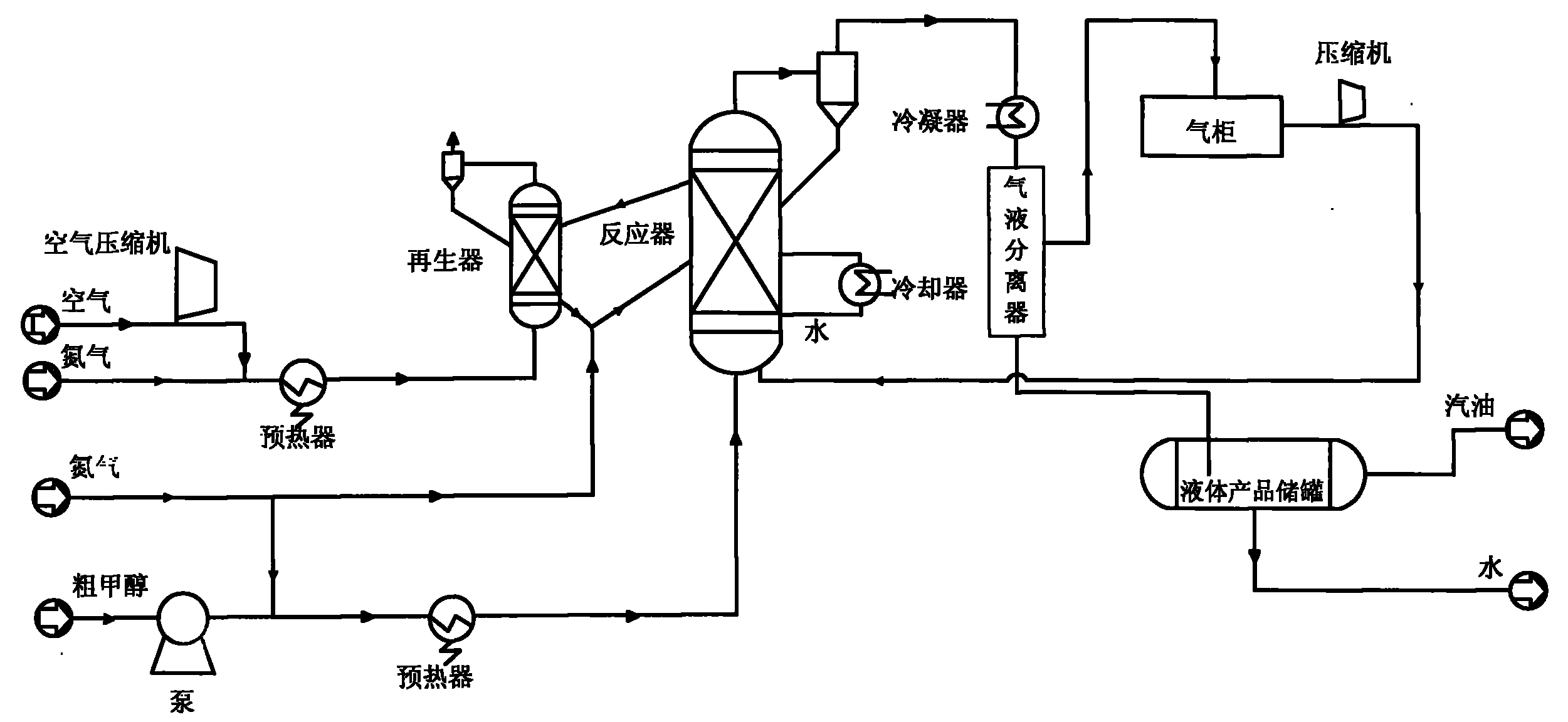

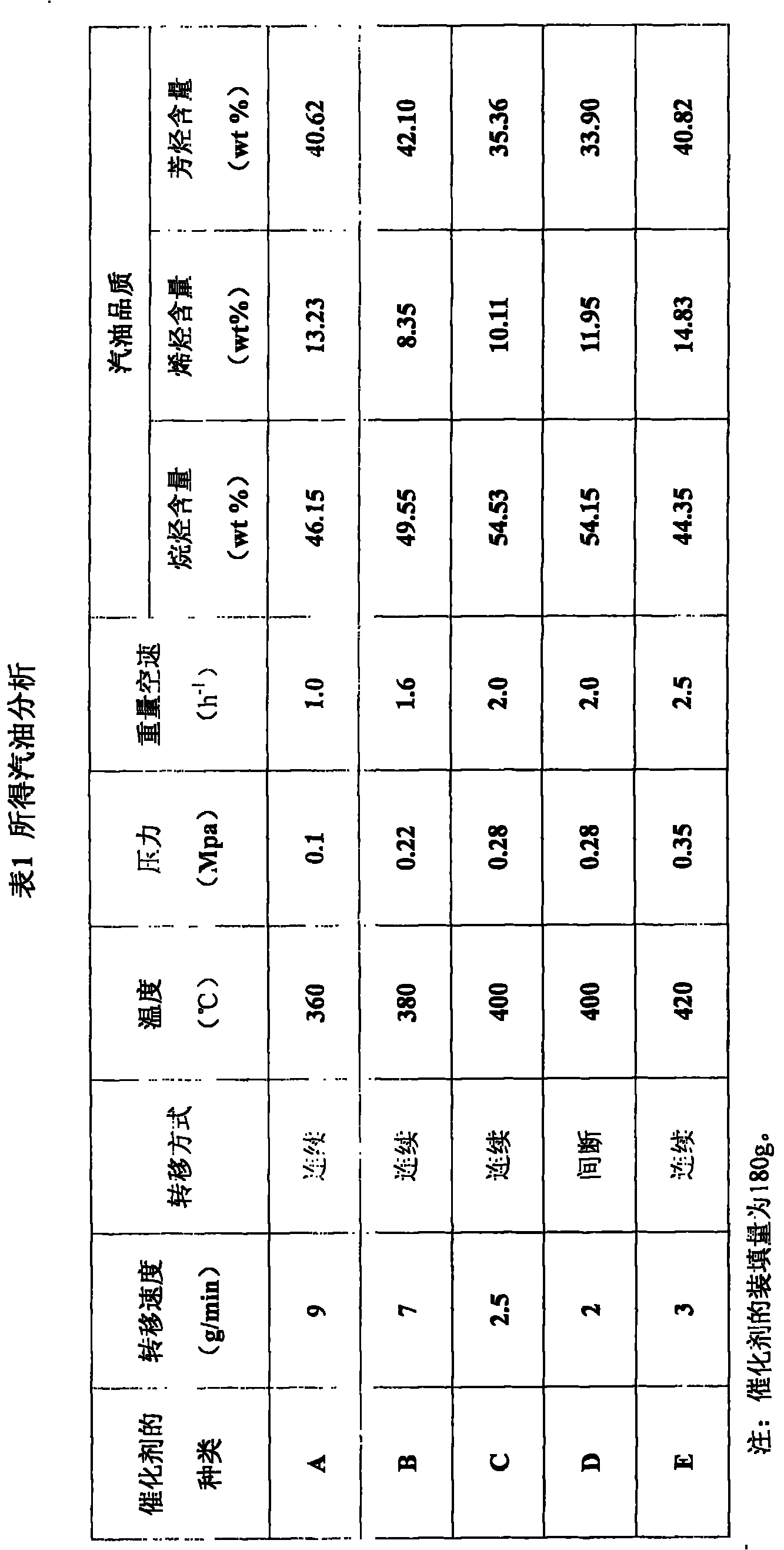

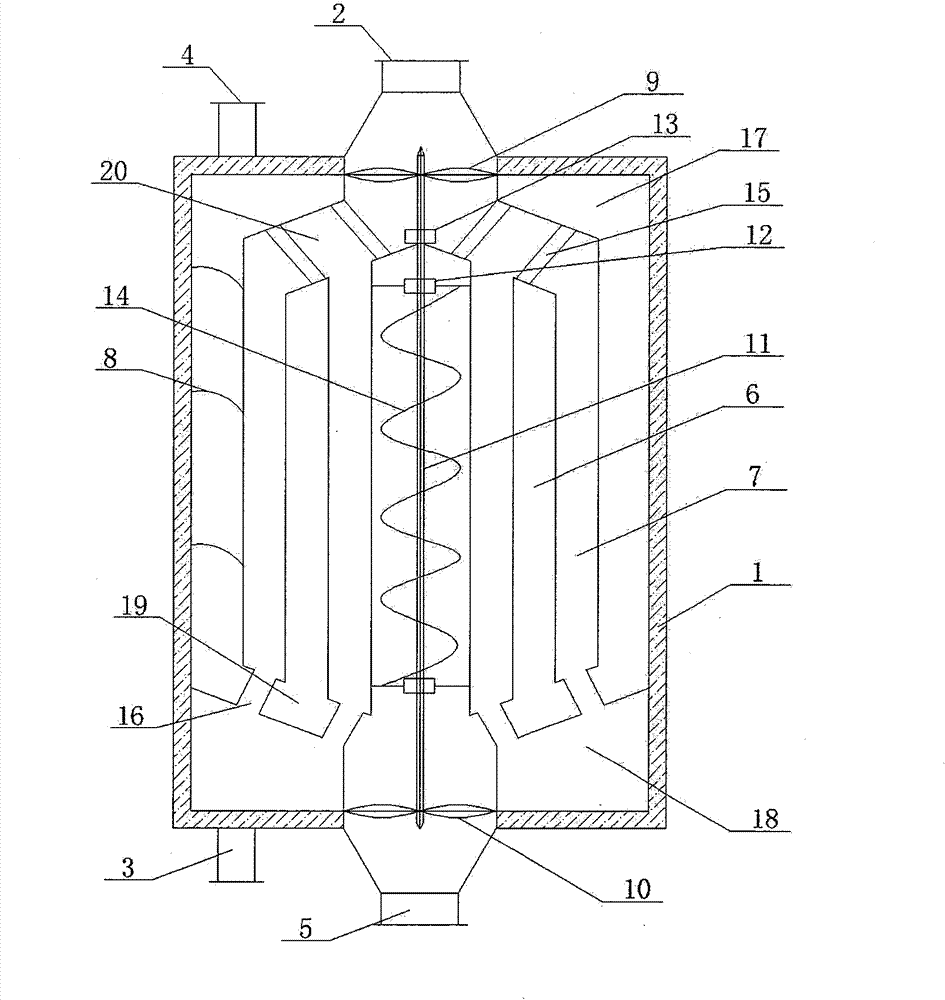

Method of producing gasoline by fluidized bed process methanol

InactiveCN101775310ASolve the problem of excess methanolSolve the problem of excessLiquid hydrocarbon mixture productionBio-feedstockFluidized bedGasoline

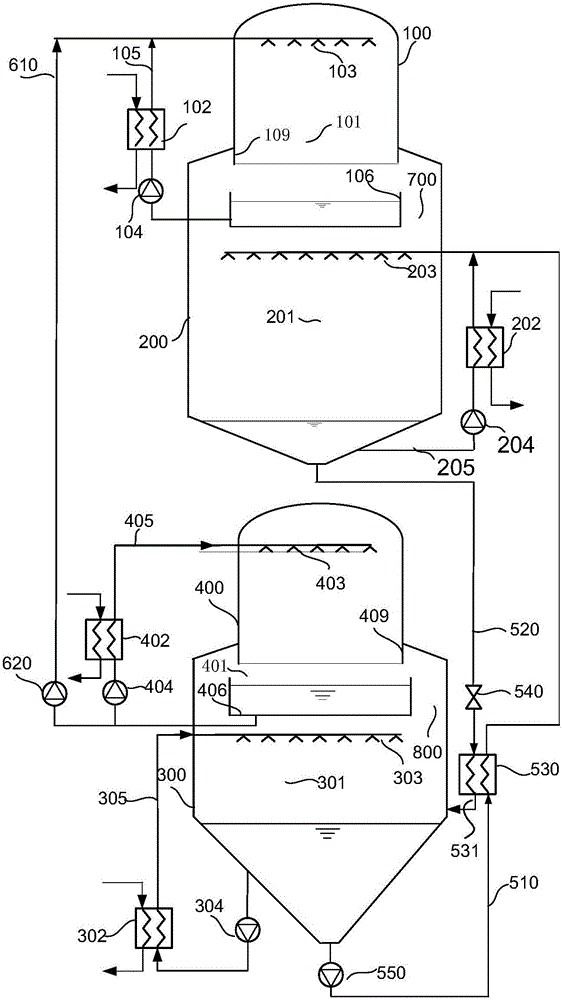

The invention relates to a method of producing gasoline by fluidized bed process methanol, in which crude methanol steam enters a fluidized bed reactor from the lower part to be contacted and reacted with a catalyst; a part of the catalyst after reaction is taken out continuously or discontinuously from the upper part of the reactor in a certain output amount for regeneration, and then the catalyst is supplemented with the same output amount from the lower part of the reactor by the regenerator, which is repeated and circulated. Reaction products flow out from the top of the fluidized bed reactor, and after gas-solid separation, the obtained catalyst powder enters the fluidized bed reactor again, gas firstly enters to be cooled, then gas-liquid separation is carried out, separated light hydrocarbon gas is collected by a gas holder and then is sent by compression into the fluidized bed reactor for light hydrocarbon circulation, and liquid separation is carried out on the separated liquid to obtain the gasoline and water. The technology used in the invention has the advantages that the catalyst can be regenerated continuously, a spare reactor is not needed, the nature of the catalyst is constant, the quality of the gasoline is high (octane value RON 93 plus), the conversion rate of the methanol is 100 percent, and the heat transfer intensity is high.

Owner:山西天和煤气化科技有限公司

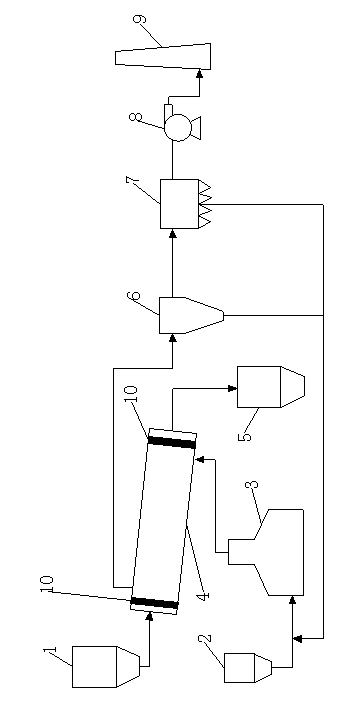

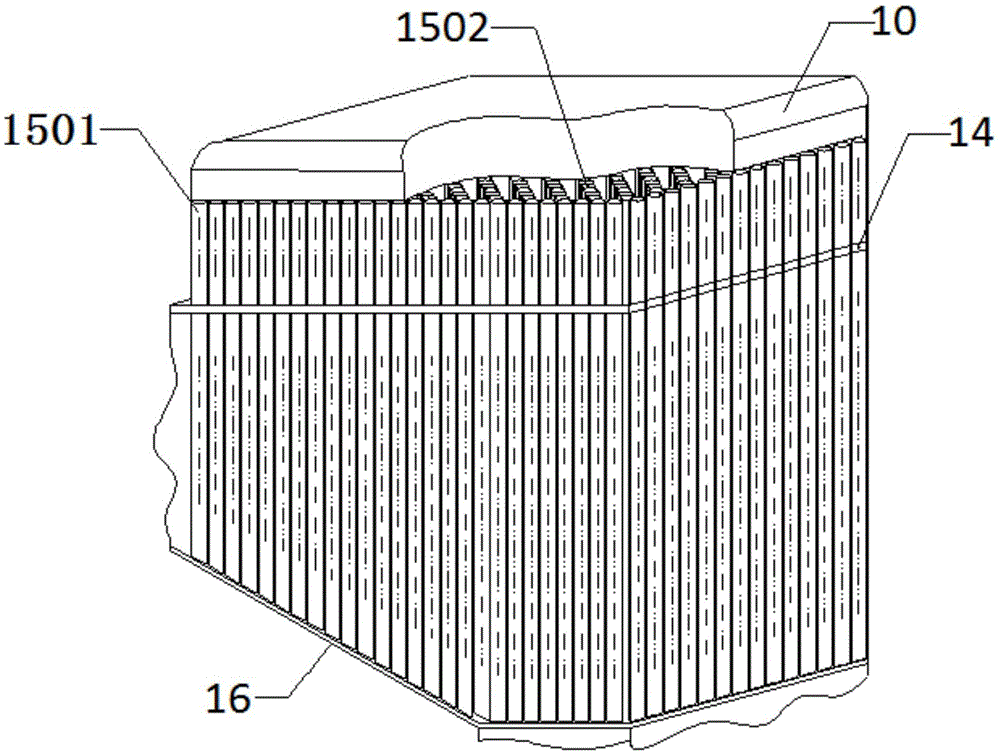

Efficient drying and quality-improving device and method for brown coal

The invention relates to an efficient drying and quality-improving device and method for brown coal. In the prior art, no efficient drying and quality-improving device or method for brown coal, which is used for improving the utilization value of the brown coal, exists. The efficient drying and quality-improving device is characterized by comprising a coal storage bin, a fuel bin, a hot blast stove, a cylinder-type dryer, a product bin, a cyclone dust collector, an electrical dust collector and a plurality of pipelines, wherein both the product bin and the coal storage bin are connected with the cylinder-type dryer; the cylinder-type dryer is connected with the cyclone dust collector; and the cyclone dust collector, the electrical dust collector, the fuel bin are all connected with the hot blast stove. The method is characterized in that the raw material of the brown coal is conveyed into the cylinder-type dryer from the coal storage bin; the hot blast stove generates high-temperature flue gas at the temperature of 700-900 DEG C, and the flue gas is conveyed into the cylinder-type dryer; the raw material of the brown coal is dried by the high-temperature flue gas and conveyed into the product bin from the cylinder-type dryer for sealing and cooling, so that the finished product of the brown coal is obtained after cooling. According to the device and the method, the moisture in the brown coal can be reduced substantially, and a part of ash content in the brown coal can also be reduced, so that the utilization value of the brown coal can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

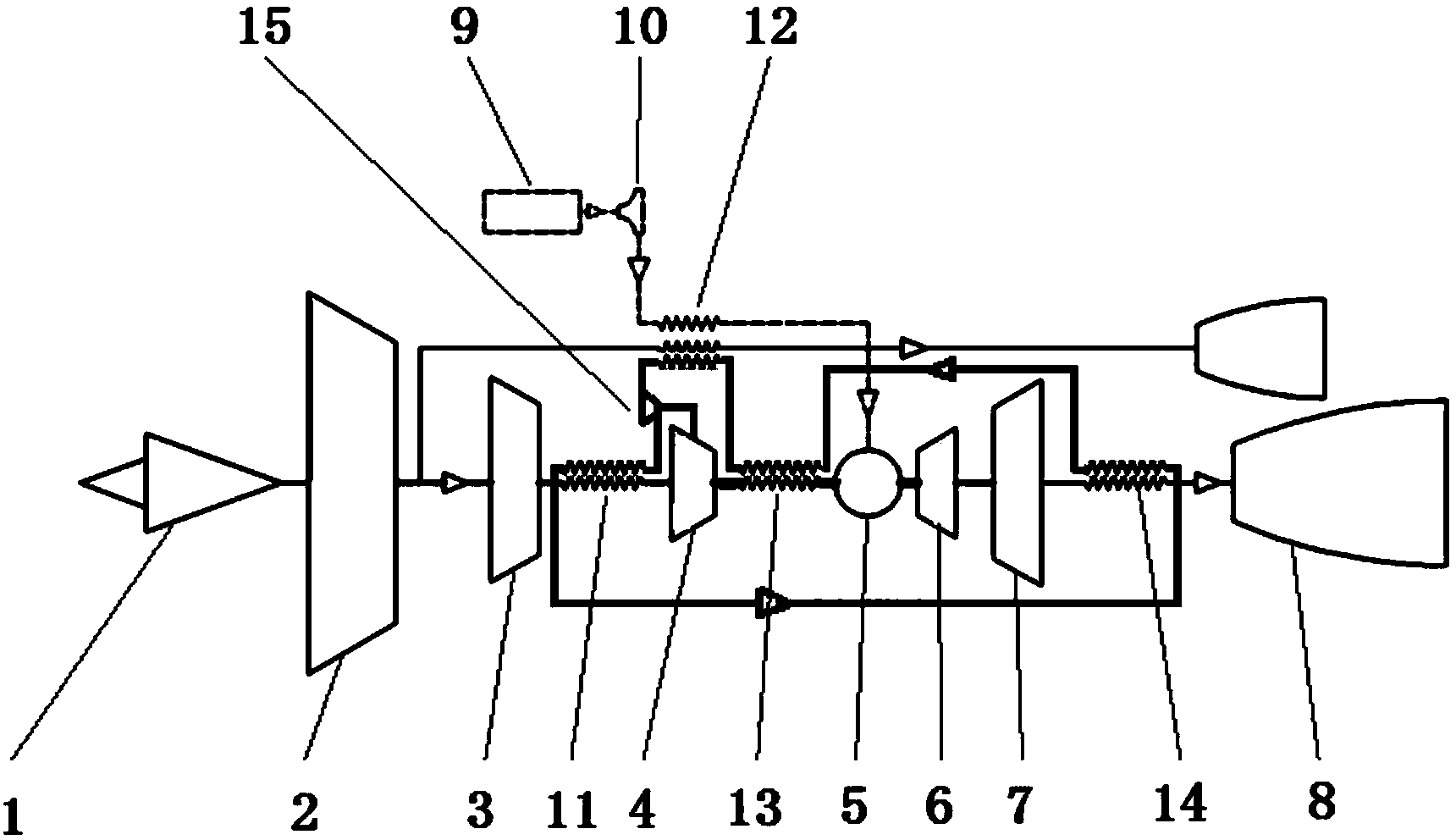

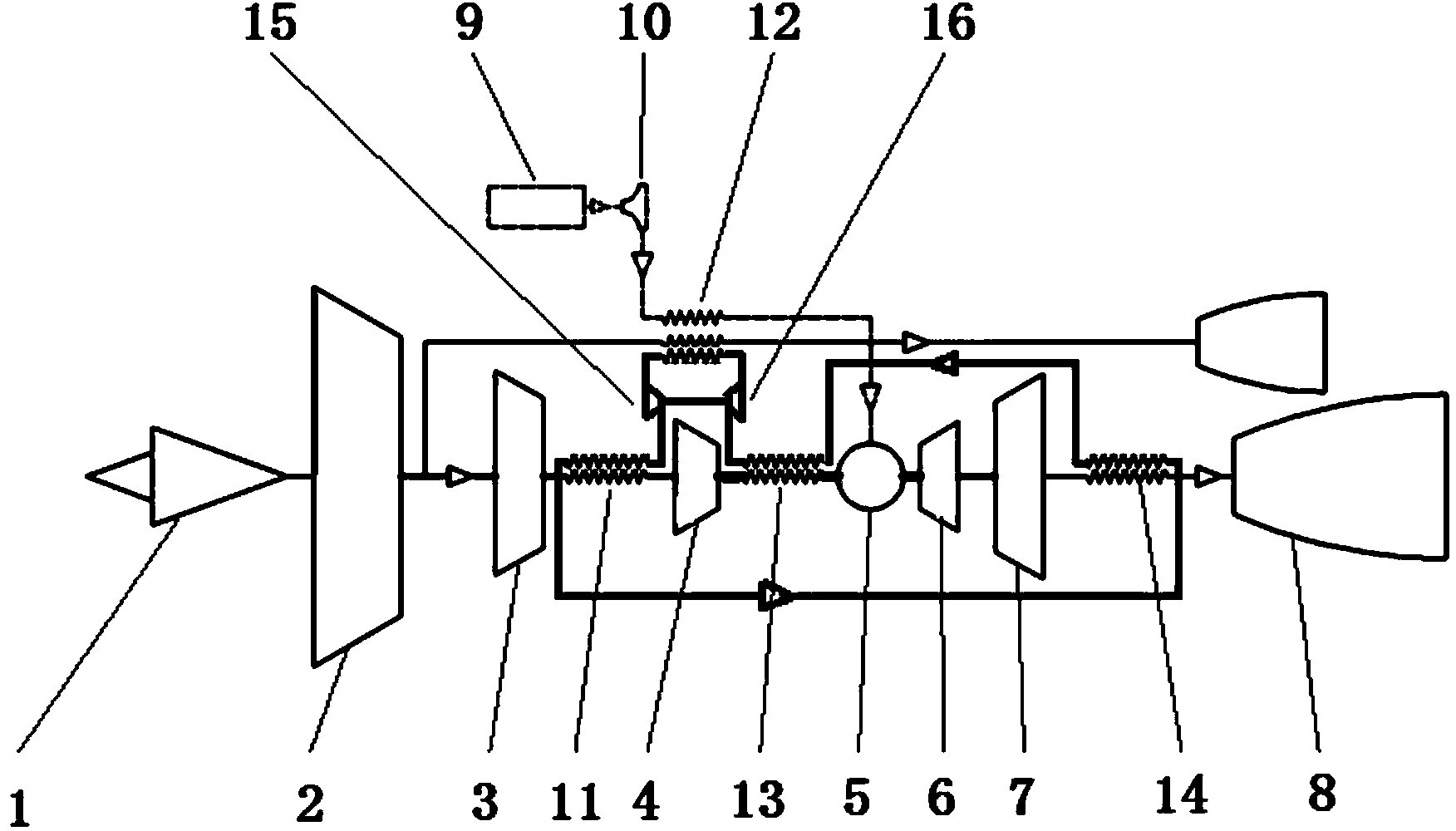

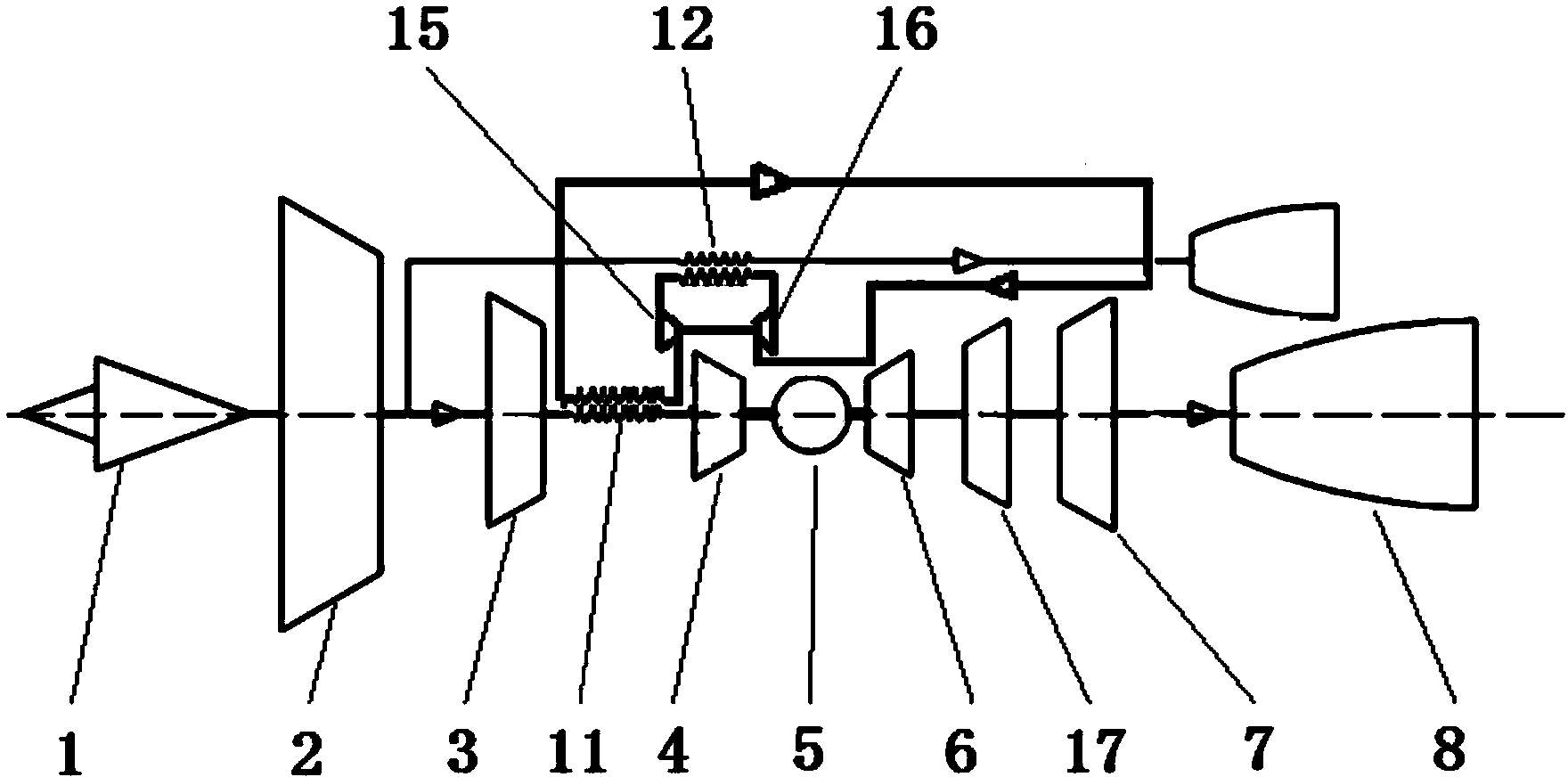

Intercooling or intercooling recuperating layout for aero-engine

ActiveCN104110309AAvoid losses along the wayLarge heat capacityTurbine/propulsion engine coolingGas turbine plantsBrayton cycleEngineering

The invention provides an intercooling or intercooling recuperating layout for an aero-engine. The layout comprises a Brayton cycle in a main flow path and a supercritical state fluid cycle, wherein the two cycles are mutually independent and are coupled through a micro-scale heat exchanger. The micro-scale heat exchanger is a supercritical micro-scale compact rapid heat exchanger comprising a heat exchanging element and two working mediums, wherein the two working mediums exchange heat through the heat exchanging element. The micro-scale heat exchanger is characterized in that one of the working mediums employs a supercritical state fluid, the other working medium is not limited, the size of the heat exchanging element is in a micro-scale range, the critical pressure of the supercritical state fluid is at least 0.5 MPa, the temperature of the supercritical state fluid is at least 200 DEG C higher than critical temperature, and micro-scale refers to that the geometric scale of the basic heat exchanging element is no more than 2 mm. The intercooling or intercooling recuperating layout provided by the invention overcomes the disadvantages of conventional intercooling or intercooling recuperating layouts, improves the cycle efficiency of the aero-engine and reduces the oil consumption rate of the aero-engine.

Owner:BEIHANG UNIV

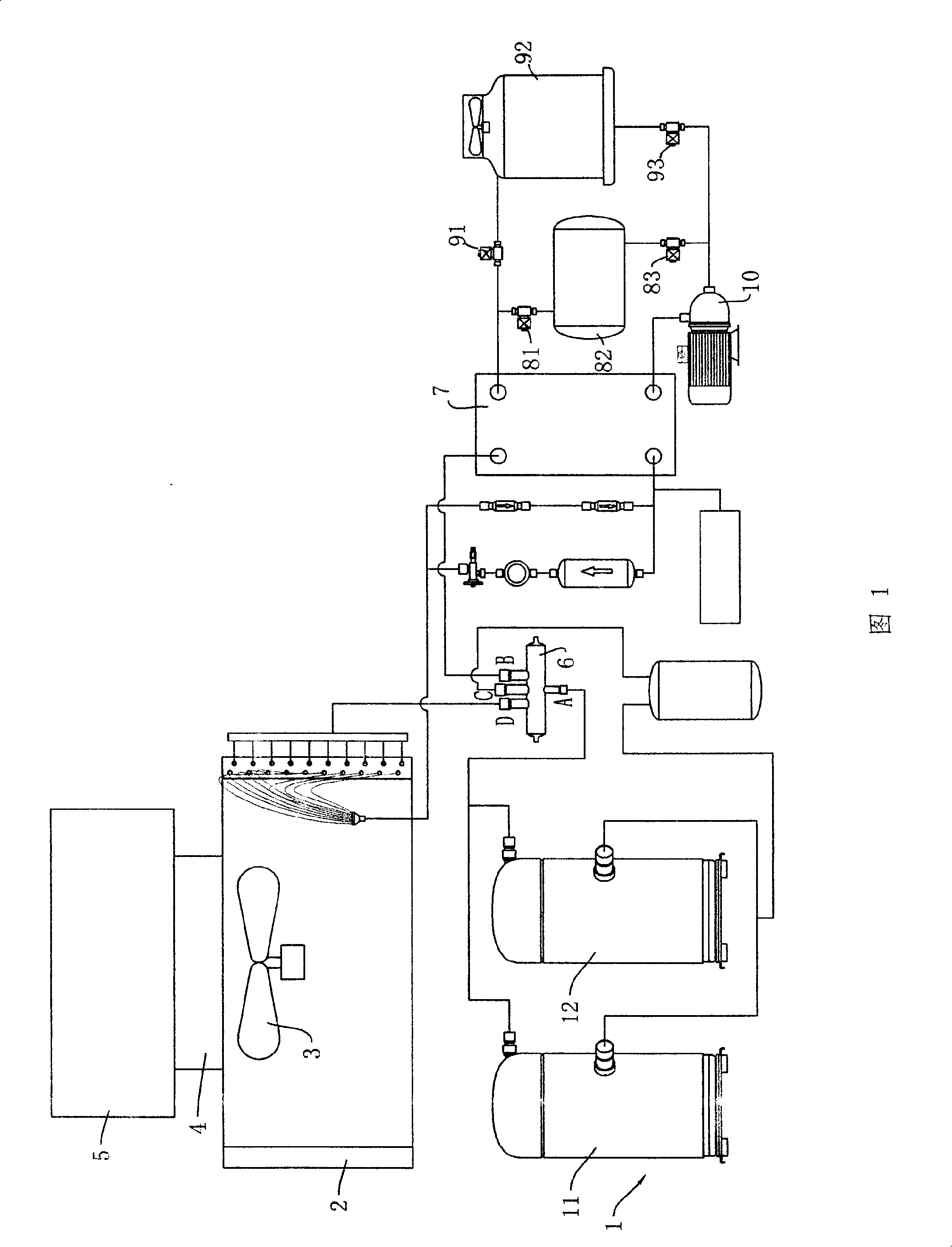

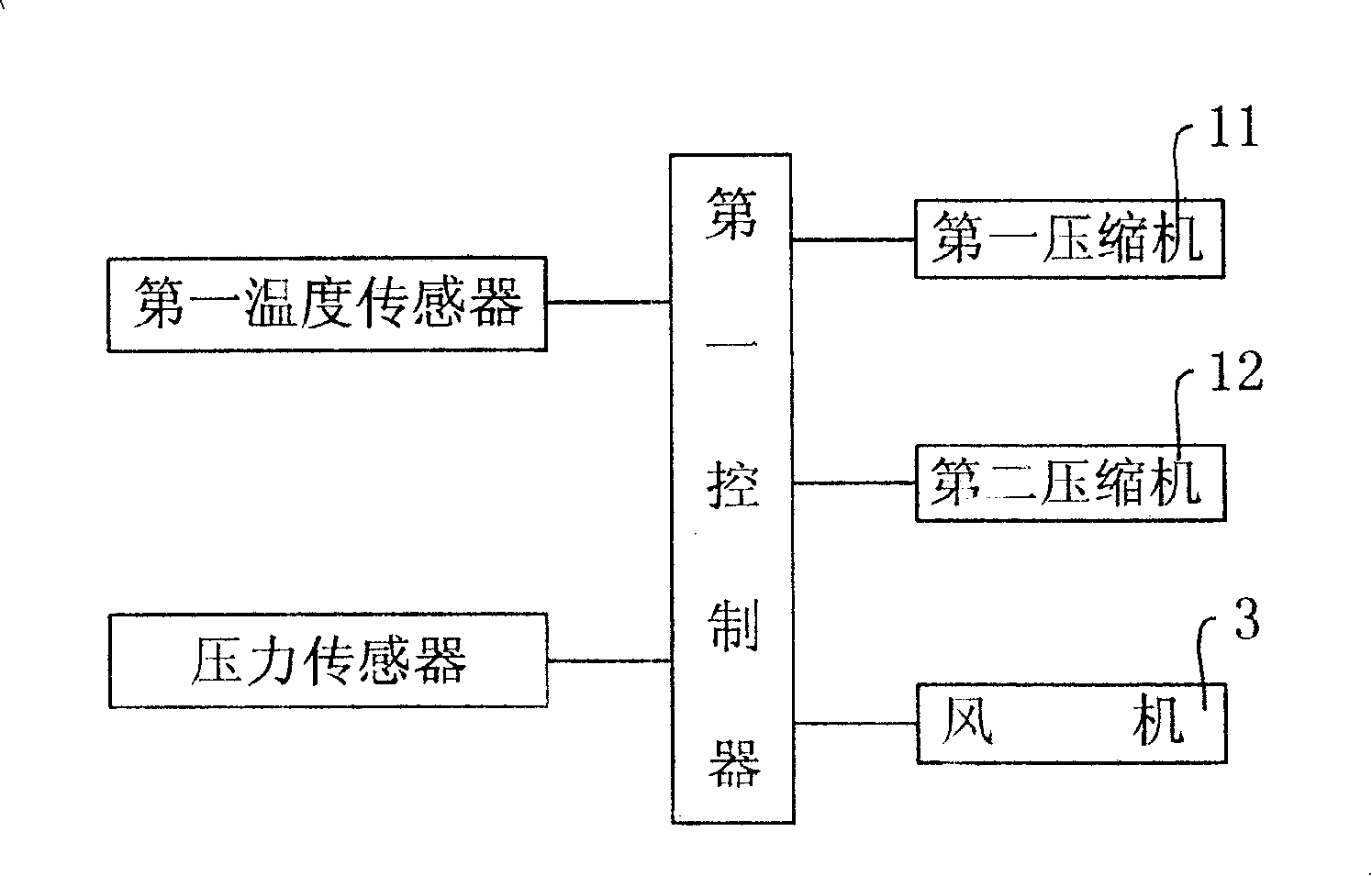

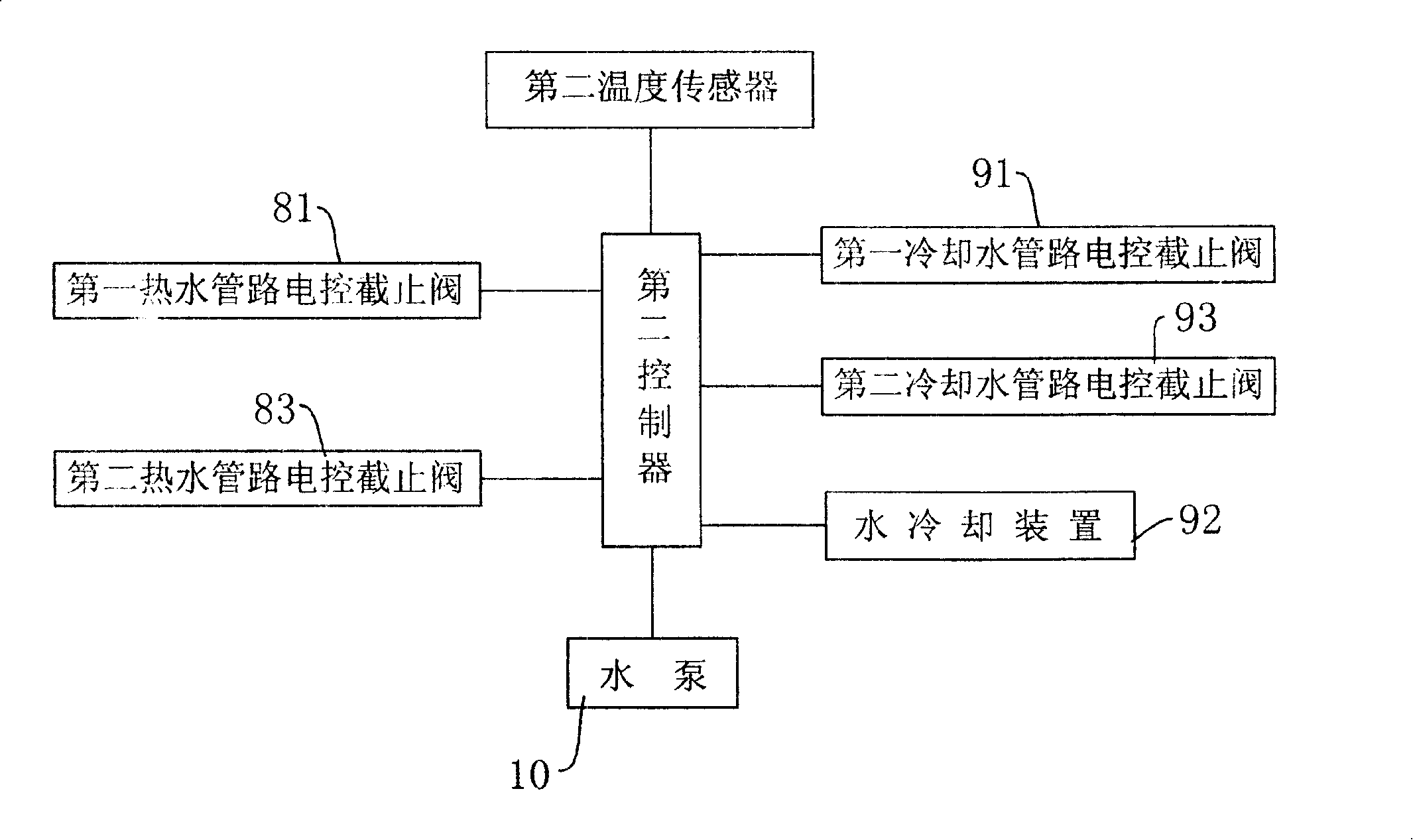

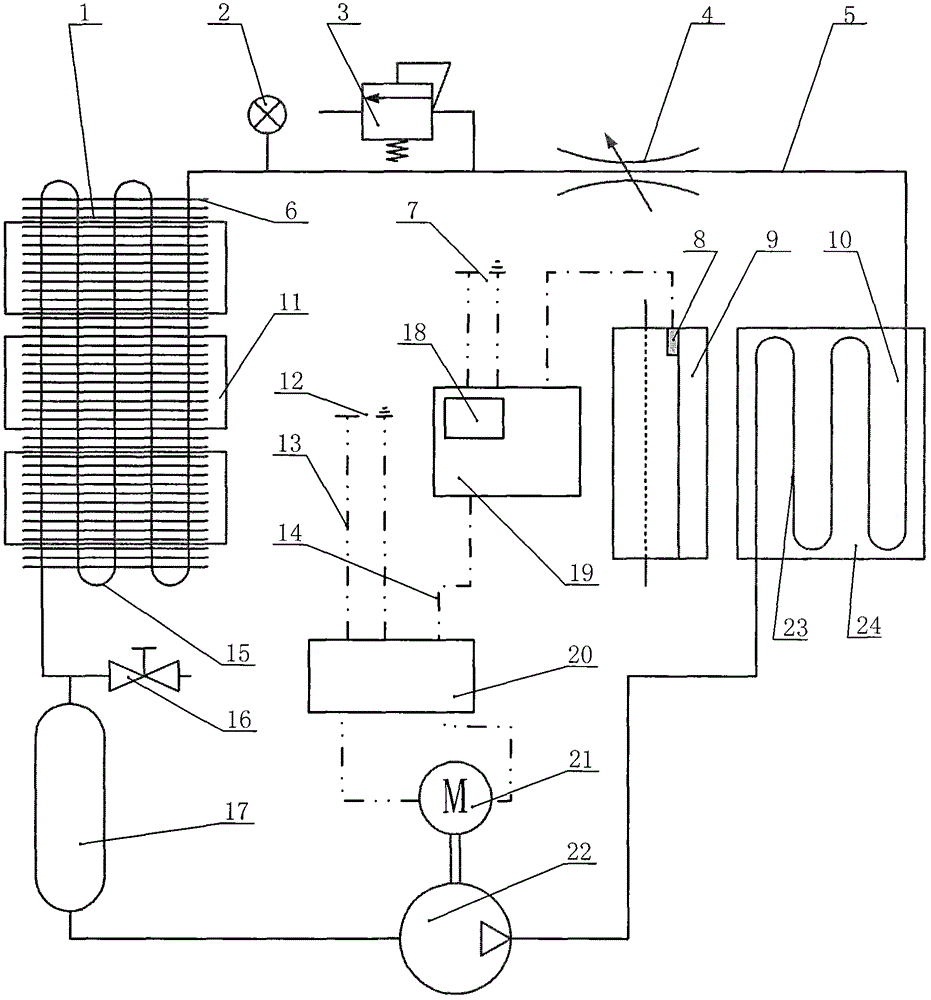

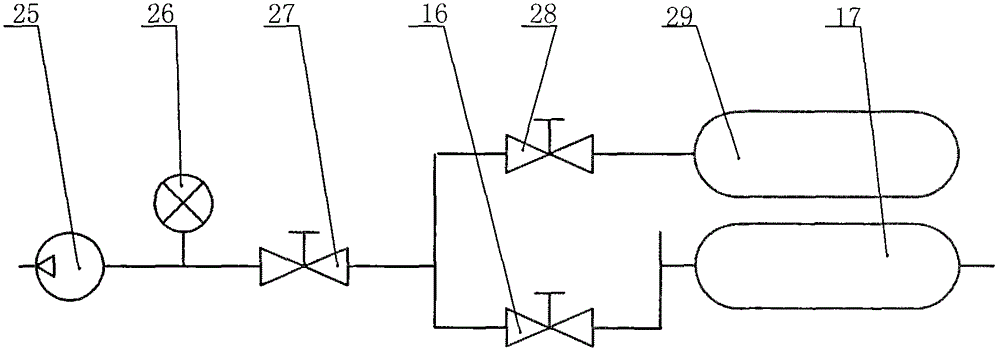

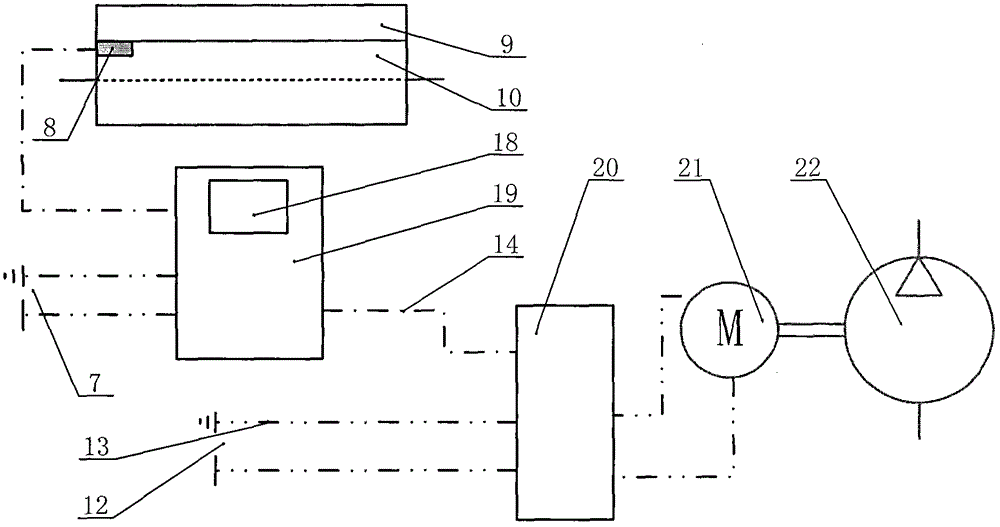

Air source heat pump hot water units

InactiveCN101221007AReduce speedIncrease speedFluid heatersRefrigeration safety arrangementAir volumeEngineering

The invention discloses an air supply heat pump hot water assembly. The key points of the invention mainly are that at least two compressors are connected in parallel; a first temperature sensor, a pressure sensor and a first controller are also connected in parallel; a first control circuit which compares the temperature signal measured by the first temperature sensor with a set value of environment temperature and leads the corresponding compressor to enter an on state according to the comparison result is arranged on the first controller, and a second control circuit which compares the pressure signal measured by the pressure sensor with a set value of pressure and controls the rotate speed of a fan according to the comparison result is also arranged on the first controller. The invention fundamentally solves the problem that the hot water quantity required by users is not matched with the heating capacity of the assembly when running in winter and summer, and the invention can guarantee the safe and reliable running of the compressor through changing the air flow of the fan. Furthermore, the invention additionally adopts a connecting air channel and a cold water circulation device to recycle the cooling energy wasted before, so as to enhance the utilization rate of the hot water assembly and reduce the energy cost of users.

Owner:山东科灵节能装备股份有限公司

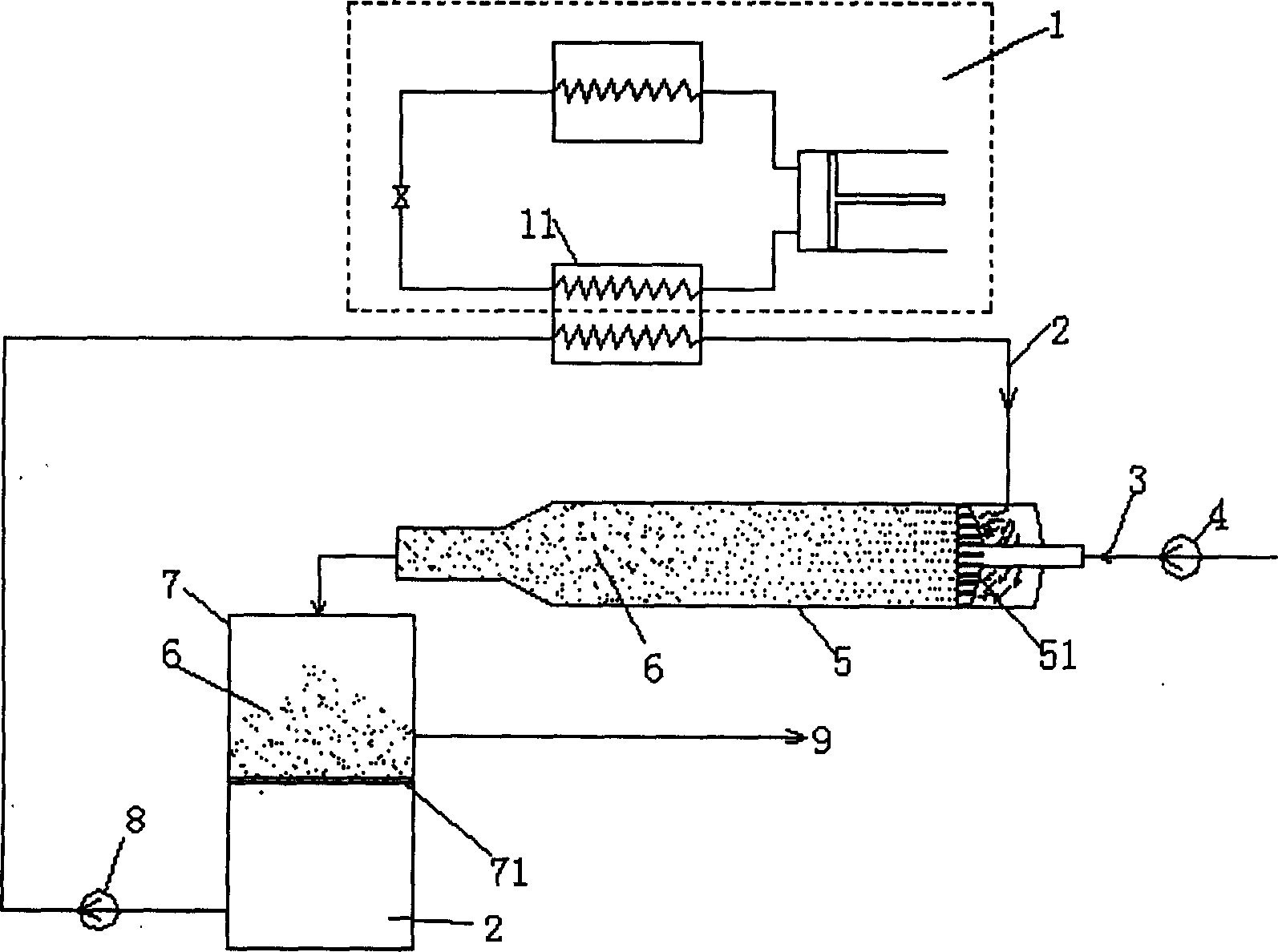

Method and apparatus for making fluidic ice

The present invention is fluid ice making method and apparatus. The method includes cooling the cool carrying medium in fluid to below 0 deg.c with evaporator, spraying ice making water to the cooled cool carrying medium in fluid to form mixed fluid of ice grain and cool carrying medium and separating ice from the cool carrying medium in fluid to obtain fluid ice. The apparatus for making fluid ice includes evaporator, ice making unit, water sprayer, filter with filtering net and circulating pump connected via pipeline. The present invention has high heat efficiency, high practicality, simple structure and low running cost.

Owner:SOUTHEAST UNIV

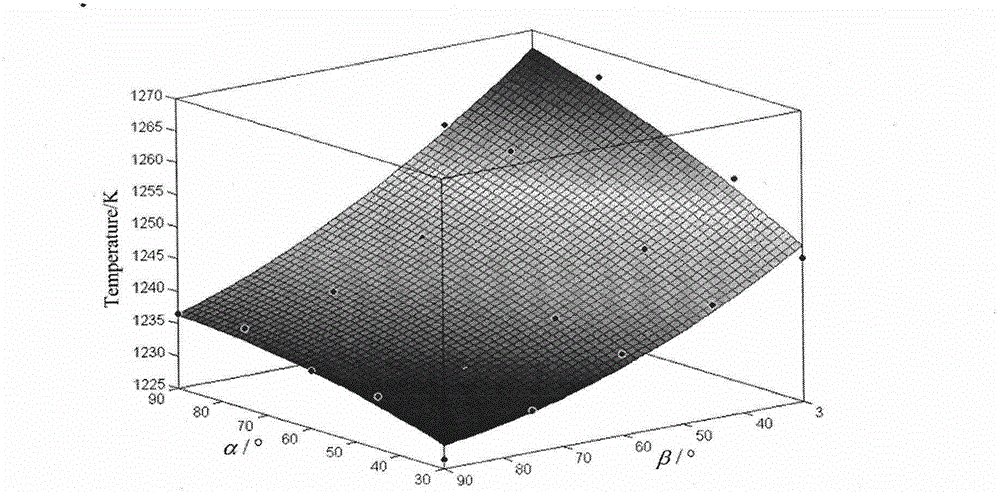

Optimizing method of simplified model cooling structure of transition section

InactiveCN104573247AReduce the temperatureIncrease heat exchange intensitySpecial data processing applicationsReduced modelCombustor

The invention relates to an optimizing method of a simplified model cooling structure of a transition section. The method comprises the steps of building a double-cavity simplified model according to the function and structure characteristic of the transition section of a combustor of a gas turbine; providing optimally-designed initial similar model for modeling according to the commonly-used orthogonal design in engineering application; performing optimization analysis by the interior point method according to optimal model built based on the wall surface average temperature T and the minimum pressure P and the limitation; calculating the wall surface average temperature, minimum pressure and cooling efficiency of the transition section of the simplifying structure. With the adoption of the method, the demands on simple molding of the transition section structure and analyzing cooling performance in the gas turbine design stage can be met well; design people can be assisted to quickly extract the impact cooling characteristics of such structure, and therefore, the cockamamie works of the traditional finite element analysis and test can be avoided, and as a result, the quick performance evaluation and rapid modification of the primary design scheme can be achieved, and the design cycle is also reduced.

Owner:JILIN UNIV

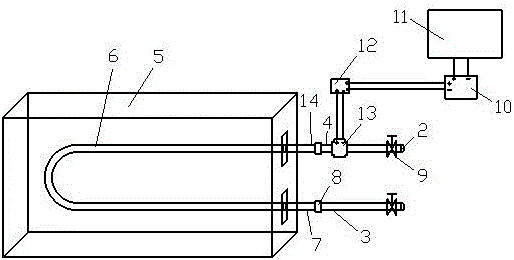

Forced cooling device based on latent heat exchanging

InactiveCN104677158ASolve the cooling problemReduce energy consumptionIndirect heat exchangersEngineeringHigh pressure

A forced cooling device based on latent heat exchanging comprises a high-temperature evaporator, a low-temperature condenser, a throttle, a delivery pump, a liquid trap, a safety valve, a stop valve, a temperature control system and a working medium filling device which are connected through high-pressure hoses. The phase change latent heat of working media is used to take away heat, and the forced cooling device is mainly used for solving the radiation problems of large-power electronic components. The delivery pump delivers the liquid working media in the liquid trap to the evaporator, the liquid working media absorb heat and is gasified, the gaseous working media flow into the condenser, is liquefied and release heat to the environment, and liquid working media converge into the liquid trap under gravity action. The temperature control system controls the rotation speed of the delivery pump through the temperature feedback at a cold end and a hot end, and accordingly the heat exchanging power of a working medium flow control device. The safe and nontoxic R134a is used as the working media, and equipment and the environment cannot be damaged even leakage occurs.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fresh air supply system for cooling tower

ActiveCN101699210AUniform dynamic fieldReduce air temperatureTrickle coolersCooling towerNatural ventilation

The invention provides a fresh air supply system for a cooling tower and belongs to the field of thermal power generation or nuclear power generation, in particular to technology capable of realizing fresh air supply to the inside of a natural draft counter-flow wet cooling tower. The fresh air supply system of the cooling tower adopts an air duct structure, is arranged at the bottom periphery of the cooling tower and extends to central area of the tower opening from the outer edge of the air inlet of the cooling tower. Each air duct forms a certain inclination angle with the direction of a circumferential tangent and a certain inclination angle with a radial direction. Thus, the fresh air can be led into the cooling tower, the cooling efficiency of the cooling tower is improved, the internal air dramatic field in the cooling tower is improved, the optimal matching between the water flow distribution rules and the air distribution rules is realized and the temperature of circulating water is reduced.

Owner:SHANDONG UNIV +1

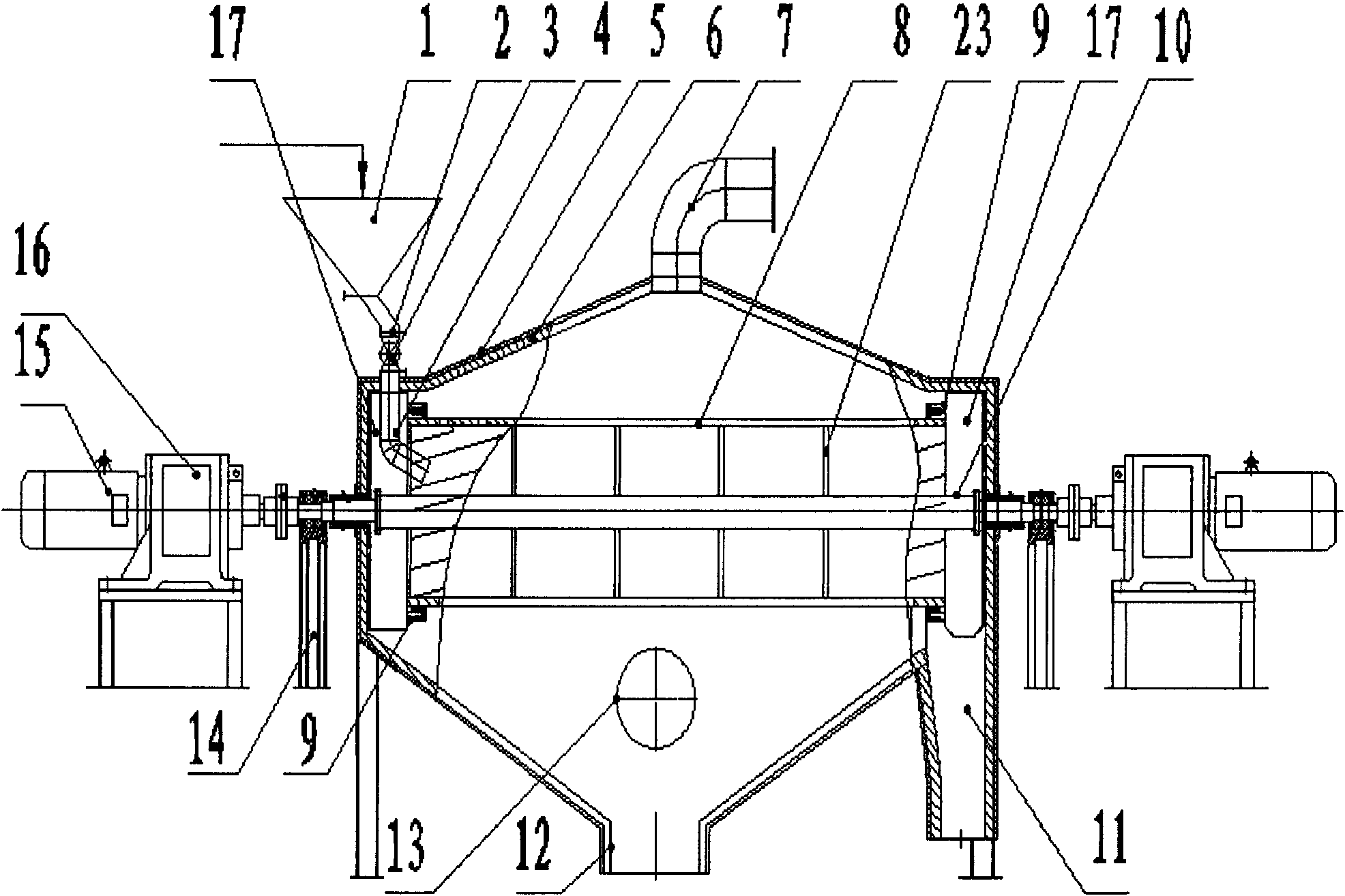

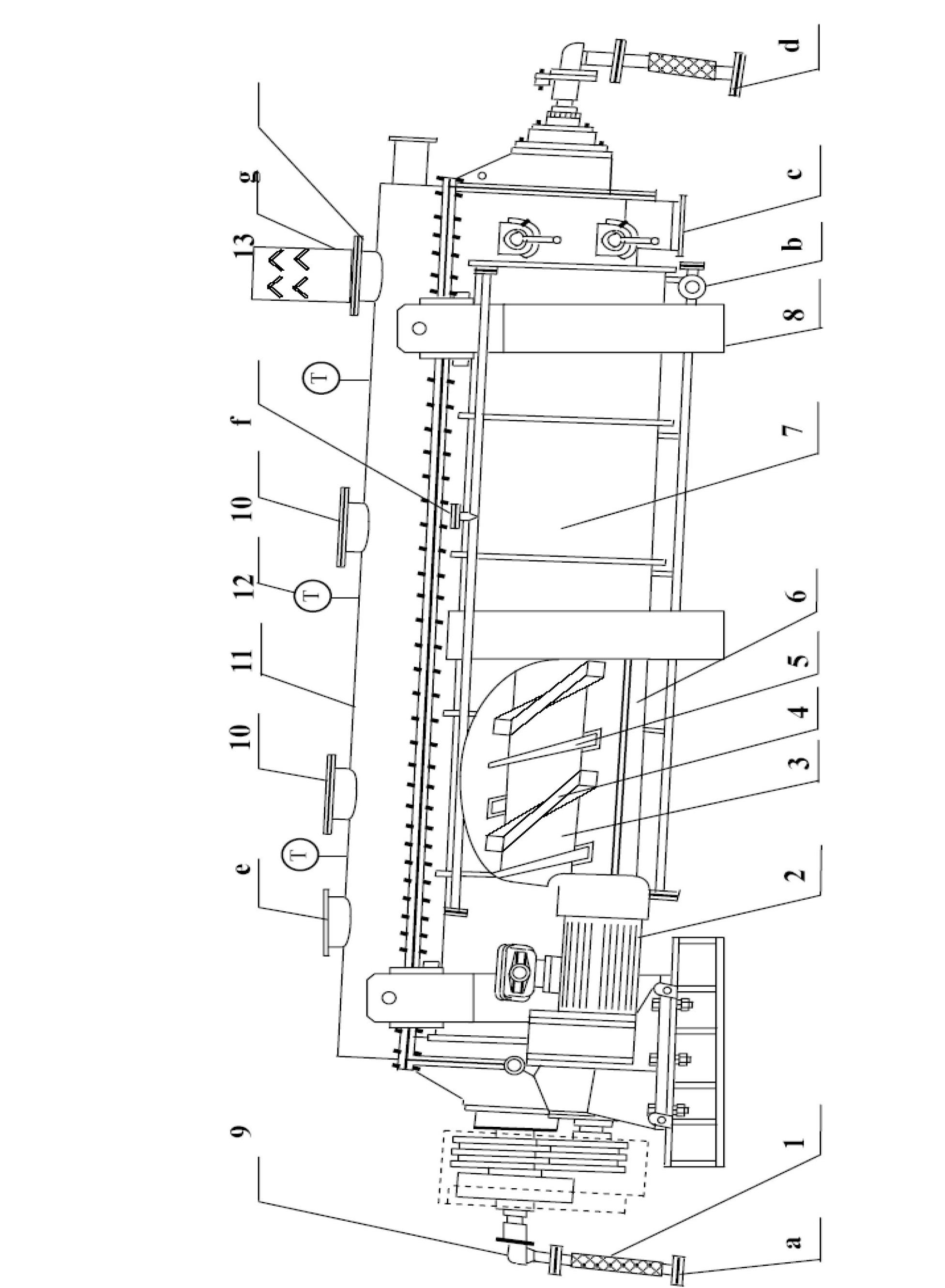

Perforated tumble dryer

InactiveCN102288014AReduce consumptionLow running costDrying chambers/containersDrying machines with progressive movementsCoalEngineering

The invention relates to equipment for quickly and efficiently drying a large amount of solid materials. The equipment is characterized in that: a porous roller is arranged in a box body of which the inner wall is coated with a heat preservation material; a plurality of small holes are formed in the roller; and a sieve screen and a guide plate are arranged on the inner wall of the roller. In the drying equipment, gases such as air, nitrogen, steam, fume, gas and the like are as dry hot media according to site conditions, and the drying equipment has the advantages of high heat exchanging intensity, short drying time, high thermal efficiency, relatively compact volume, high sealing performance, high safety, environment friendliness and the like. The equipment is suitable for drying granular solid materials in industrial and agricultural raw materials and products, and is suitable for drying oil shale and coal when the temperature of the drying hot media is below 300 DEG C.

Owner:吴启成

Cold and hot dual-purpose special functional clothes

InactiveCN105962476AConvenient sourceSimple materialGarment special featuresChemical industryDual purposeEngineering

The invention provides cold and hot dual-purpose special functional clothes. A plastic hose is distributed on the inner side of a coat in a zigzag bent mode. A water outlet of the plastic hose is connected with a water inlet of a heat conductive copper pipe through a micro direct-current circulating water pump, the micro direct-current circulating water pump is connected with a storage battery through a wire, a water outlet of the heat conductive copper pipe is connected with a water inlet of the plastic hose, a fastening device is arranged on the area, corresponding to the waist of a human body, of the coat, the fastening device is provided with a storage bag used for storing a cold storage bag or a heat storage bag, and a heat exchange part of the heat conductive copper pipe is arranged in the cold storage bag or the heat storage bag. The clothes integrate an efficient refrigerating and cooling function and an efficient heating and cold preventing function, can be used for cooling in summer and heating in winter, and can well solve the problem that space is limited when cooling and heat preservation are achieved in a closed space.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

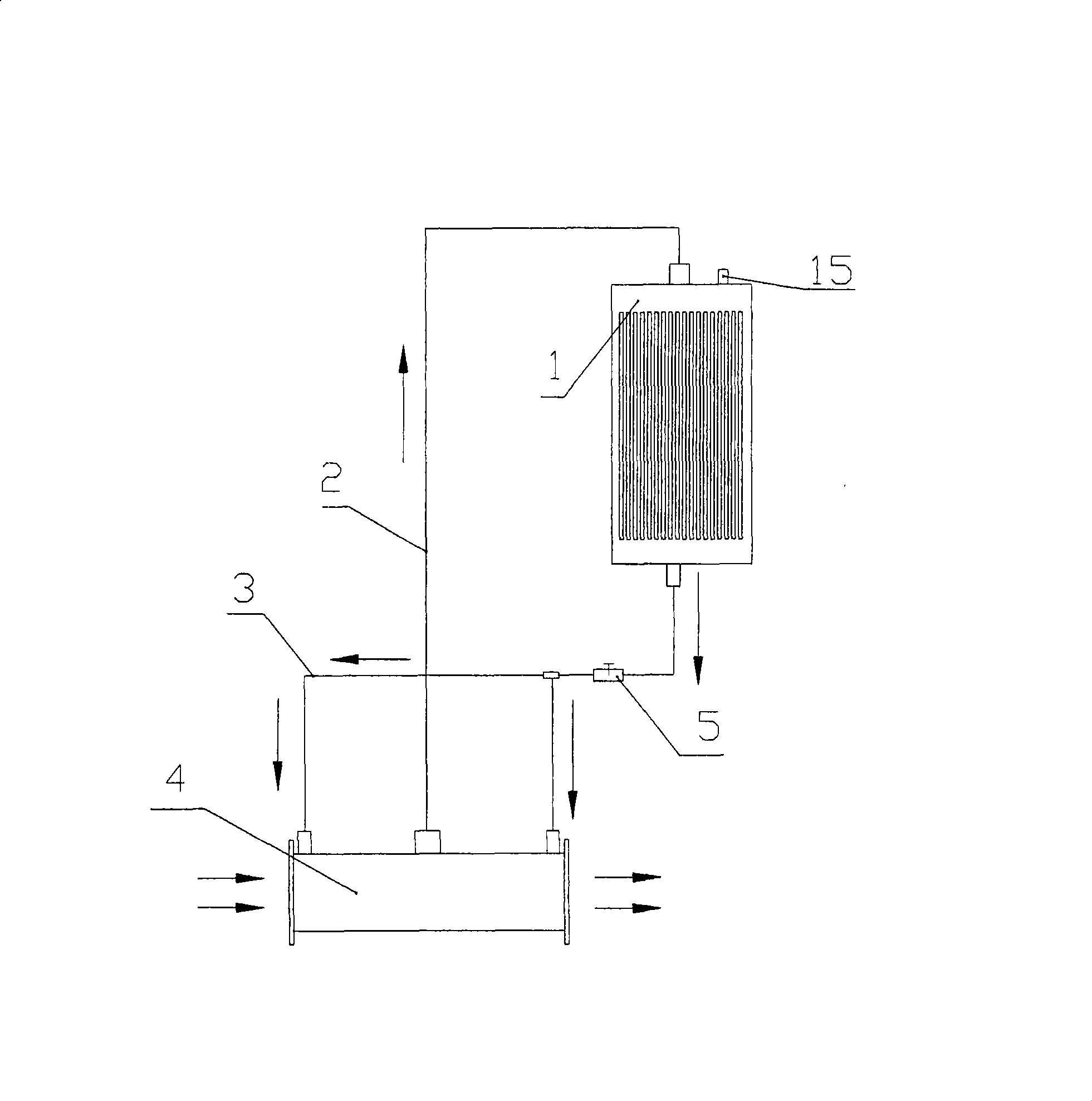

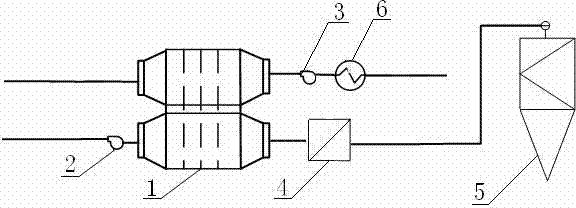

Thermal management method and device for micro dimension composite composite phase change cooling for automobile

ActiveCN101382399AIncrease heat exchange intensityHigh surface convective heat transfer coefficientExhaust apparatusSilencing apparatusEvaporationEngineering

The invention discloses a management method of micro scale composite phase change cooling automobile and a device thereof, and relates to the engine technology. The method utilizes the characteristic that the composite phase change heat exchange of the evaporation and boiling of working medium in a micro channel has extremely high heat exchange strength, thus improving the heat exchange efficiency greatly; the management device consists of a heat absorption and conversion device, an air-cooled type condenser, an electromagnetic valve, a liquid backflow pipe and a steam insulating pipe; the liquid inlet of the heat absorption and conversion device is connected with the liquid outlet of the air-cooled type condenser by the liquid backflow pipe; the steam outlet of the heat absorption and conversion device is connected with the steam inlet of the air-cooled type condenser by the steam insulating pipe; and the electromagnetic valve is arranged on the liquid backflow pipe and the management device is vacuumized. The management method and the device of the invention reduce the over-high temperature of the tail gas of the automobile effectively, lead a three-way catalytic device of the automobile to work normally and reduce the content of pollutants in the tail gas of the automobile effectively.

Owner:中科五环新能源汽车热管理技术(武汉)有限公司

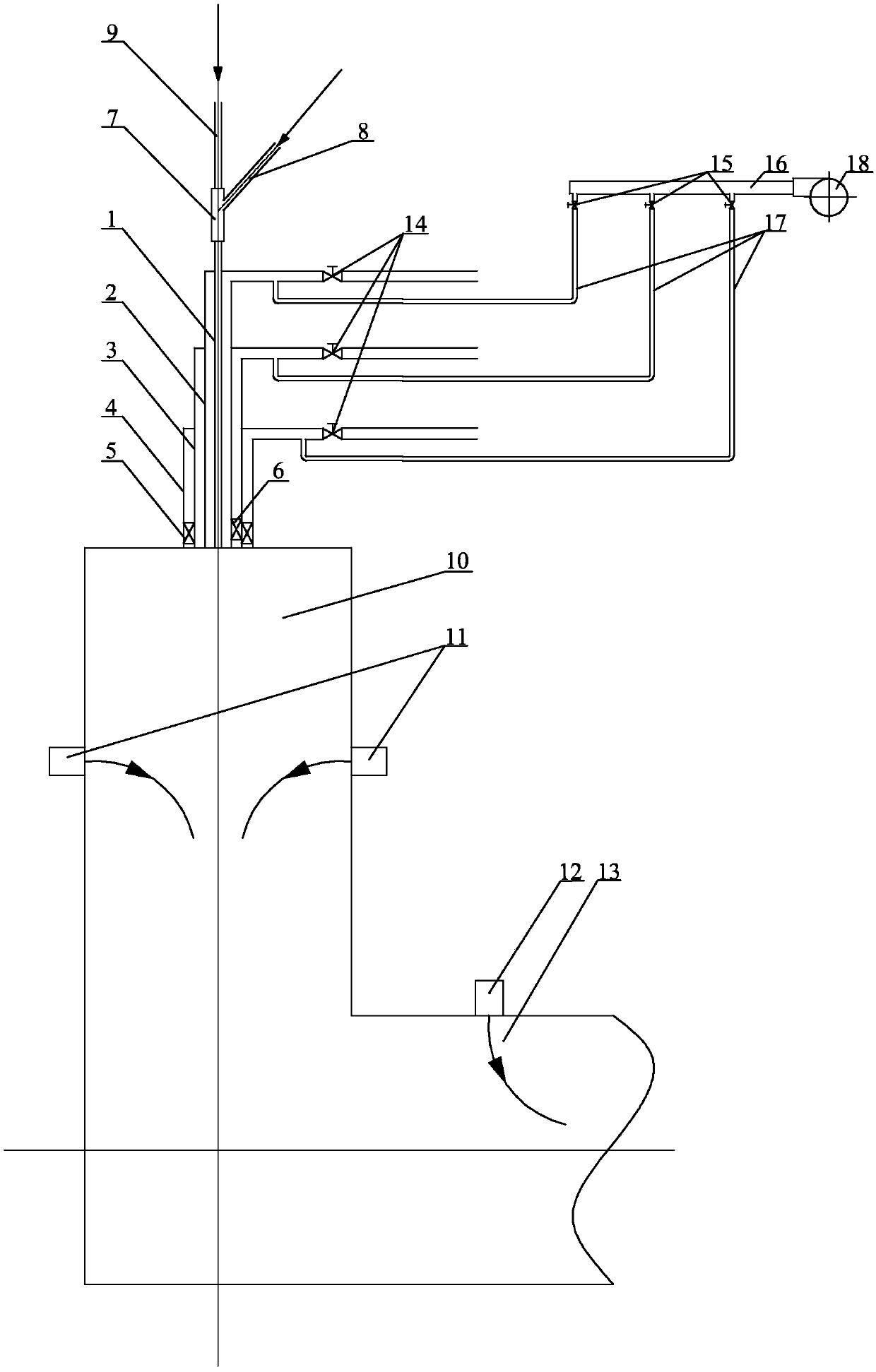

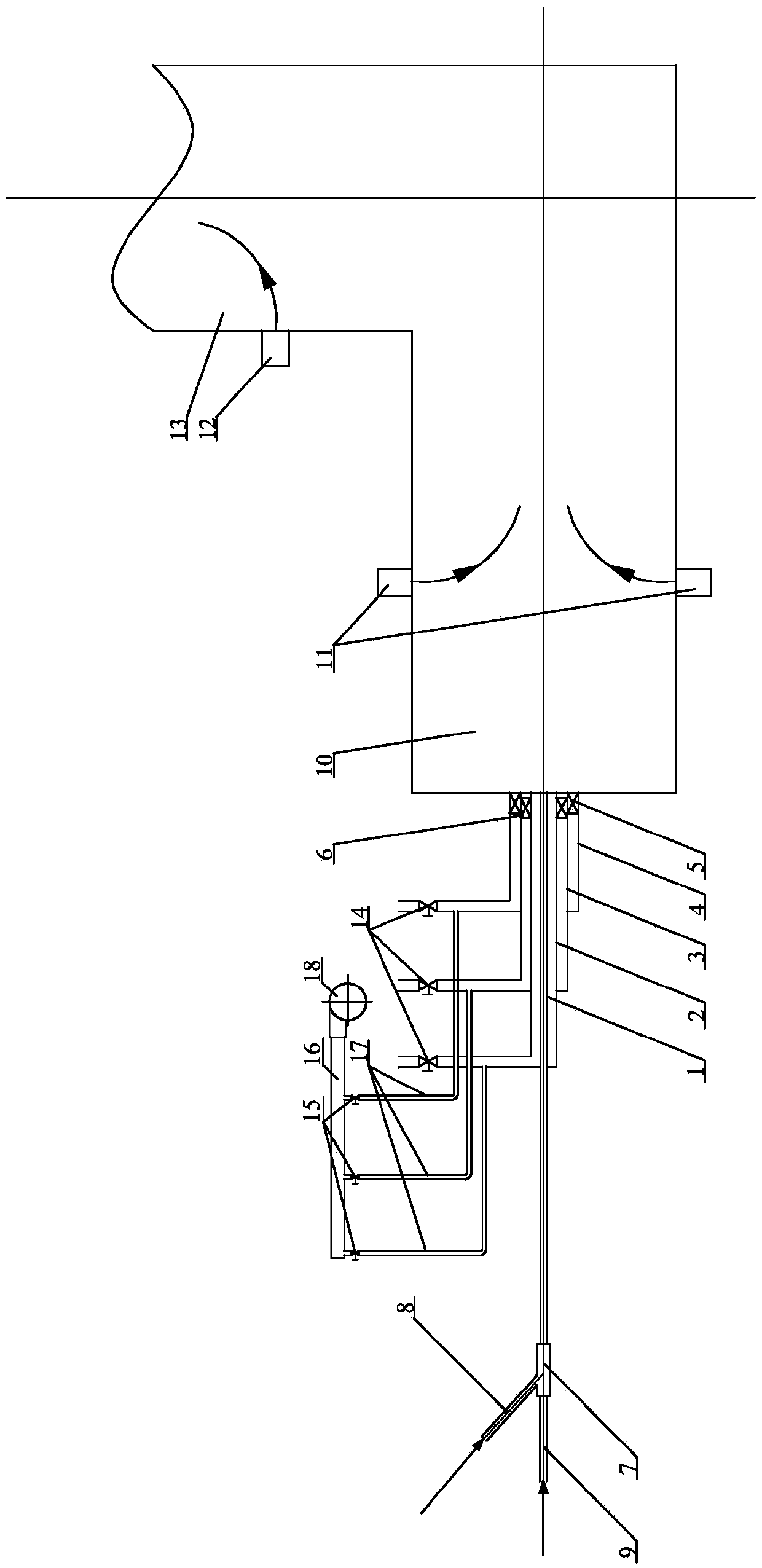

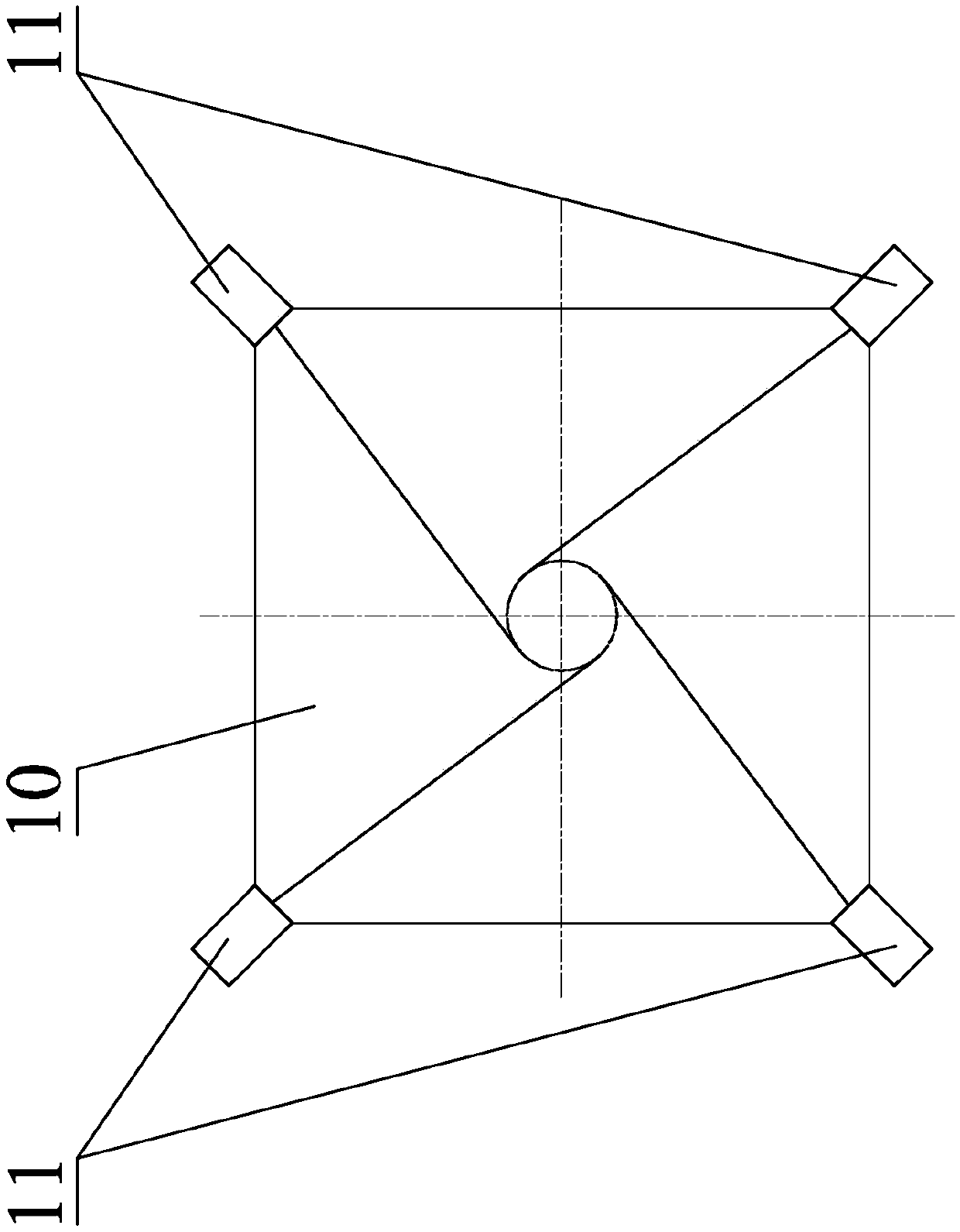

Industrial pulverized coal boiler boiler-inside denitration combustion device with reducing agent being sprayed to main combustion area of combustor

InactiveCN109654484AEmission reductionShort stayCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorBoiler furnace

The invention provides an industrial pulverized coal boiler boiler-inside denitration combustion device with a reducing agent being sprayed to a main combustion area of a combustor, relates to the boiler boiler-inside denitration combustion device and aims to solve the problems of high NOx emission quantity of present industrial pulverized coal boilers and poor adaptive capacity of boiler-inside denitration on load. The industrial pulverized coal boiler boiler-inside denitration combustion device comprises the combustor, a recirculating smoke pipeline and a draft fan, the combustor comprises aprimary air pipe, a direct current secondary air pipe, a swirl flow inner secondary air pipe, a swirl flow outer secondary air pipe, a first axial swirl flow blade and a second axial swirl flow blade, and the industrial pulverized coal boiler boiler-inside denitration combustion device further comprises a mixer, an amino reducing agent conveying pipe, a thick pulverized coal conveying pipe, threesecondary air pipelines, three secondary air pipeline valves, three recirculating smoke pipeline valves, three recirculating smoke branch pipelines, four first-stage overfire air nozzles and a plurality of second-stage overfire air nozzles. The industrial pulverized coal boiler boiler-inside denitration combustion device with the reducing agent being sprayed to the main combustion area of the combustor is used for the field of boiler combustion.

Owner:HARBIN INST OF TECH

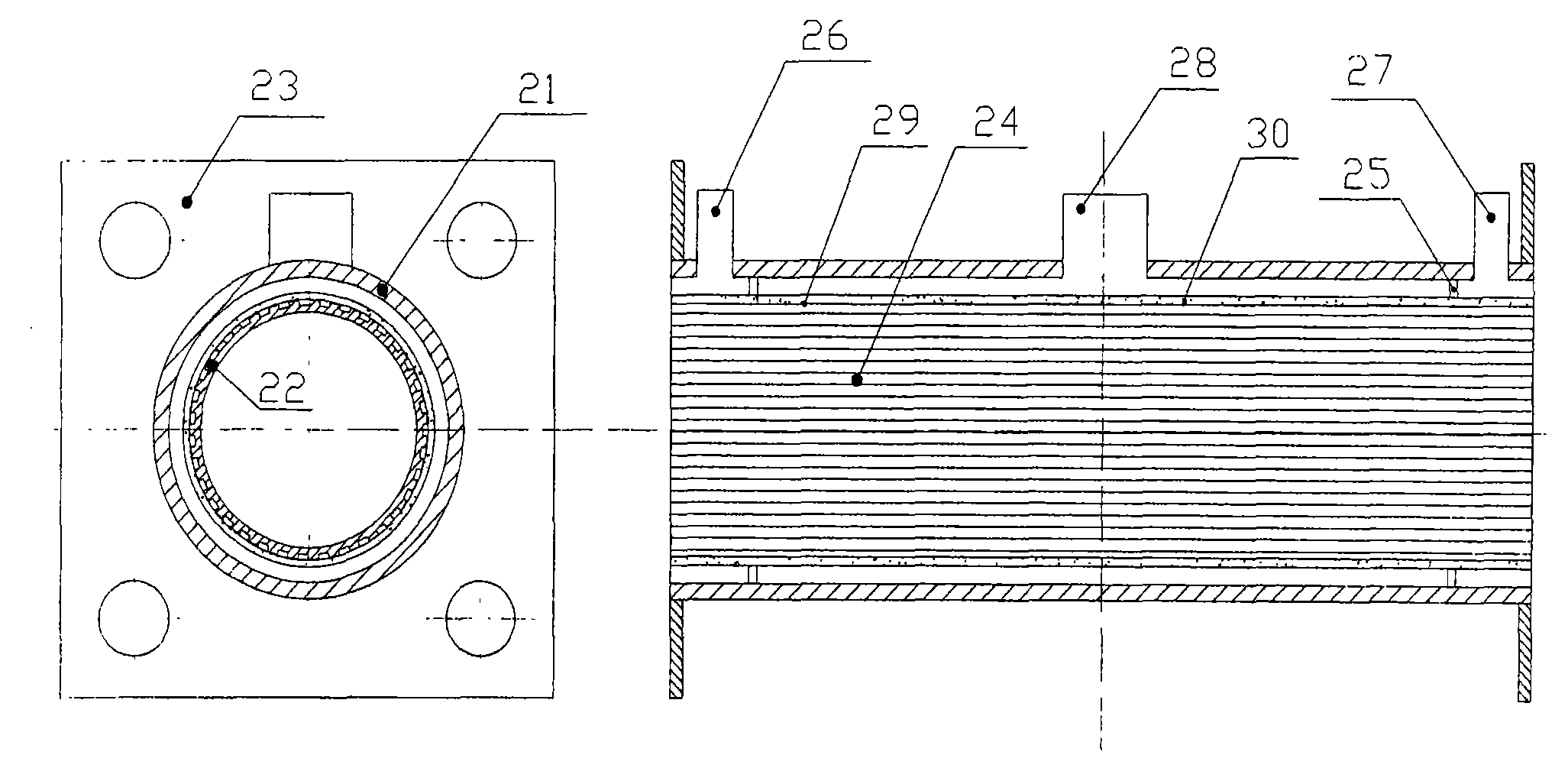

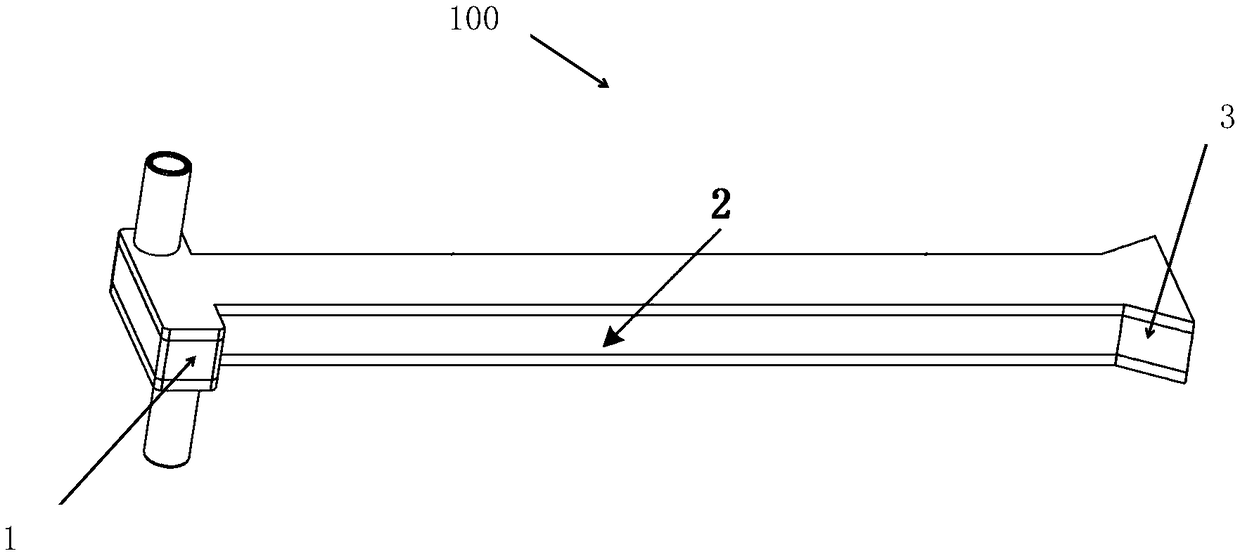

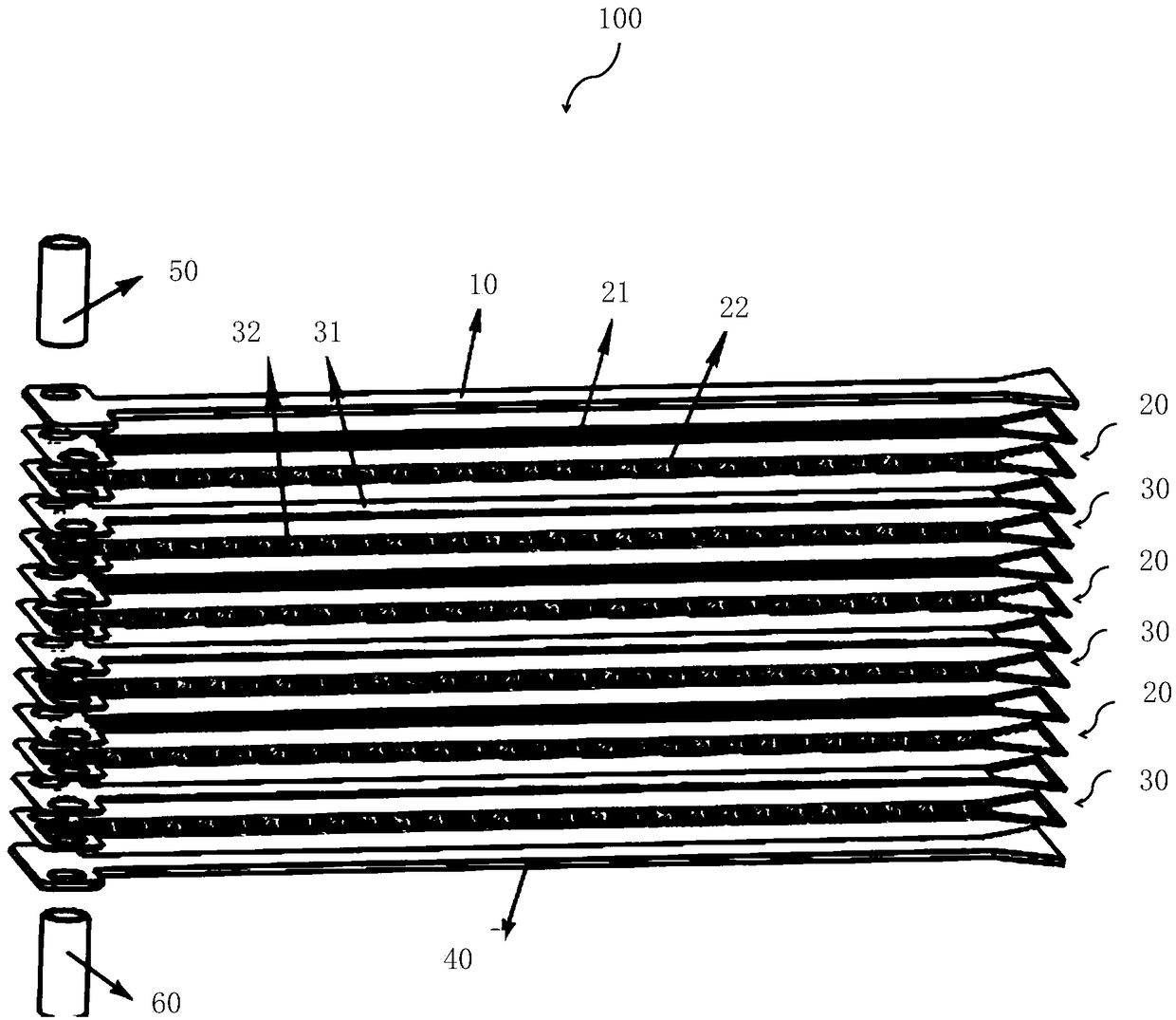

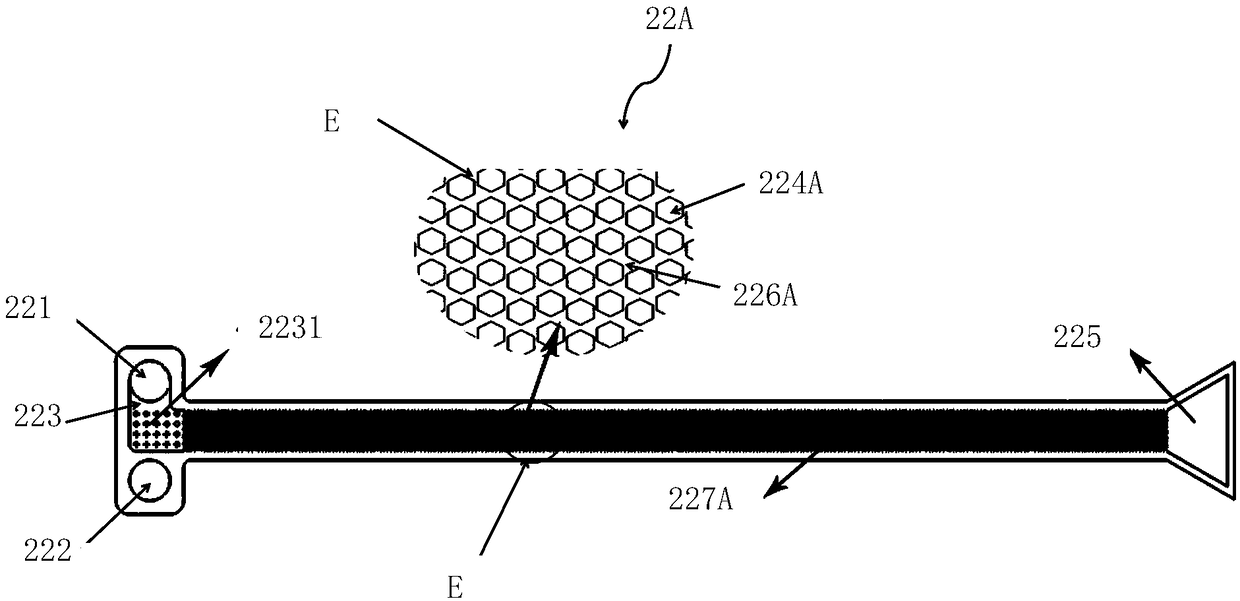

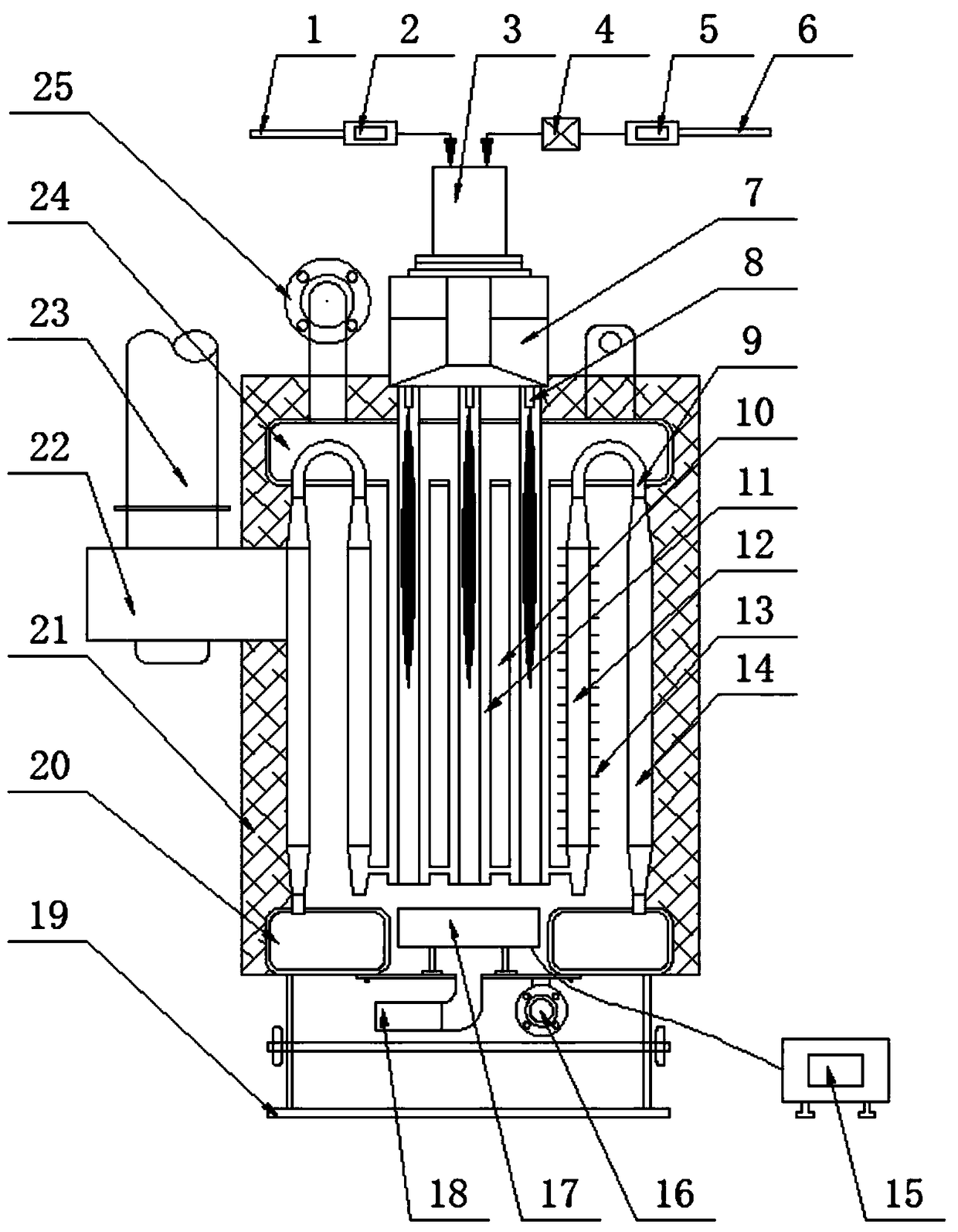

Regenerative throttling assembly, combined microchannel throttling refrigerator and device

ActiveCN108759145AImprove heat transfer efficiencyIncrease disturbanceMechanical apparatusCompression machinesWave shapeRefrigerated temperature

The invention relates to a regenerative throttling assembly, a combined microchannel throttling refrigerator and a device. The refrigerator is the overlaid chute-shaped and wave-shaped combined microchannel throttling refrigerator and is formed by staggeredly overlaying multiple chute-shaped and wave-shaped regenerative throttling components; each regenerative throttling component comprises a regenerative throttling upper plate and a regenerative throttling lower plate overlaid up and down; the regenerative throttling upper plates and the regenerative throttling lower plates comprise inlet sections, regenerative throttling sections and expansion sections connected sequentially; multiple line grooves in parallel are arranged on the regenerative throttling upper plates; multiple W-shaped fold line grooves in parallel are arranged on the regenerative throttling lower plates; the line grooves on the regenerative throttling upper plates and the fold line grooves on the regenerative throttling lower plates are staggered and communicate at the staggered part; the expansion sections communicate with the inlet sections through the regenerative throttling sections so as to form multiple regenerative throttling channels; and a working medium forms a mesh-shaped whirl mesh flow when flowing in the channels, so that the disturbance is improved, and the heat exchange efficiency between platesheets and the working medium is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

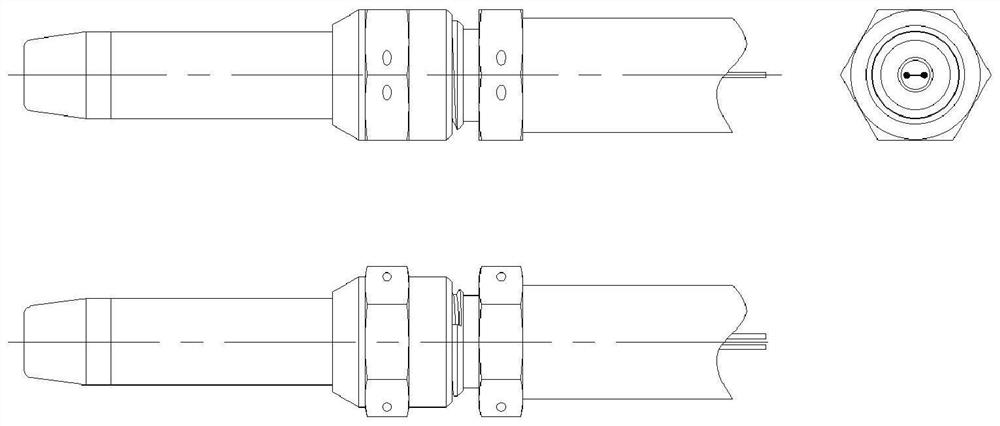

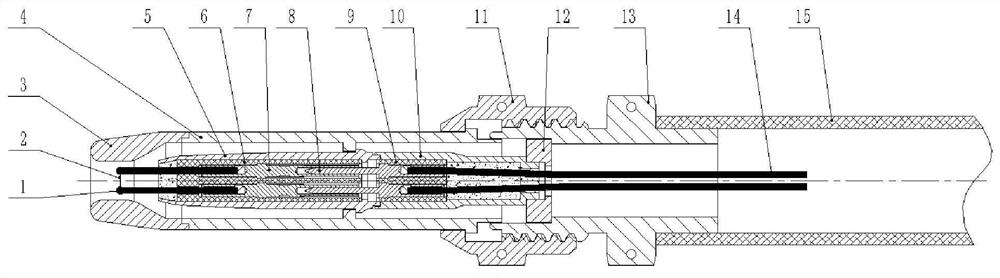

Air-breathing pluggable thermocouple probe for engine air inlet total temperature dynamic distortion test

ActiveCN112525366AImprove reliabilityImprove dynamic performanceThermometer detailsEngine testingEngineeringThermocouple device

The invention belongs to the technical field of aero-engine air inlet dynamic temperature distortion testing, and particularly relates to an air-breathing type pluggable thermocouple probe for the engine air inlet total temperature dynamic distortion test. The air-breathing pluggable thermocouple probe comprises a thermocouple support 1, a micro thermocouple 2, a galvanic couple socket, a galvaniccouple contact pin, an air collecting head 3, a probe outer shell 4, a locking nut 11, a positioning ring 12, a probe tail shell 13, a galvanic couple extension line 14 and an air entraining pipe 15.

Owner:AECC SICHUAN GAS TURBINE RES INST

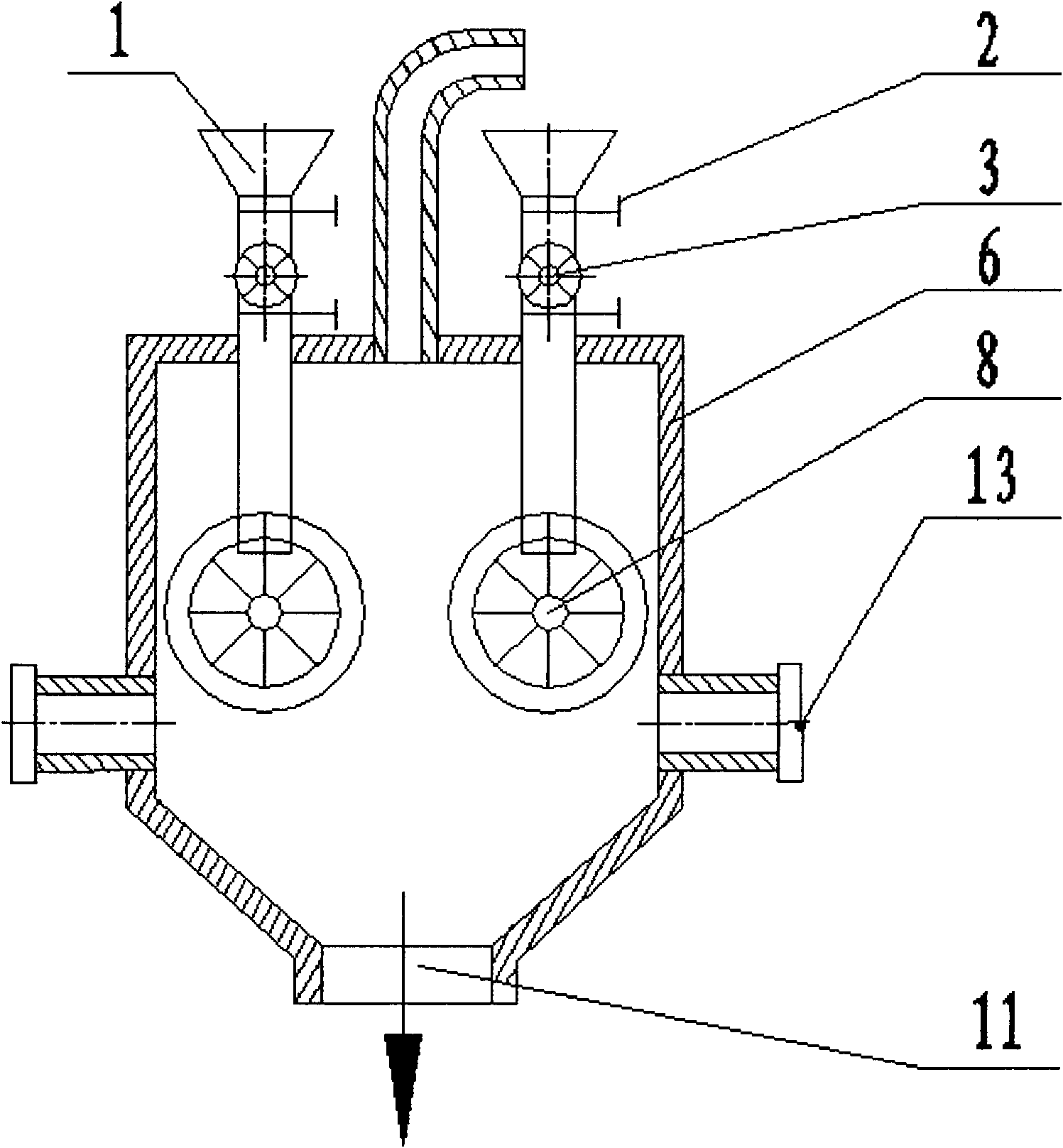

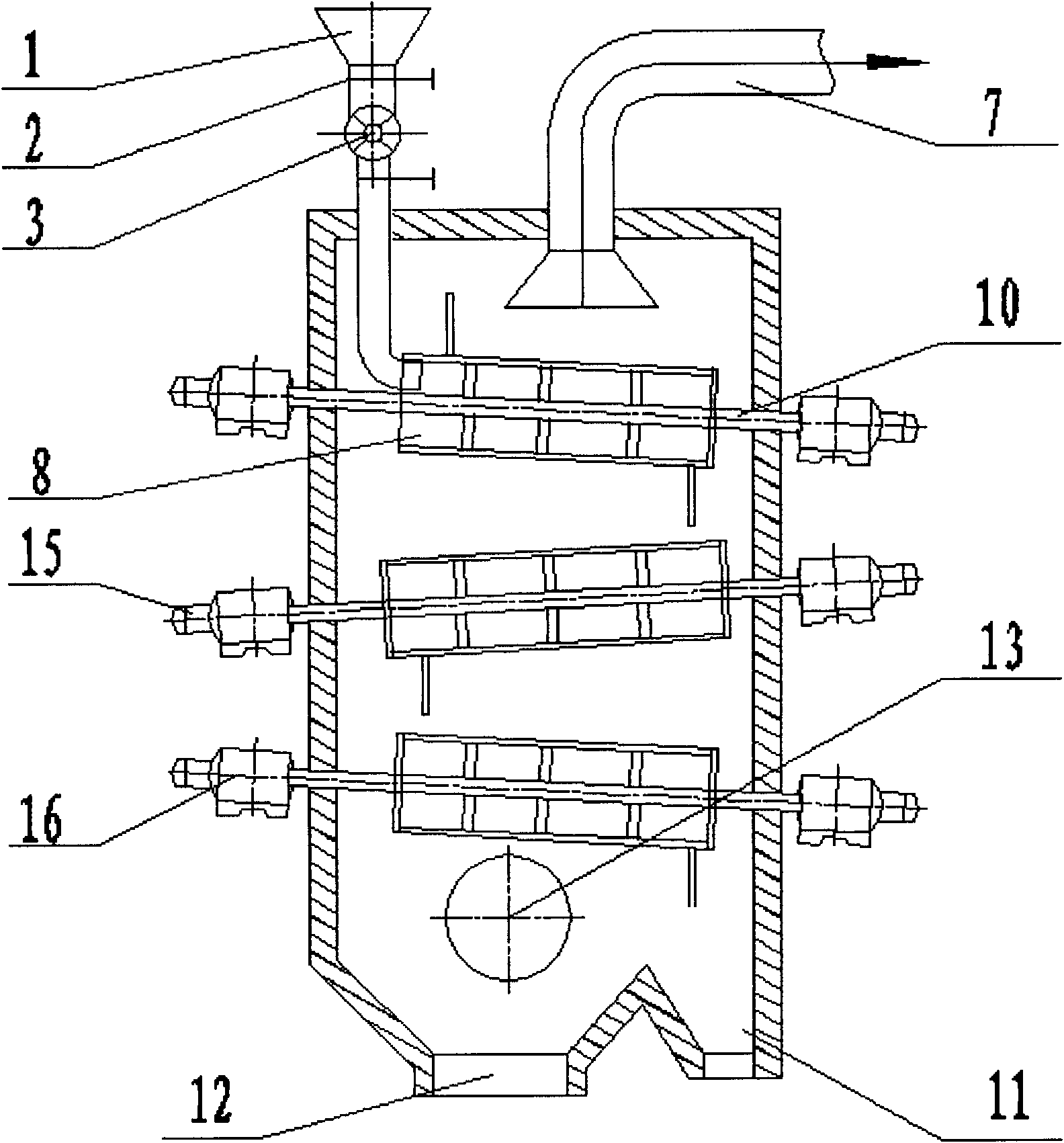

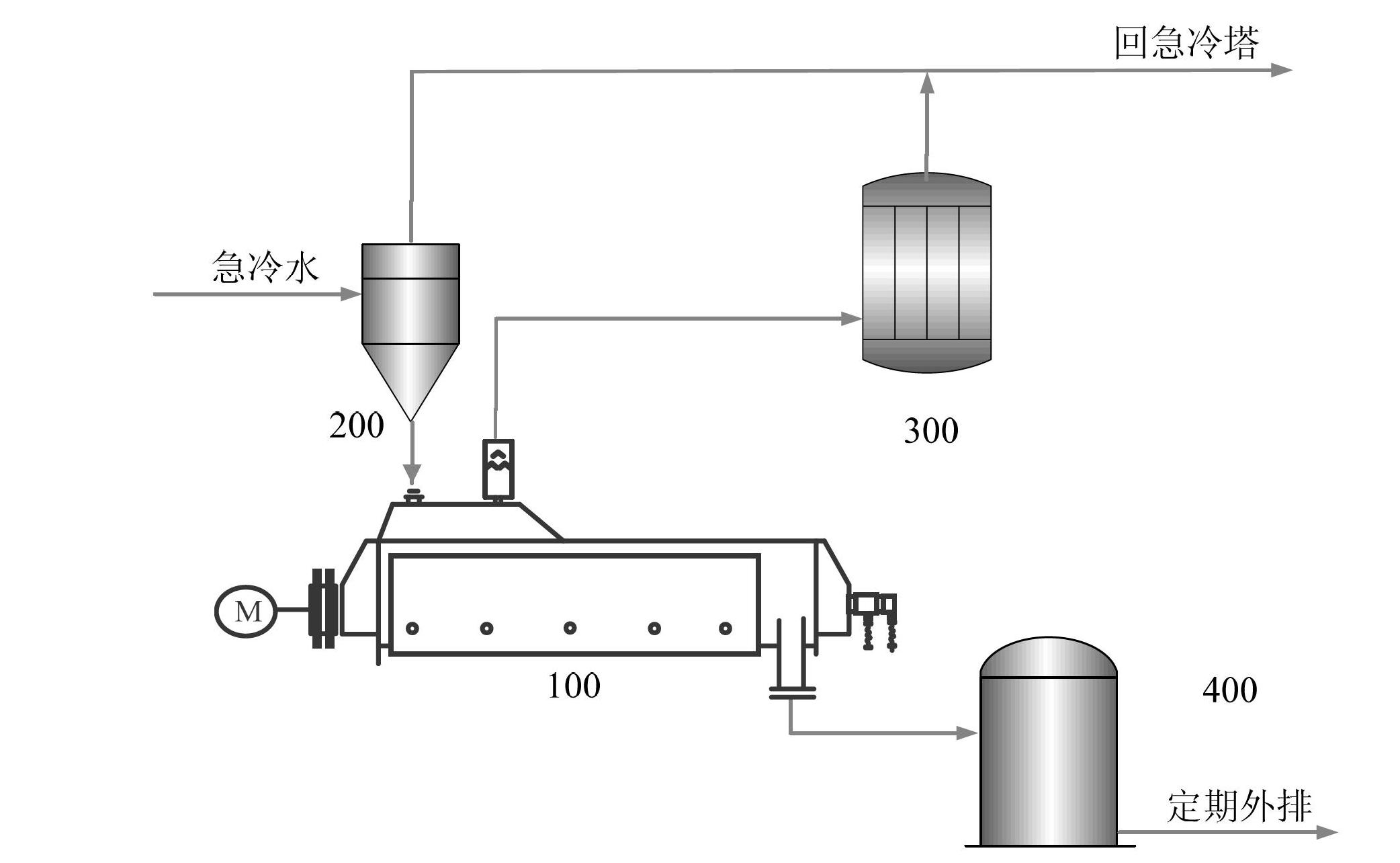

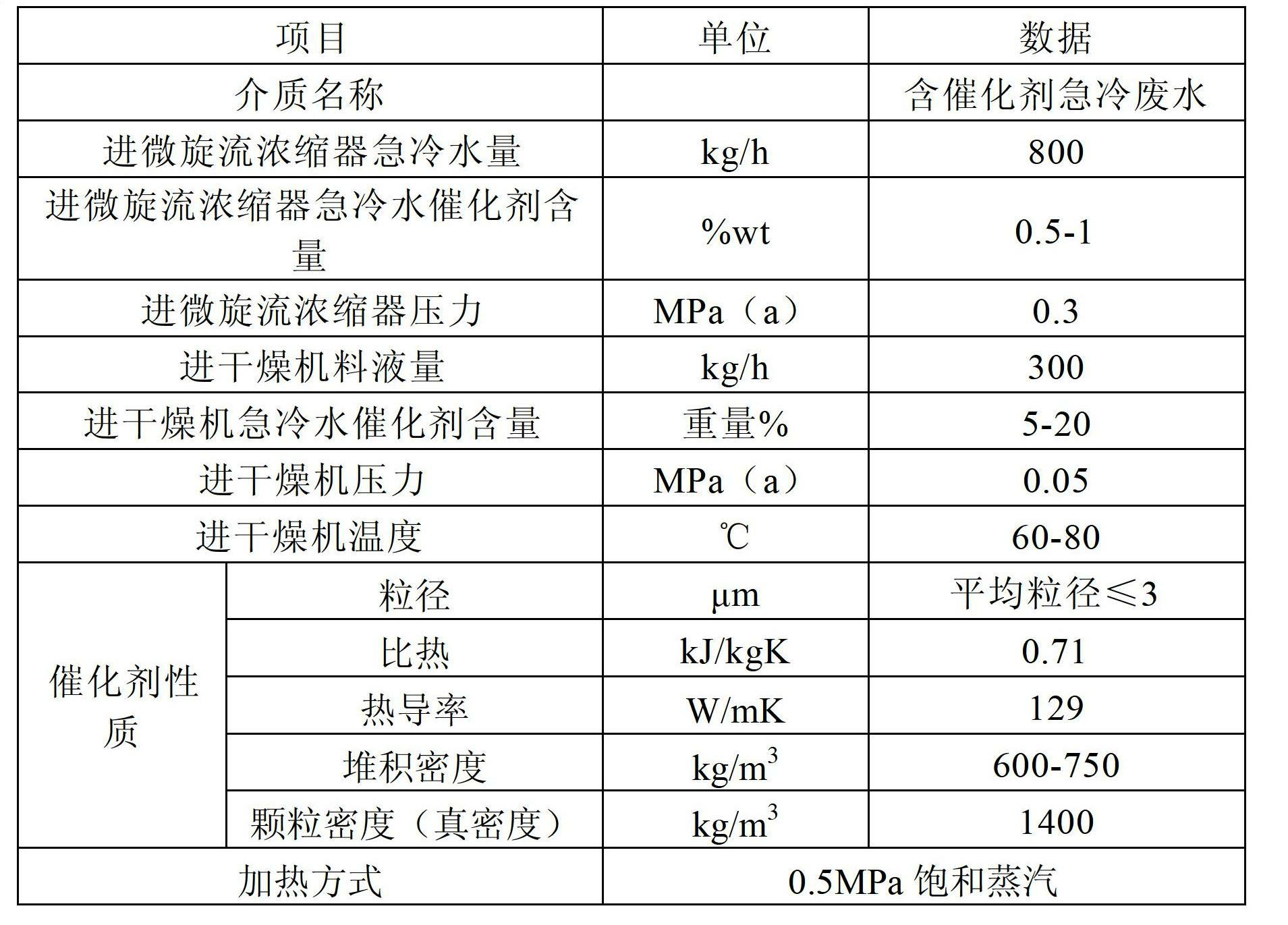

Method and device for concentrating and coupled-drying catalyst in quenched wastewater in process of using methanol to prepare olefin

InactiveCN102658213ALower minimum temperatureHigh viscosityCentrifugal force sediment separationCatalyst activation/preparationWastewaterMethanol

The invention relates to a method and device for concentrating and coupled-drying a catalyst in quenched wastewater in the process of using methanol to prepare olefin, and provides the method for concentrating and coupled-drying the catalyst in quenched wastewater in the process of using methanol to prepare olefin. The method comprises the following steps of: carrying out concentrating treatment on the quenched wastewater containing catalyst in the process of using the methanol to prepare olefin to obtain a concentrated phase of the catalyst; and drying the concentrated phase of the catalyst and recovering the catalyst in a solid form, wherein a self-returning blade drying machine is adopted for drying. The invention also provides a device for concentrating and coupled-drying a catalyst in quenched wastewater in the process of using methanol to prepare olefin.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

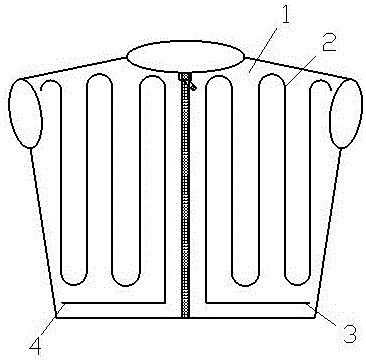

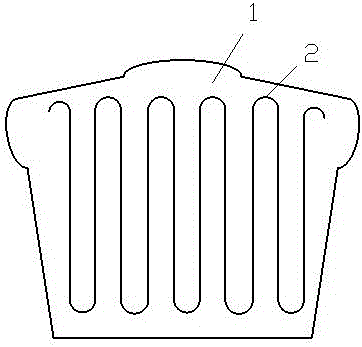

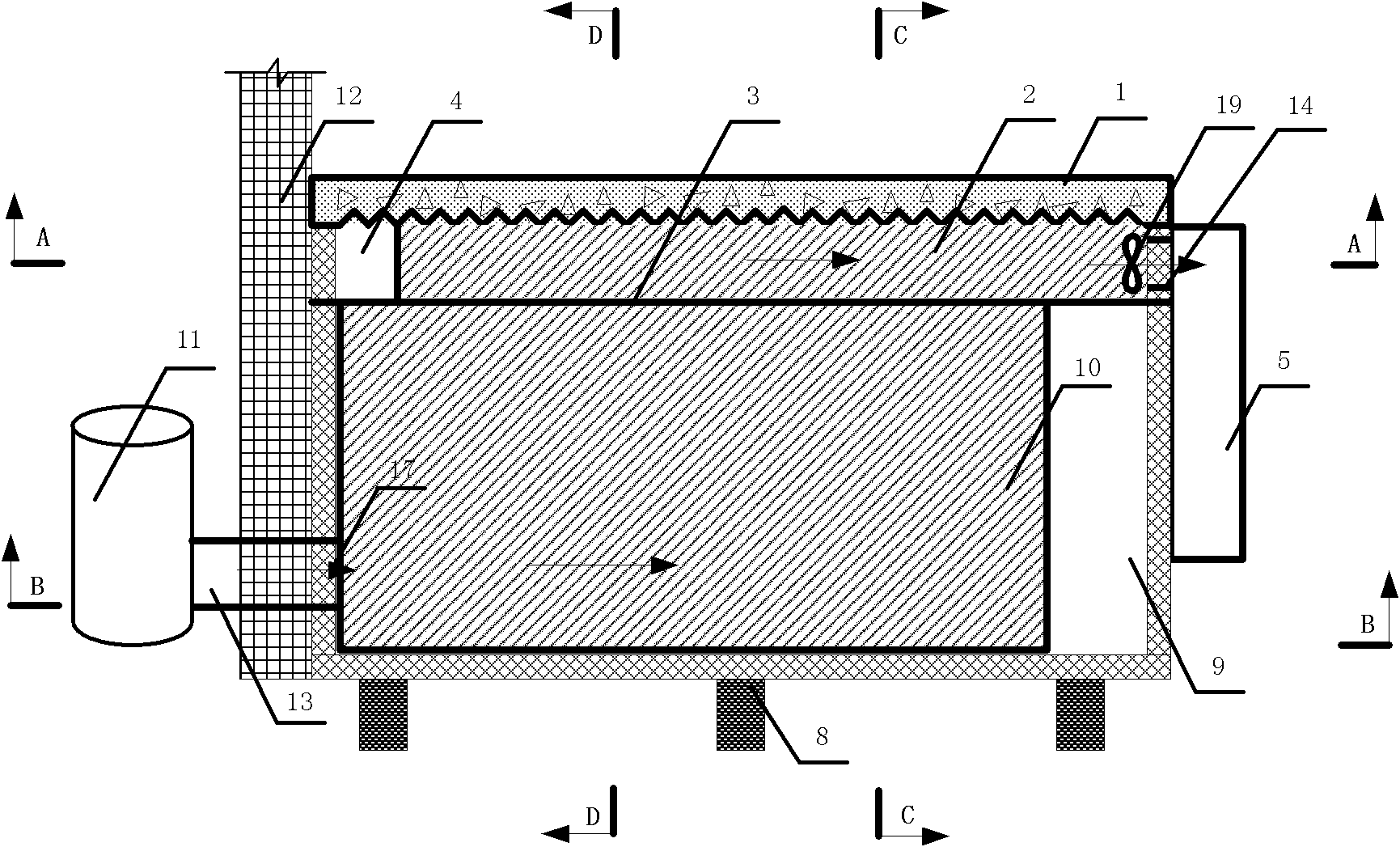

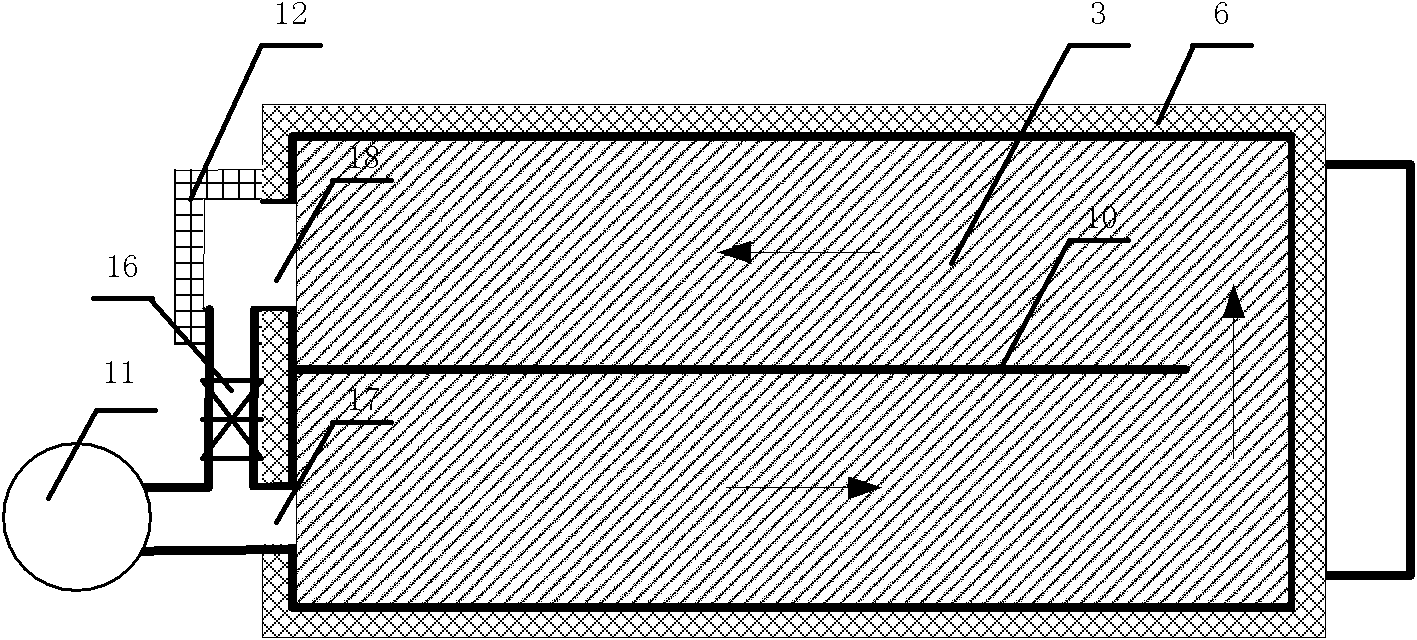

Energy-saving kang with double flow channels

ActiveCN101984297ALow-cost and high-efficiency solar heat utilization at low temperatureLow running costLighting and heating apparatusCombustion-air/flue-gas circulation for stovesFlueBiomass

An energy-saving kang with double flow channels belongs to the technical fields of the utilization of solar energy and biomass energy and the building energy conservation. The energy-saving kang with double flow channels contains not only a stove, a kang plate, a flue baffle plate, a flue gas inlet, a flue gas circulation channel, a flue gas outlet, a chimney and other parts of the traditional kang, but also a solar air heat collecting system. In the energy-saving kang, the folded metal plate on the lower surface of the upper kang plate is utilized to increase the heat-transfer intensity of the air and the kang plate and the uniformity of the temperature distribution of the kang surface; the baffle plate is used to effectively separate the air and the flue gas circulation channel; and the solar energy and the heat of the flue gas can be utilized simultaneously, and the solar heat collecting device can not be damaged. All the parts in the energy-saving kang are prepared from common materials and by common preparation technology, thus the energy-saving kang has the advantages of simple production technology, low production cost and the like. The energy-saving kang is mainly used in the single building of a village in Northern China, can solve the indoor heating problem in winter and can reduce the coal consumption while lowering the environment pollution.

Owner:TSINGHUA UNIV

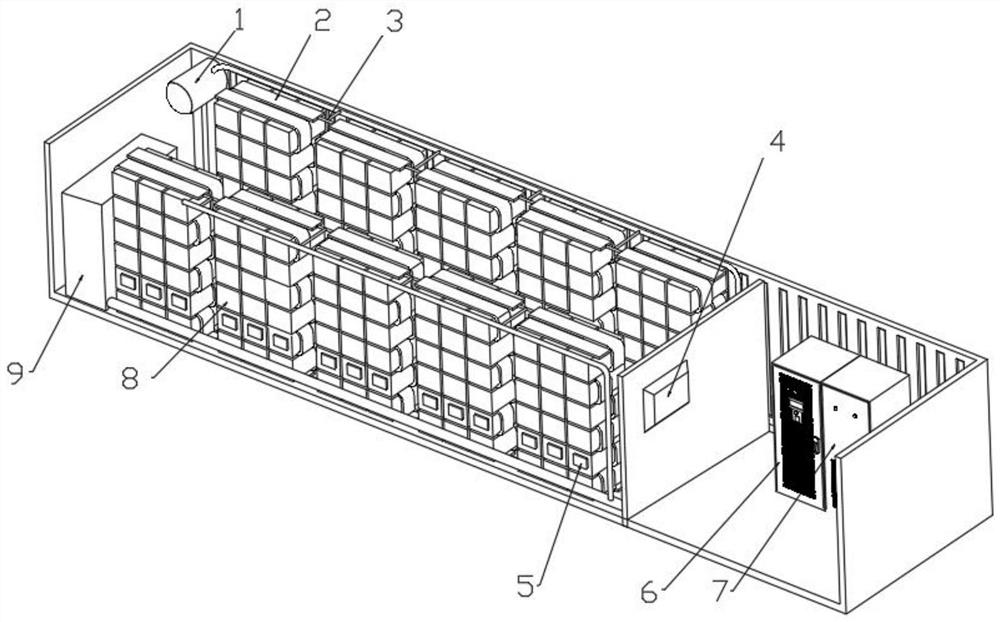

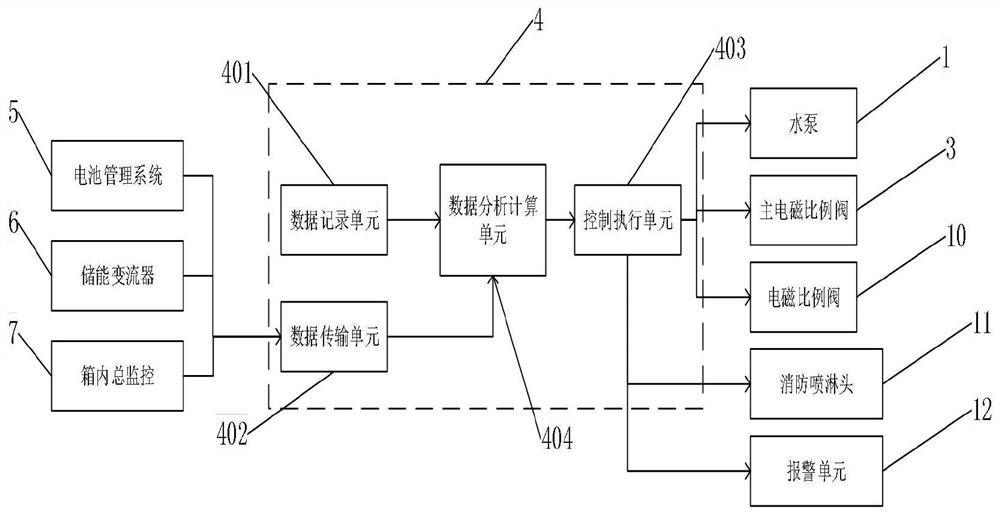

Lithium battery thermal safety management system and management and control method

ActiveCN112310491AImprove consistencyGuaranteed uptimeCells structural combinationElectrical batterySafety management systems

The invention discloses a lithium battery thermal safety management system and a management and control method. The lithium battery thermal safety management system comprises a water pump, a thermal safety management system, a battery management system, an energy storage converter, an in-box main monitor, a plurality of battery modules and a cooling-water machine; a liquid cooling channel is laidon the surface of a battery module; the water pump is communicated with the cooling-water machine through a liquid cooling channel to form a closed loop, an electromagnetic proportional valve is arranged on the liquid cooling channel, and the battery module comprises a plurality of single batteries; the thermal safety management system comprises a data transmission module, a data recording module,a data analysis and calculation module and a control execution module; the invention further provides a lithium battery thermal safety management and control method adopting the lithium battery thermal safety management system, the heat generation difference of the lithium battery caused by different aging degrees in the service process can be identified, and heat dissipation can be regulated andcontrolled as required, so that the consistency and the running performance of the running temperature of the battery are improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

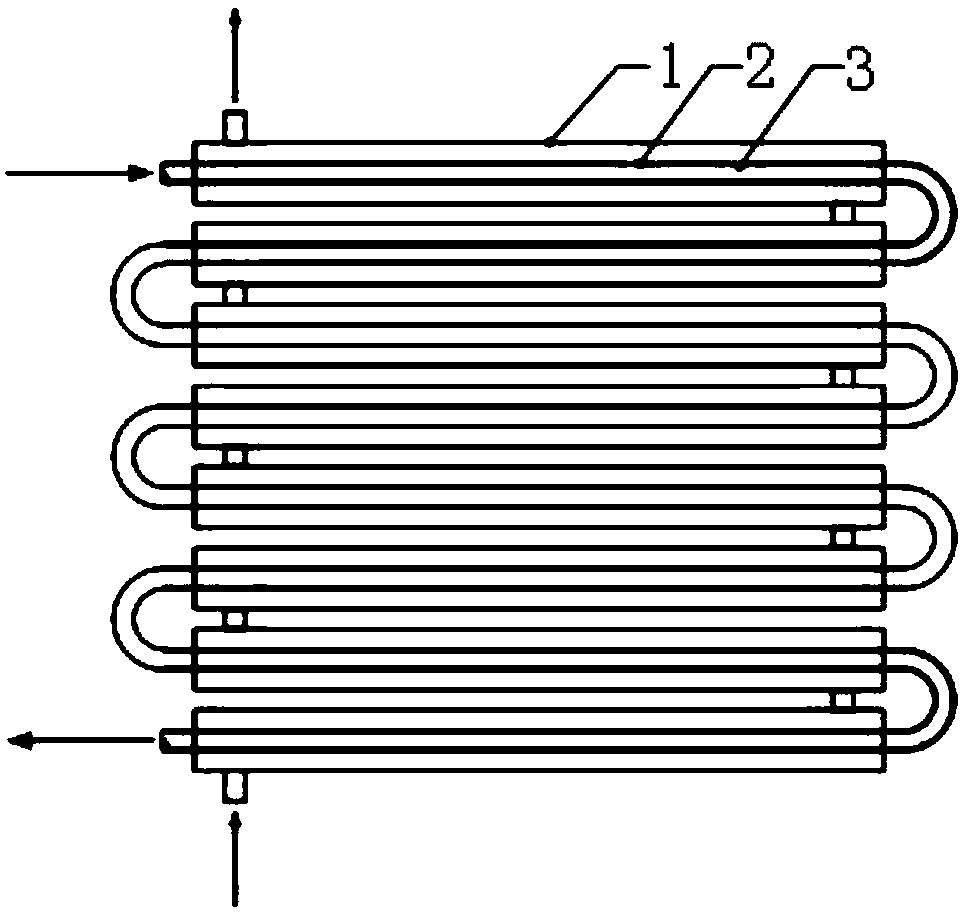

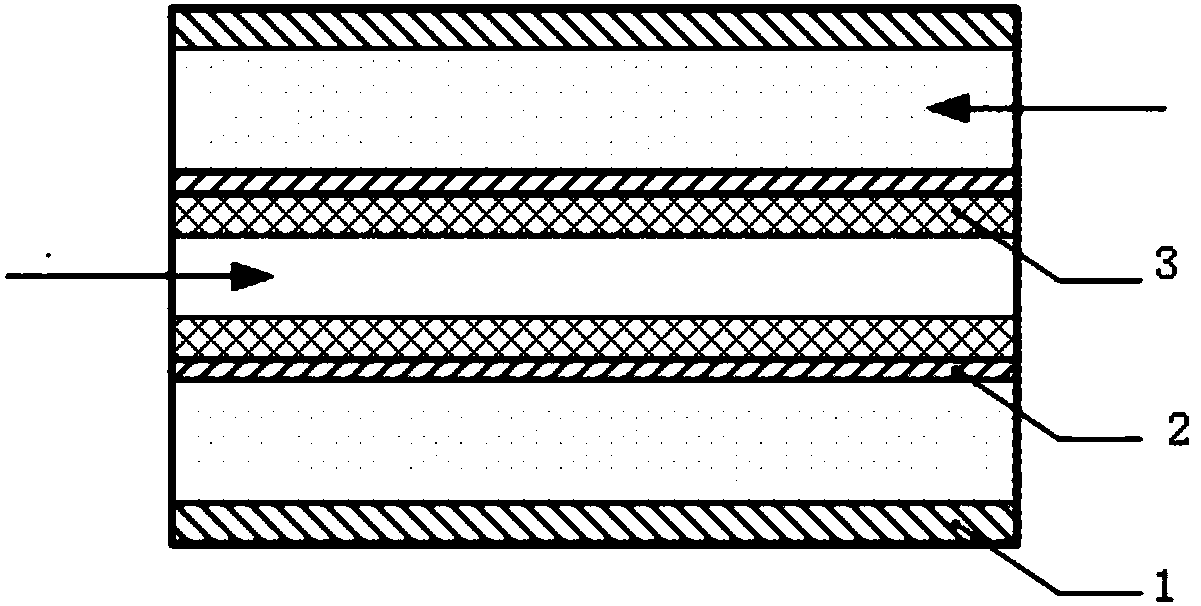

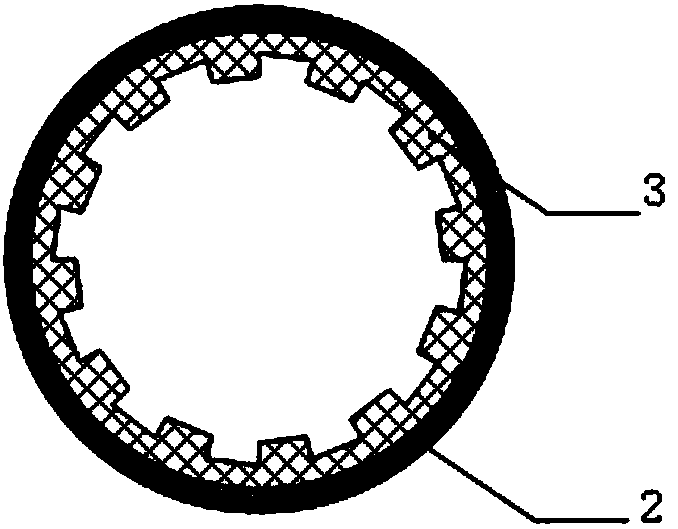

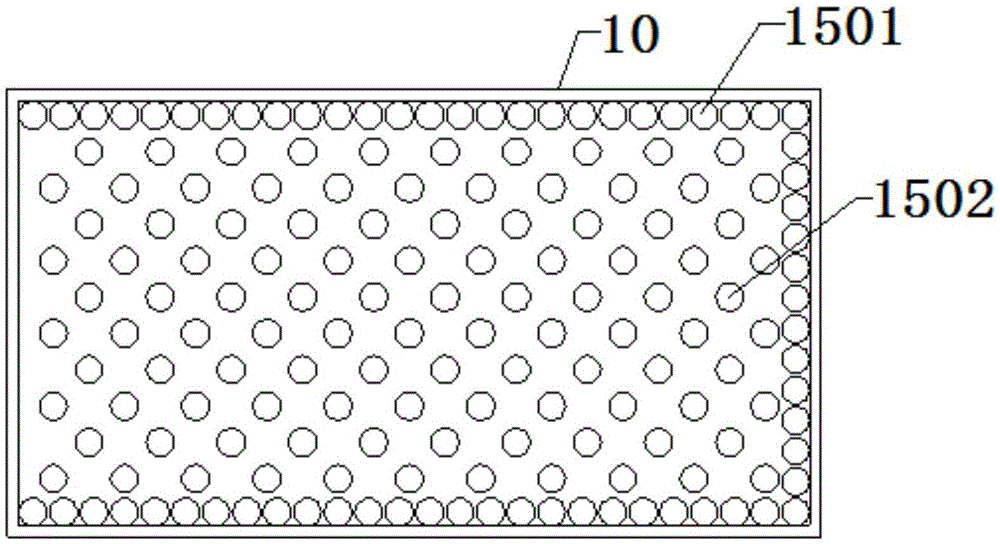

Efficient CO2 gas cooler

PendingCN107830751AImprove thermal conductivityUneven velocity distributionStationary tubular conduit assembliesHeat exchange apparatusEngineeringGas cooler

The invention discloses an efficient CO2 gas cooler. According to the efficient CO2 gas cooler, sleeve heat exchanger inner tubes penetrate a plurality of rows of vertically-arranged sleeve heat exchanger outer tubes in a coiled manner, porous foam metal layers are paved on tube inner walls of hot fluid inlet sections and hot fluid outlet sections of the sleeve heat exchanger inner tubes, the porous foam metal layers and the tube inner walls are tightly attached, porous metal foam materials of the porous foam metal layers are of three-dimensional structures, and holes are communicated. According to the efficient CO2 gas cooler, the porous foam material density is low, and the length of heat exchange tubes can be decreased while the heat exchange strength of the CO2 gas cooler is improved;and under the condition that the heat exchange amount is same, the heat exchange area can be reduced, metal consumption is reduced, the weight of heat exchangers is small, and the structure is more compact.

Owner:TIANJIN UNIV OF COMMERCE

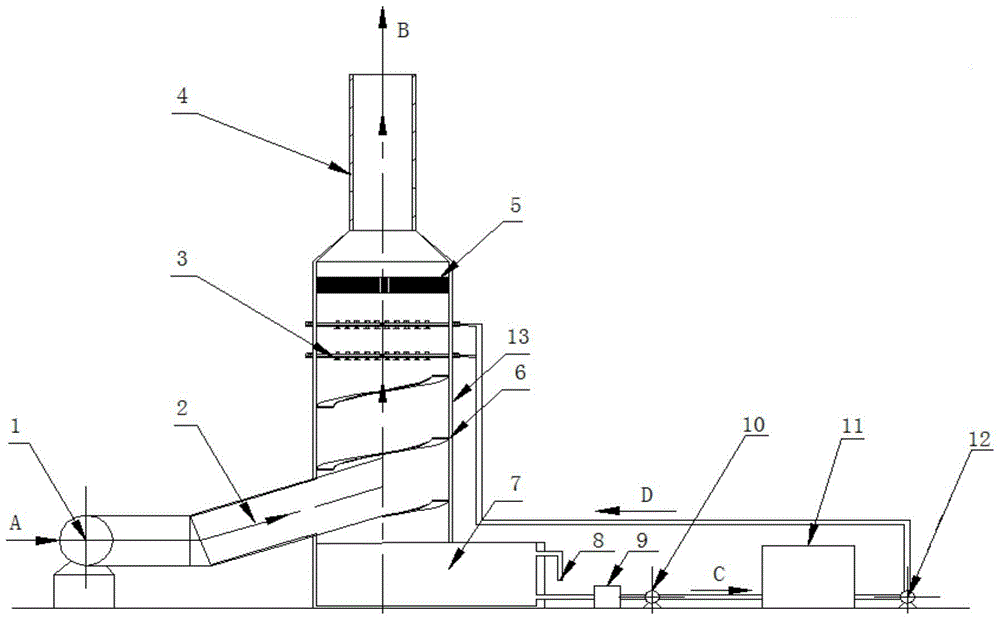

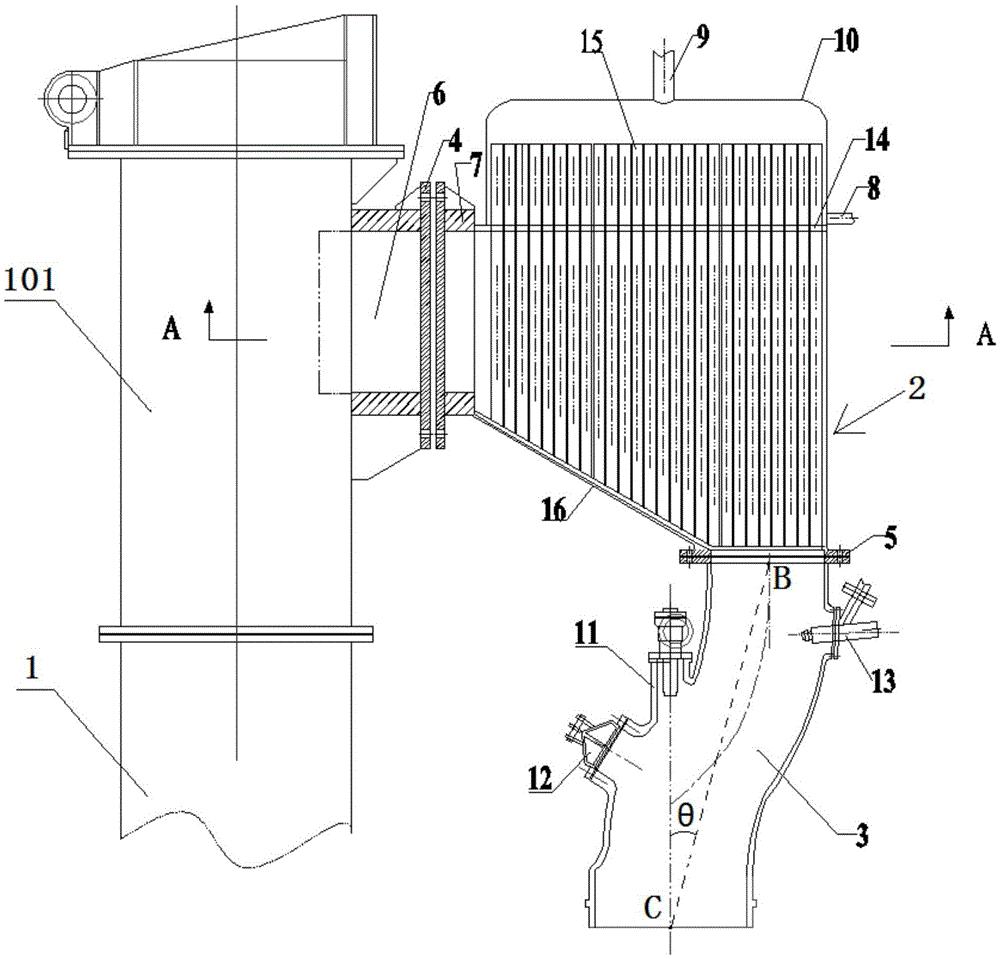

Smoke rotational flow condensation type heat exchange device and method for aluminum oxide calcining kiln

InactiveCN105698549AEvenly distributedReduce loadCharge composition/stateIncreasing energy efficiencyRed mudRotational flow

The invention provides a smoke rotational flow condensation type heat exchange device and method for an aluminum oxide calcining kiln. The smoke rotational flow condensation type heat exchange device comprises a fan, sprayers, a chimney, a fog receiver, a water recycling tank, an overflow pipe, a dust collector, a hot water pump, a cold water pump, spiral flow guide plates, an air pipe and a user. The smoke rotational flow condensation type heat exchange method comprises the steps that 150-170 DEG C hot and wet smoke from the aluminum oxide calcining kiln enters the lower portion of a condensation heat-exchange tower through the fan and the air pipe, and operates upwards after passing the spiral flow guide plates; and after spraying convective heat exchange through the sprayers, cooling water is heated to 80 DEG C from 50 DEG C and then joints condensate water in the smoke, and afterwards, mixed water is delivered to the user to be used through the hot water pump after entering the water recycling tank. The smoke rotational flow condensation type heat exchange device and method have the advantages that recycled hot water can be used for washing of red mud and a flat plate in aluminum oxide production, or heating for the user, or ORC waste heat power generation. 80%-90% or above of the heat in the moisture-heat-containing smoke can be recycled, and the economic benefit and the effects of energy conservation, emission reduction and environmental protection are significant.

Owner:北京中冶设备研究设计总院有限公司

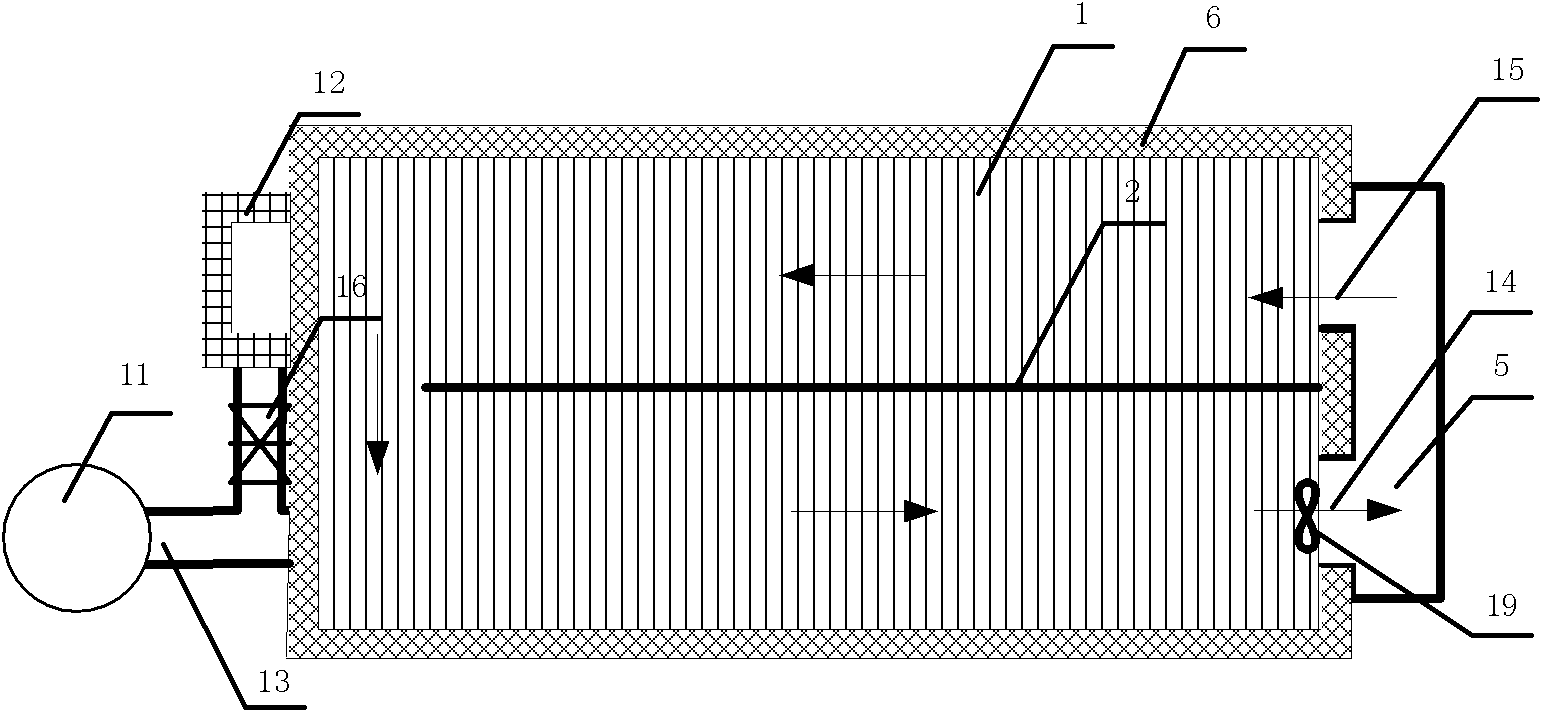

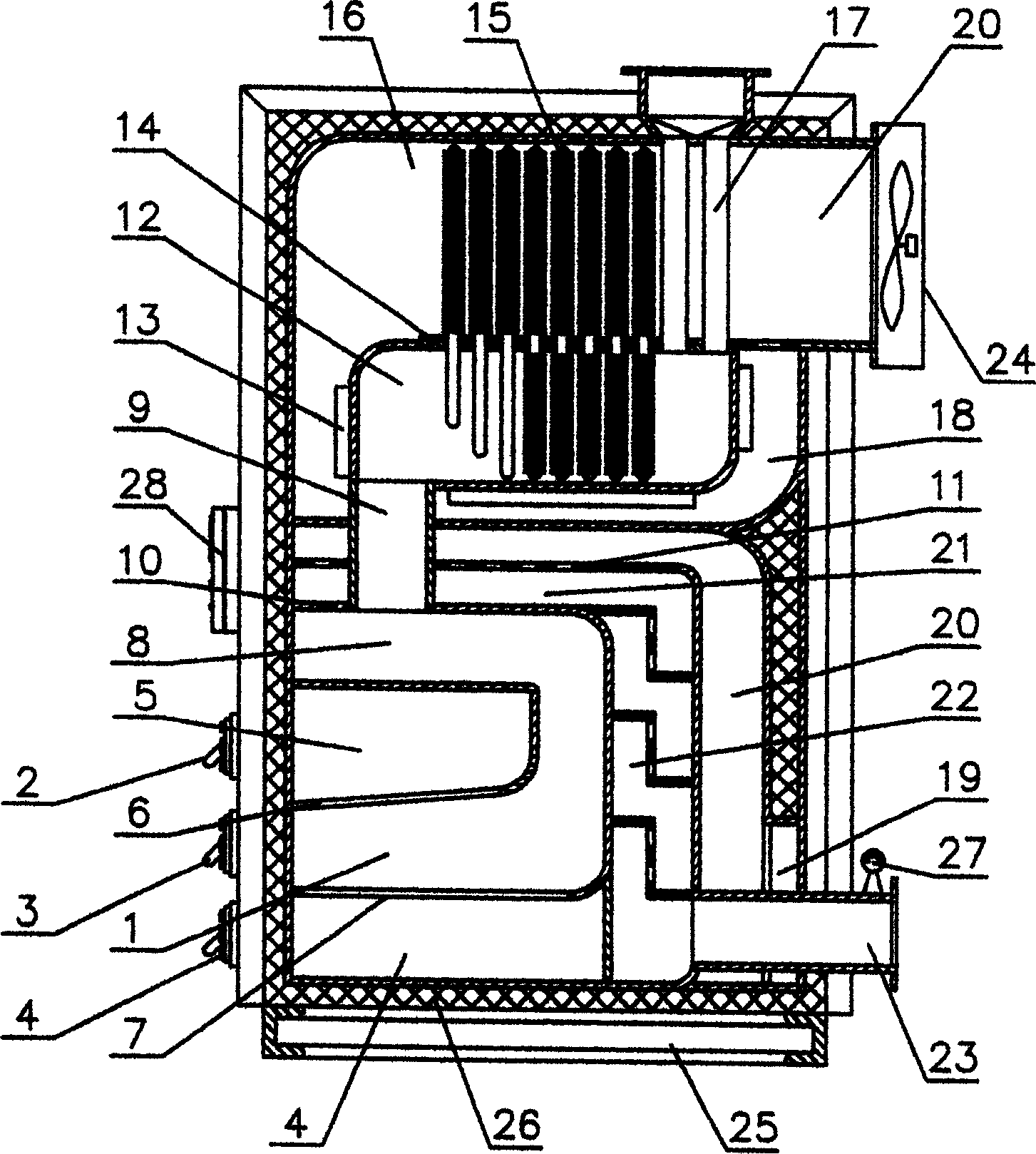

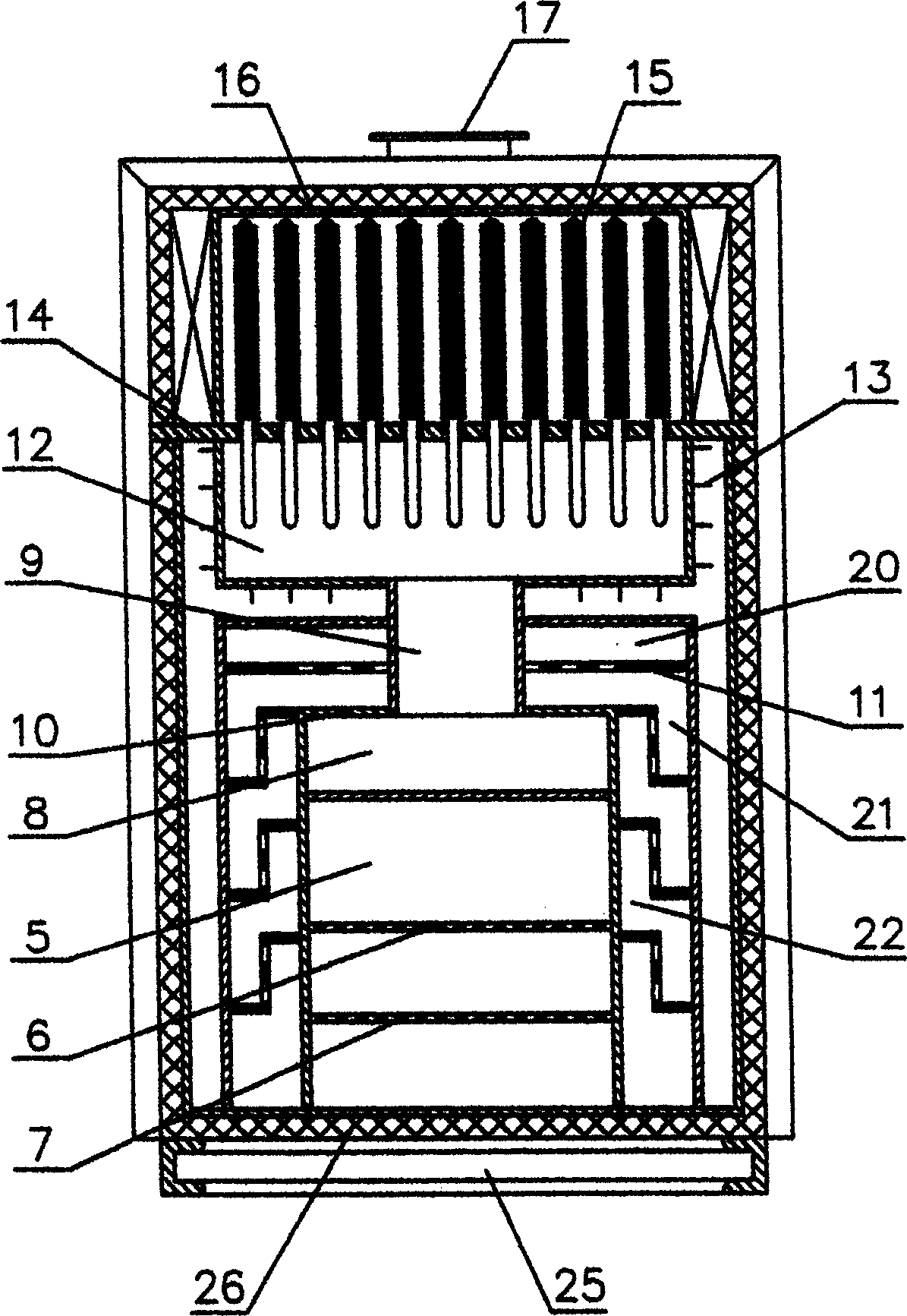

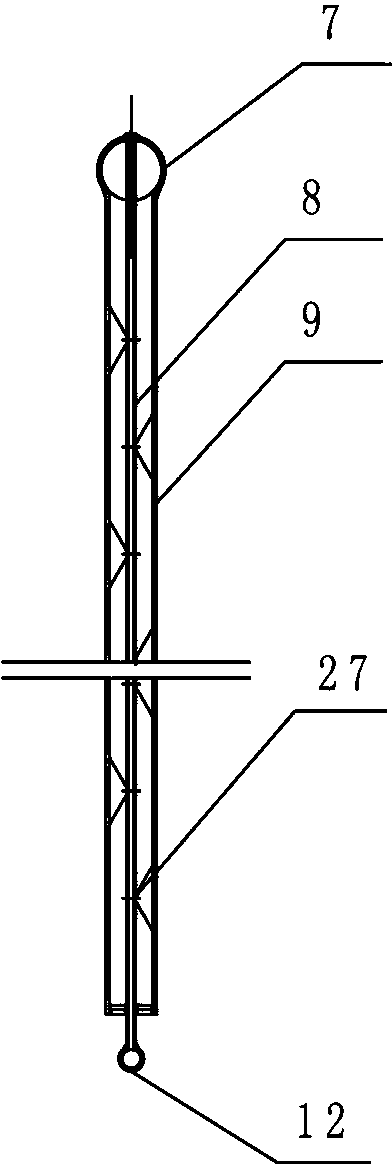

Double layer back burning radiation jet flow hot pipe air heating furnace

The present invention relates to a double-layer back-combustion radiation jet heat-pipe hot-air furnace. It is a high-effective high-temp, novel hot-air indirectly-heating hot-air furnace which is made up by using heat-pipe heat-exchanger with high efficiency and small flow resistance and high-temp, radiation jet impact heat-exchanger with double-layer back-combustion furnace cavity by means of back flame path series-connection. Said invention also provides its concrete structure, its hot-air temperature can be up to 200-500deg.C and its heat efficiency can be up to about 85%.

Owner:吴江市普天热管技术推广应用研究所

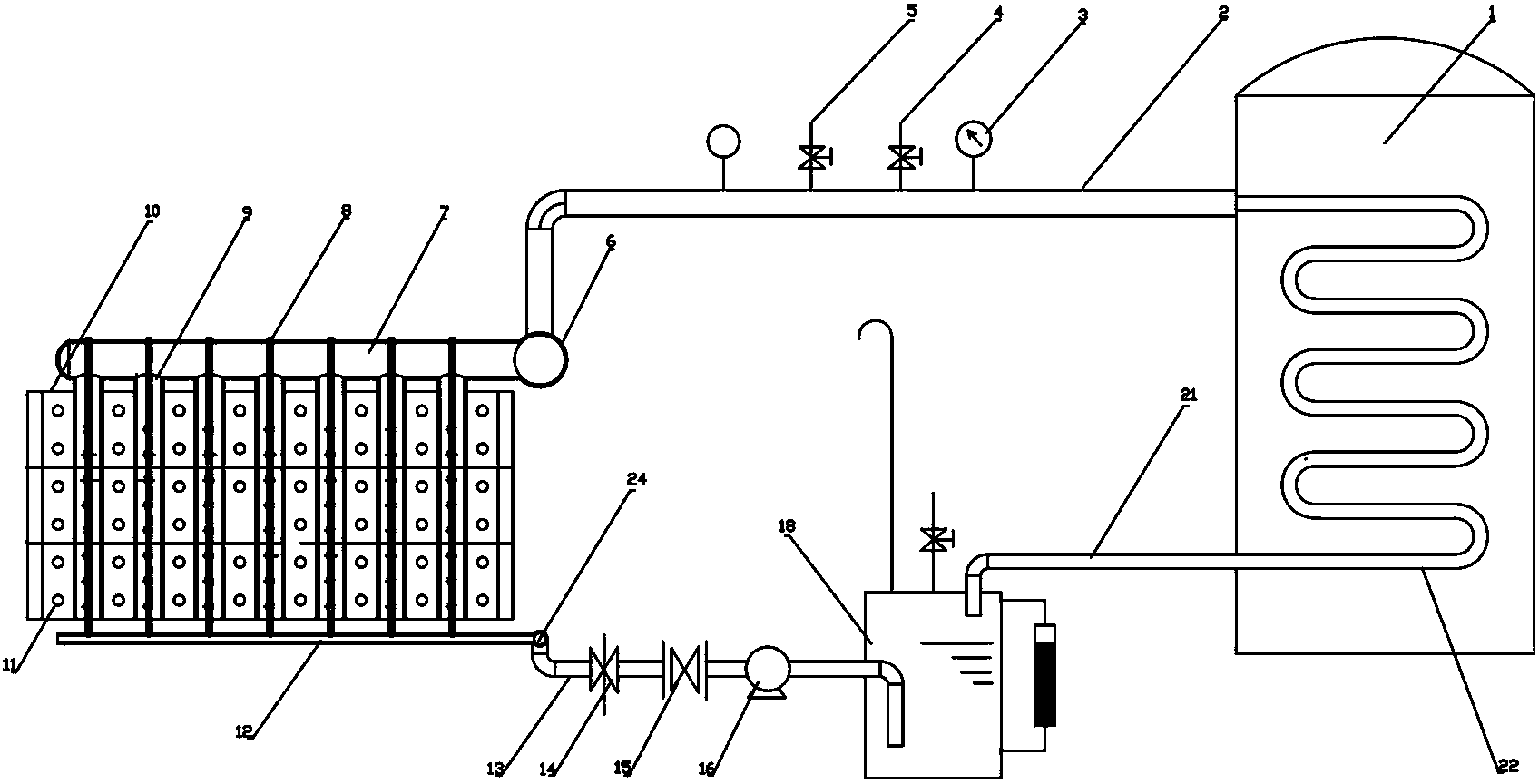

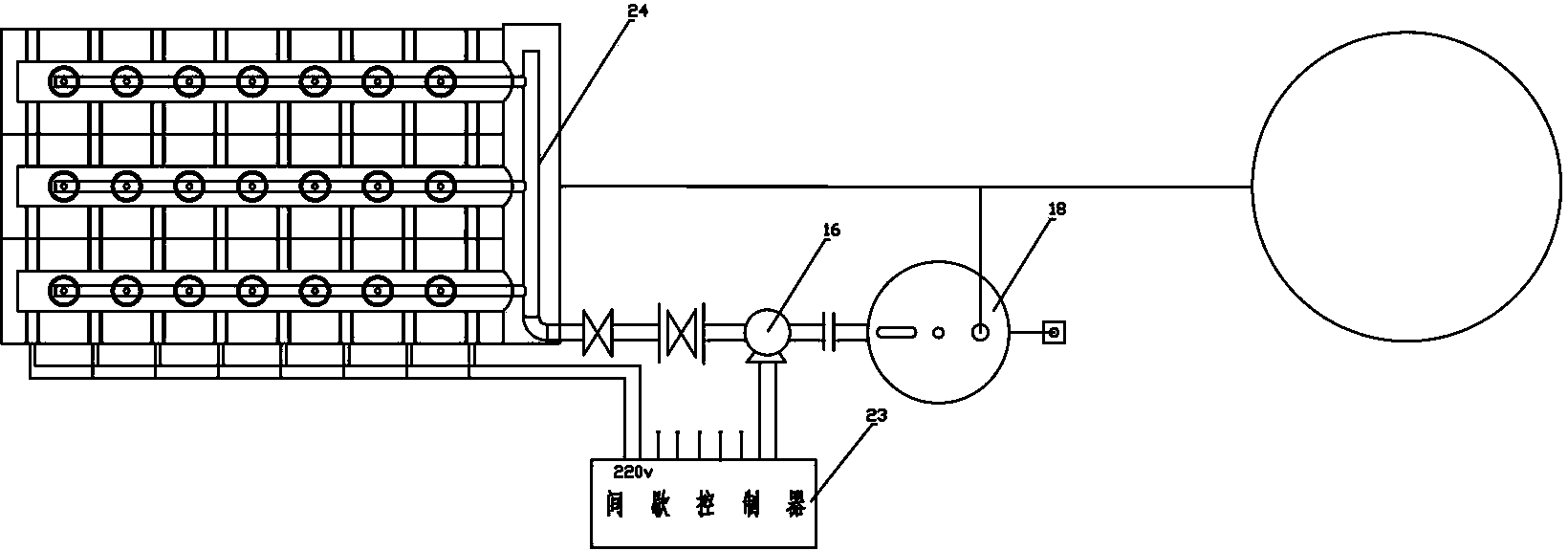

Evaporating pipe and evaporating pipe type heat storage boiler heat exchange system

InactiveCN104279546AReduce use costAdjustable evaporation and condensationSteam generation heating methodsSteam boilersThermal energyElectricity

The invention provides an evaporating pipe and a heat storage boiler heat exchange system adopting the evaporating pipe. The evaporating pipe can generate steam in a heat accumulator, the heat storage boiler heat exchange system has a heat storage and emission process, electric energy is converted into heat energy to be stored in a storage tank during off-peak electricity, the electric energy is discharged to serve other fields through a heat exchanger during peak electricity, and energy conservation and environmental protection are achieved while using cost can be lowered. In addition, in the heat storage boiler heat exchange system, a water pump is controlled by an intermittent controller to realize adjustability in evaporation and condensation amount, and the purposes of water inlet temperature recovery in a heat pipe and secondary vaporization are achieved.

Owner:LIAONING JIASHENG MINING

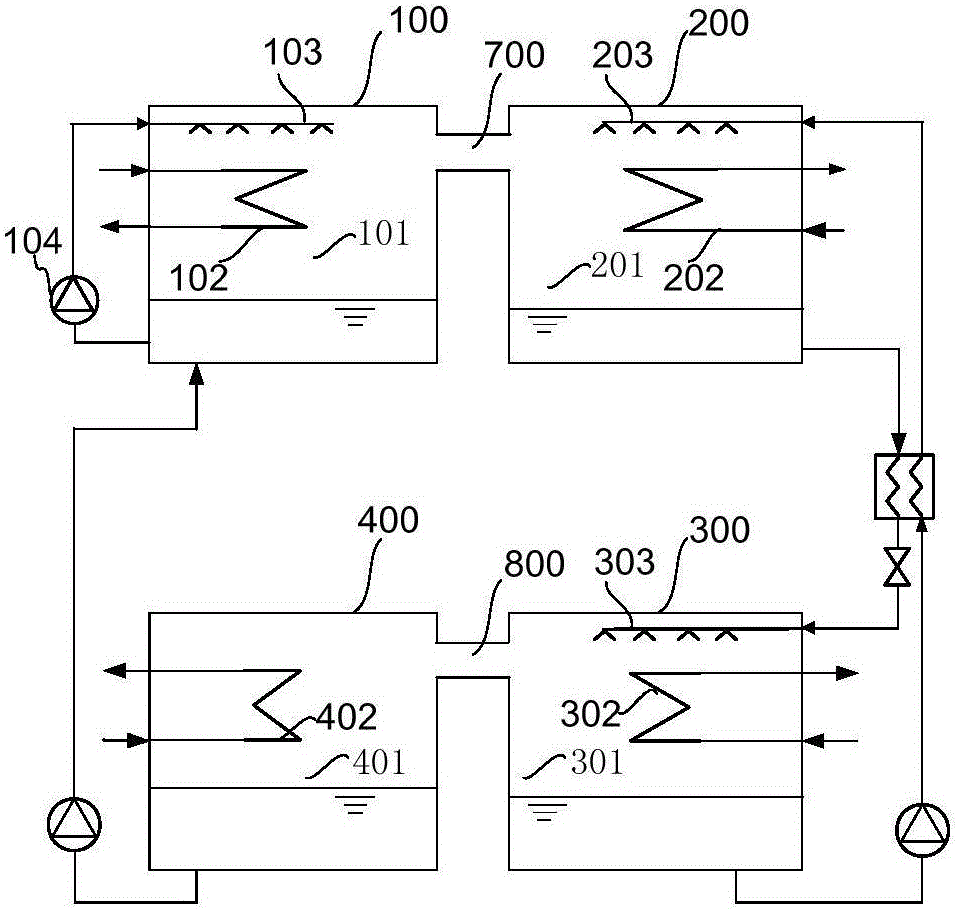

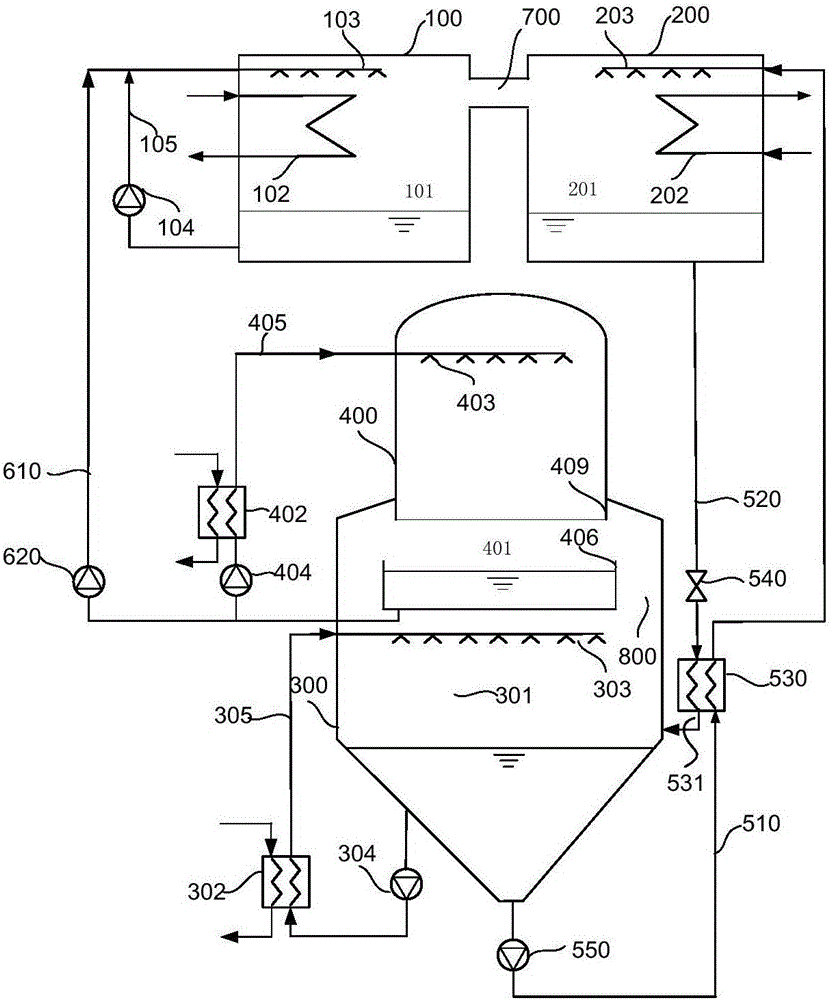

Absorption heat pump and condenser and method thereof

ActiveCN106091477AReduce volumeImprove performanceHeat pumpsEvaporators/condensersSteam condensationEngineering

The invention discloses an absorption heat pump and a condenser and a method thereof. The condenser comprises a condensation cavity, a condensation heat exchanger, a condenser condensation working medium spraying device, a condenser condensation working medium spraying pipe and a condenser condensation working medium spraying pump; the condenser condensation working medium spraying device is arranged in the condensation cavity; the condenser condensation working medium spraying pipe is arranged out of the condensation cavity; the condensation heat exchanger and the condenser condensation working medium spraying pump are arranged on the condenser condensation working medium spraying pipe; the condenser condensation working medium spraying pump conveys a condensation working medium in the condensation cavity to the condenser condensation working medium spraying device by the condenser condensation working medium spraying pipe via the condensation heat exchanger; the condenser condensation working medium spraying pipe is connected with a heat fluid side of the condensation heat exchanger; and a cold fluid side of a cooling heat exchanger is connected with a condensation heat medium pipe. The absorption heat pump can reinforce the heat and mass transfer process of condenser working medium steam condensation to reduce the size of the condenser.

Owner:陕西双宇博达能源工程有限公司

Pulsation combustion type ultrasonic-assisted reinforced heat transfer boiler

PendingCN109442748AExtend your lifeImprove combustion efficiencyWater heatersRecuperatorEnergy conservation

The invention relates to a pulsation combustion type ultrasonic-assisted reinforced heat transfer boiler. A pulsation combustion system comprises a gas mixing chamber and a pulsation combustor, the gas mixing chamber is connected with an air inlet pipe and a natural gas inlet pipe correspondingly, a plurality of straight pipe heat exchange pipes, a liquid inlet, a liquid outlet, a mixed gas inlet,a mixed gas outlet, a liquid inlet pipe plate and a condensed water drain outlet are arranged on a heat exchanger, the liquid inlet is connected with the liquid inlet pipe plate, the plurality of straight pipe heat exchange pipes are connected between the liquid inlet pipe plate and the liquid outlet in parallel, a flame nozzle of the pulsation combustor is connected to the mixed gas inlet, the mixed gas outlet is connected with a chimney, and the ultrasonic-assisted reinforced heat transfer system comprises an ultrasonic transducer and a pressure regulator, and the ultrasonic transducer is connected to the pressure regulator. The system is scientific and reasonable in structural design, the problems of scaling of the boiler, pipe explosion of a water-cooling wall pipe and an arch pipe and overheating bulging of the pot barrel lower part can be solved, meanwhile, the combustion efficiency of the natural gas can be improved, the energy is saved, and the heat exchange efficiency is improved.

Owner:TIANJIN UNIV OF SCI & TECH

Heat pipe type anti-adhesion crude gas waste heat recycling system

ActiveCN105605954ASafe recyclingEconomic recyclingCorrosion preventionIndirect heat exchangersHeat pipeWaste management

The invention discloses a heat pipe type anti-adhesion crude gas waste heat recycling system, and belongs to the field of technologies for recycling crude gas waste heat in coking technological procedures. The heat pipe type anti-adhesion crude gas waste heat recycling system comprises a riser, a heat pipe heat exchange device and a special-shaped connecting pipe. A riser extension section is arranged on the top of the riser in the vertical direction and is communicated with the special-shaped connecting pipe via the heat pipe heat exchange device; optional heat exchange devices in the riser are omitted. The heat pipe heat exchange device comprises a heat-insulation tank, inlets of the heat-insulation tank are formed in the side surfaces of the heat-insulation tank, outlets of the heat-insulation tank are formed in the bottom surface of the heat-insulation tank, the inlets of the heat-insulation tank are connected with the outlets of the heat-insulation tank by a bottom heat-insulation plate which is obliquely arranged, and the bottom heat-insulation plate is detachably fixed to the bottom surface of the heat-insulation tank. The heat pipe type anti-adhesion crude gas waste heat recycling system has the advantage that crude gas waste heat resources can be safely, economically and efficiently recycled by the aid of the heat pipe type anti-adhesion crude gas waste heat recycling system.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

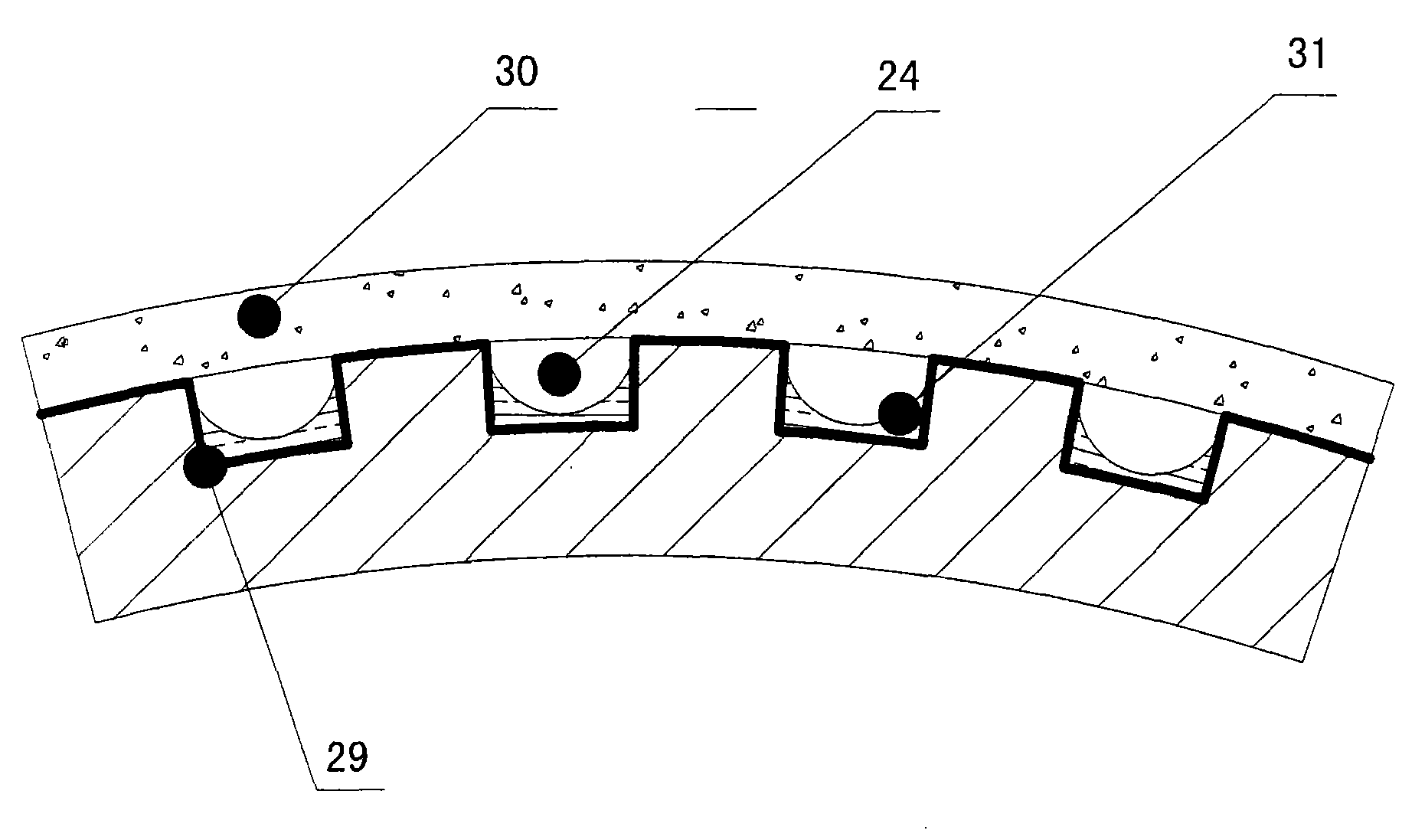

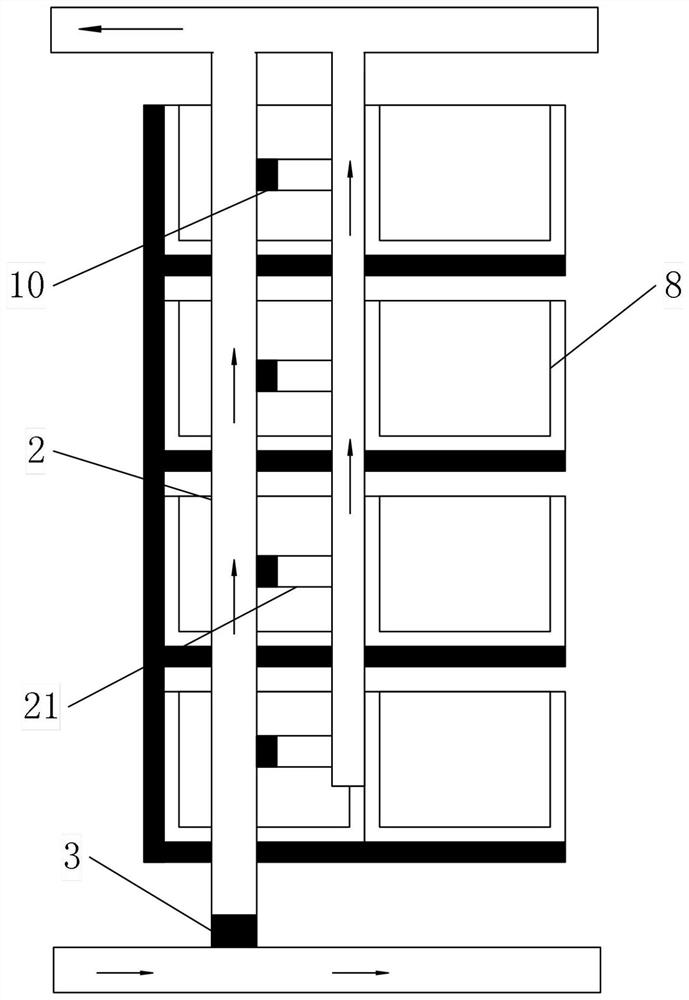

Spiral double-pipe heat exchanger

InactiveCN102818461AImprove heat transfer coefficientIncrease heat exchange intensityStationary tubular conduit assembliesImpellerCombustion

A spiral double-pipe heat exchanger belongs to the field of heat-exchanging apparatuses. A hot-working-medium inlet, a cold-working-medium collecting chamber and a cold-working-medium outlet are arranged on the upper end of a spiral double-pipe heat exchanger body; a hot-working-medium collecting cavity, a hot-working-medium outlet and a cold-working-medium inlet are arranged on the lower end of the heat exchanger body; the heat exchanger body is formed by a plurality of pipes which have different diameters and are sleeved with each other; two adjacent pipes are isolated by a spiral rib, so as to form a spiral channel and form separated cold / hot channels from the centre pipe to the outside; an inlet of a cold-hot working medium heat exchanging channel is configured into a hollow cone, and the outlet is respectively introduced into the upper and the lower collecting cavities by each conduit; the hot-working-medium inlet of the double-pipe heat exchanger is provided with a driving turbine; the cold-working-medium inlet of the double-pipe heat exchanger is provided with an impeller; and the turbine and the impeller are connected by a rotating shaft fixed in a central cylinder. The heat exchanger can fully use the exhaust gas of the combustion motor to drive the cooling airflow automatically, thereby enhancing the heat-exchanging strength; and the heat exchange coefficient of the spiral channel is enhanced by more than 100% compared with the common double-pipe heat exchanger.

Owner:刘福贵

Man-made board dry waste heat recycle method

InactiveCN102927841ALarge amount of waste heat resourcesDustyCombustion processIndirect heat exchangersCold airEvaporation

The invention relates to a man-made board dry waste heat recycle method which includes the following steps: step one, dry tail gas discharged from a cyclone separator is driven by a hot end fan and flows through a tail gas filter, and therefore dust in the tail gas can be filtered; step two, an evaporation section flowing through a heat pipe exchanger is directly emptied when temperature of the evaporation section is reduced after heat exchange; step three, temperature of cold air driven by a cool end fan is raised after a condensation section of the heat pipe exchanger absorbs heat; and step four, the cold air is used as a material drying medium after being heated by a hot oil exchanger or as preheat air to be delivered to a boiler without entering into the hot oil exchanger. The man-made board dry waste heat recycle method has the advantages that a high-efficiency heat exchanger is used to recover waste heat in man-made board dry tail gas, in the process of heat exchange, heat exchange components are in a phase-change heat exchange state, heat exchange intensity is large, and therefore a great deal of low-temperature waste heat can be effectively recovered. A high-efficiency dust remover is arranged in front of the heat exchanger, and therefore the problems that the heat exchanger is prone to dust stratification and blockage and the like are solved.

Owner:NANJING FORESTRY UNIV

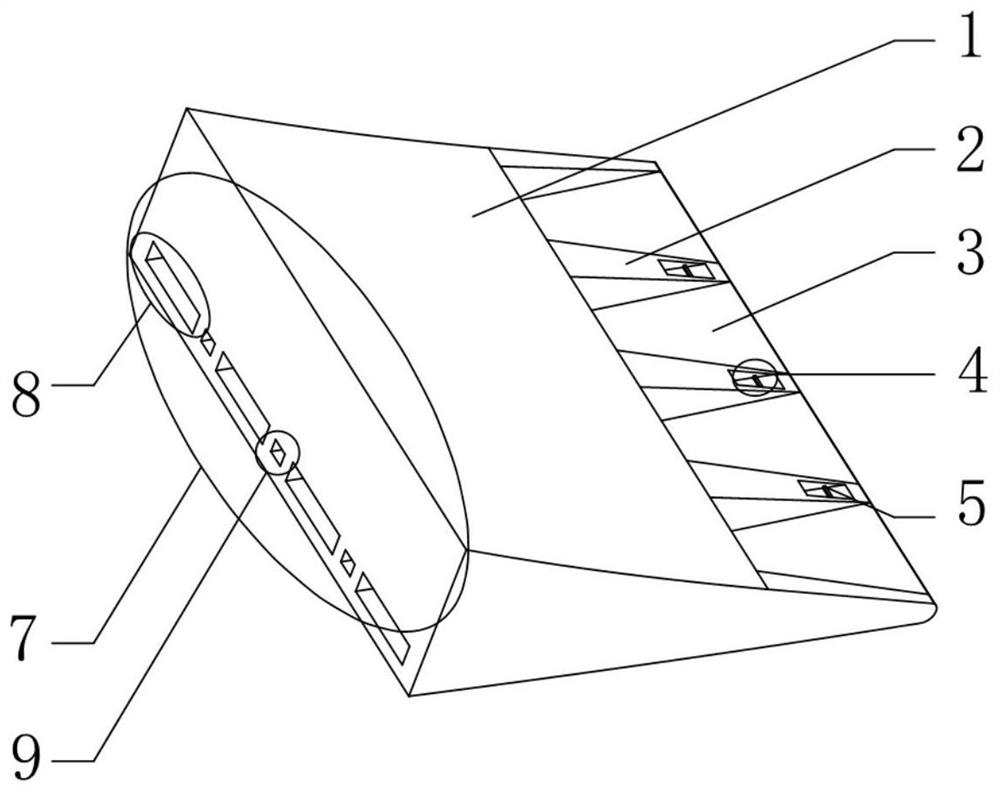

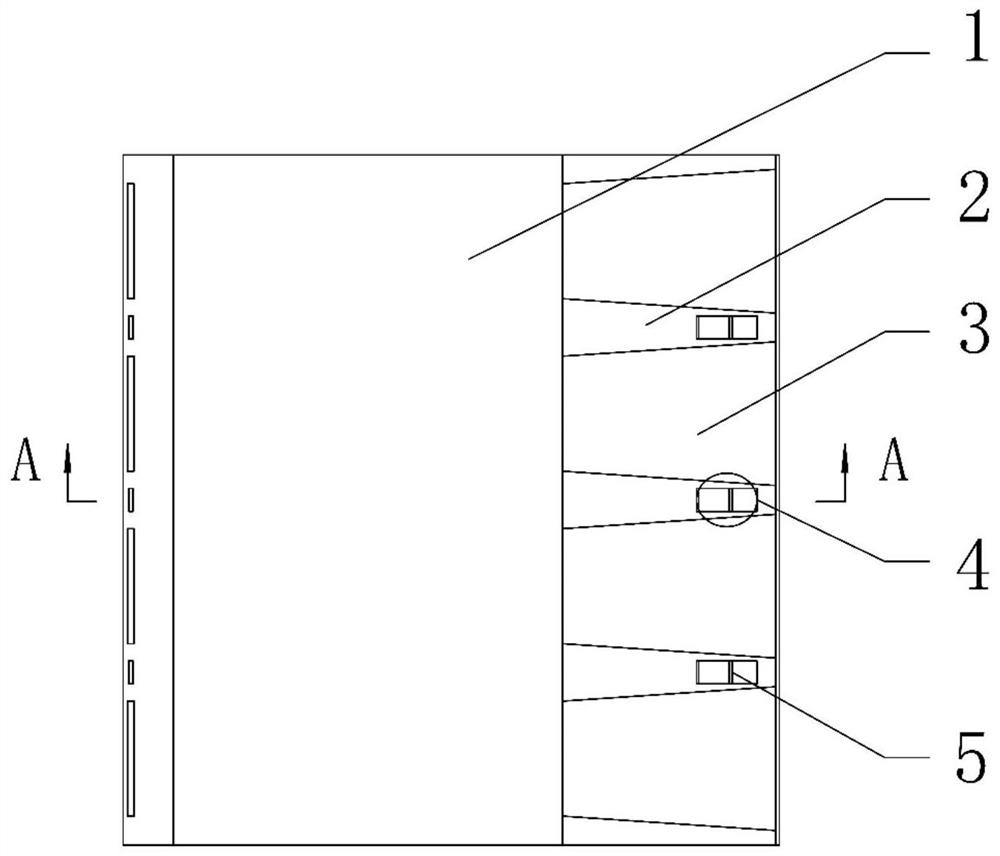

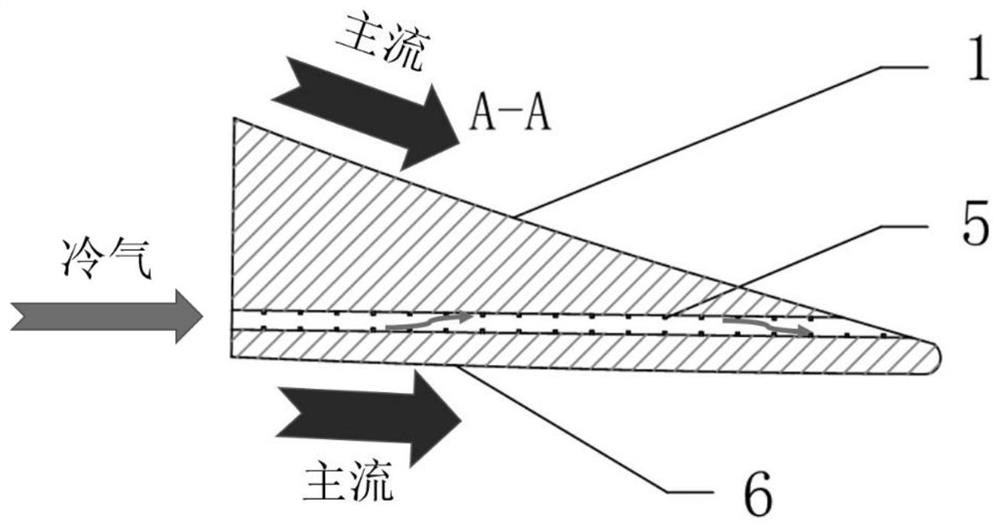

Through seam type half-split seam trailing edge cooling structure and turbine blade

ActiveCN113107610ASimple structureImprove cooling effectBlade accessoriesEfficient propulsion technologiesCold airThermodynamics

The invention provides a through seam type half-split seam trailing edge cooling structure, which is arranged in a turbine blade trailing edge area and is formed by cutting off part of the wall surface of a turbine blade trailing edge pressure surface, only reserving the wall surface on one side of a suction surface and arranging a plurality of separation ribs. Through seams in the flowing direction of cooling airflow are formed in the separating ribs; and the center line of the through seams is parallel to the center line of a trailing edge cold air inlet cavity. According to the cooling requirements on the separation ribs, the rectangular cooling holes are formed in the separation ribs, the cooling airflow is divided into two parts at the outlet of the trailing edge cold air cavity, the main part cools the surface of a crack through the outflow seams, and the remaining part cools the separation ribs through the rectangular cooling holes, the cooling airflow and convection heat exchange in the separation ribs to separate the separation ribs; meanwhile, internal heat exchange with the inner wall surface of the trailing edge suction surface is enhanced, the heat exchange strength between the separation ribs and the suction surface side is enhanced, and the overall comprehensive cooling effect of the trailing edge is improved. Meanwhile, the adopted separation rib cooling holes are simple in structure and convenient to machine, and have good implementability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

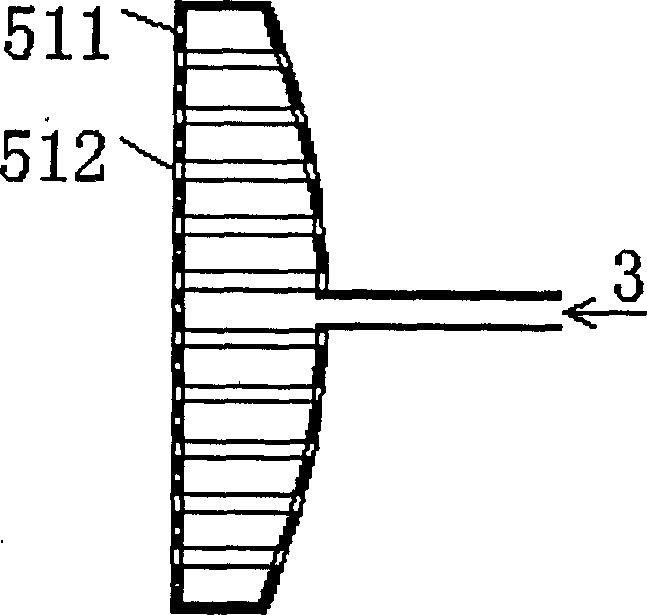

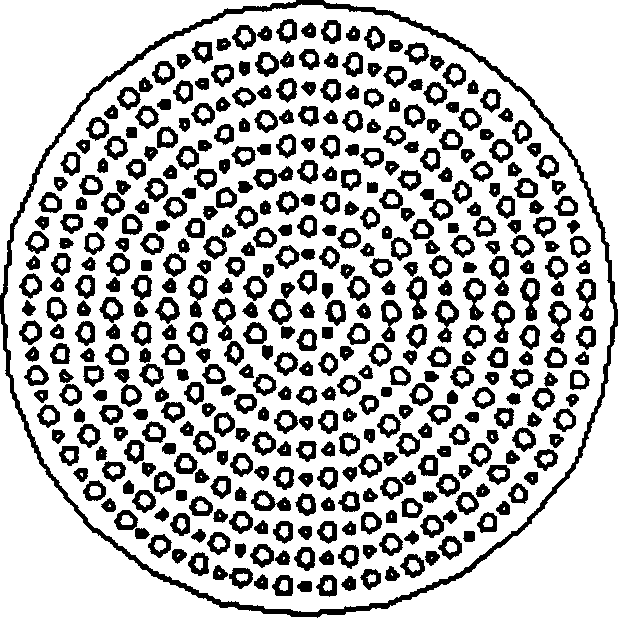

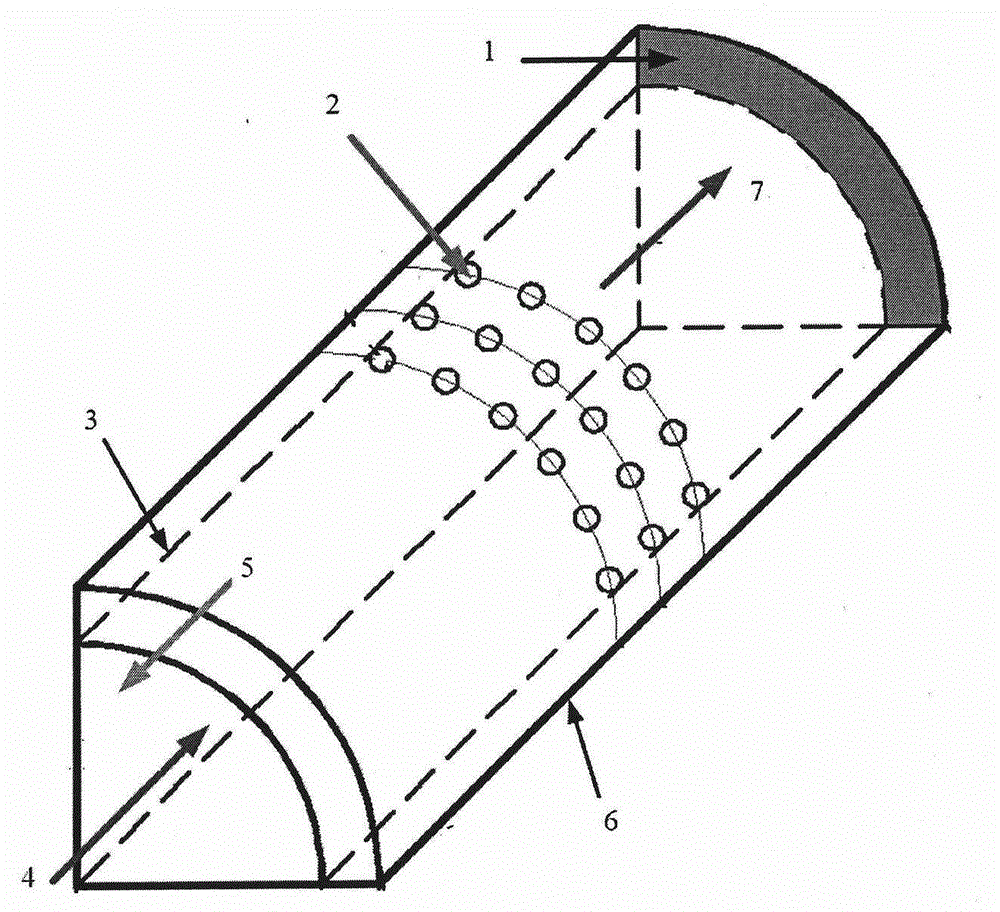

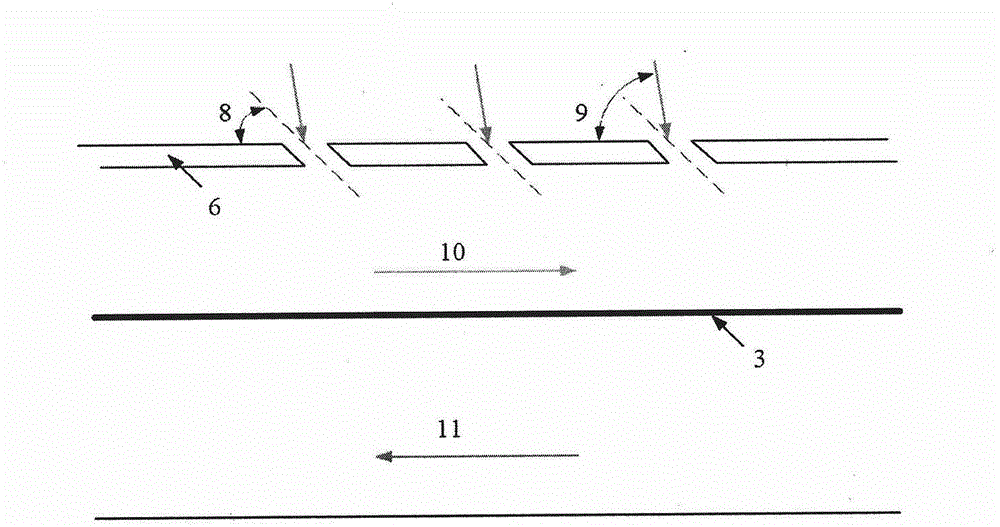

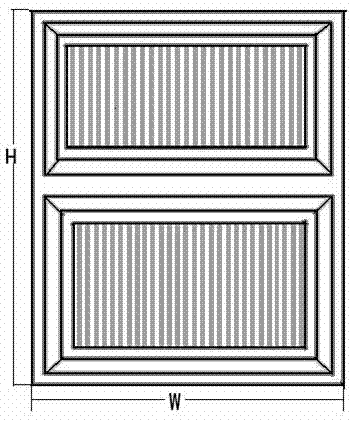

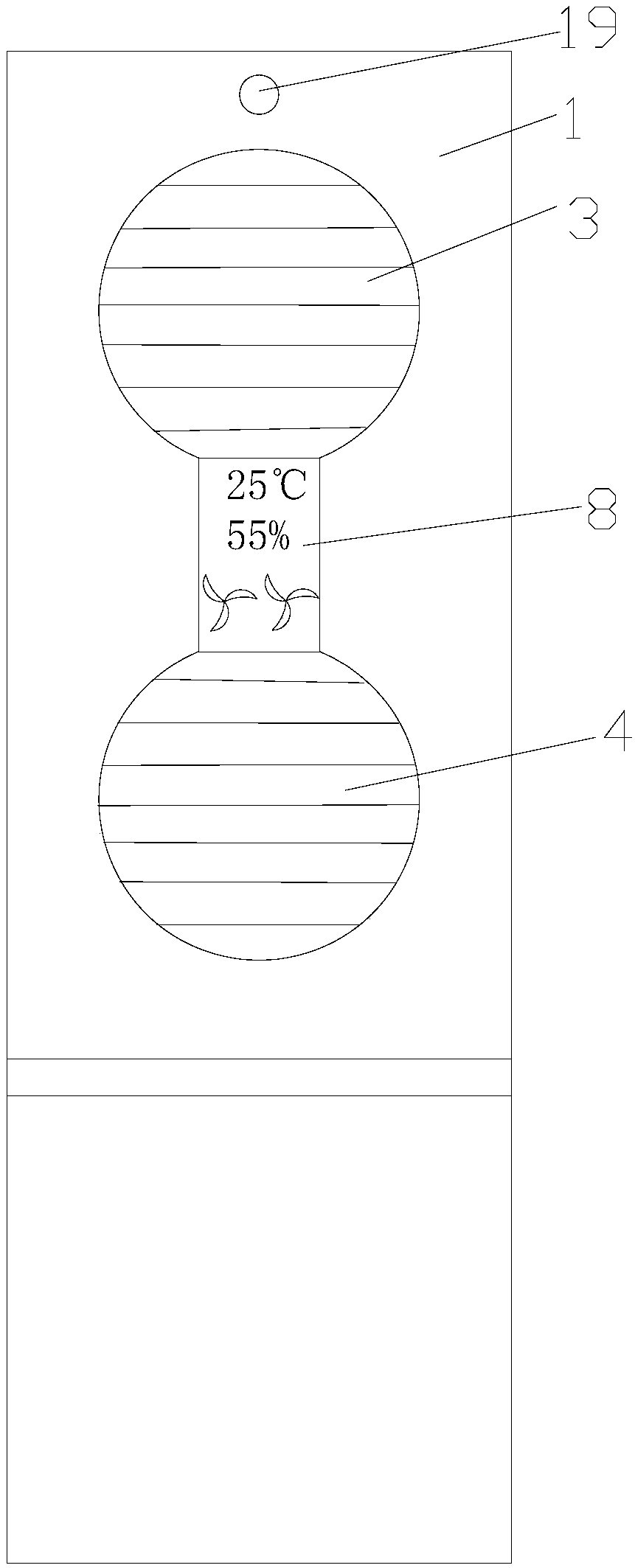

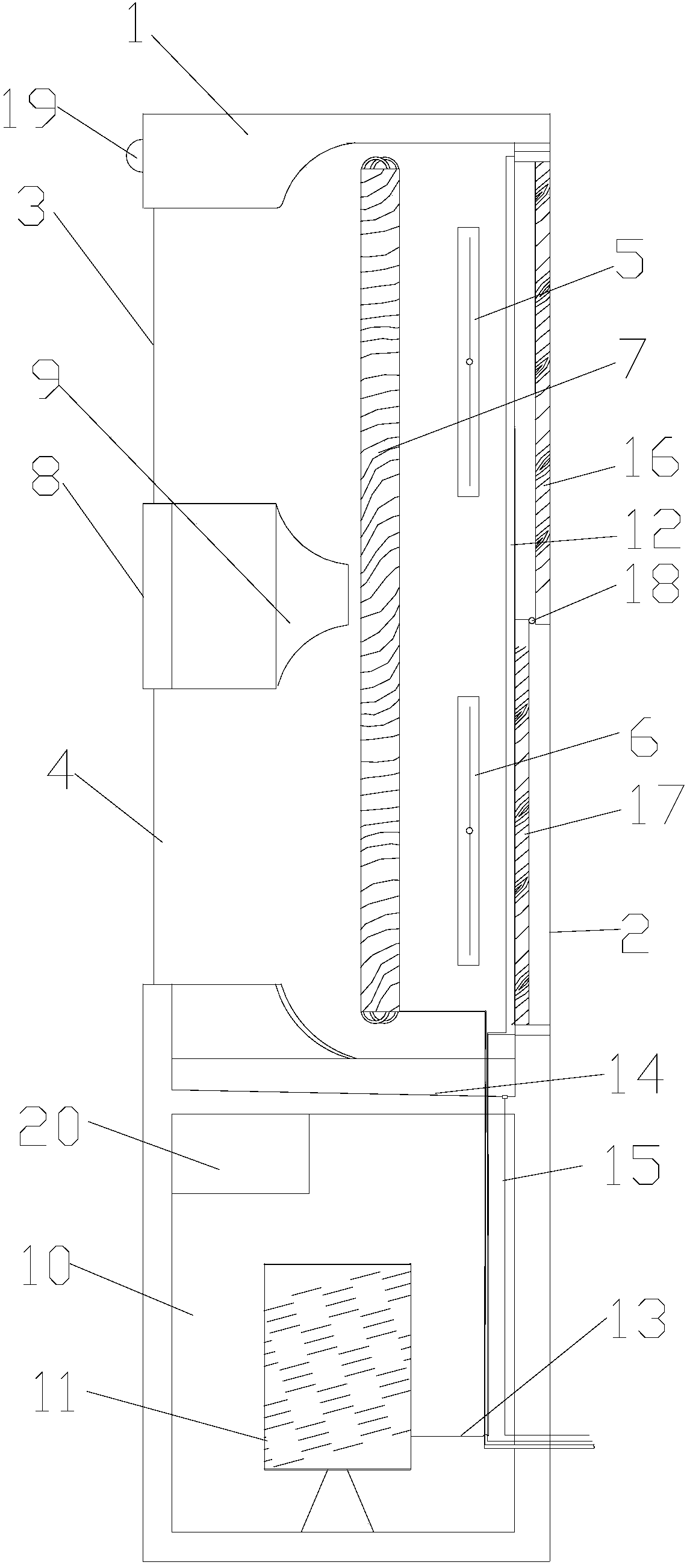

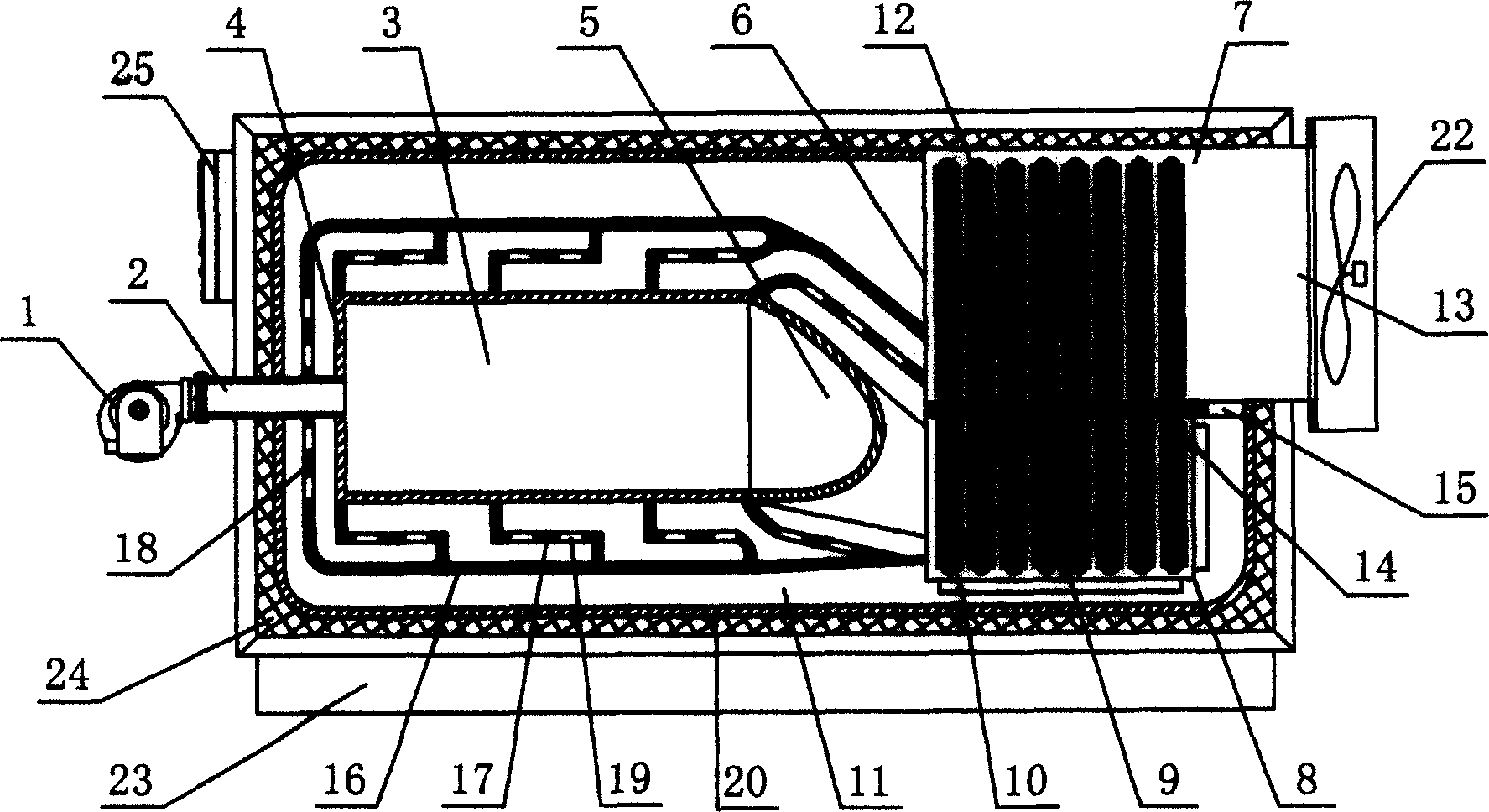

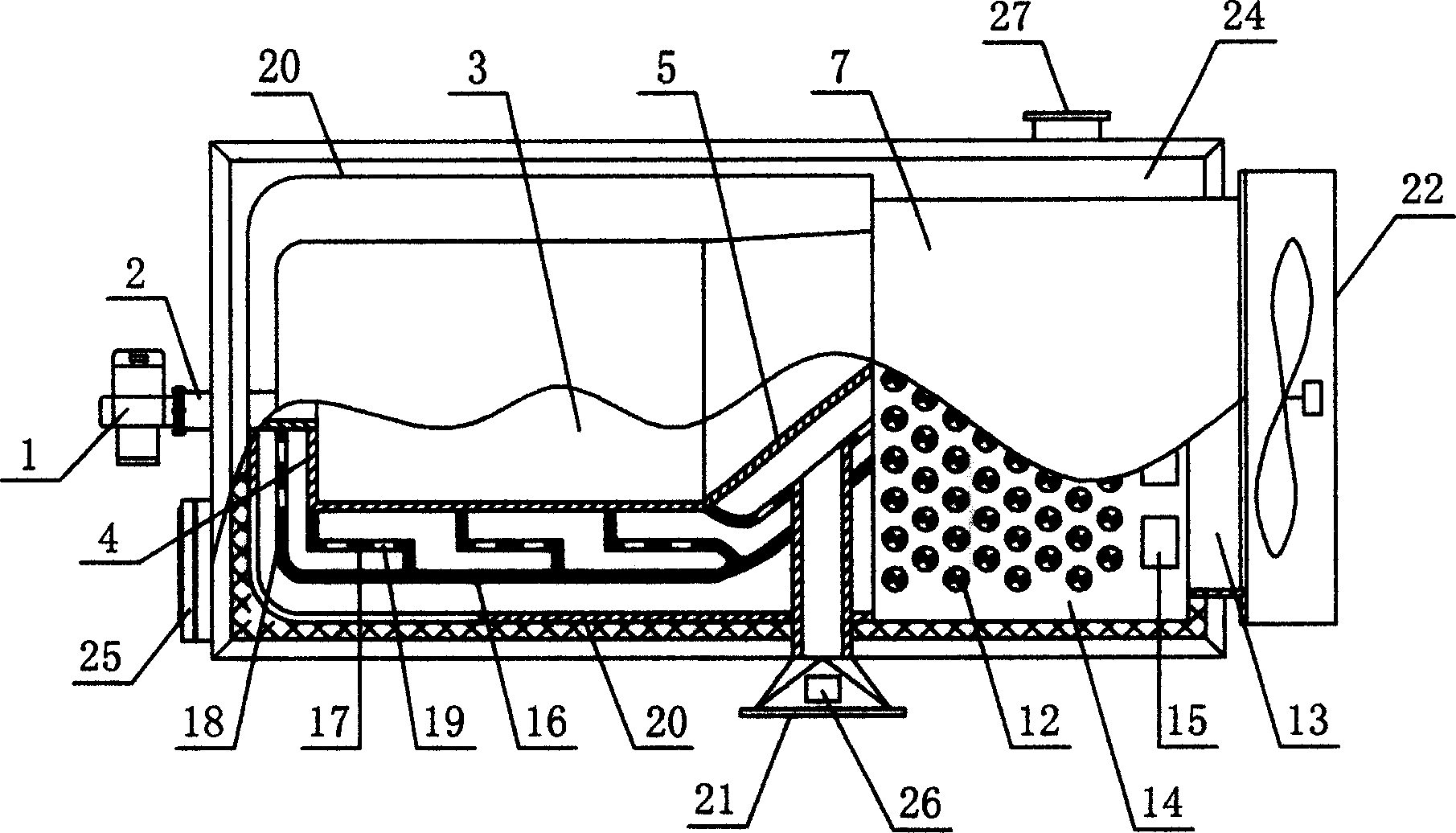

Air conditioner

InactiveCN108375107AIncrease flow rateDiffusion fastMechanical apparatusCondensate preventionEngineeringHeat exchanger

The invention discloses an air conditioner. The air conditioner comprises a shell (1), an air inlet (2) and an air outlet are formed in the shell (1), the air outlet comprises a first air outlet (3) located on the upper part and a second air outlet (4) located on the lower part, the shell (1) is internally provided with a first axial fan (5) corresponding to the first air outlet (3), and the shell(1) is internally provided with a second axial fan (6) corresponding to the second air outlet (4). A rotating shaft of the first axial fan (5) is parallel to a rotating shaft of the second axial fan(6), and a heat exchanger (7) is arranged between the two axial fans and the two air outlets. The air conditioner solves the problems of small air supply distance of a cabinet air conditioner, slow diffusion rate of indoor temperature and low heat transfer intensity in the prior art are solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

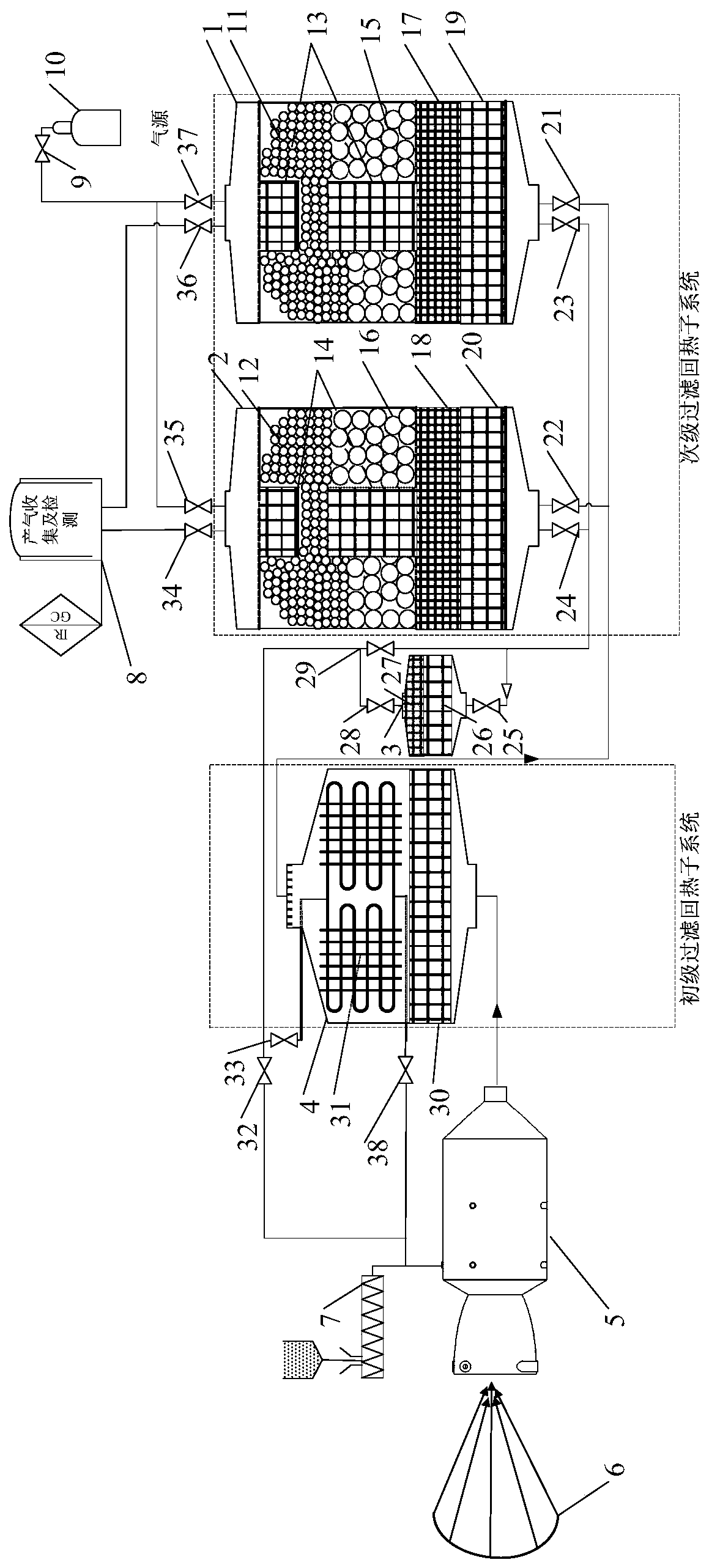

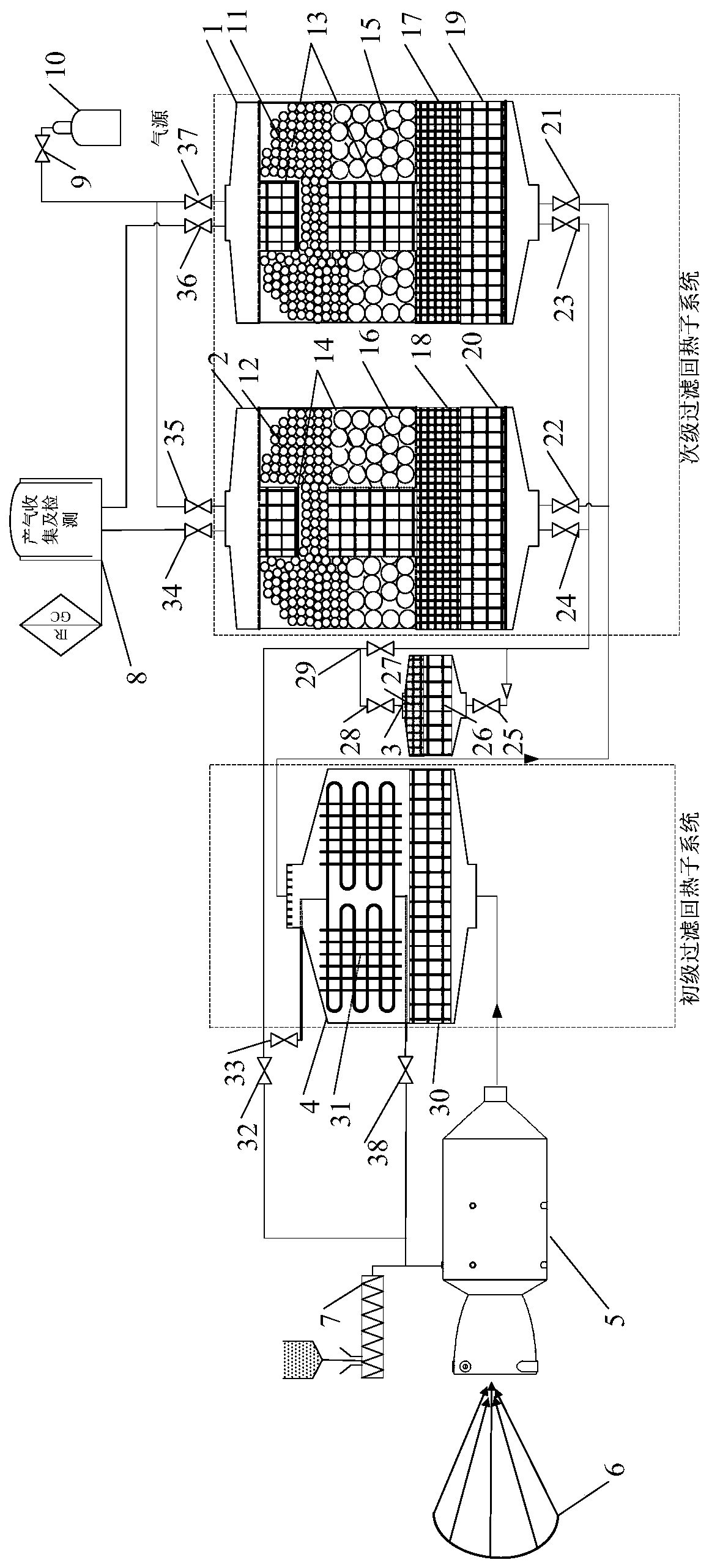

Regeneration and filtration integrated system for high-temperature solar thermal chemical tail gas treatment

ActiveCN110038404AImprove heat transfer effectReduce usageGas treatmentDispersed particle filtrationInsulation layerFiltration

The invention relates to a regeneration and filtration integrated system for high-temperature solar thermal chemical tail gas treatment. The integrated system comprises a primary filtration and regeneration subsystem, a secondary filtration and regeneration subsystem composed of two heat storage tanks in parallel, a backflushing filter and connecting pipeline valves, wherein insulation layers wrapthe heat storage tanks, and bottom contraction sections are provided with ash discharge ports. The system involved in the invention has two stages of filtration and two stages of regeneration; the staged regeneration of reaction air inlet between the stages can be realized through valve switching and the intermediate backflushing filter; coarse filtration, fine filtration and heat storage and regeneration in the stages are layered in order; the secondary filtration and regeneration subsystem which bears a main heat-generating function is provided with filtration performance, heat exchange strength, sealing effect and piezoresistive loss by means of the coupling of fixed beds and fluidized beds. An operation mode of the system comprises primary regeneration during daytime with non-fluctuating solar irradiation, two stages of regeneration during daytime with fluctuating solar irradiation, auxiliary heat regeneration and release before system start-up, and system ash removal. The systemhas the advantages of high efficiency and wide application range, and realizes gradient utilization of gas production waste heat.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Fuel oil (gas) vertical radiation jet heat pipe heat-blast stove

The invention relates to a fuel oil (gas) verticle radiation jet heat pipe blast stove that is the high temperature radiation jet impact heat exchanger. Reverse fire channels combine the new type high efficiency high temperature hot air indirect heating blast stove. The smoke form the burning firepot would enter into the U shaped smoke channel located at the down side section of the hot pipe heat exchanger from the reverse fire channel, heating the hot pipe heat absorbing section that inserted into the smoke channel. And the working medium would be vaporized after absorbing vaporization latent heat. Vacuum phase changes to the hot pipe fin heat releasing section in the hot air generating room in pipe board. And the air would be fast heated at the intake of fan. The hot air with the temperature of 200-300 degree centigrade would entry into the firepot. And the air would be heated after several times of high temperature radiation. Finally, it would be connected to the hot air application occasion. The heat exchanger intensity would be improved by impacting the outside high temperature surface by high speed air flow. The temperature of hot air could achieve 300-600 degree centigrade. The smoke releasing temperature is below 180 degree centigrade. The heat exchange efficiency would achieve 90%.

Owner:吴江市普天热管技术推广应用研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com