Perforated tumble dryer

A dryer and drum technology, applied in progressive dryers, drying chambers/containers, drying, etc., can solve the problems of oil recovery rate decline, oil decomposition in oil shale, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

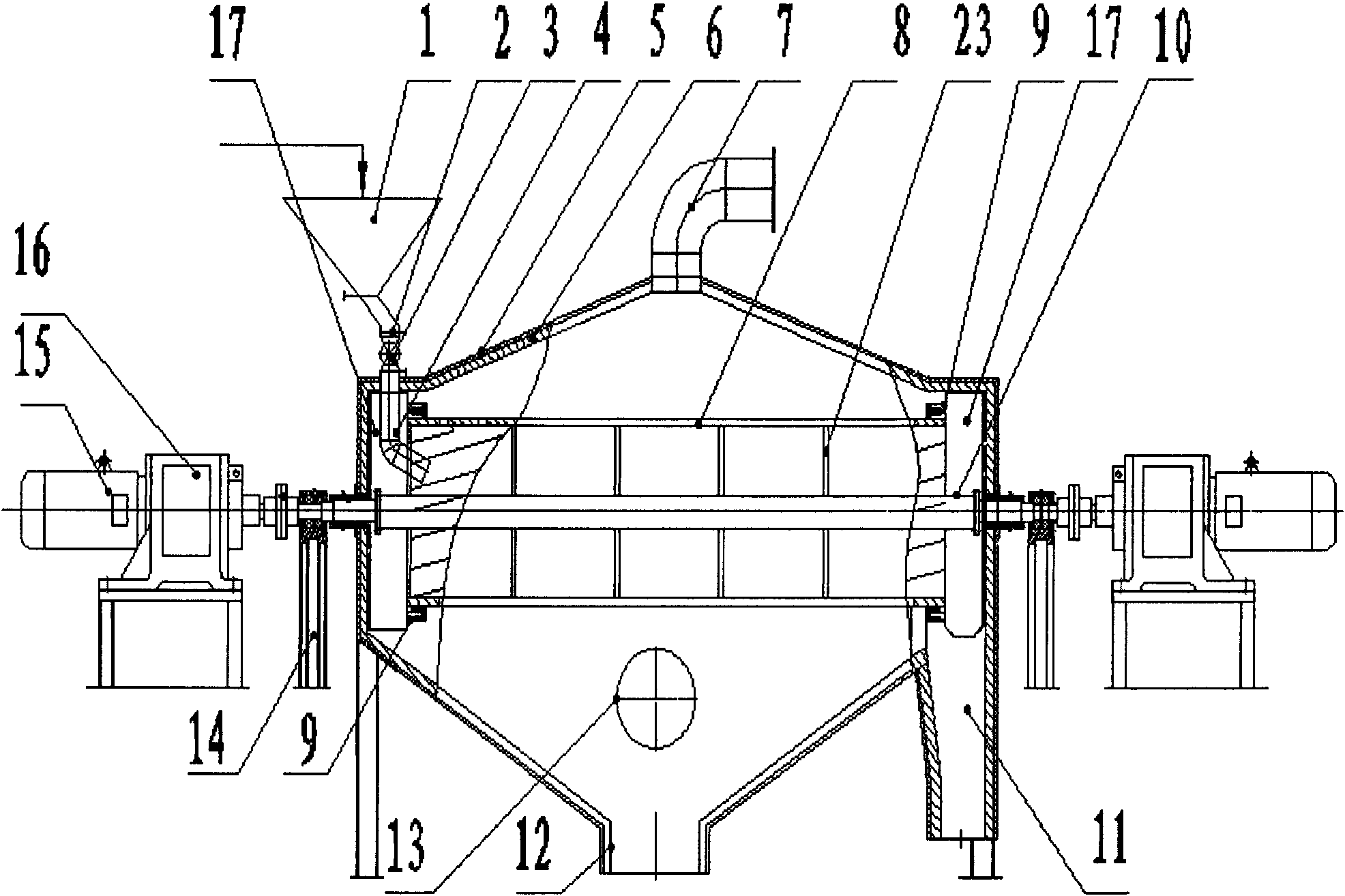

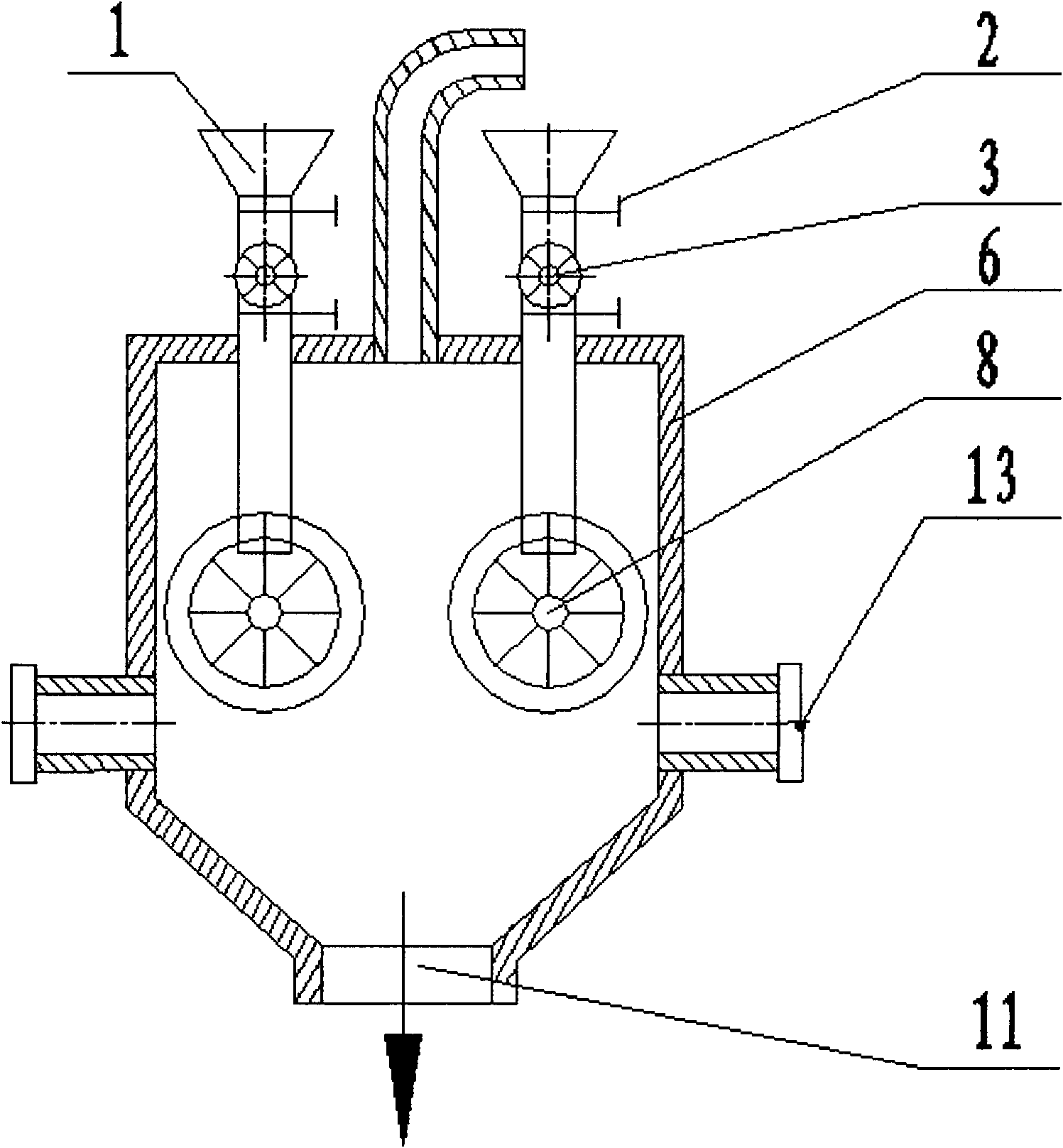

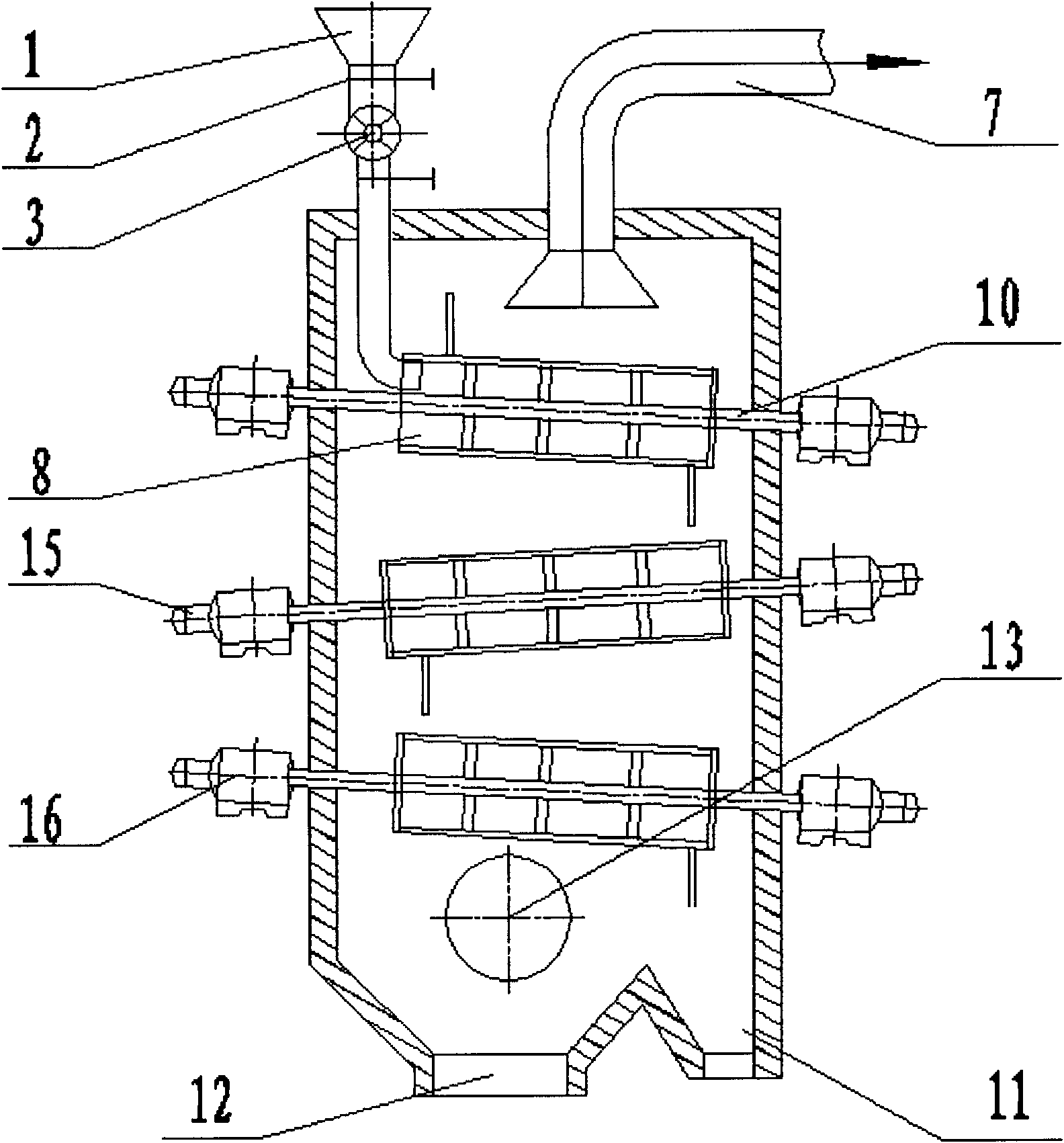

[0030] The working principle and connection mode of the porous drum dryer of the present invention are as follows: figure 1 As shown, during the production operation, the solid material enters the hopper 1 through the transport belt, passes through the star feeder 3 and enters the perforated drum 8 of the perforated drum dryer through the introduction pipe 4, and enters the upper and lower parts of the star feeder 3 Each is equipped with a gate valve 2. When the star feeder 3 or the perforated drum 8 fails, the gate valve 2 can be closed for maintenance, which is safe and reliable. Both the material inlet and outlet are provided with a sealing cover 17, the sealing cover 17 is fixed on the box body 5 of the dryer, and the contact part between the sealing cover 17 and the drum 8 is sealed with a sealing ring 9; the outer wall of the drum of the dryer is passed through a rib 23 It is connected with the main shaft 10 of the drum, and the two ends of the main shaft 10 of the drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com