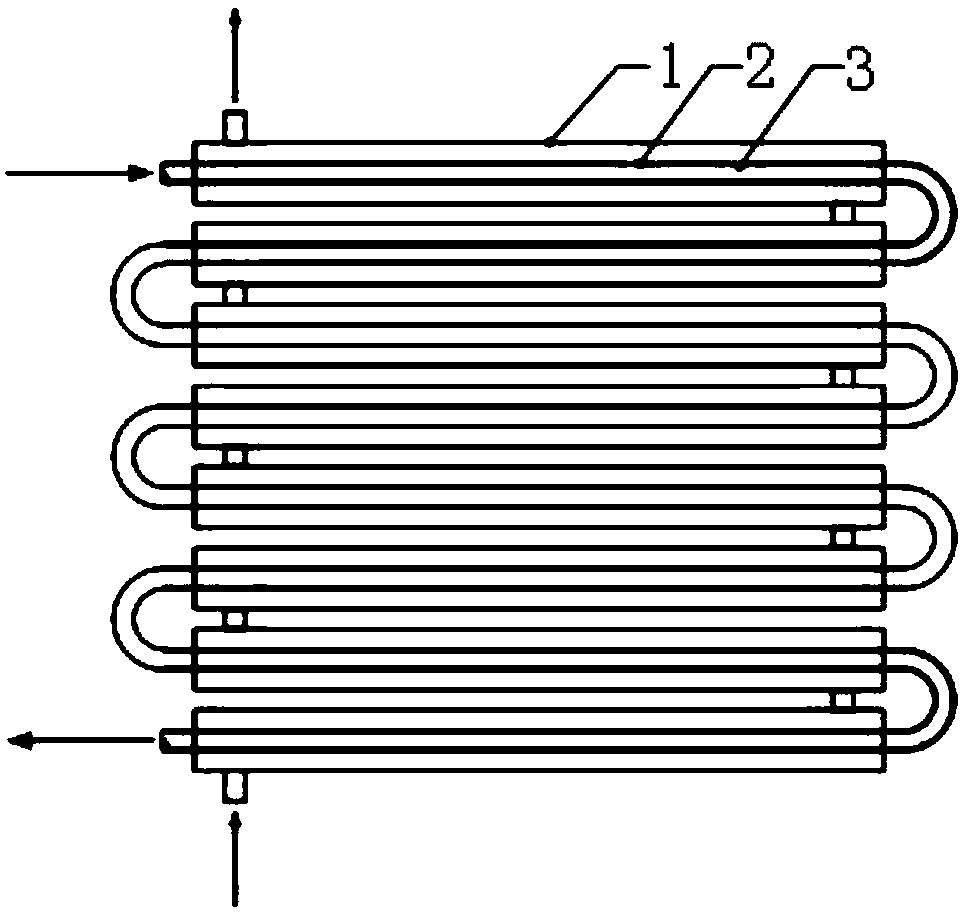

Efficient CO2 gas cooler

A gas cooler, high-efficiency technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of low convective heat transfer coefficient and low convective heat transfer coefficient, and achieve enhanced convective heat transfer coefficient , Improve heat transfer performance and alleviate the effect of greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

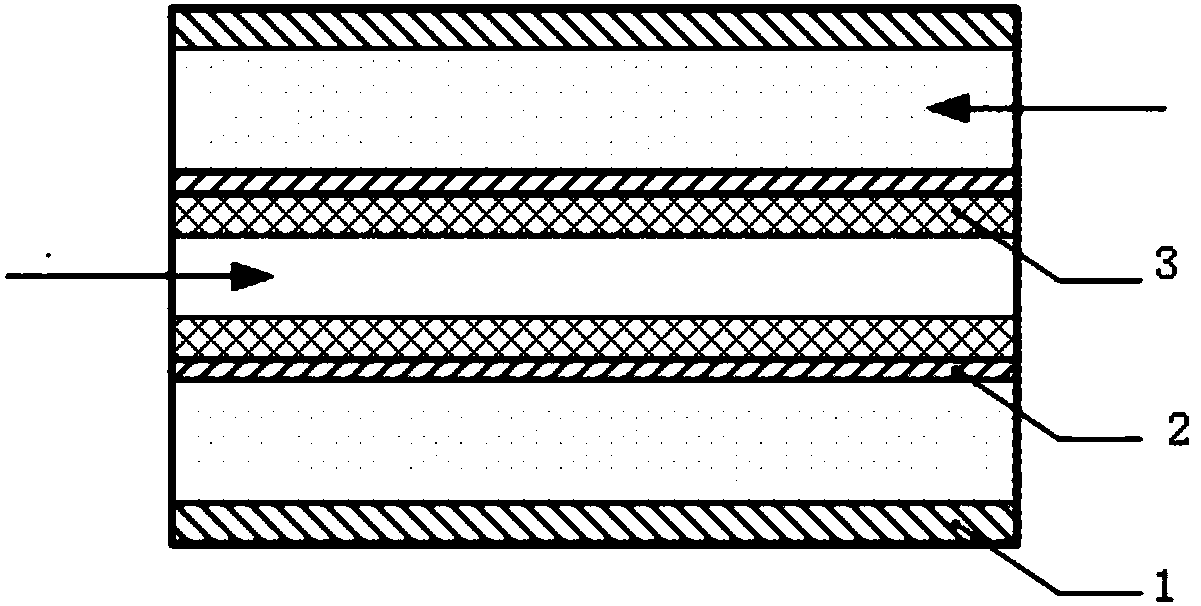

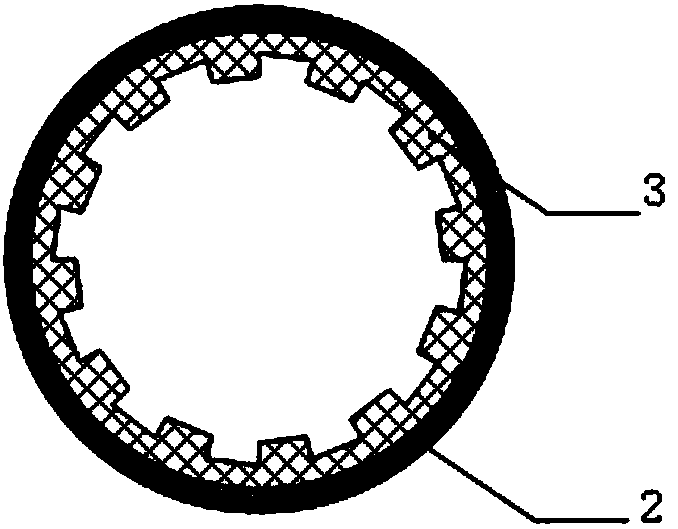

[0027] The inner tube of the casing heat exchanger is generally made of copper, and the metal foam layer is one or more of copper foam, aluminum foam, iron foam, and nickel foam. There are straight or spiral channels on the surface of the metal foam layer. Figure 2-1 is a cross-sectional view of the inner pipe (straight channel metal foam layer) of the sleeve heat exchanger, and Figure 2-2 is a partial schematic diagram of the linear channel . Since the inner tube of the casing heat exchanger is not integrated with the metal foam, and the materials may be different, in order to make the two tightly connected, the two should adopt an interference fit, and the diameter of the metal foam layer is larger than the heat exchange of the casing. The inner diameter of the inner tube wall of the device is 0.1-0.3mm larger.

Embodiment 2

[0029] The difference from Embodiment 1 is that Fig. 2-3 is a cross-sectional view of the inner pipe of the casing heat exchanger (helical linear channel metal foam layer in a single direction), and Fig. 2-4 is a partial schematic diagram of the helical channel. The purpose of changing the surface shape of the metal foam layer is mainly to increase the heat exchange area and improve the heat exchange efficiency of the heat exchange tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com