Heat pipe type anti-adhesion crude gas waste heat recycling system

A waste heat recovery system and waste gas technology, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as the influence of hot surface layout, high production accidents, dry boiler bursting, etc., and achieve waste heat recovery efficiency. High and efficient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

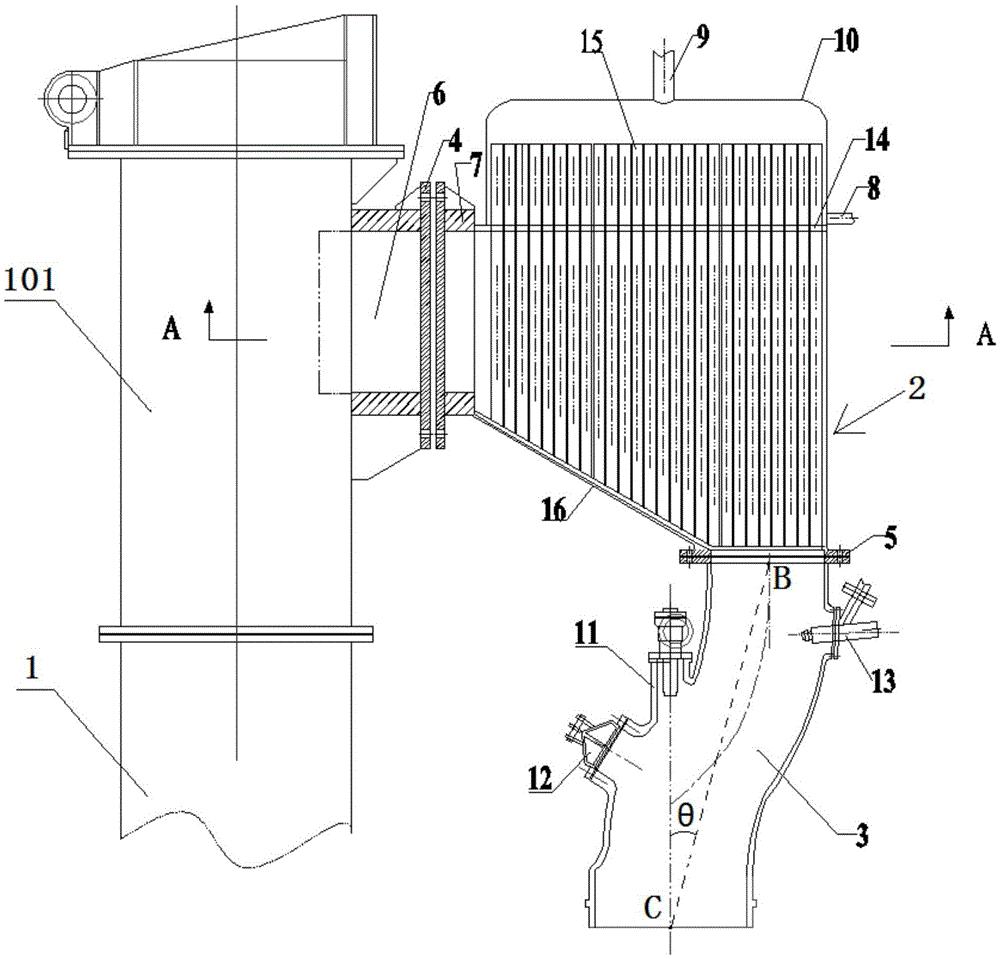

[0034] combine Figure 1~3 , the heat pipe waste heat recovery system for anti-bonding raw gas in this embodiment includes a rising pipe 1, a heat pipe heat exchange device 2 and a special-shaped connecting pipe 3. The top of the rising pipe 1 is vertically provided with an extending section 101 of the rising pipe. The riser pipe extension section 101 communicates with the special-shaped connecting pipe 3 through the heat pipe heat exchange device 2 , and no heat exchange device is installed in the riser pipe 1 .

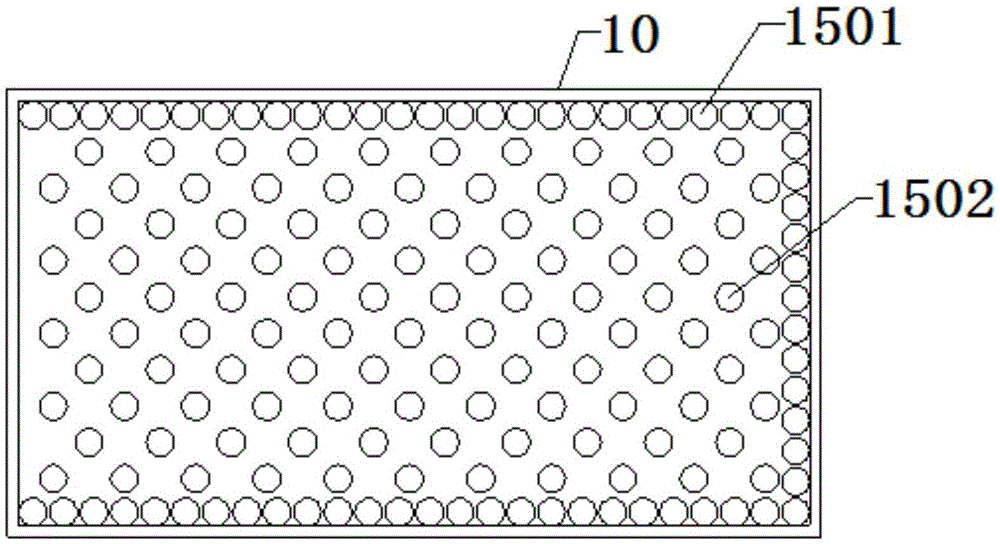

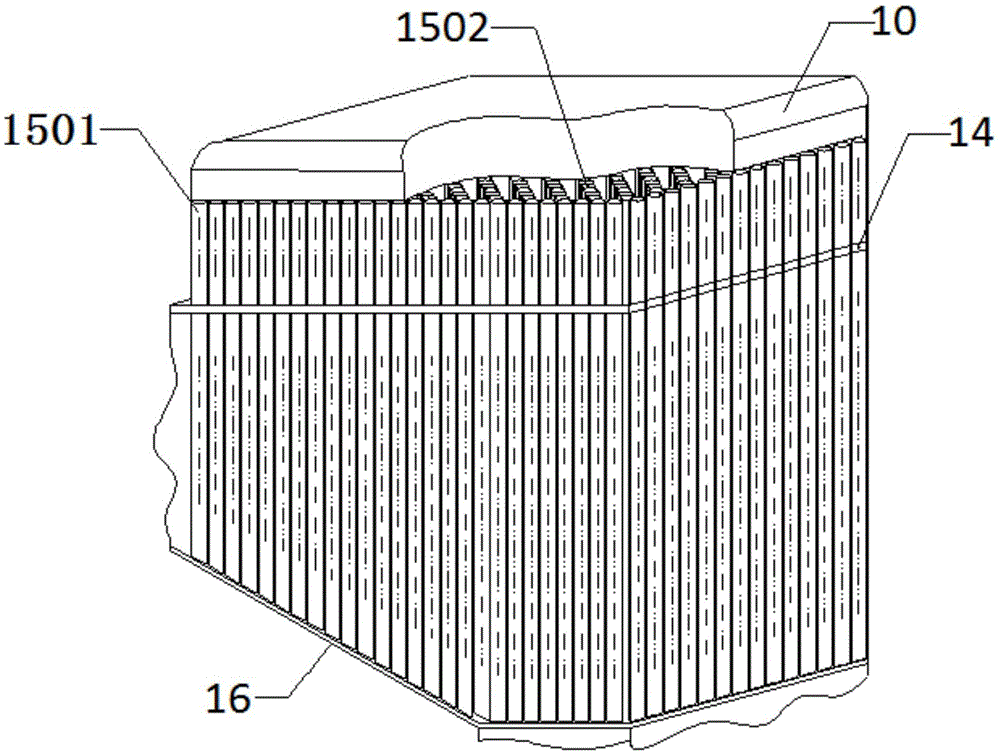

[0035] Specifically, the heat pipe heat exchange device 2 includes a heat insulating box 10, a partition plate 14, a heat pipe 15, a water inlet pipe 8 and a steam discharge pipe 9. The entrance of the heat insulating box 10 is located at the side of the heat insulating box 10, and the The outlet is located on the bottom surface of the heat insulation box 10, and the inlet of the heat insulation box 10 and the outlet of the heat insulation box 10 are connected by an...

Embodiment 2

[0051] The heat pipe type waste heat recovery system for anti-bonding raw gas of this embodiment has the same basic structure as that of Embodiment 1, except that the inner diameter of the three rows of internal heat pipes 1502 near the entrance of the heat insulation box 10 is larger than that of other rows of internal heat pipes The inner diameter of 1502 is 20%; the distance between two adjacent edge heat pipes 1501 is 10mm, the distance between two adjacent inner heat pipes 1502 in the same row is 120mm, and the connection line between points B and C and the vertical line The angle is 45°.

Embodiment 3

[0053] The heat pipe type waste heat recovery system for anti-bonding raw gas of this embodiment has the same basic structure as that of Embodiment 1, except that the inner diameters of the two rows of internal heat pipes 1502 near the entrance of the heat insulating box 10 are larger than those of other rows of internal heat pipes The inner diameter of 1502 is 30%; the distance between two adjacent edge heat pipes 1501 is 7mm, the distance between two adjacent inner heat pipes 1502 in the same row is 80mm, and the line connecting points B and C and the vertical line The angle is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com